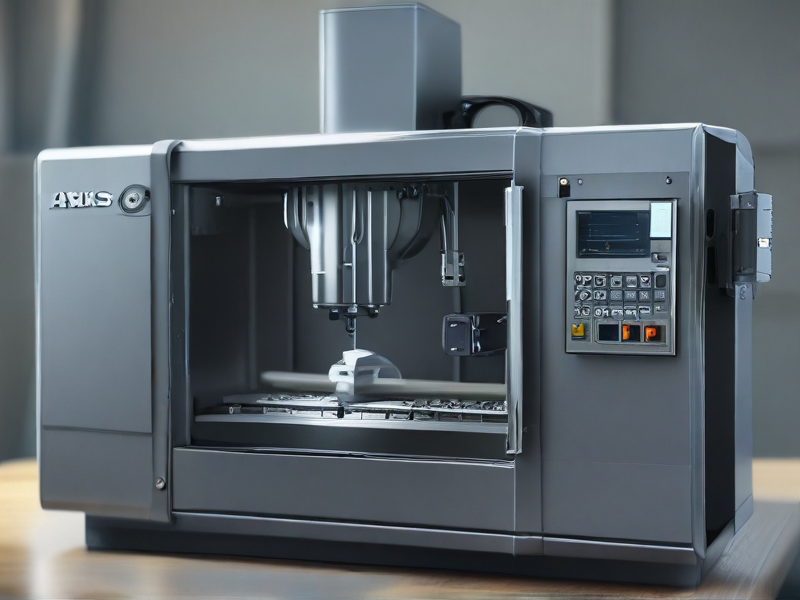

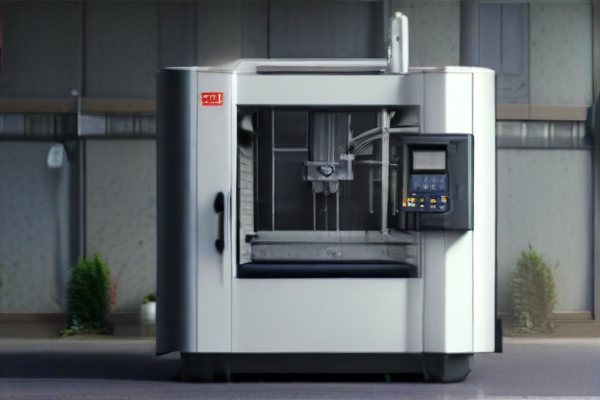

## Discover Reliable 3-Axis CNC Machines at SourcifyChina Factory for Precision Manufacturing

Explore SourcifyChina’s factory for high-quality 3-axis CNC machines, known for their reliability and precision. Ideal for various manufacturing needs, these machines ensure top performance and accuracy in production processes.

Choosing SourcifyChina Factory for purchasing a 3-axis CNC machine offers unparalleled advantages. Their impeccable quality control ensures machines meet international standards, providing buyers with reliable and durable machinery. Each machine undergoes rigorous testing to guarantee high performance and precision.

SourcifyChina Factory stands out due to its customer-centric approach. With a dedicated team offering 24/7 support, buyers can address any concerns promptly, ensuring smooth operation and minimal downtime. This commitment to customer satisfaction underscores their reputation for excellence.

Furthermore, competitive pricing makes SourcifyChina Factory an attractive option. Despite offering top-notch machinery, their cost-effective pricing ensures that buyers get the best value for their investment. This combination of quality and affordability makes them a preferred supplier.

In addition to quality and pricing, SourcifyChina Factory offers comprehensive training and support. Their team provides detailed manuals, training sessions, and ongoing technical support to ensure buyers can maximize machine efficiency. This holistic support approach streamlines the integration process.

Moreover, the factory’s strategic location simplifies logistics. Situated in a key manufacturing hub in China, they benefit from efficient supply chains and reduced shipping times, ensuring timely delivery to international buyers. This efficiency enhances buyer satisfaction and project timelines.

Ultimately, choosing SourcifyChina Factory for a 3-axis CNC machine purchase ensures high-quality, cost-effective machinery supported by excellent customer service and efficient logistics. This comprehensive package provides buyers with a smooth, reliable purchasing experience from a reputable supplier.

