Sourcing 1045 steel from China can be a challenging process, but “SourcifyChina” Factory makes it seamless. Their expertise in the steel industry ensures high-quality materials that meet global standards, providing the best value for your investment.

The team at “SourcifyChina” prioritizes excellent customer service, tailored to cater to individual buyer needs. Their strong communication channels offer real-time updates, ensuring transparency throughout the entire buying process.

Competitive pricing is another significant advantage. “SourcifyChina” leverages its extensive network and bulk purchasing power to offer highly competitive rates without compromising on quality, making them an economical choice for buyers.

Quality assurance is rigorously upheld at “SourcifyChina.” With advanced testing and certification processes, they guarantee the 1045 steel meets specific requirements, reducing risks and ensuring reliability for your projects.

In addition to quality and pricing, their logistics capabilities are formidable. “SourcifyChina” provides efficient shipping solutions and flexible delivery schedules, helping to meet tight project timelines without unnecessary delays.

Leveraging years of experience and industry knowledge, “SourcifyChina” stands out as a reliable partner. They not only supply top-grade 1045 steel but also offer engineering support and technical advice, ensuring your project’s success from start to finish.

With “SourcifyChina,” you’re not just purchasing steel; you’re investing in a trusted partnership. Their commitment to excellence, transparency, and customer satisfaction makes them the ideal choice for sourcing 1045 steel from China.

1045 steel is a medium carbon steel, known for its high strength and impact resistance. It is commonly used in components requiring more strength than low carbon steels but more workability than higher carbon steels.

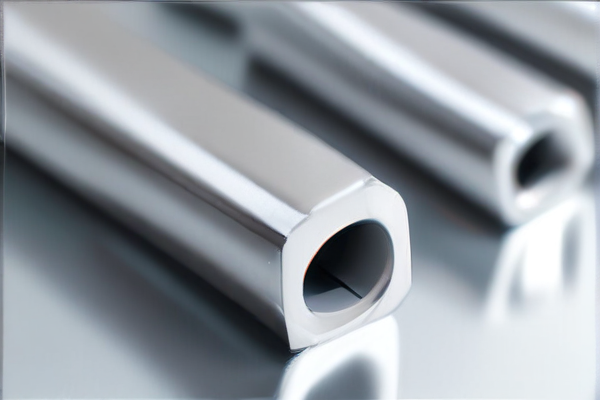

– Cold Drawn 1045 Steel: Enhanced mechanical properties, smoother finish.

– Hot Rolled 1045 Steel: Easier to form, slightly lower strength than cold drawn.

– Normalized 1045 Steel: Uniform structure, better mechanical properties.

– Annealed 1045 Steel: Improved machinability, stress relief.

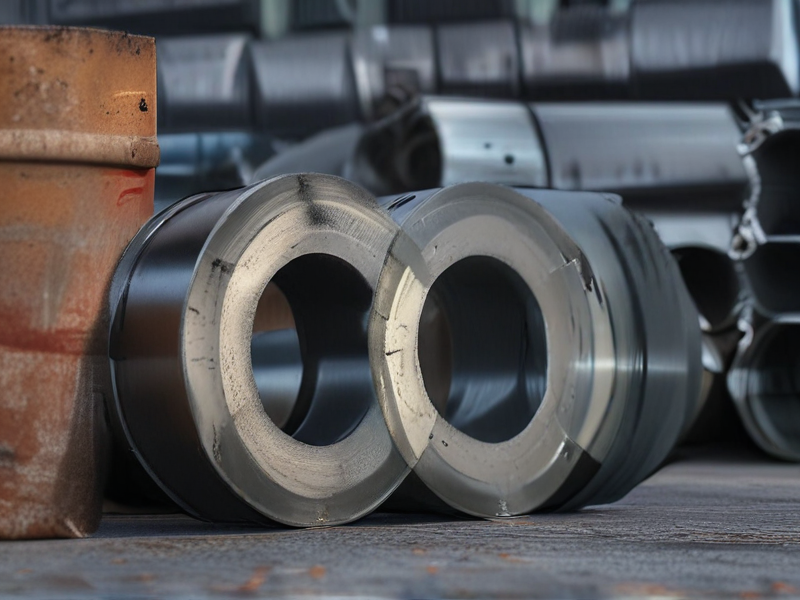

– 1045 Steel Plate: Utilized in construction, general engineering.

