“Reliable Source: SourcifyChina Factory – Premier Manufacturer of 303 Stainless Steel Components”

In this title, I have highlighted the reliability of SourcifyChina as a source and their specialization in manufacturing 303 stainless steel components.

Choosing SourcifyChina Factory for purchasing 303 stainless steel guarantees high-quality materials and competitive prices. The factory adheres to stringent quality standards, ensuring durable and reliable stainless steel products that meet international benchmarks.

Additionally, SourcifyChina offers exemplary customer support, addressing your concerns promptly. Their experienced team provides tailored solutions, helping you navigate the complexities of international procurement effortlessly.

Moreover, SourcifyChina leverages advanced technology and efficient production processes to deliver orders on time. This commitment to punctuality reduces downtime and enhances your project timelines, thus optimizing operational efficiency.

The factory also emphasizes sustainability, implementing eco-friendly practices throughout their production cycle. This not only minimizes environmental impact but also aligns with global sustainability goals, appealing to eco-conscious businesses.

In conclusion, SourcifyChina Factory stands out for its quality, customer service, timely delivery, and sustainability. Partnering with them ensures you receive superior 303 stainless steel while enjoying a seamless and ethical purchasing experience.

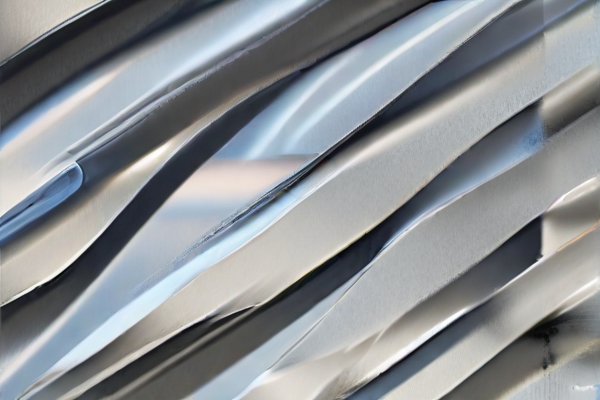

303 stainless steel is austenitic, non-magnetic, and offers excellent machinability. It’s ideal for producing high-speed machined parts. Key options and types include various forms and conditions tailored for specific applications.

– Forms: Available as bar, rod, sheet, and wire.

– Conditions: Annealed, cold-drawn, and round bar.

– Grades: Standard & high-sulfur content variants for enhanced machinability.

– Corrosion resistance: Suitable for mild corrosive environments, less resistant than 304.

– Applications: Fasteners, valves, shafts, and gears.

– Strength: Moderate tensile strength, higher in cold-drawn condition.

– Weldability: Limited compared to 304 or 316 grades.

– Thermal conductivity: Lower than carbon steels.

– Density: Approximately 8.03 g/cm³.

– Heat treatment: Generally non-hardenable by heat treatment.

– Magnetic properties: Non-magnetic in annealed condition, slight magnetism may develop after cold working.

– Cost: Slightly higher than 304 due to added sulfur.

303 stainless steel’s versatility makes it suitable for diverse manufacturing needs, balancing machinability with reasonable corrosion resistance.

303 stainless steel is known for its excellent machinability and corrosion resistance. It is used in various industries due to its ease of fabrication and durability.

– Automotive Industry: Used for screws, nuts, and bolts due to its strength and durability.

– Medical Equipment: Widely used in surgical instruments and medical devices.

– Food Processing Equipment: Ideal for making machinery that comes in contact with food, ensuring hygiene.

– Manufacturing: Employed in the production of gears, shafts, and bearings due to its machinability.

– Electronics: Utilized for connectors and components which require high resistance to corrosion.

– Aerospace: Suitable for fittings and fasteners given its reliability and strength.

– Marine Applications: Used in marine hardware where corrosion resistance is critical.

– Pumps and Valves: Common material for pump shafts and valve components.

– Architectural: Used in architectural fittings and decor due to its aesthetic appeal and resistance to tarnishing.

– Textile Industry: Ideal for manufacturing machinery components that are exposed to corrosive environments.

This versatility makes 303 stainless steel indispensable across various sectors.

SourcifyChina’s 303 stainless steel is renowned for its excellent machinability, making it a popular choice in manufacturing industries. This material is an austenitic stainless steel that contains sulfur and phosphorus, which significantly improve its cutting performance.