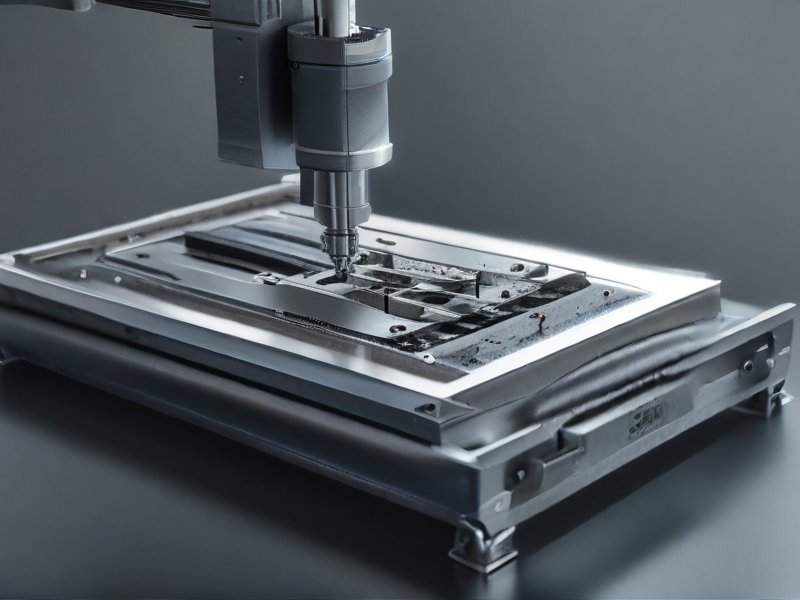

A 3-axis CNC machine is versatile, primarily used for simple milling and drilling tasks. They operate along the X, Y, and Z axes, providing precision for diverse applications.

– Types of 3-Axis CNC Machines:

– Vertical Milling Machines: Best for flat and irregular surfaces.

– Horizontal Milling Machines: Suitable for heavy, larger materials.

– Gantry CNC Machines: Ideal for large, flat workspaces.

– Options and Features:

– Spindle Speed: Ranges to match material hardness.

– Tool Changers: Automatic or manual options.

– Table Sizes: Vary to accommodate different sheet sizes.

– Software Compatibility: Different machines use specific programming languages.

– Precision and Accuracy: High-end models offer micrometric precision.

– User Interface: Varieties from simple controls to advanced touchscreens.

– Cooling Systems: Options include mist, air, or liquid cooling.

– Power Requirements: Machines vary from low to high power needs.

– Applications:

– Prototyping: Fast and accurate creation of models.

– Production Runs: Efficient for small to medium batches.

– Custom Parts: Ideal for customized, intricate part fabrication.

Understanding these types and options is vital for selecting the right 3-axis CNC machine suited to your specific tasks and requirements.

A 3-axis CNC machine precisely controls cutting tools along three axes—X, Y, and Z—enabling the creation of complex shapes. This technology is widely used across various industries due to its versatile applications and significant precision.

– Automotive: Manufacturing components like engine parts and custom car accessories.

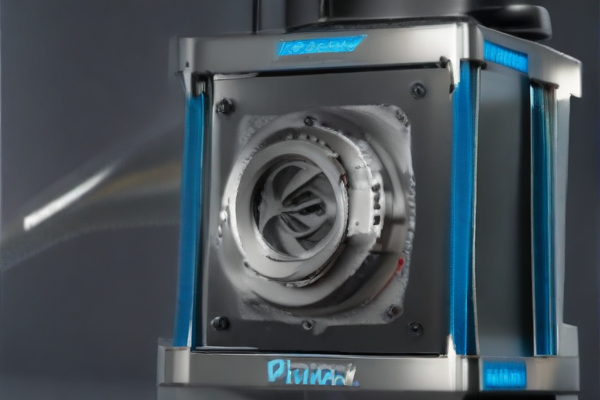

– Aerospace: Crafting parts for aircraft, including turbine blades and structural components.

– Medical: Producing surgical tools and prosthetic devices with high precision.

– Woodworking: Creating intricate wood designs, from furniture parts to decorative items.

– Prototyping: Rapidly developing prototypes for product development and testing.

– Jewelry: Designing and creating detailed jewelry pieces.

– Textile: Cutting materials and creating patterns for clothing and accessories.

– Electronics: Manufacturing enclosures, circuit boards, and other electronic components.

– Metalwork: Fabricating metal parts for various industrial applications.

– Education: Training students and researchers in mechanical engineering and design.

– Signage: Producing custom signs and displays for marketing and advertising.

– Plastics: Cutting and shaping plastic parts for consumer goods and industrial use.

– Tool and Die Making: Crafting molds and dies used in manufacturing processes.

– Maritime: Building and repairing boat parts and accessories.

– Art and Sculpture: Creating detailed sculptures and customized art pieces.

– Packaging: Manufacturing custom packaging solutions.

– Robotics: Producing precision parts for robot assembly and automation.

