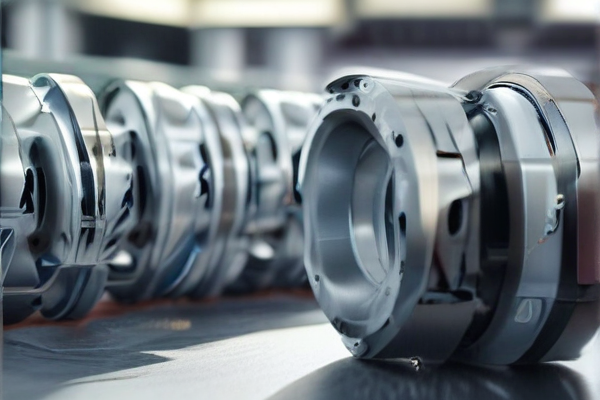

SourcifyChina offers extensive experience in CNC manufacturing, guaranteeing high-quality products. Our seasoned team ensures precision and reliability, essential for competitive markets. With state-of-the-art machinery, we deliver top-notch functionality and accuracy in every project.

Choosing SourcifyChina means partnering with a factory that values transparency and timely communication. We prioritize your requirements and provide regular updates throughout the production process, ensuring you stay informed and at ease.

Moreover, our favorable pricing structure allows businesses to maintain budgetary control without compromising on quality. SourcifyChina supports scalable solutions, making us ideal for both small orders and large-scale production needs.

Our commitment to stringent quality control measures ensures each product meets international standards. We conduct rigorous inspections and testing to guarantee excellence, providing peace of mind with every shipment.

Most importantly, SourcifyChina emphasizes fostering long-term relationships with clients. We strive for continuous improvement and adapt to evolving needs, ensuring your trust and satisfaction in our CNC manufacturing capabilities.

Choose SourcifyChina, where top-tier quality, unmatched expertise, and dedicated customer support come together to enhance your business’s success.

China’s CNC manufacturing offers a wide array of options, including milling, turning, and electrical discharge machining (EDM). With advanced technology and competitive pricing, it has become a global hub for precision parts and components.

Types

and Options:

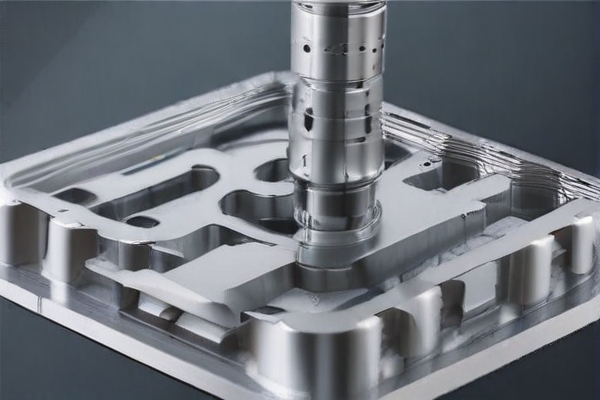

– CNC Milling: Utilizes rotary cutters to remove material.

– CNC Turning: Employs lathe machinery to create cylindrical parts.

– Electrical Discharge Machining (EDM): Removes material using electrical discharges.

– 5-Axis CNC Machining: Provides greater precision by allowing movement across five axes.

– Custom CNC Machining: Tailored solutions specific to client designs.

– Prototype CNC Machining: Ideal for developing and testing new products.

– High-Speed CNC Machining: Focuses on producing parts rapidly with high precision.

– Low-Volume CNC Production: Suited for small runs or custom projects.

– CNC Grinding: Offers high precision for finishing parts.

– CNC Drilling: Specializes in creating precise holes in materials.

Benefits:

– Cost-Efficiency: Competitive labor costs reduce overall expenses.

– Advanced Technology: Equipped with state-of-the-art machinery.

– Quality Assurance: Adheres to strict quality control standards.

– Experience: Skilled workforce with extensive experience in various industries.

– Scalability: Capable of both low and high-volume production.

– Rapid Turnaround: Fast production times for urgent projects.

– Material Versatility: Works with metals, plastics, and composites.

– Custom Solutions: Provides bespoke options tailored to client specifications.

– Global Shipping: Efficient logistics for international delivery.