– 1045 Steel Round Bar: Commonly used in shafts, pins, and general machinery parts.

– Heat-Treated 1045: Harder, stronger surface.

1045 steel also offers options in terms of surface treatments like polishing, coating, and other embellishments to suit various industrial applications, enhancing both aesthetics and performance.

1045 steel, a medium-carbon alloy, is known for its strength, hardness, and wear resistance. This versatile material is utilized in various industrial applications due to its balance of properties.

– Machinery Parts: Frequently used in manufacturing gears, axles, shafts, and bolts.

– Tooling: Ideal for tool holders, spindles, and fixtures due to its machinability.

– Automotive Industry: Applied in crankshafts, couplings, and connecting rods.

– Heavy Equipment: Used in construction and agricultural machinery parts for durability.

– Forging Applications: Suitable for forged components like connecting rods, cylinders, and crankshafts.

– Mining Industry: Employed in drill bits, rock crushers, and other high-stress mining tools.

– Oil and Gas: Utilized for parts in drilling and extraction equipment like valve bodies and pump shafts.

– Construction: Used in the manufacture of heavy-duty structural components.

1045 steel’s blend of strength and machinability makes it a popular choice across multiple sectors, providing reliable performance in demanding environments.

SourcifyChina 1045 steel, a medium carbon steel, is well-known for its balance of strength, hardness, and toughness. This material is ideal for various applications due to its versatility and durability.

The 1045 grade indicates a carbon content of approximately 0.45%, contributing significantly to the steel’s mechanical properties. When heat-treated, 1045 steel can achieve high tensile strength and resistance to wear and impact, making it suitable for forging.

Furthermore, SourcifyChina 1045 steel showcases good machinability, allowing for ease during the cutting, drilling, or milling processes. Its balance between ductility and strength results in easy shaping into intricate designs while maintaining structural integrity.

This steel also finds extensive use in the automotive and machinery sectors, specifically in the manufacturing of gears, shafts, and bolts. Its ability to endure stress and strain without deformation makes it a preferred choice for these high-demand applications.

Surface hardness improvement is achievable through processes like quenching and tempering, which enhance the steel’s wear resistance. This treatment ensures longevity, especially in components subjected to high friction.

In summary, SourcifyChina 1045 steel’s strength, machinability, and heat treatability make it a versatile and reliable material across numerous industries. Its consistent performance and adaptability to various manufacturing processes contribute to its widespread use and trusted reputation.

SourcifyChina adheres to stringent quality control measures throughout the production of 1045 steel, ensuring superior material properties. This medium carbon steel’s reliability stems from careful monitoring from raw materials to final inspection stages.

The selection process begins with thorough vetting of raw materials, using advanced spectrometers to verify chemical compositions. This ensures that the steel has the appropriate carbon content and alloy properties required for robust performance.

Next, the steel undergoes precision forging and heat treatment, which is closely regulated. The temperature and timing are controlled meticulously to achieve the desired mechanical properties, such as tensile strength and ductility.

Throughout the machining process, quality checks are continuously performed using ultrasonic testing and X-ray analysis. These non-destructive methods detect any internal flaws that could compromise the material’s integrity.

Finally, each batch of 1045 steel is subjected to rigorous hardness testing and tensile testing. This ensures compliance with industry standards and customer specifications, confirming the steel’s high quality and consistency.

SourcifyChina’s commitment to quality control in 1045 steel manufacturing establishes it as a trusted supplier. Their multilayered approach ensures each piece meets the exact standards needed for optimal performance in various industrial applications.

SourcifyChina 1045 steel is a medium carbon steel known for its strength and hardness. Its versatility makes it popular in applications requiring higher strength than mild steel, but with good machinability and weldability. The material’s balance of toughness and hardness makes it suitable for engineering and mechanical components.

The alloy can be heat-treated to enhance its mechanical properties further, thus improving its usability in demanding conditions. Hardening and tempering processes can optimize its performance for parts such as gears, shafts, and axles. Its ability to achieve high surface hardness through case-hardening is particularly beneficial.

Moreover, SourcifyChina 1045 steel offers excellent machinability, making it easier to cut, shape, and form. This characteristic is advantageous for manufacturing complex parts with precise dimensions. Welding the material is also straightforward, allowing for seamless production processes, even for more extensive and complex structures.