– Renewable Energy: Fabricating parts for solar panels and wind turbines.

– Molds for Injection Molding: Crafting intricate molds used in plastic injection molding.

3-axis CNC machines provide unparalleled accuracy and efficiency, supporting advancements in technology and manufacturing by offering a broad range of applications across diverse industries.

The “SourcifyChina 3 Axis CNC Machine” is constructed using high-grade aluminum alloy, ensuring durability and lightweight attributes. The aluminum frame provides robust structural integrity while being resistant to corrosion, thereby enhancing longevity.

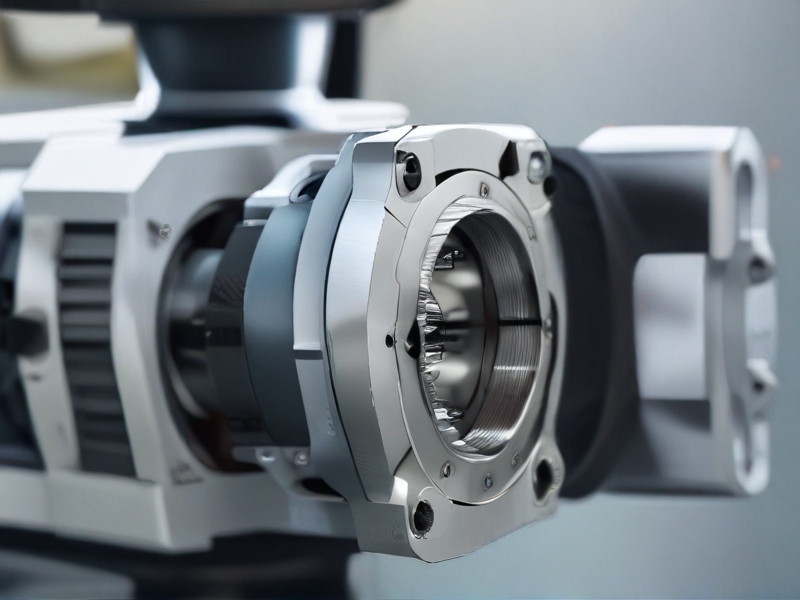

Steel is utilized for critical components such as the spindles and screws, offering superior strength and precision. The use of hardened steel assures minimal wear and tear, maintaining high performance and accuracy over prolonged periods of operation.

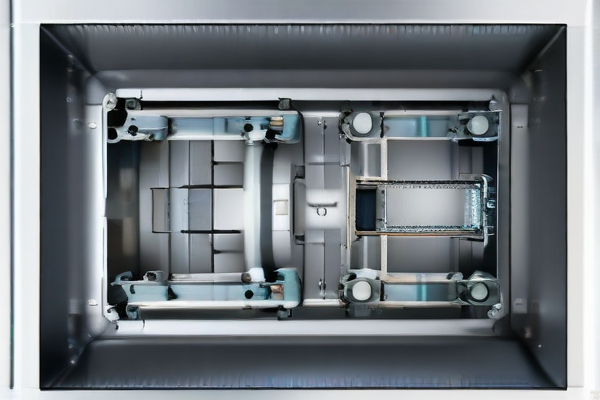

The work surface is generally made of a composite material or heavy-duty plastic, which combines rigidity with a smooth finish. This design minimizes vibrations during machining, leading to precise and clean cuts.

For electronic components, high-quality circuit boards and heat-resistant wiring are employed. This ensures reliable and safe operation, even under continuous use conditions, thereby boosting the machine’s overall efficiency.

In conclusion, the materials used in the SourcifyChina 3 Axis CNC Machine are carefully selected to balance durability, functionality, and performance. From the aluminum frame to the steel elements and specialized electronics, each material is chosen to optimize the machine’s operation and longevity.

SourcifyChina’s 3-axis CNC machine undergoes a stringent quality control manufacturing process to ensure top-tier performance and reliability. From initial material selection to final assembly, each step is meticulously monitored to meet precise engineering specifications and standards.

Material quality is crucial, with rigorous inspection protocols in place before components enter production. High-grade metals and composites are selected to withstand intensive use and environmental stress, ensuring longevity and durability in various applications.