– Support Services: Offers design consultancy and post-manufacturing support.

China CNC manufacturing has become a global leader in providing high-quality, cost-effective solutions for various industries, contributing significantly to advances in technology and production efficiency.

– Automotive Industry: Precision parts, engines, and custom components.

– Aerospace Sector: High-tolerance components for aircraft and spacecraft.

– Medical Devices: Surgical instruments, implants, and diagnostic equipment.

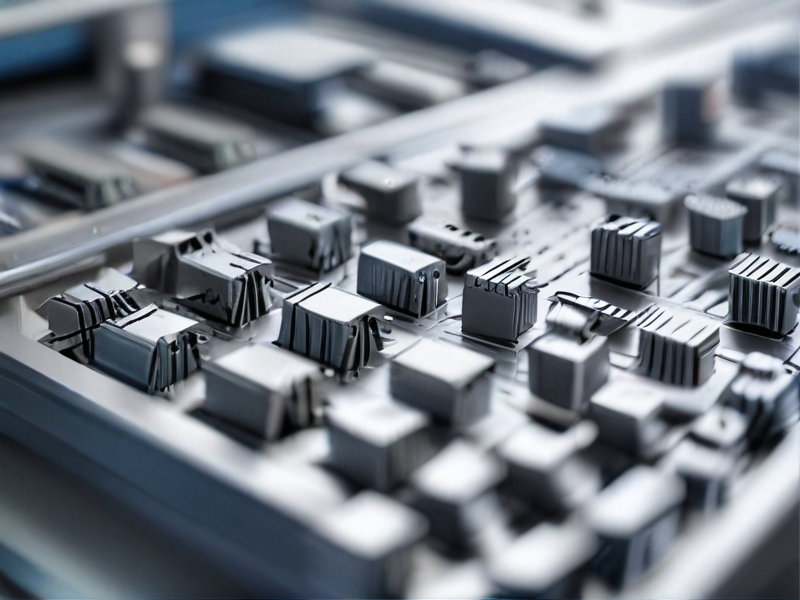

– Consumer Electronics: Cases, components, and heat sinks.

– Industrial Machinery: Tools, molds, and custom machinery parts.

– Energy Sector: Parts for wind turbines, solar panels, and nuclear reactors.

– Custom Prototyping: Rapid prototyping for product development.

– Telecommunications: Housings, frames, and connectors.

– Defense and Military: High-precision components for equipment and vehicles.

– Robotics: Custom gears, joints, and frames.

– Marine Industry: Parts for boats and submersibles.

– Construction Equipment: Durable parts and machinery components.

– Agricultural Machinery: Precision farming tools and machinery parts.

– Textile Machinery: Components for sewing, weaving, and spinning machines.

– Food Processing: Custom parts and machinery for food manufacturing.

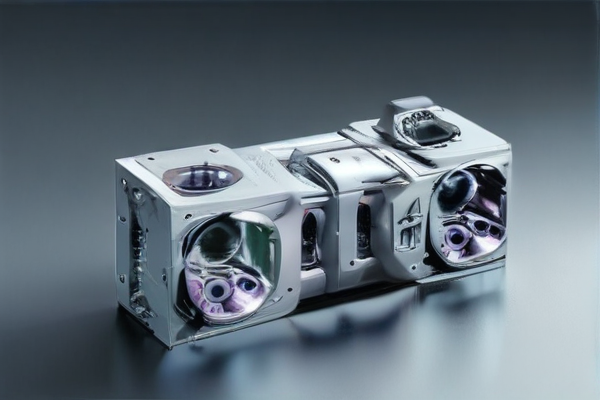

– Optics and Photonics: Precision components for lenses and optical systems.

– Packaging Machinery: Custom components for packaging machines.

– Home Appliances: Parts for various household devices.

– Sports Equipment: Custom gears and mechanical parts.

– Printing Machinery: Components for high-speed printing machines.

– Medical Research: Precision instruments for laboratory research.

– Renewable Energy Equipment: Parts for hydroelectric and geothermal facilities.

– Automation Solutions: Custom parts for automated systems.

– Tool and Die Making: High-precision dies and molds.

– Petrochemical Industry: Custom parts for processing equipment.