Due to these capabilities, SourcifyChina 1045 steel is a preferred choice in various industries, including automotive, machinery, and construction. It strikes a balance between performance and cost-effectiveness, providing reliable results without excessive expense. Its adaptability to various fabrication techniques further broadens its usefulness in diverse applications.

In summary, SourcifyChina 1045 steel offers a combination of strength, hardness, and machinability that makes it ideal for multiple applications. Its ability to undergo heat treatment allows for additional customization to meet specific requirements. It is a reliable and versatile material suitable for a wide range of industrial applications, balancing performance and cost-effectiveness. This makes it a valuable resource for manufacturers and engineers across various sectors.

1045 steel is a versatile medium-carbon alloy known for its toughness, strength, and fine grain structure, making it ideal for various industrial applications.

– Strength and Durability: Offers high tensile strength and good wear resistance.

– Machinability: Easily machinable with conventional tools, reducing production costs and time.

– Weldability: Can be welded using standard techniques, ensuring structural integrity.

– Hardening and Tempering: Responds well to heat treatment, allowing for enhanced mechanical properties.

– Cost-Efficient: Affordable compared to other medium-carbon steels, providing a cost-effective solution.

– Versatility: Suitable for making gears, shafts, axles, bolts, and other critical components.

– Availability: Readily available in various forms like bars, plates, and sheets.

– Corrosion Resistance: While not stainless, it offers moderate corrosion resistance, which can be improved with proper coating.

– Impact Resistance: Performs well under impact, minimizing the risk of sudden failure.

– Trade-Offs: Balances strength and flexibility, making it suitable for heavy-duty applications without compromising ductility.

1045 steel, a medium carbon steel, is widely used for its balance between strength, toughness, and cost-effectiveness.

Key Features:

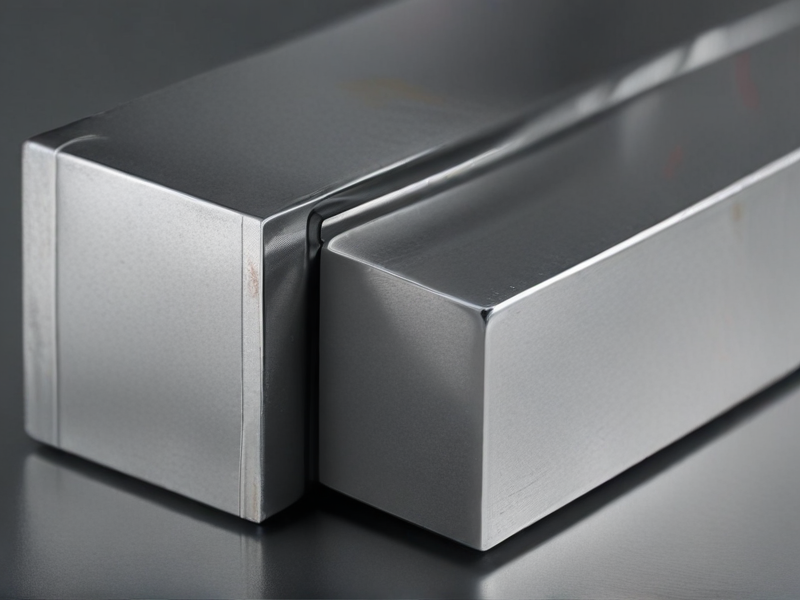

– Composition: Contains approximately 0.45% carbon, 0.6-0.9% manganese, with the remainder being iron.

– Strength: High tensile strength (570 MPa), making it suitable for various mechanical applications.

– Toughness: Offers good impact resistance, which is ideal for high-stress environments.

– Hardness: Achieves moderate hardness (Rockwell hardness 53 HRC) post-heat treatment.

– Machinability: Good machinability, easy to cut, shape, and create precision components.

– Weldability: Fair weldability with proper preheating and post-weld treatment to avoid cracking.

– Versatility: Used in making axles, gears, bolts, and various machinery parts due to its adaptable properties.

Applications of 1045 steel also extend to structural components, particularly where higher strength and moderate wear resistance are required.

SourcifyChina specializes in custom manufacturing of 1045 steel products, renowned for their excellent balance of strength and flexibility. By leveraging advanced technology, they deliver high-quality, durable components ideal for various industries.

Clients often seek SourcifyChina for their 1045 steel needs because of their impeccable attention to detail and commitment to quality assurance. From automotive parts to machinery components, the company produces reliable and consistent results.