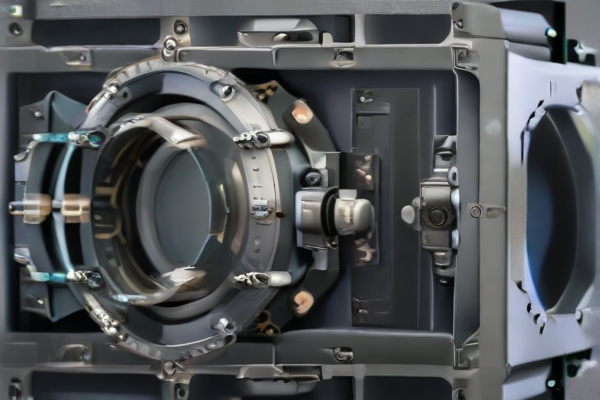

Precision machining processes are utilized, incorporating advanced techniques such as laser cutting and automated milling. Every component is produced to tightly controlled tolerances, helping to maintain the machine’s overall accuracy and performance.

After machining, key components undergo thermal treatment and stress relief processes to enhance structural integrity and rigidity. This step minimizes the risk of deformation under operational loads and prolongs the machine’s service life.

Assembly takes place in a controlled environment where skilled technicians ensure that components fit together seamlessly. Specialized jigs and fixtures are used to maintain alignment and accuracy during the assembly process, further ensuring that the final product meets exacting standards.

Each CNC machine then undergoes a rigorous series of functional tests, including operational stress tests and precision measurements. These extensive evaluations guarantee that the machine not only meets but often exceeds industry benchmarks for performance and reliability.

Finally, an end-of-line inspection is conducted to ensure all aspects of the machine, from operational efficiency to safety features, are in compliance with international standards. Documentation and traceability are maintained throughout the process, ensuring that each unit can be tracked for quality assurance purposes.

In conclusion, SourcifyChina’s commitment to quality is evident in its comprehensive manufacturing process. By focusing on material selection, precision machining, robust assembly, and thorough testing, the company ensures that every 3-axis CNC machine delivers exceptional performance and reliability. This meticulous approach solidifies their reputation as a leading manufacturer in the CNC machine industry.

The SourcifyChina 3-axis CNC machine showcases impressive precision and durability, making it ideal for custom manufacturing tasks. This state-of-the-art equipment handles intricate designs efficiently, optimizing production time and minimizing waste.

One of its standout features is its user-friendly interface, which allows operators to swiftly input and modify commands. This increases flexibility and enables quick adjustments to meet specific project requirements.

Additionally, the machine supports a wide range of materials, from metals to plastics. This versatility makes it useful across various industries, including automotive, aerospace, and electronics.

Equipped with advanced software, the SourcifyChina CNC machine delivers high repeatability, ensuring consistent quality across multiple runs. Its robust build minimizes maintenance needs and enhances operational reliability.

Overall, the SourcifyChina 3-axis CNC machine excels in both performance and adaptability, making it a valuable asset for manufacturers seeking to optimize their production capabilities. With consistent output, reduced downtime, and versatile material handling, this machine is a cost-effective solution for precision manufacturing.

A 3-axis CNC (Computer Numerical Control) machine is an essential tool in modern manufacturing, providing precision, efficiency, and versatility. This equipment operates along three linear axes (X, Y, and Z), allowing for intricate designs and high accuracy in machining processes.

– Precision and Accuracy: 3-axis CNC machines offer high precision, ensuring consistent and repeatable quality in production.

– Increased Productivity: Automation reduces manual labor and speeds up production cycles, enhancing productivity.

– Versatility: Capable of handling various materials like metals, plastics, and wood, meeting diverse manufacturing needs.

– Cost-Effective: Reduces waste and errors, leading to cost savings in material and labor.

– Complex Geometry: Allows the creation of complex shapes and intricate designs that would be challenging with manual machining.

– User-Friendly: Advanced software integration makes programming and operation easier, even for users with minimal experience.

– Improved Safety: Automation minimizes human contact with cutting tools, enhancing workplace safety.

– Consistency: Ensures uniformity in large production runs, crucial for industries like automotive and aerospace.

– Customization: Easily adjustable software settings allow for quick changes and customization of designs.

– Maintenance: Typically robust and durable, requiring less frequent maintenance compared to traditional machinery.

In summary, 3-axis CNC machines significantly improve manufacturing precision, efficiency, and versatility, making them indispensable in various industrial applications.

A 3-axis CNC (Computer Numerical Control) machine is a versatile and essential tool in modern manufacturing, allowing for precise and automated machining of complex parts.

Key features include:

– Three Axes Movement: It controls movement along the X, Y, and Z axes for versatile machining.

– High Precision: Capable of achieving tight tolerances, crucial for high-quality production.

– Computer-Controlled Operations: Utilizes CAM software to convert digital designs into precise machine instructions.

