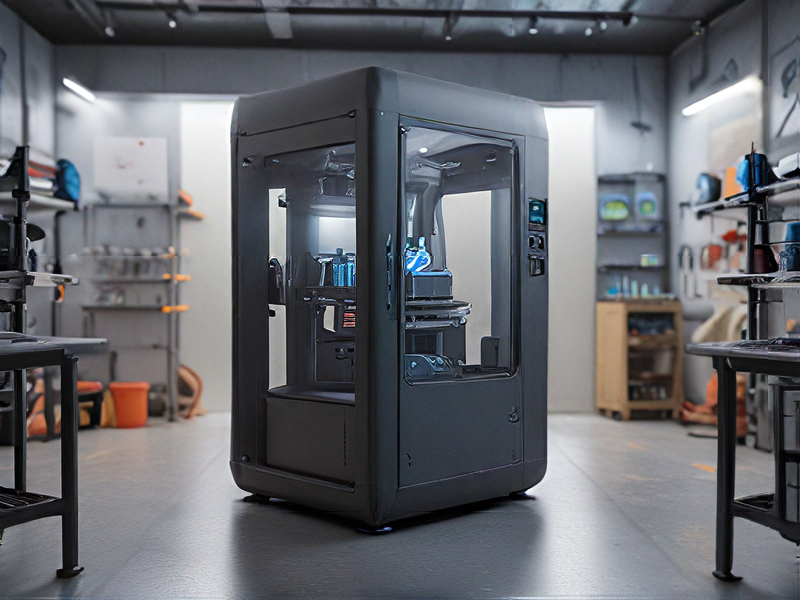

Technology and Applications of 3d print shop

3D printing shops have revolutionized manufacturing and prototyping across various industries. These shops utilize additive manufacturing technologies to create three-dimensional objects from digital designs. One key application is rapid prototyping, enabling designers and engineers to quickly iterate and test concepts before full-scale production. This saves time and reduces costs compared to traditional prototyping methods.

Customization is another significant advantage. 3D printing shops can produce personalized products tailored to individual preferences or specific requirements. This is particularly valuable in industries like healthcare, where custom prosthetics, implants, and medical models can be created with high precision.

Art and design industries also benefit greatly from 3D printing shops. Artists can bring intricate and complex designs to life, pushing the boundaries of creativity with materials ranging from plastics to metals and even ceramics. This democratizes access to production capabilities that were once limited to large manufacturing facilities.

Education has also been transformed by 3D printing shops. They provide hands-on learning opportunities for students to understand design principles, engineering concepts, and even historical artifacts through physical replication.

Moreover, 3D printing shops contribute to sustainable practices by minimizing material waste compared to subtractive manufacturing methods. They enable on-demand production, reducing the need for large inventories and transportation costs associated with traditional supply chains.

Looking forward, advancements in materials and printing technologies promise even greater versatility and efficiency for 3D printing shops. From aerospace components to consumer goods and beyond, the applications of 3D printing continue to expand, offering innovative solutions across diverse industries.

Quality Testing Methods for 3d print shop and how to control quality

Quality control in a 3D print shop is crucial to ensuring consistent and high-quality outputs. Several methods can be employed:

1. Visual Inspection: Regular visual checks of printed parts for surface finish, layer adhesion, and dimensional accuracy.

2. Dimensional Accuracy Testing: Using calipers or 3D scanners to verify that printed parts match design specifications.

3. Layer Adhesion Testing: Applying controlled stress to printed parts to test the strength of layer bonds.

4. Surface Quality Assessment: Utilizing surface roughness testers to ensure smooth finishes where required.

5. Functional Testing: Testing printed parts under real-world conditions to verify functionality and durability.

6. Material Testing: Testing material properties such as tensile strength, flexibility, and heat resistance to ensure they meet specifications.

To control quality effectively:

– Establish Standard Operating Procedures (SOPs): Document procedures for each step of the printing process.

– Calibration and Maintenance: Regularly calibrate machines and perform maintenance to ensure consistent performance.

– Training: Train staff in quality standards, equipment operation, and troubleshooting.