– Railway Industry: High-precision components for trains and rail systems.

– Plastic Injection Molding: Molds for creating plastic components.

– Aviation Maintenance: Custom tools and components for aircraft maintenance.

Despite covering various applications, this concise list demonstrates the vast capabilities and contributions of China CNC manufacturing across numerous sectors, boosting global innovation and production efficiency.

SourcifyChina excels in CNC manufacturing, utilizing a wide range of materials tailored to meet specific client needs. They work with metals like aluminum, stainless steel, copper, and brass, ensuring durability and precision.

Aluminum is favored for its lightweight yet strong properties, making it ideal for various industrial applications. Stainless steel, on the other hand, offers excellent resistance to corrosion, making it a reliable choice for harsh environments. Copper and brass provide superior electrical and thermal conductivity, perfect for specialized components.

In addition to metals, SourcifyChina also utilizes high-performance plastics in their CNC processes. Materials such as PEEK, nylon, and polycarbonate offer unique benefits like high strength-to-weight ratios and chemical resistance. These plastics enable the creation of complex, lightweight components suited for industries ranging from aerospace to medical devices.

Each material undergoes rigorous quality checks to ensure precision and adherence to specifications. The combination of cutting-edge CNC technology and diverse material options allows SourcifyChina to cater to a wide array of industries.

This meticulous approach guarantees that every finished product meets the highest standards of quality and functionality. For businesses seeking reliable and versatile CNC machining services, SourcifyChina is a top choice.

SourcifyChina’s CNC manufacturing process begins with rigorous material selection to ensure product longevity and reliability. Each material undergoes meticulous quality checks before production, setting the foundation for superior craftsmanship.

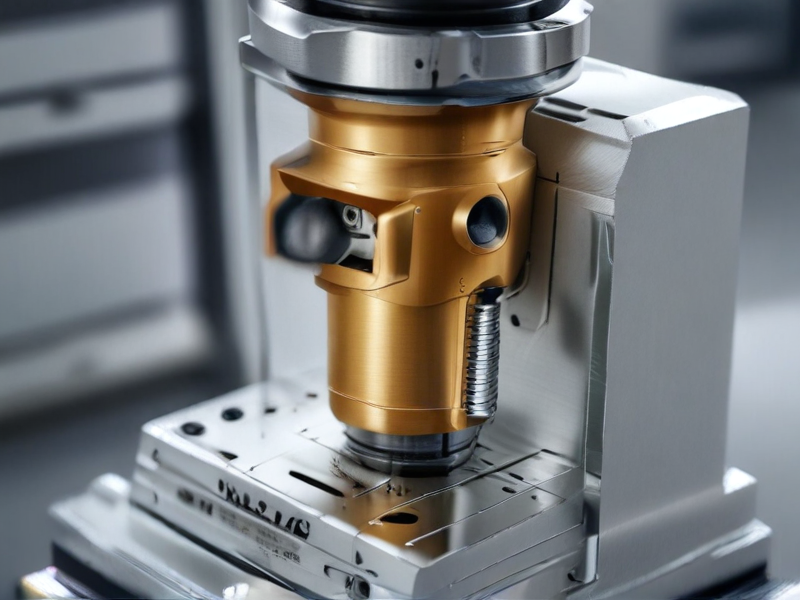

Precision is a cornerstone of SourcifyChina’s operations. Advanced CNC machines are calibrated regularly to maintain accuracy. Operators follow strict protocols, with each component undergoing multiple inspections to meet exact specifications.

Automated systems play a crucial role in quality control. Real-time monitoring and error detection software mitigate risks, ensuring that any anomalies are promptly addressed. This guarantees enhanced efficiency and fewer defective products.

Final assembly and post-production inspection are integral to the process. Components are carefully assembled, and the finished products are subjected to stringent testing. This includes dimensional accuracy, surface finish, and functional performance assessments.

Customer feedback is highly valued. SourcifyChina actively seeks client input to refine its quality control practices continually. This proactive approach helps to maintain high standards and adapt to evolving industry requirements.

In essence, SourcifyChina’s unwavering commitment to quality control in CNC manufacturing sets it apart. Through meticulous material selection, precision in machining, advanced automated systems, and comprehensive post-production inspections, SourcifyChina ensures that every product meets the highest standards of quality and reliability.