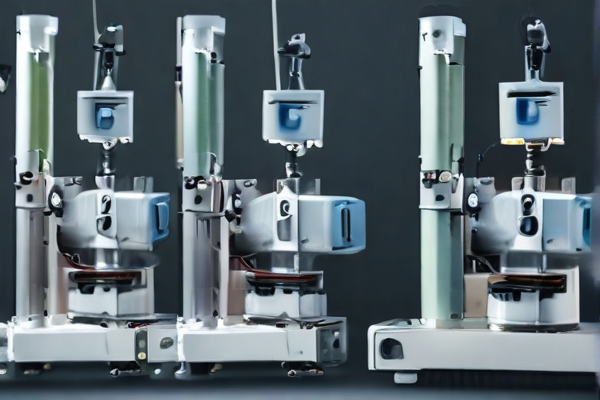

– Automated Tool Changes: Many models feature automatic tool changers, reducing manual intervention and improving efficiency.

– Sturdy Construction: Built with robust materials to minimize vibrations and maintain accuracy.

– Spindle Speed Control: Variable speed options to accommodate different materials and cutting conditions.

– User-friendly Interface: Often includes touchscreens and intuitive controls for easier operation.

– Coolant Systems: Integrated cooling systems to prolong tool life and maintain workpiece quality.

– Safety Features: Emergency stop buttons, protective enclosures, and other safety mechanisms to ensure operator safety.

– Versatility: Suitable for a wide range of materials including metals, plastics, and wood.

– High-Speed Machining: Efficiently handles both roughing and finishing processes.

– Material Holding Systems: Features like vacuum tables or clamps for securely holding the workpiece during operation.

These capabilities make 3-axis CNC machines indispensable tools in industries ranging from aerospace to woodworking.

The SourcifyChina 3-axis CNC machine offers precision and versatility for custom products and projects, making it ideal for a wide range of applications in various industries.

With advanced control systems, this CNC machine can handle intricate designs and detailed work, ensuring high-quality outputs for both small and large-scale productions.

Whether for prototyping or full-scale manufacturing, the SourcifyChina 3-axis CNC machine excels in creating components with exceptional accuracy, reducing material waste, and improving efficiency.

Custom projects benefit from its adaptability, as it supports various materials, including metals, plastics, and wood, catering to diverse production needs.

Overall, the SourcifyChina 3-axis CNC machine stands out as a reliable and efficient solution for businesses looking to enhance their manufacturing capabilities and achieve superior results.

SourcifyChina, a leading provider in the manufacturing sector, specializes in the design and production of 3-axis CNC (Computer Numerical Control) machines, renowned for their precision and reliability. Leveraging advanced technology and engineering expertise, the company delivers state-of-the-art CNC machines that cater to a broad spectrum of industries including automotive, aerospace, and consumer electronics. SourcifyChina is dedicated to enhancing manufacturing efficiency and product quality, offering tailored solutions that meet the unique needs of each client. Their 3-axis CNC machines are celebrated not just for their meticulous craftsmanship but also for their robust performance and ease of operation. By integrating innovative features and rigorous quality control processes, SourcifyChina ensures that its clients achieve optimal productivity and accuracy in their machining operations. Moreover, with a strong commitment to customer service and continuous improvement, the company has established itself as a trusted partner in the global manufacturing landscape, driving progress and innovation in the CNC machining domain.

The aerospace and defense industries demand exceptional precision and reliability, making the 3-axis CNC machine an indispensable asset in these sectors. These machines are used extensively in the manufacturing of complex parts such as turbine blades, engine components, and structural elements of aircraft. The ability to execute intricate geometries with high accuracy ensures that the stringent tolerances required for aerospace applications are consistently met. In the defense sector, 3-axis CNC machines are employed to create components for weapon systems, surveillance equipment, and armored vehicles, where precise machining is crucial for both performance and safety. Additionally, the capabilities of 3-axis CNC machines streamline production processes, reducing lead times and enhancing overall efficiency, which is vital in defense operations that require rapid, reliable deployment of assets.

In the marine industry, 3-axis CNC machines play a critical role in the fabrication of crucial ship components and marine equipment. This includes everything from propellers and engine parts to intricate fittings and custom-designed features of yachts and commercial vessels. The marine environment presents unique challenges, requiring materials and components that can withstand corrosive conditions and extreme mechanical stresses. The precision and flexibility of 3-axis CNC machines allow for the production of parts that meet these rigorous demands, ensuring durability and performance at sea. Furthermore, these machines enable rapid prototyping and customization, which is particularly valuable in the development of innovative marine technologies and bespoke maritime solutions. Through the efficient and precise capabilities of 3-axis CNC machining, the marine industry can achieve a higher standard of quality and performance, fulfilling both commercial and exploratory objectives on the water.