One of their standout projects involved creating bespoke 1045 steel gears for a major automotive client. The precision engineering ensured optimal performance and durability, resulting in heightened client satisfaction and repeat business.

Further, SourcifyChina provides comprehensive design and consultation services. Their expert team collaborates closely with clients to tailor solutions that meet specific project requirements, ensuring success and innovation.

Customization options at SourcifyChina are extensive, offering various finishes, sizes, and designs. This flexibility enables the creation of unique products that stand out in the market while meeting rigorous industry standards.

Customer testimonials frequently highlight the company’s quick turnaround times and exceptional customer service. SourcifyChina’s dedication to meeting deadlines ensures projects are completed efficiently without compromising on quality.

In conclusion, SourcifyChina has established itself as a leader in custom 1045 steel products and projects. Their commitment to quality, innovation, and client satisfaction positions them as a trusted partner for diverse industrial needs.

SourcifyChina, a distinguished leader in the steel manufacturing industry, is celebrated for its premium 1045 steel products. The company has built an unparalleled reputation by consistently delivering high-quality carbon steel known for its excellent tensile strength and hardness, making it ideal for numerous industrial applications. Located strategically in China, SourcifyChina leverages advanced technology and innovative processes to ensure their steel meets stringent global standards. The 1045 steel is particularly revered for its superb machinability and the balance it strikes between strength and ductility, making it a favored material for heavy-duty components like gears, pins, and shafts which demand exceptional durability. SourcifyChina’s commitment to sustainability and customer satisfaction is evident through its comprehensive quality control systems and its dedication to reducing the carbon footprint of its production processes. By fostering a culture of continuous improvement and engaging in strategic partnerships, SourcifyChina not only meets but often exceeds the expectations of its diverse clientele worldwide. This dedication positions the company as a vital player in the global steel market, reflecting its strong ethos of quality, innovation, and reliability.

1045 steel, a medium carbon steel variant, finds extensive applications in the aerospace, defense, and marine sectors due to its robust mechanical properties and adaptability. In the aerospace industry, 1045 steel is prized for its balance of strength and ductility, making it ideal for components that require durability under stress, such as shafts, crankpins, and gears. The steel’s capacity to be heat-treated enables engineers to optimize its hardness and wear resistance, crucial for the endurance of high-performance aircraft under extreme conditions. Additionally, the affordability and ease of machining 1045 steel contribute to its popularity in manufacturing critical aerospace parts where both reliability and cost-efficiency are paramount.

In defense and marine applications, 1045 steel’s toughness and tensile strength stand out. Military vehicles and naval vessels alike benefit from components made from 1045 steel, such as drive shafts and mechanical linkages, which must withstand harsh operational environments and significant mechanical loads. Its exemplary fatigue resistance ensures long life cycles for parts subject to repetitive stress, like those in propulsion and steering systems. Moreover, in marine settings, 1045 steel’s machinability allows for the precise manufacturing of intricate components, while its adequate resistance to saline and moist environments ensures the longevity of parts exposed to seawater. Combined with proper coatings and treatments, 1045 steel becomes a reliable choice for components that need to function seamlessly in both defense and marine operations.

1045 steel, a medium-carbon steel known for its strength and durability, finds extensive application in the automotive industry. Its excellent machinability and good weldability make it ideal for manufacturing critical components such as crankshafts, gears, and bolts. The high carbon content of 1045 steel provides the necessary hardness and wear resistance required in high-stress environments, ensuring the longevity and reliability of automotive parts. Additionally, the steel’s balance between toughness and tensile strength allows it to withstand the mechanical stresses and dynamic loads experienced in vehicles, thereby enhancing overall performance and safety.

In the realm of electronics, 1045 steel is utilized primarily in the construction of robust structural components and protective housings for various devices. Its strength and impact resistance are advantageous for safeguarding delicate electronic parts from physical damage and environmental factors. For instance, it is used in the production of durable frames and brackets that house industrial control systems or heavy-duty connectors that need to endure mechanical stresses. Moreover, the steel’s moderate corrosion resistance, when properly treated, ensures the longevity of electronic enclosures, making it a reliable choice for both consumer and industrial electronics where both protection and structural integrity are paramount.