SourcifyChina specializes in high-precision CNC manufacturing, offering a wide array of tailored solutions to suit the needs of various industries. Their advanced technology ensures consistent and accurate production.

Leveraging state-of-the-art CNC machinery, SourcifyChina excels in both metal and plastic fabrication. Their equipment includes multi-axis milling and turning centers capable of intricate designs and complex geometries.

Quality is paramount at SourcifyChina. Each project undergoes rigorous testing and inspection processes to meet or exceed industry standards. Their commitment to excellence ensures top-notch results for every client.

SourcifyChina also prides itself on flexible production capabilities, whether for prototyping or large-scale orders. Their agile operations can accommodate tight deadlines and custom specifications.

In addition to manufacturing, SourcifyChina offers comprehensive support services, including design assistance, material selection, and post-production finishing. This streamlined approach ensures smooth project execution from start to finish.

Ultimately, SourcifyChina’s CNC manufacturing capabilities make them a reliable partner for businesses seeking high-quality, precision-engineered components. Their dedication to innovation and customer satisfaction sets them apart in the competitive manufacturing landscape.

China’s CNC manufacturing has revolutionized the global production landscape, offering cost-effective and highly efficient solutions.

– Cost Efficiency: Lower labor and operational costs lead to more affordable production, benefiting businesses globally.

– Precision and Quality: Advanced CNC machines ensure high precision and consistent quality in both low and high-volume production runs.

– Scalability: Chinese manufacturers offer scalable production capacities, making it easy to adjust volumes as needed.

– Speed: Quick turnaround times are ensured by streamlined operations and advanced technology.

– Technological Advancements: Chinese CNC manufacturers are at the forefront of adopting cutting-edge technologies, ensuring competitive and high-quality outputs.

– Customization: High degrees of customization cater to specific needs, offering tailored solutions for various industries.

– Material Variety: Access to a wide range of materials ensures that specific manufacturing demands can be met efficiently.

– Global Supply Chain Integration: Strong logistics and supply chain networks enhance the reliability of delivery and reduce lead times.

– Intellectual Property Protections: Increasing regulatory measures in China are improving intellectual property protections, providing added security for international businesses.

– Eco-friendly Practices: Adoption of sustainable practices and green technologies are reducing environmental impacts.

Engaging Chinese CNC manufacturing offers significant economic and strategic advantages, enhancing global competitiveness and operational efficiency.

China CNC manufacturing is renowned for its precision, affordability, and efficiency, making it a preferred choice for global industries. Here are some key features:

– High Precision and Accuracy: Advanced technology ensures tight tolerances and exceptional consistency.

– Cost-Effectiveness: Lower labor costs and economies of scale reduce overall expenses.

– Rapid Production: Capable of handling high-volume orders with quick turnaround times.

– State-of-the-Art Technology: Utilizes the latest in CNC machinery and software.

– Wide Material Compatibility: Can machine metals, plastics, composites, and more.

– Customization Options: Offers tailored solutions to meet specific requirements.

– Skilled Workforce: Highly trained operators and engineers ensure quality.

– Quality Assurance: Rigorous testing and inspection procedures.

– Global Shipping: Efficient logistics and export services.

– After-Sales Support: Comprehensive customer service and technical assistance.

SourcifyChina specializes in CNC manufacturing, providing a comprehensive solution for custom products and projects. They cater to various industries, delivering high-precision components and assemblies promptly and efficiently. With advanced machinery and skilled professionals, they uphold stringent quality standards, ensuring client specifications are met with utmost accuracy.

Their expertise spans a variety of materials, including metals, plastics, and composites, making them a versatile partner for any manufacturing requirement. SourcifyChina’s commitment to innovation enables them to handle complex designs and produce intricate parts that align perfectly with their clients’ vision.

From prototypes to large-scale production, SourcifyChina offers scalable solutions. Their robust supply chain and strategic partnerships ensure seamless operations and timely delivery. This reliability has established them as a trusted name in CNC manufacturing across China and beyond.

Customer satisfaction is a priority for SourcifyChina, reflected in their transparent communication and personalized service. They provide comprehensive support from initial consultation through to final product delivery, fostering strong, long-term client relationships.