Automotive Application:

In the automotive industry, 3-axis CNC (Computer Numerical Control) machines play a pivotal role in enhancing manufacturing precision and efficiency. These machines are essential for producing complex components such as engine blocks, transmission cases, and custom car parts with high accuracy. By automating the milling process, 3-axis CNC machines reduce human error and increase production speed, allowing for the high-volume manufacturing necessary in the auto industry. They facilitate the creation of highly detailed and intricate parts that ensure optimal performance and durability. Moreover, the capability to produce prototype parts swiftly enables automotive companies to innovate and iterate design concepts, speeding up the development cycle and reducing time-to-market for new models.

Electronics Application:

In the electronics sector, 3-axis CNC machines are invaluable for the fabrication of circuit boards, enclosures, and heat sinks, among other components. The precision offered by these machines is crucial for the miniaturization of electronic devices, which require intricate designs and tight tolerances to function correctly. 3-axis CNC machines are employed to drill holes for components, engrave intricate patterns, and mill housings to accommodate various electronic parts. This precision machining ensures that components fit together seamlessly, which is essential for maintaining the functionality and reliability of electronic devices. Additionally, CNC machines offer flexibility in material usage, from metals to polymers, allowing for the production of diverse electronic components tailored to specific thermal and electrical requirements.

In the construction industry, 3-axis CNC (Computer Numerical Control) machines revolutionize the way materials such as metal, wood, and composites are cut, shaped, and finished. These machines enable precise and complex geometries that would be challenging, if not impossible, to achieve manually. Builders and architects leverage 3-axis CNC machines to fabricate components such as intricate window frames, customized molds for concrete, and detailed interior features. The automation and precision that CNC technology brings significantly reduce material wastage and enhance efficiency, leading to faster project completion times and reduced labor costs. The integration of CAD (Computer-Aided Design) systems further streamlines the process, allowing for accurate replication of designs from digital blueprints to physical components with unmatched fidelity.

In the energy sector, 3-axis CNC machines play a pivotal role in the manufacture and maintenance of critical components used in power generation and distribution. For instance, these machines are instrumental in producing precision parts for turbines, including intricate blade profiles and housings for both wind and steam turbines. The high accuracy and repeatability of CNC machining ensure that components meet stringent industry standards, which is vital for the reliability and performance of energy systems. Additionally, 3-axis CNC machines aid in the fabrication of parts for solar panels, energy storage systems, and even components for electrical grids. By allowing for the rapid prototyping and production of innovative energy solutions, CNC technology supports the development and deployment of more sustainable and efficient energy systems, ultimately contributing to the global push for cleaner energy.

The industrial equipment industry has been revolutionized by the integration of 3-axis CNC machines, enhancing manufacturing precision and efficiency. These machines are designed to manipulate tools along three linear axes—X, Y, and Z—enabling intricate and consistent cutting, drilling, and milling operations on a variety of materials including metals, plastics, and composites. This allows for the production of highly detailed components essential for machinery and equipment across sectors such as automotive, aerospace, and medical devices. The ability to program CNC machines to execute complex designs directly from CAD models has substantially reduced the margin for human error, leading to higher quality and consistency in produced parts. Moreover, the automation of these processes decreases labor costs and accelerates production timelines, adding to the overall productivity of the industrial equipment sector.

Furthermore, 3-axis CNC machines are pivotal in prototyping and small-batch production, where precision and flexibility are critical. Companies can swiftly transition from one project to another without extensive retooling, accommodating custom specifications with ease. This agility is particularly beneficial for industries that demand rapid development cycles and high customization, such as consumer electronics and customized machinery production. Additionally, the data-driven nature of CNC machining contributes to better inventory management and just-in-time manufacturing, minimizing waste and optimizing resource utilization. Through continuous advancements and integration of new technologies like IoT and AI, 3-axis CNC machines remain at the forefront of industrial innovation, driving advancements in productivity, precision, and efficiency in the industrial equipment industry.

The application of 3-axis CNC (Computer Numerical Control) machines in the field of medical devices is transformative, offering high precision and efficiency critical to producing complex components. These machines enable the manufacture of medical instruments such as surgical tools, implants, and prosthetics with micron-level accuracy. Their ability to meticulously control movements along the X, Y, and Z axes ensures consistent results, which is paramount in the medical industry where the slightest deviation can have significant consequences on patient outcomes. For instance, bone screws and dental implants must adhere to stringent specifications, and the 3-axis CNC machine excels in maintaining these rigorous standards, thus improving the overall quality and safety of medical devices.