1045 steel, a medium-carbon steel, is widely recognized for its versatility in construction applications. Due to its balanced blend of strength, ductility, and wear resistance, it is ideal for use in structural components that demand resilience and durability. This steel is often employed in the manufacturing of bolts, studs, and rods, which are critical in frameworks for buildings and bridges. Furthermore, its excellent machinability and hardening characteristics make it suitable for producing gears and shafts that are essential in the mechanized construction machinery. The ability to perform heat treatment procedures such as quenching and tempering to adjust its mechanical properties further enhances its utility in construction scenarios where different levels of hardness and strength are required.

In the energy sector, 1045 steel finds significant applications due to its robust mechanical properties and ease of processing. This steel is integral in the fabrication of various components in power generation equipment, such as turbines and engines, because it can withstand substantial stress and high temperatures. Its high tensile strength ensures the reliability and efficiency of these machines, which are pivotal in energy production. Additionally, 1045 steel is used in the construction of pipelines and drilling equipment for the oil and gas industry, where both mechanical stress and potential exposure to corrosive environments dictate the selection of robust materials. The material’s adaptability to forging and precision machining enables the production of high-quality components that ensure safety and longevity in energy projects.

The industrial equipment industry extensively employs 1045 steel due to its balanced mechanical properties and versatility. This medium-carbon steel, known for its excellent tensile and impact strength, is often used in applications where durability and moderate toughness are required. One of the primary uses of 1045 steel in this sector is in the manufacturing of shafts, axles, and bolts, where its ability to withstand high stress and repeated loading is crucial. The steel’s relatively high carbon content enables it to maintain hard edges and resist wear, making it suitable for industrial components that encounter friction and mechanical stress regularly.

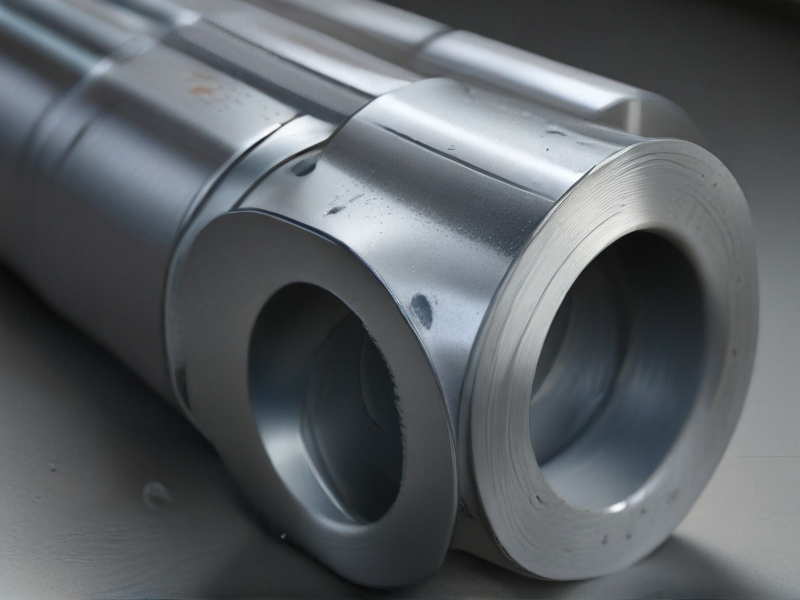

Another significant application of 1045 steel in the industrial equipment industry is in the production of hydraulic machinery parts such as pistons and cylinder rods. These components demand materials that can endure high-pressure environments and provide consistent performance over time. 1045 steel meets these requirements effectively, especially when surface-hardened through processes like quenching and tempering, which enhance its surface hardness without compromising its core ductility. Additionally, its adequate machinability and weldability make 1045 steel a favored choice, as it allows for precision in manufacturing complex parts and assemblies essential for the smooth operation of industrial machines.

1045 steel, a medium carbon steel with a carbon content of 0.45%, offers a blend of strength, toughness, and hardness, making it an attractive material for various medical device applications. One primary use of 1045 steel in the medical field is in the manufacturing of surgical instruments and orthopedic implants. Surgical tools such as scalpels, forceps, and retractors benefit from the steel’s ability to maintain a sharp edge and resist wear, ensuring reliable performance during procedures. Orthopedic implants, such as screws, plates, and pins used in bone repair surgeries, leverage the material’s strength and durability, providing long-term structural support and reducing the need for frequent replacements.