SourcifyChina is a prominent CNC manufacturing company based in China, specializing in delivering high-precision and custom machining services to a diverse array of industries worldwide. The company leverages state-of-the-art technology and an extensive range of advanced CNC machines to provide top-tier, cost-effective solutions tailored to meet the specific needs of their clients. Their comprehensive services encompass milling, turning, drilling, and a variety of other specialized machining processes, ensuring high accuracy and superior quality in every project. SourcifyChina’s commitment to excellence is reflected in their rigorous quality control protocols and adherence to international standards, securing their reputation as a reliable partner in the global manufacturing sector. With a dedicated team of skilled engineers and technicians, SourcifyChina continually innovates and adapts to the evolving demands of the market, positioning themselves as a leader in the CNC manufacturing industry. The company’s focus on customer satisfaction, timely delivery, and consistent performance underscores its mission to bridge the gap between cutting-edge manufacturing capabilities and the dynamic needs of its clients.

China CNC (Computer Numerical Control) manufacturing has become a pivotal asset in the aerospace, defense, and marine industries due to its precision, efficiency, and scalability. In the aerospace sector, where stringent tolerances and high standards for safety and performance are mandatory, CNC machining ensures the production of complex, intricate components such as turbine blades, engine parts, and airframe structures with unparalleled accuracy. This level of precision is crucial for maintaining the integrity and functionality of aerospace systems under extreme conditions. Moreover, China’s robust CNC manufacturing capabilities, coupled with its advancements in materials and metallurgical sciences, allow for the production of lightweight yet durable composites that enhance fuel efficiency and overall aircraft performance.

In the defense and marine industries, CNC manufacturing in China plays a significant role in the fabrication of critical components that demand reliability and durability. Defense applications, such as missile guidance systems, weapon components, and armored vehicle parts, benefit from the precision machining offered by CNC technology, ensuring they meet strict military specifications and performance standards. Similarly, in the marine industry, CNC machining is used to produce complex parts for shipbuilding, including propellers, shafts, and engine components, which require high resistance to corrosion and wear in harsh oceanic environments. The cost-effectiveness and scalability of China’s CNC manufacturing make it an attractive solution for producing large volumes of high-quality components, thereby supporting the operational readiness and technological advancement of aerospace, defense, and marine sectors globally.

China’s CNC (Computer Numerical Control) manufacturing industry has become a critical player in the global automotive sector. The precision and scalability offered by Chinese CNC machining services are integral to the production of complex automotive components such as engine parts, transmission systems, and chassis components. These parts require high levels of accuracy and consistency, which CNC machining uniquely provides. Chinese manufacturers leverage advanced software and machinery to produce parts that meet international standards and specifications. Additionally, the cost-effective nature of Chinese CNC manufacturing helps automotive companies reduce production costs while maintaining high quality, enabling competitive pricing and fostering innovation in vehicle design and functionality.

In the realm of electronics, China’s CNC manufacturing capabilities play a pivotal role in the production of intricate and high-demand components like circuit boards, enclosures, and connectors. The precision offered by CNC machines ensures that these components meet the stringent tolerances required for electronic devices. The efficiency and speed of Chinese CNC machining enable rapid prototyping and mass production, essential for the fast-paced electronics industry. Furthermore, China’s established supply chain infrastructure supports large-scale production and quick turnaround times, which are crucial for tech companies to remain competitive. By utilizing China’s CNC manufacturing services, electronics companies can achieve superior product quality, maintain cost-effectiveness, and accelerate time-to-market for new innovations.

China CNC (Computer Numerical Control) manufacturing has profoundly impacted the construction industry by dramatically enhancing precision, efficiency, and cost-effectiveness. CNC technology allows for the meticulous cutting, shaping, and molding of construction materials such as steel, aluminum, and concrete with unparalleled accuracy. This precision reduces material wastage, which is especially beneficial in large-scale construction projects. Additionally, CNC machines can operate continuously and execute complex designs that would be challenging to replicate manually. China’s expertise in CNC manufacturing has resulted in faster production times and reduced labor costs, thereby making advanced architectural projects more feasible and financially viable.