Moreover, 3-axis CNC machines significantly streamline the prototyping and production processes for custom medical devices. Personalized medical solutions, including custom implants and prosthetics tailored to individual patients’ anatomical requirements, benefit enormously from the machine’s capabilities. By facilitating rapid prototyping, these machines allow for the quick iteration and testing of design concepts, thereby accelerating the time-to-market for innovative medical solutions. This speed and efficiency in customization are particularly valuable in scenarios that demand swift responses, such as in trauma surgeries where patient-specific implants are needed promptly. Overall, the deployment of 3-axis CNC machines in the medical device sector enhances both the precision and flexibility of manufacturing, ultimately leading to improved patient care and outcomes.

The 3-axis CNC (Computer Numerical Control) machine is a staple in the machining and manufacturing industry, renowned for its precision and efficiency. This technology allows for the automated control of cutting tools along three axes—X, Y, and Z—enabling the creation of complex geometries with high accuracy. In machining applications, 3-axis CNC machines are utilized for tasks such as drilling, milling, and cutting a wide range of materials, including metals, plastics, and wood. The machine’s capability to make precise cuts and intricate patterns is invaluable for producing components with tight tolerances, which is essential in industries like aerospace, automotive, and medical device manufacturing.

In the realm of manufacturing, 3-axis CNC machines drastically improve productivity and consistency. Their programmability allows for the repetitive production of identical parts with minimal manual intervention, significantly reducing human error and labor costs. These machines are typically used to fabricate parts for assembly lines, custom tooling, and even prototypes. By automating complex and repetitive tasks, manufacturers can keep up with high-demand production schedules while maintaining superior quality. Additionally, 3-axis CNC machines integrate well with computer-aided design (CAD) and computer-aided manufacturing (CAM) software, streamlining the entire production process from concept to final product. This integration further enhances efficiency, enabling rapid adjustments and scalability within the manufacturing operation.

Sure! Here are some frequently asked questions (FAQ) and their answers related to manufacturing 3-axis CNC machines with quality work from SourcifyChina factory:

1. What is a 3-axis CNC machine?

A 3-axis CNC machine is a computer-controlled machine tool that moves along three linear axes (X, Y, and Z) to precisely cut, shape, and engrave materials. It is widely used in manufacturing for tasks requiring high precision.

2. Why choose SourcifyChina for manufacturing a 3-axis CNC machine?

SourcifyChina is renowned for its strict quality control, integrated supply chain, and advanced manufacturing techniques. Their expertise ensures the production of reliable and high-performance CNC machines at competitive prices.

3. What materials can a 3-axis CNC machine handle?

A 3-axis CNC machine from SourcifyChina can handle a variety of materials, including metals (aluminum, steel, titanium), plastics, wood, and composites, making it versatile for different applications.

4. How do you ensure the quality of the CNC machines?

SourcifyChina employs a rigorous quality control process, which includes precision testing, calibration, and comprehensive inspections. Every machine undergoes functionality and performance tests before shipment.

5. What are the key features of SourcifyChina’s 3-axis CNC machines?

Key features include high-speed spindles, advanced control systems, robust construction, user-friendly interfaces, and compatibility with various CAD/CAM software. These features ensure precision, efficiency, and ease of use.

6. Can I customize the CNC machine to fit my specific needs?

Yes, SourcifyChina offers customization options. Clients can specify parameters such as machine size, spindle power, control system, and additional features to match their unique manufacturing requirements.

7. What kind of support does SourcifyChina provide after purchase?

SourcifyChina provides technical support, training, and maintenance services. They also offer a warranty period during which any defects or issues are addressed promptly.

8. How long does it take to manufacture and deliver a CNC machine?

The lead time varies based on customization and order volume but is typically between 4 to 8 weeks. SourcifyChina ensures timely updates and communicates any potential delays proactively.

9. Are there any financing options available?

When manufacturing a 3-axis CNC machine through SourcifyChina factory, here are some key tips to ensure efficient production and high-quality output within a concise write-up:

1. Specify Requirements Clearly: Provide detailed specifications and requirements for your 3-axis CNC machine, including dimensions, types of materials, accuracy levels, and intended applications.

2. Technical Documentation: Ensure you have comprehensive technical drawings and blueprints. Share these with SourcifyChina to avoid any miscommunication.

3. Quality Control: Inquire about SourcifyChina’s quality assurance processes. Schedule regular inspections and request sample units to check for adherence to standards.

4. Component Sourcing: Verify the sources of critical components and materials to ensure they meet your quality expectations. SourcifyChina should have reliable suppliers for motors, controllers, and linear guides.