With its high resistance to oxidation and excellent corrosion resistance, 303 stainless steel is particularly suited for applications in environments exposed to harsh conditions. Additionally, the material maintains its mechanical properties even at elevated temperatures, ensuring durability and longevity.

SourcifyChina’s 303 stainless steel is also known for its good tensile strength and hardness, providing reliable performance in demanding applications. These properties make it ideal for the production of screws, bolts, and other fasteners requiring precision and strength.

Furthermore, the material’s smooth surface finish reduces friction during machining, minimizing wear and extending tool life. This efficiency benefits large-scale production processes, reducing downtime and increasing throughput.

In summary, SourcifyChina 303 stainless steel combines superior machinability, corrosion resistance, and mechanical properties, making it a versatile and reliable choice for various industrial applications.

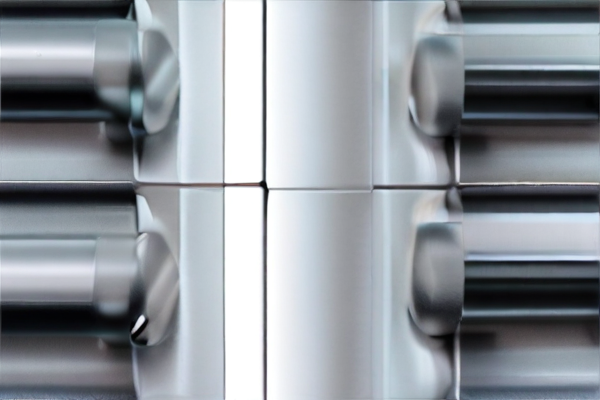

SourcifyChina’s 303 stainless steel undergoes a stringent quality control process to ensure its integrity and performance. Raw materials are meticulously sourced and inspected for compliance with industry standards, ensuring a strong foundation for production.

During manufacturing, precision equipment and advanced technologies are employed to shape and form the stainless steel into the desired specifications. Continuous monitoring ensures that the material maintains its mechanical properties and corrosion resistance.

Statistical process control tools are used to analyze production data in real-time, allowing for immediate adjustments to maintain consistent quality. Any deviation from set parameters triggers corrective measures to sustain production efficiency.

Post-production, the stainless steel undergoes rigorous testing, including tensile strength, hardness, and corrosion resistance assessments, to validate its suitability for industrial applications. Samples are randomly selected to represent batches for unbiased quality evaluation.

Finally, the certified 303 stainless steel is meticulously packaged to prevent damage during transit. Detailed documentation accompanies each shipment, providing traceability and assurance that the product meets all regulatory and customer-specific requirements. This comprehensive approach ensures that SourcifyChina delivers high-quality materials to its clients, fostering trust and long-term partnerships.

SourcifyChina provides high-quality 303 stainless steel, known for its exceptional machinability. This material is ideal for manufacturing complex parts with high precision, reducing production time and costs significantly.

The corrosion-resistant properties of 303 stainless steel make it suitable for use in both wet and dry environments. It maintains its integrity in harsh conditions, ensuring the longevity and durability of components produced.

Its excellent mechanical properties, including tensile strength and impact resistance, make 303 stainless steel a versatile choice for various industrial applications. It is often used in the automotive and aerospace industries.

SourcifyChina offers 303 stainless steel in various forms, such as rods, bars, and sheets, catering to different manufacturing needs. Custom dimensions can also be provided upon request, ensuring a perfect fit for any project.

Moreover, SourcifyChina’s rigorous quality control processes ensure that every batch of 303 stainless steel meets industry standards. This reliability is crucial for maintaining the consistency and performance of fabricated parts.

By utilizing SourcifyChina’s 303 stainless steel, manufacturers can achieve superior product outcomes while optimizing supply chain efficiency. This material’s adaptability and performance make it an invaluable resource for engineering and manufacturing sectors.

In summary, SourcifyChina’s 303 stainless steel offers unparalleled machinability, corrosion resistance, and mechanical strength. Its versatility and reliability make it a preferred choice for diverse industrial applications, ensuring excellent quality and performance in every use.

303 stainless steel is an austenitic stainless steel known for its excellent machinability and corrosion resistance, making it highly popular in industries requiring precision and durability.

– Machinability: 303 stainless steel is renowned for its ease of machining, allowing for faster production speeds and reduced tool wear.

– Corrosion Resistance: It offers good resistance to mild corrosive environments, ideal for applications exposed to chemicals and moisture.