In the energy sector, China’s CNC manufacturing capabilities have revolutionized the production of critical components for various energy applications, including wind turbines, solar panels, and energy storage systems. CNC machines are instrumental in fabricating highly complex and precise parts essential for the efficient operation of these energy systems. For instance, the aerospace-grade materials used in wind turbine blades benefit enormously from the precision cutting and drilling offered by CNC technology. Furthermore, the demand for renewable energy technologies has driven advancements in CNC equipment, making the production of photovoltaic cells and battery components more efficient and scalable. China’s leadership in CNC manufacturing thus supports its broader goals of advancing sustainable energy solutions, reinforcing its position as a global leader in both CNC technology and renewable energy production.

China CNC (Computer Numerical Control) manufacturing plays a pivotal role in the industrial equipment sector, providing precision and efficiency that are essential for modern production processes. As industries demand higher accuracies and consistent repeatability in manufacturing, CNC machinery from China has met these needs with advanced technology and competitive pricing. Companies in automotive, aerospace, and heavy machinery heavily rely on Chinese CNC machines to fabricate complex components that require meticulous tolerances. The affordability coupled with cutting-edge features, such as multi-axis machining and automation integration, ensures that manufacturers can scale operations without compromising on quality. Thus, Chinese CNC manufacturing has become a cornerstone for industries looking to optimize their production capabilities, reduce operational costs, and maintain high standards of precision.

Additionally, the versatility of Chinese CNC machines extends to a wide array of applications, from crafting delicate electronic parts to robust engineering components. This flexibility allows manufacturers to adapt swiftly to changing market demands and innovate with new product designs. The rapid development of CNC technology in China has led to machines that are not only sophisticated but also user-friendly, reducing the skills barrier and training time for operators. Industrial equipment producers benefit from shorter lead times and enhanced productivity, thanks to the reliability and speed of Chinese CNC systems. Moreover, China’s robust supply chain and strong focus on R&D mean continuous improvements and cutting-edge advancements are always on the horizon, solidifying its position as a global leader in CNC manufacturing for industrial equipment. These elements collectively contribute to the increased competitiveness and sustainability of various industrial sectors worldwide.

China’s CNC (Computer Numerical Control) manufacturing industry has become a crucial player in the production of medical devices, leveraging advanced automation and precision engineering to meet the stringent standards required in the healthcare sector. CNC technology in China enables the production of complex medical components with high precision and consistency, which are essential for devices such as surgical instruments, implants, and diagnostic equipment. Utilizing state-of-the-art CNC machines, manufacturers can produce intricate parts with tight tolerances and refined surface finishes, ensuring the reliability and safety of medical devices. This capability not only augments the performance and longevity of medical instruments but also addresses the growing demand for customized solutions, as CNC technology allows for rapid prototyping and scalable production of tailor-made components according to specific patient needs.

In addition to the technical advantages, China’s CNC manufacturing sector offers cost-effective solutions without compromising on quality. The competitive pricing is a result of streamlined manufacturing processes, economies of scale, and the integration of advanced technologies such as AI and IoT in production lines. These efficiencies benefit medical device companies globally, enabling them to reduce production costs while maintaining high standards of quality and compliance with international regulations. Furthermore, the Chinese government’s support for the manufacturing sector through policies and initiatives aimed at fostering innovation has led to continuous improvements in CNC technology and production capabilities. As a result, China has positioned itself as a strategic partner for global medical device manufacturers seeking reliable, high-quality, and cost-effective manufacturing solutions.

China CNC manufacturing has become a cornerstone in the global machining and manufacturing industry, delivering precision, efficiency, and cost-effectiveness. With advancements in Computer Numerical Control (CNC) technology, Chinese manufacturing firms have rapidly scaled up their capabilities to cater to a wide range of industrial applications. CNC machining in China involves the use of automated tools and machinery, which are programmed via computer software to execute intricate and precise movements. This level of precision is crucial for producing mechanical components that adhere to exact specifications. Industries such as automotive, aerospace, electronics, and medical device manufacturing heavily rely on CNC machined parts from China to maintain their competitive edge.