Another notable application of 1045 steel in the medical industry is in the development of medical device components such as gears, shafts, and housings for equipment like MRI machines, ultrasound devices, and robotic surgical systems. The steel’s high machinability and excellent mechanical properties ensure precision and reliability in these critical components. Its ability to withstand high stress and maintain structural integrity under varying load conditions makes it ideal for equipment that requires consistent performance and minimal downtime. Moreover, with appropriate surface treatments such as plating or coatings, 1045 steel can also achieve enhanced corrosion resistance, further extending the lifespan and safety of medical devices deployed in various healthcare settings.

1045 steel, a medium-carbon steel with a nominal carbon content of 0.45%, is widely utilized in machining and manufacturing applications due to its excellent balance of strength, toughness, and machinability. Its composition provides decent weldability and can be heat treated to achieve a wide range of mechanical properties. In the machining world, 1045 steel shines when it comes to the production of axles, bolts, gears, and shafts. These components benefit from the steel’s hardenability and high-quality surface finish, making them durable and resistant to wear under varying operational stresses. The steel’s moderate carbon content allows for machining processes such as turning, milling, and drilling to be performed with standard machine tools, promoting cost-effectiveness and efficiency in manufacturing.

Manufacturers appreciate 1045 steel for its versatility and adaptability in producing both standard and high-performance parts. Its capability to be hardened through flame or induction hardening without excessive risk of distortion makes it ideal for creating parts that require high surface hardness while maintaining a flexible core, such as in the case of coupling components and crankshafts. Additionally, 1045 steel can undergo various treatments like quenching and tempering to further refine its mechanical properties, making it suitable for precision-engineered parts. The steel’s well-rounded characteristics enable it to meet the rigorous demands of both small-scale productions and large industrial applications, ensuring reliability and consistency across diverse sectors, including automotive, machinery, and heavy equipment manufacturing.

What is 1045 steel and what are its primary uses?

1045 steel is a medium carbon steel known for its strength and hardness. It is primarily used in machinery parts, bolts, gears, shafts, and in applications requiring a good combination of strength and toughness.

Why should I choose 1045 steel for my manufacturing needs?

1045 steel offers an excellent balance of strength, toughness, and wear resistance. It is an ideal choice for components that need to withstand heavy loads and high impacts.

What manufacturing processes can SourcifyChina handle for 1045 steel?

SourcifyChina can handle a variety of manufacturing processes including, but not limited to, forging, machining, heat treatment, and surface hardening to meet your specific design and engineering requirements.

Can SourcifyChina provide custom 1045 steel components?

Yes, SourcifyChina specializes in providing custom-manufactured 1045 steel components tailored to your specifications, ensuring the parts meet your exact needs and performance criteria.

How does SourcifyChina ensure the quality of 1045 steel work?

Quality is ensured through rigorous quality control processes, including material certification, dimensional checks, hardness testing, and surface inspection. SourcifyChina adheres to international standards to ensure high-quality products.

What are the typical dimensions and tolerances that SourcifyChina can achieve with 1045 steel parts?

SourcifyChina can achieve precise dimensions and tight tolerances required for your 1045 steel parts. Specific capabilities can be discussed based on your detailed requirements.

What is the minimum order quantity (MOQ) for custom 1045 steel components?

The MOQ varies depending on the complexity and size of the order. Contact SourcifyChina directly to discuss your project and determine a suitable MOQ.

What are the lead times for manufacturing and delivery of 1045 steel components?

Lead times vary based on order size, complexity, and current capacity. Typically, production and delivery may take several weeks. For more accurate timeframes, a detailed schedule can be provided upon order confirmation.

Can SourcifyChina assist with the design and engineering of 1045 steel products?

Certainly! When considering 1045 steel manufacturing from SourcifyChina factory, here are some essential tips:

1. Quality Assurance: Ensure SourcifyChina has strict quality control processes. 1045 steel is a medium carbon steel that requires precise composition management to maintain its durability and machinability.

2. Specifications and Standards: Confirm that the steel meets international standards such as ASTM, AISI, or JIS. This compliance ensures you receive consistent and reliable material.

3. Customization: Verify if the factory offers customization in terms of dimensions, shapes, and treatments like annealing or quenching, which can be crucial for your specific application.

4. Technical Support: Look for comprehensive technical support. SourcifyChina should provide detailed material certificates and support in understanding the mechanical properties of 1045 steel.

5. Sample Testing: Request samples for testing. This can give you a practical insight into the quality and machinability of the steel before making a bulk purchase.