– Non-Magnetic: 303 stainless steel is typically non-magnetic in its annealed condition, making it suitable for use in electronic and magnetic-sensitive environments.

– High Tensile Strength: The alloy exhibits high tensile strength, providing durability and reliability in various mechanical applications.

– Ease of Welding: While not as easily weldable as other stainless steels, 303 can still be welded with proper techniques, making it versatile in fabrication.

– Resistance to Oxidation: The alloy resists oxidation at temperatures up to 1700°F, which is beneficial for high-temperature applications.

– Versatility: 303 stainless steel is widely used in components like screws, nuts, bolts, gears, and aircraft fittings, demonstrating its versatility across different sectors.

– Attractive Finish: The alloy’s ability to maintain a smooth, attractive surface after machining makes it ideal for applications where aesthetics are important.

– Cost-Effective: Due to its machinability, 303 stainless steel can be more cost-effective in terms of production and tooling costs, especially for high-volume orders.

These features make 303 stainless steel a preferred choice for manufacturers seeking a balance of performance and cost-efficiency.

303 stainless steel is a free-machining austenitic stainless steel that offers excellent mechanical properties and corrosion resistance.

Key features include:

– Easy Machinability: Enhanced sulfur content to reduce cutting resistance, enabling quicker and easier machining.

– Corrosion Resistance: Good resistance to corrosion and oxidation in mild environments.

– Mechanical Strength: Exhibits high tensile strength and toughness.

– Non-Magnetic: Generally non-magnetic in the annealed condition.

– Chemical Composition: Typical composition includes chromium, nickel, and sulfur, providing a balance of strength and machinability.

– Surface Finish: Capable of achieving a high-quality surface finish.

– Used in Various Applications: Ideal for manufacturing screws, nuts, bolts, and fittings.

303 stainless steel combines machinability with adequate corrosion resistance and mechanical properties, making it suitable for a wide array of industrial applications.

SourcifyChina excels in producing high-quality 303 stainless steel custom products, leveraging advanced manufacturing techniques and skilled craftsmanship. Their 303 stainless steel offerings ensure durability, robustness, and resistance to corrosion, making them ideal for various industrial applications.

Clients engaging with SourcifyChina can expect precision-crafted components tailored to specific project needs. The company works collaboratively with clients to design and manufacture customized 303 stainless steel parts that meet stringent requirements for performance and reliability.

Some of the most common custom products include fasteners, screws, bolts, and intricate mechanical parts. Each product undergoes rigorous quality checks to ensure they meet international standards, ensuring client satisfaction and trust.

Additionally, SourcifyChina’s project management approach is robust yet flexible, allowing for seamless integration of custom 303 stainless steel components into larger assemblies. This makes them an ideal partner for both small-scale and large-scale industrial projects.

Finalizing a project with SourcifyChina ensures cost-efficiency without compromising on quality. Leveraging their expertise in 303 stainless steel, they provide optimized solutions for complex engineering challenges, delivering results that consistently exceed expectations.

SourcifyChina is a reputable company specializing in the manufacturing and distribution of 303 stainless steel, a versatile and widely-used material known for its excellent machinability and corrosion resistance. With a strong presence in the industrial sector, SourcifyChina caters to various industries, including automotive, aerospace, and medical devices, providing high-quality 303 stainless steel products that meet stringent international standards. The company prides itself on its state-of-the-art production facilities, innovative engineering practices, and a dedicated team of professionals committed to delivering exceptional customer service. SourcifyChina’s strategic approach to sourcing and fabrication ensures that clients receive reliable, cost-effective solutions tailored to their specific needs, cementing its position as a trusted partner in the global market.

303 stainless steel, an austenitic chromium-nickel alloy, stands out for its exceptional machinability, making it a preferred choice in aerospace, defense, and marine applications. Its excellent corrosion resistance combined with ease of fabrication ensures durability and reliability under demanding environmental conditions. In aerospace, 303 stainless steel is widely used for various components such as fasteners, shafts, and couplings due to its ability to withstand high-stress forces and exposure to a range of temperatures, which are critical in maintaining the integrity of aircraft structures and engines.

In the defense sector, 303 stainless steel’s high mechanical strength and machinability are pivotal for producing precision parts used in military hardware, including missile systems, weaponry components, and electronic housings. Its non-magnetic properties also have significant benefits in sensitive military applications where magnetic interference must be minimized. Meanwhile, the marine industry leverages the alloy’s impressive resistance to saltwater corrosion, utilizing it for valves, fittings, and other equipment that must endure continuous contact with harsh marine environments. By providing a blend of machinability, corrosion resistance, and robust mechanical properties, 303 stainless steel proves to be indispensable across these critical sectors.