Moreover, the vast network of Chinese suppliers and manufacturers offers an unparalleled advantage in terms of scalability and lead times. These firms possess advanced facilities equipped with state-of-the-art CNC mills and lathes, enabling them to handle large volume orders without compromising on quality. The integration of rigorous quality control processes ensures that every component meets international standards, further enhancing the credibility of Chinese CNC manufacturing. Additionally, the cost benefits are significant, making it an attractive option for businesses around the globe. Companies can reduce their manufacturing expenses by outsourcing precision machining to China, while still maintaining high-quality standards, thus fostering innovation and cutting-edge development in their respective fields.

Certainly! Below is a list of FAQs with answers regarding manufacturing quality CNC work from SourcifyChina factory, formatted with tags for the questions:

1. What types of CNC machining services does SourcifyChina offer?

SourcifyChina provides a wide range of CNC machining services, including milling, turning, drilling, and grinding. We cater to various industries such as automotive, aerospace, electronics, and medical devices.

2. How does SourcifyChina ensure high-quality CNC manufacturing?

We implement stringent quality control processes, utilize advanced CNC machines, and employ skilled technicians. Additionally, we adhere to international standards such as ISO 9001 to maintain consistent quality.

3. Can SourcifyChina handle both small and large production runs?

Yes, we are equipped to manage both small batch manufacturing and large-scale production runs. Our facility is designed to be flexible, ensuring timely delivery regardless of order size.

4. What materials can SourcifyChina work with?

We work with a variety of materials, including metals (such as aluminum, stainless steel, and titanium) and plastics (like ABS, polycarbonate, and nylon). If you have specific material requirements, we can accommodate them.

5. How does SourcifyChina ensure precision and accuracy in CNC machining?

We use state-of-the-art CNC machines that are regularly calibrated and maintained. Our team continually monitors production and performs rigorous testing to ensure each piece meets exact specifications.

6. What is the typical turnaround time for a CNC machining project?

Turnaround times vary based on project complexity and order size, but we strive to deliver most orders within 2-4 weeks. Expedited services are also available upon request.

7. Does SourcifyChina offer prototyping services?

Yes, we offer rapid prototyping services to help you validate designs before moving to full-scale production. This helps to minimize risks and ensure product readiness.

8. How do I get a quote for my CNC machining project?

You can request a quote by contacting us directly through our website or by emailing our sales team with details about your project, including CAD files and material specifications. We typically respond within 24 hours.

9. What payment methods does SourcifyChina accept?

We accept a variety of payment methods including wire transfer, PayPal, and major credit cards. Payment terms can be tailored to suit our clients’ needs.

10. How does SourcifyChina handle shipping and logistics?

SourcifyChina, through its automated sourcing platform, facilitates the handling of shipping and logistics by offering comprehensive services that simplify the import process from China. The company collaborates with experienced freight forwarders to manage the shipping and logistics efficiently, ensuring that the products are delivered in a timely and cost-effective manner. This includes handling customs clearance fees, documentation fees, storage costs, and insurance to minimize the risk of delays and damage to the products

Sourcing CNC manufacturing from China can be highly beneficial for cost-effectiveness and production quality. Here are some key tips:

1. Select the Right Supplier:

– Research and References: Use online platforms and industry referrals to find reputable suppliers.

– Certifications: Ensure the factory has ISO 9001 or other relevant certifications.

– Visit If Possible: A personal visit can verify the capabilities and standards of the factory.

2. Clear Communication:

– Specifications: Provide detailed engineering drawings and specifications.

– Language: Make sure to communicate clearly, possibly through bilingual agents.

3. Prototyping and Samples:

– First Article Inspection (FAI): Request initial samples before full-scale production.

– Quality Assurance: Use these samples for detailed inspection to ensure they meet your standards.

4. Contracts and Agreements:

– Detailed Contracts: Specify terms regarding quality, delivery times, costs, and intellectual property.

– Payment Terms: Negotiate favorable payment terms—commonly, partial upfront and the remainder upon delivery.

5. Quality Control:

– In-House QC: Many Chinese factories have their own QC processes.

– Third-Party Inspection: Hire independent inspectors to perform quality checks.

6. Shipping and Logistics:

– Incoterms: Understand and agree on Incoterms (e.g., FOB, CIF) to clarify responsibilities.