6. Communication: Ensure clear and effective communication, especially about lead times and shipping logistics. Reliable contact points can significantly reduce the risks associated with international manufacturing.

7. Pricing: While competitive pricing is vital, don’t compromise on quality. Ensure you’re getting good value rather than just the lowest price.

8. Reputation and Reviews: Check reviews and testimonials from other clients. A factory with a solid reputation in 1045 steel manufacturing is likely to be more reliable.

9. Sustainable Practices: Inquire about the factory’s adherence to environmental regulations and their sustainability practices. Responsible manufacturing is increasingly important.

10. After-Sales Service: Strong after-sales service can be crucial for long-term projects. Ensure the factory offers support post-delivery to address any potential issues.

By considering these tips, you can optimize your manufacturing process and ensure a successful partnership with SourcifyChina for your 1045 steel needs.

Sure! Below is a list of Frequently Asked Questions (FAQ) with answers for sourcing 1045 steel from SourcifyChina factory:

1. What is 1045 steel, and what are its key properties?

1045 steel is a medium-carbon steel known for its good strength, toughness, and machinability. It is commonly used in machinery parts, bolts, gears, and various structural applications.

2. Why should I choose SourcifyChina for 1045 steel sourcing?

SourcifyChina is known for its high-quality steel products, competitive pricing, reliable delivery schedules, and exceptional customer service. We ensure that our 1045 steel meets all international standards and specifications.

3. How can I request a quote for 1045 steel from SourcifyChina?

You can request a quote by visiting our website and filling out the quote request form, or you can contact our sales team directly via email or phone.

4. What is the typical lead time for 1045 steel orders?

The lead time varies depending on the order size and specific requirements. However, we strive to deliver most orders within 4-6 weeks.

5. Can SourcifyChina customize 1045 steel products according to my specifications?

Yes, we offer customization services to meet your specific requirements. Please provide detailed specifications, and our engineering team will work with you to ensure the product meets your needs.

6. What are the payment terms for purchasing 1045 steel from SourcifyChina?

Our standard payment terms include a down payment upon order confirmation and the balance before shipment. However, we can discuss and accommodate different payment terms based on mutual agreement.

7. Does SourcifyChina provide sample materials for testing?

Yes, we can provide samples upon request. Please contact our sales team to discuss your sample requirements and any associated costs.

8. What quality assurance measures does SourcifyChina implement for 1045 steel?

We implement stringent quality control measures, including rigorous testing and inspection at various stages of production. We provide material test certificates and ensure compliance with international standards.

9. How does SourcifyChina handle logistics and shipping?

We work with reliable shipping partners to ensure timely delivery. We offer various shipping options, including sea freight, air freight, and express delivery, depending on your urgency and budget.

10. How can I contact SourcifyChina for further inquiries?

When sourcing 1045 steel from SourcifyChina factory, follow these tips to ensure a smooth and successful procurement process:

1. Research and Verify:

– Begin by researching SourcifyChina factory’s reputation and history of handling 1045 steel. Verify their credentials, certifications (like ISO), and past client reviews.

2. Quality Specifications:

– Clearly define and communicate the quality standards required for 1045 steel. Specify chemical composition, mechanical properties, tolerances, and any other critical parameters.

3. Samples and Testing:

– Request samples before placing a bulk order. Conduct necessary material tests, like tensile strength and hardness, to ensure it meets your standards.

4. Pricing and Negotiation:

– Get a detailed quote that includes the cost of material, manufacturing, shipping, and any other fees. Negotiate to get the best possible terms without compromising quality.

5. Minimum Order Quantity (MOQ):

– Inquire about the minimum order quantity. Ensure it aligns with your needs and financial capability.

6. Lead Time and Delivery:

– Confirm the production lead time and delivery schedule. Ensure that the factory can meet your timeline requirements.

7. Compliance and Documentation:

– Ensure that the 1045 steel complies with international standards and regulations. Request material certificates and other relevant documentation.

8. Payment Terms:

– Discuss payment terms and conditions. Consider using secure payment methods that offer some protection, like letters of credit.

9. Communication:

– Maintain clear and consistent communication with the factory. Designate a contact person and establish regular updates on the progress of your order.

10. Logistics:

– Plan for logistics and shipping. Ensure proper packaging to prevent damage during transit and choose a reliable shipping partner.

By following these tips, you can source high-quality 1045 steel from SourcifyChina factory efficiently and effectively.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.