5. Cost Management: Discuss cost implications early. SourcifyChina offers competitive pricing, but be clear on your budget constraints and find areas to optimize.

6. Lead Times: Communicate your timeline requirements. Factor in time for manufacturing, quality checks, and potential revisions.

7. Compliance and Standards: Ensure that the machines comply with international standards and certifications relevant to your target markets (e.g., CE marking for Europe).

8. Customization Options: Ask about customization capabilities. SourcifyChina is flexible and can cater to specific requests such as unique bed sizes or advanced control systems.

9. Post-Sales Support: Confirm availability of after-sales support and spare parts. Reliable technical support is vital for troubleshooting and maintenance.

10. Non-Disclosure Agreements (NDAs): Protect your intellectual property by signing NDAs, ensuring your designs and specifications are secured.

Implementing these tips when working with SourcifyChina will streamline the manufacturing process, ensure quality, and maintain cost-effectiveness for your 3-axis CNC machines.

Sure, here are some Frequently Asked Questions (FAQ) and their answers for sourcing a 3-axis CNC machine from SourcifyChina factory, formatted with the questions in bold:

1. What is the lead time for sourcing a 3-axis CNC machine from SourcifyChina factory?

The lead time generally ranges from 4 to 8 weeks, depending on the machine’s specifications and customizations. It’s best to contact the factory directly for the most accurate estimate.

2. Does SourcifyChina factory offer customization options for their 3-axis CNC machines?

Yes, SourcifyChina factory provides a range of customization options including spindle power, table size, and additional features such as automatic tool changers. You can discuss your specific needs with their sales team.

3. What are the payment terms for purchasing a 3-axis CNC machine?

Typical payment terms include a 30% deposit upon order confirmation and the remaining 70% before shipment. However, terms can be tailored based on mutual agreement.

4. Do they offer installation and training services?

Yes, SourcifyChina factory offers both on-site installation and training services to ensure proper setup and operation of the CNC machine. Virtual training options may also be available.

5. What kind of warranty and post-sales support is available?

The factory generally offers a one-year warranty on mechanical parts and a six-month warranty on electronic components. Post-sales support includes troubleshooting assistance and the availability of spare parts.

6. Can I request a sample or a demonstration before placing a bulk order?

Yes, you can request a live demonstration via video conferencing or visit the factory for an in-person demo. Sample parts machined on a similar machine can also be provided upon request.

7. Are there any certifications available for the 3-axis CNC machines?

SourcifyChina factory ensures their machines comply with international standards and can provide certifications like CE and ISO upon request.

8. What shipping methods do you offer?

They offer various shipping methods including sea freight, air freight, and express courier services. The choice of shipping method depends on your urgency and budget constraints.

9. How can I get a quote for a 3-axis CNC machine?

You can obtain a quote by contacting SourcifyChina factory directly through their website, email, or phone. Providing detailed specifications will help in getting a more accurate quote.

10. Are there any minimum order requirements?

Sourcing a 3-axis CNC machine from SourcifyChina factory can be streamlined with these steps:

1. Research and Define Requirements:

– Specify machine dimensions, precision levels, and functionality.

– Determine your budget and timeline.

2. Find Reliable Suppliers:

– Visit the SourcifyChina website and explore CNC machine suppliers.

– Utilize platforms like Alibaba or GlobalSources for additional options.

3. Screen and Verify Suppliers:

– Check supplier credentials, certifications, and previous customer reviews.

– Request product catalogs and detailed specifications.

4. Request Quotes:

– Send detailed inquiries to shortlisted suppliers.

– Compare prices, service terms, and shipping costs.

5. Evaluate Samples and Prototypes:

– Request sample parts or arrange for a machine demonstration.

– Assess build quality, precision, and performance.

6. Negotiate Terms:

– Discuss payment terms, warranty, and after-sales support.

– Ensure clarity on lead times and delivery schedules.

7. Conduct Factory Audit:

– If possible, visit the factory to inspect facilities and production processes.

– Alternatively, hire a third-party inspection service.

8. Finalize and Place Order:

– Review the final contract, focusing on specifications, delivery terms, and payment conditions.

– Place order after thorough evaluation and mutual agreement.

9. Follow Up:

– Maintain communication for updates on production and shipping.

– Prepare for quality inspection upon arrival.

10. Prepare for Installation and Training:

– Plan for installation logistics.

– Arrange for operator training if offered by the supplier.

By diligently following these steps, you can secure a high-quality 3-axis CNC machine from SourcifyChina, ensuring smooth procurement and reliable operation.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.