– Customs and Duties: Be aware of import regulations and duties in your country.

7. Cultural Sensitivity:

– Relationship Building: Building a good relationship with your supplier can lead to better cooperation and problem-solving.

– Face and Respect: Show respect and understanding for Chinese business culture and practices.

Utilizing these tips can facilitate a smoother and more successful partnership with a CNC manufacturing factory in China.

1. What services does SourcifyChina Factory offer?

SourcifyChina Factory provides comprehensive CNC manufacturing solutions, including CNC milling, turning, precision machining, prototyping, and mass production. They handle various materials such as metals, plastics, and composites.

2. How can I request a quote for CNC manufacturing?

To request a quote, you can visit the SourcifyChina Factory website and fill out the request form with your project details, including specifications, quantities, and any special requirements. The team will get back to you with a detailed quote.

3. What are the lead times for CNC manufacturing at SourcifyChina Factory?

Lead times vary depending on the complexity and size of the project. For prototypes, it typically ranges from 1-2 weeks. For mass production, it could take 3-6 weeks or longer. It’s best to discuss specific timelines with their team.

4. Which industries does SourcifyChina Factory serve?

SourcifyChina Factory serves a wide range of industries, including automotive, aerospace, medical, electronics, and consumer goods. They specialize in delivering high-precision components tailored to specific industry standards.

5. How does SourcifyChina Factory ensure quality control?

SourcifyChina Factory implements stringent quality control processes, including in-line inspections, final product testing, and the use of advanced measuring equipment. They adhere to international quality standards and can provide certification upon request.

6. Can SourcifyChina Factory handle both small and large orders?

Yes, SourcifyChina Factory is equipped to handle both small-scale prototype orders as well as large-scale production runs, providing flexibility to accommodate varying project needs.

7. What materials can SourcifyChina Factory work with for CNC machining?

SourcifyChina Factory can machine a variety of materials, including aluminum, stainless steel, brass, copper, plastics (like ABS and POM), and other custom materials based on specific project requirements.

8. Is it possible to get a customized CNC manufacturing solution?

Absolutely! SourcifyChina Factory offers customizable solutions tailored to your specific project needs. You can discuss your exact requirements with their engineering team to ensure the final product meets your expectations.

9. Does SourcifyChina Factory offer after-sales support?

Yes, SourcifyChina Factory provides after-sales support, including assistance with any issues related to the manufactured products, future modifications, or guidance on additional services.

When sourcing CNC manufacturing from China via platforms like Sourcify, it’s crucial to follow best practices to ensure you find the right supplier. Here are some tips to guide you through the process:

1. Research and Vet Suppliers: Use Sourcify to access a wide range of pre-vetted suppliers. Look for those specializing in CNC manufacturing with a solid track record and positive customer reviews. Prioritize factories with ISO certifications and compliance with industry standards.

2. Assess Capabilities: Ensure the supplier’s capabilities match your project requirements. Check their machinery, technology, and production capacities to confirm they can handle your order volume and precision needs.

3. Quality Control: Quality is paramount in CNC manufacturing. Verify the supplier’s quality control processes, including inspections and testing. Ask for samples or a trial run to assess their workmanship before committing to a large order.

4. Communication: Clear and frequent communication is essential. Ensure the factory has English-speaking staff or use reliable translation services. Discuss specifications, tolerances, materials, and any other critical details in writing to prevent misunderstandings.

5. Production and Delivery Timeline: Confirm realistic production timelines and ensure they can meet your deadlines. Consider potential delays in shipping and customs when planning your project timeline.

6. Cost and Payment Terms: Get detailed quotations and compare the cost of CNC services from multiple suppliers. Clarify payment terms, including any upfront deposit and balance payments upon delivery or approval of final products.

7. Visit the Factory: If possible, visit the factory to get a firsthand look at their operations, equipment, and working conditions. This can significantly enhance your confidence in their capabilities and reliability.

8. Legal and Contracts: Draft clear contracts detailing all terms of the agreement, including intellectual property protections, confidentiality clauses, and penalties for non-compliance.

By following these tips, you can secure a reliable CNC manufacturing partner in China through Sourcify, ensuring high-quality production and smooth cooperation.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.