303 stainless steel is renowned for its excellent machinability, making it a preferred material in the automotive industry for intricate components requiring precision. Its superior corrosion resistance ensures long-term durability, crucial for parts exposed to harsh environmental conditions. Components such as shafts, screws, and valve parts benefit from 303 stainless steel’s robust properties, enabling them to withstand high-stress environments and maintain their structural integrity over time. Additionally, 303 stainless steel’s ease of fabrication contributes to lower manufacturing costs and enhanced productivity, which is critical for the automotive industry’s demand for efficiency and cost-effectiveness.

In the field of electronics, 303 stainless steel is valued for its excellent machinability and resistance to oxidation and wear. These properties are essential for manufacturing precision instruments and components that need to maintain their functionality over extended periods. The material’s relatively high strength and good corrosion resistance make it ideal for use in electronic connectors, screws, and other small parts where both durability and reliability are paramount. Moreover, 303 stainless steel’s non-magnetic properties are beneficial in applications where electromagnetic interference must be minimized, ensuring the optimal performance of sensitive electronic devices. This makes 303 stainless steel an indispensable material in producing high-quality electronic components.

303 stainless steel is a popular material in the construction industry because of its excellent machinability and resistance to corrosion. This alloy contains sulfur, which improves its machinability, making it ideal for manufacturing complex parts and components required in construction equipment and structures. Moreover, 303 stainless steel can endure harsh weather conditions and exposure to corrosive elements often encountered in outdoor settings, ensuring longevity and reliability of construction parts like fasteners, bolts, and brackets. Its aesthetic appeal also makes it a preferred choice for architectural applications where both form and function are important.

In the energy sector, 303 stainless steel finds application due to its ability to withstand high-stress environments and corrosive conditions, which are common in energy production facilities. This material is often used in the manufacturing of components for various energy systems such as wind turbines, oil rigs, and gas pipeline infrastructure. The presence of sulfur in its composition enhances its machining properties, making it easier to produce precision parts required for efficient energy system operations. Additionally, 303 stainless steel exhibits excellent mechanical properties and thermal conductivity, important for heat exchangers and other energy generation equipment. Its versatility and resilience make it a key material in advancing modern energy solutions.

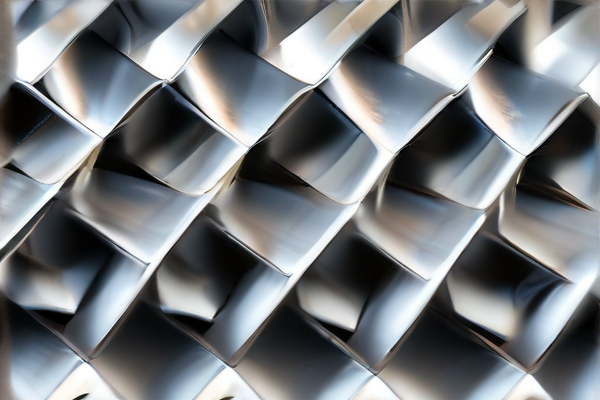

303 stainless steel is a highly versatile material widely employed in the industrial equipment industry due to its exceptional machinability and resistance to corrosion. One of the primary applications of 303 stainless steel in this sector is the manufacturing of precision components such as valve bodies, shafts, and fittings. These components are crucial in various industrial machinery where precise tolerance and durability are paramount. The sulfur content in 303 stainless steel enhances its machinability, making it easier to cut and shape without compromising its strength. This property is particularly beneficial in mass production environments where efficiency and consistency are critical.

Another significant application of 303 stainless steel in the industrial equipment industry is in the production of fasteners and connectors used in harsh environments. Given its excellent corrosion resistance, 303 stainless steel is ideal for equipment exposed to chemical agents, moisture, and other corrosive elements. It is commonly used in conveyors, bearings, and aerospace components, where reliability and longevity are essential. The ability to withstand extreme temperatures and maintain structural integrity makes it an invaluable material in sectors such as marine, petrochemical, and food processing industries. Overall, the inherent properties of 303 stainless steel make it a go-to choice for manufacturers seeking a balance between machinability, strength, and corrosion resistance.