– Data Analysis: Collect and analyze data from quality tests to identify trends and areas for improvement.

– Feedback Loop: Implement a feedback system to address issues and continuously improve processes.

By integrating these methods and controls, a 3D print shop can maintain high standards of quality, meet customer expectations, and minimize waste and rework.

Tips for Procurement and Considerations when Purchasing from 3d print shop

Tips for Procurement and Considerations when Purchasing from a 3D Print Shop

1. Define Requirements Clearly: Specify the exact dimensions, materials, and finish for your 3D printed parts. Detailed CAD files and specifications help avoid misunderstandings.

2. Choose the Right Material: Select materials based on the part’s intended use. Common options include PLA, ABS, PETG, and specialized materials like nylon or metal composites for specific needs.

3. Assess the Print Quality: Check the print resolution and layer height capabilities of the shop. Higher resolution (lower layer height) provides better detail but may increase cost.

4. Evaluate the Shop’s Expertise: Look for shops with experience in your industry or type of project. Reviews and portfolio examples can provide insights into their capabilities.

5. Request Samples: Before placing a large order, request samples to evaluate the quality and adherence to your specifications.

6. Consider Turnaround Time: Understand the shop’s lead times and ensure they can meet your deadlines. Discuss any rush order capabilities and associated costs.

7. Check for Additional Services: Some 3D print shops offer design assistance, post-processing, and assembly services. These can be valuable if your project requires more than just printing.

8. Review Pricing Structures: Get detailed quotes and understand the pricing model—whether it’s per part, per volume, or based on machine time. Compare quotes from multiple shops.

9. Inspect the Technology Used: Ensure the shop uses up-to-date 3D printing technology. Different technologies (e.g., FDM, SLA, SLS) have varying strengths and are suitable for different applications.

10. Evaluate Communication and Support: Effective communication is key to a successful project. Choose a shop that offers good customer support and is responsive to inquiries and issues.

Following these tips can help ensure you receive high-quality 3D printed parts that meet your needs and expectations.

FAQs on Sourcing and Manufacturing from 3d print shop in China

Certainly! Here are some FAQs regarding sourcing and manufacturing from a 3D print shop in China:

1. What types of 3D printing technologies are available?

– Common technologies include FDM (Fused Deposition Modeling), SLA (Stereolithography), SLS (Selective Laser Sintering), and more specialized methods for metal or ceramic printing.

2. How can I ensure the quality of 3D printed parts?

– It’s crucial to request samples and check certifications like ISO standards. Establish clear specifications and quality control measures in your agreement.

3. What are typical lead times for 3D printing orders?

– Lead times vary based on complexity and quantity but typically range from a few days to a few weeks. Discuss timelines upfront to align expectations.

4. What materials can I use for 3D printing?

– PLA, ABS, PETG, and nylon are common for FDM. Resin materials like acrylates and epoxy derivatives are used in SLA. Metals like titanium and aluminum are possible with metal 3D printing.

5. Can the print shop handle large-volume orders?

– Yes, but capacity may vary. Ensure the shop can meet your quantity requirements and discuss scalability options if needed.

6. What are the shipping options and costs?

– Typically, shipments from China offer various options (air, sea, express). Costs depend on volume, weight, and urgency. Factor these into your budget planning.

7. How do I protect my intellectual property (IP)?

– Sign non-disclosure agreements (NDAs) and ensure the manufacturer has robust IP protection measures. Consider patenting your designs where applicable.

8. What are the payment terms and methods accepted?

– Terms vary but often include initial deposits and final payments upon completion. Payment methods usually include wire transfers, credit cards, or online payment platforms.

9. What support is available post-production?

– Clarify warranty terms and after-sales support options. A reputable shop will offer assistance with defects and replacements if necessary.

10. Can I visit the facility or conduct inspections?

– Many shops welcome visits or provide virtual tours. Inspections ensure transparency and help build trust in the manufacturing process.

By addressing these FAQs, you can better navigate sourcing and manufacturing from a 3D print shop in China, ensuring a smoother and more informed collaboration.