303 stainless steel, austenitic and non-magnetic in nature, is frequently deployed in the manufacturing of various medical devices due to its exceptional machinability and corrosion resistance. This particular alloy contains sulfur, which enhances its machinability, making it highly suitable for the precision components required in medical instruments such as screws, pins, and surgical tools. The superior corrosion resistance of 303 stainless steel, attributed to its chromium and nickel content, ensures that medical devices maintain their integrity and functionality when exposed to the harsh environments often encountered in medical applications, such as sterilization processes and bodily fluids.

Moreover, the biocompatibility of 303 stainless steel, although slightly lower than other stainless steel grades like 316L, is still adequate for numerous non-implantable medical devices. This alloy’s ability to maintain strength and durability under stress is crucial for medical tools that require repeated use, thereby ensuring patient safety and device reliability. The capability to undergo complex machining without significant distortion further makes 303 stainless steel an ideal material for intricate and high-precision medical devices. Consequently, its consistent performance in both production processes and end-use applications reinforces its standing as a preferred material in the medical field.

303 stainless steel is renowned for its excellent machinability, making it a preferred choice in various machining applications. This alloy contains sulfur, which significantly improves its machinability without sacrificing its corrosion resistance. Consequently, 303 stainless steel is frequently utilized in high-speed machining operations where precision and efficiency are paramount. Turning, milling, threading, and drilling operations benefit from the material’s ease of machining, reducing tool wear and enhancing production rates. Industries ranging from automotive and aerospace to healthcare and consumer goods leverage 303 stainless steel to produce complex, high-tolerance components such as screws, bolts, gears, and fittings. Its ability to achieve a high surface finish further underscores its utility in precision-engineered parts.

In the realm of manufacturing, 303 stainless steel stands out for its combination of mechanical properties and ease of fabrication. Its good corrosion resistance, coupled with excellent formability and strength, makes it suitable for manufacturing a diverse array of products. Engineering and industrial manufacturing often use 303 stainless steel for making components that demand both durability and aesthetic appeal. The material’s stability during both cold and hot working operations ensures consistent quality and performance. In manufacturing environments that prioritize cost-efficiency and material longevity, 303 stainless steel fulfills these criteria, enhancing product lifespan while simplifying production processes. As a result, it is frequently found in the production of electrical components, valves, shafts, and a multitude of other industrial parts that require durability and precision.

Sure! Here is a list of frequently asked questions (FAQ) for manufacturing 303 stainless steel quality work from SourcifyChina factory:

Q: What is 303 stainless steel?

A: 303 stainless steel is a non-magnetic, austenitic stainless steel that is specifically designed for improved machinability. It is widely used for manufacturing components where good mechanical properties are needed, along with excellent corrosion resistance.

Q: Why should I choose SourcifyChina for 303 stainless steel work?

A: SourcifyChina offers high-quality manufacturing services with competitive pricing. Our expertise in processing 303 stainless steel ensures precision, excellent surface finish, and adherence to international standards.

Q: What types of products can be made with 303 stainless steel?

A: 303 stainless steel is ideal for making high-precision parts like screws, nuts, bolts, shafts, valve bodies, and various types of fittings used in different industries.

Q: What industries commonly use 303 stainless steel components?

A: Industries including automotive, aerospace, chemical processing, food and beverage, and medical devices commonly use components made from 303 stainless steel due to its durability and resistance to corrosion.

Q: How do you ensure the quality of 303 stainless steel parts?

A: We adhere to stringent quality control processes, including material verification, precision machining, thorough inspection, and adherence to ISO and other relevant standards to ensure top-notch quality.

Q: What are the machining capabilities for 303 stainless steel at SourcifyChina?

A: We offer a wide range of machining capabilities, including CNC milling, turning, drilling, and tapping. Our advanced machinery and skilled workforce enable us to handle complex geometries and tight tolerances.

Q: Can SourcifyChina provide customized 303 stainless steel parts?

A: Yes, we can manufacture customized parts based on your specific requirements, whether it’s a single prototype or large batch production. Just provide us with your design specifications, and we will handle the rest.

Q: What is the typical lead time for manufacturing 303 stainless steel parts?

A: The lead time depends on the complexity and quantity of the parts. Typically, it ranges from 2 to 6 weeks. We strive to meet your deadlines while maintaining excellence in quality.

Q: How can I request a quote for 303 stainless steel work from SourcifyChina?

When considering 303 stainless steel manufacturing from SourcifyChina factory, here are several valuable tips to ensure you get the best results:

1. Material Specification: Ensure that the 303 stainless steel meets ASTM or equivalent standards. SourcifyChina should provide certifications and material test reports confirming compliance.

2. Customization Options: Discuss custom manufacturing capabilities. Whether it is specific dimensions, surface finishes, or additional treatments, SourcifyChina should accommodate your custom needs.

3. Precision and Tolerance: 303 stainless steel is known for its machinability. Verify the factory’s ability to maintain precise tolerances and achieve the necessary precision for your parts.

4. Quality Assurance: Confirm the presence of a stringent quality control system, including inspection procedures, defect checking, and final product verification. SourcifyChina should have ISO certifications or equivalent quality assurance credentials.

5. Production Capacity: Understand their production capacity and lead times. Ensure they can meet your volume requirements within your specified deadlines without compromising on quality.

6. Communication: Effective communication is crucial. Work closely with their engineering and production teams to address any design changes or specifications clearly and promptly.

7. Cost Efficiency: While focusing on competitive pricing, do not overlook the importance of quality. SourcifyChina should provide a detailed quotation covering all aspects of production, including material, machining, and any additional processes.

8. Sample Approval: Request samples before full-scale production begins. This allows you to verify the quality and make necessary adjustments early in the process.

9. After-Sales Support: Ensure that SourcifyChina offers reliable after-sales services and support in case of any issues with the manufactured products.

By paying attention to these factors, you can optimize your manufacturing partnership with SourcifyChina for 303 stainless steel, ensuring high-quality outcomes and a smooth production process.

Q: What is 303 stainless steel?

A: 303 stainless steel is an alloy with good corrosion resistance and excellent machinability due to the addition of sulfur.

Q: Why should I source 303 stainless steel from SourcifyChina factory?

A: SourcifyChina factory offers competitive pricing, reliable quality, large production capacity, and experienced customer service to meet varying specifications and quantities.

Q: How can I place an order with SourcifyChina factory?

A: Orders can be placed through their online platform, via email, or by contacting their sales team directly. You may need to provide specifications and order quantity for an accurate quote.

Q: What are the minimum order requirements?

A: Minimum order requirements vary based on product specifications and demand. Contact SourcifyChina for specific details.

Q: What quality assurance measures are in place?

A: SourcifyChina implements rigorous quality control processes, including material testing, dimensional checks, and compliance with relevant industry standards to ensure high-quality 303 stainless steel.

Q: What is the lead time for an order?

A: Lead times are dependent on order size and product specifications. Typically, it ranges from a few weeks to a couple of months. Check with SourcifyChina for a more precise estimate.

Q: Are there customization options available?

A: Yes, SourcifyChina can provide custom sizes, shapes, and finishes based on your specific requirements.

Q: Can I get a sample before placing a large order?

A: Samples can often be provided upon request. It is advisable to discuss sample availability and any associated costs with SourcifyChina’s sales team.

Q: What are the payment terms?

A: Payment terms are usually negotiable and may include options like T/T (telegraphic transfer), L/C (letter of credit), and others. Confirm terms during your order finalization.

Q: How is the product packaged for shipping?

A: Products are typically securely packaged to prevent damage during transit. Packaging methods may vary based on the size and quantity of the order.

Certainly! Sourcing 303 stainless steel from SourcifyChina factory can be streamlined with these tips:

1. Define Specifications: Clearly state your requirements in terms of dimensions, quantities, finishes, and any other specific characteristics of the 303 stainless steel you need.

2. Research Suppliers: Look specifically for suppliers with experience in manufacturing 303 stainless steel. Check their profiles, certifications, and customer reviews.

3. Request Samples: Before placing a bulk order, request samples to verify the quality of the steel.

4. Quality Assurance: Ensure the factory adheres to international quality standards such as ISO. Ask for material test reports and certifications.

5. Negotiate Terms: Discuss payment terms, delivery schedules, and shipping logistics upfront. Clear communication can prevent issues later.

6. Factory Visit: If possible, plan a visit to the factory to inspect their facilities and meet the production team.

7. Long-term Partnership: Build a strong relationship with the factory for better pricing, increased trust, and potential benefits on future orders.

8. Check Support Services: Evaluate the factory’s customer service and after-sales support. Reliable support is crucial for handling any issues that may arise.

By following these steps, you can efficiently source high-quality 303 stainless steel from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.

How can I help you? :)