Technology and Applications of 3d printing metal

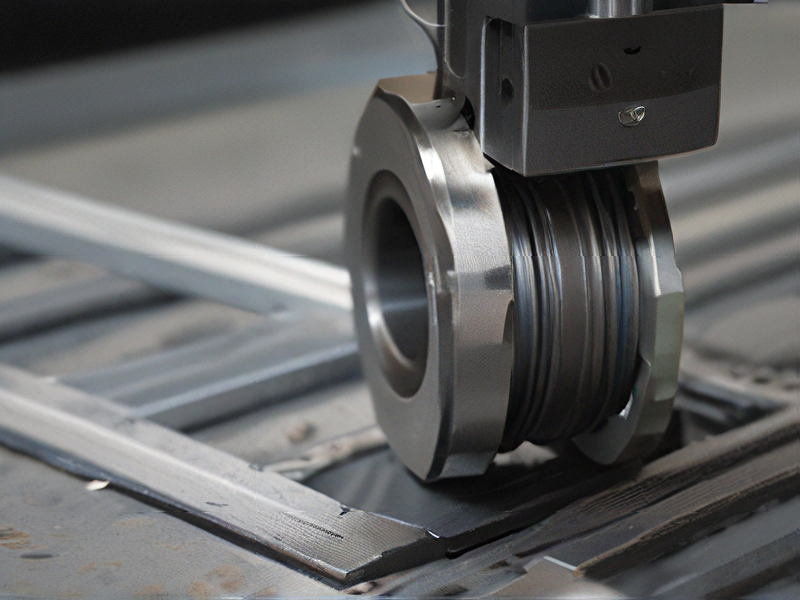

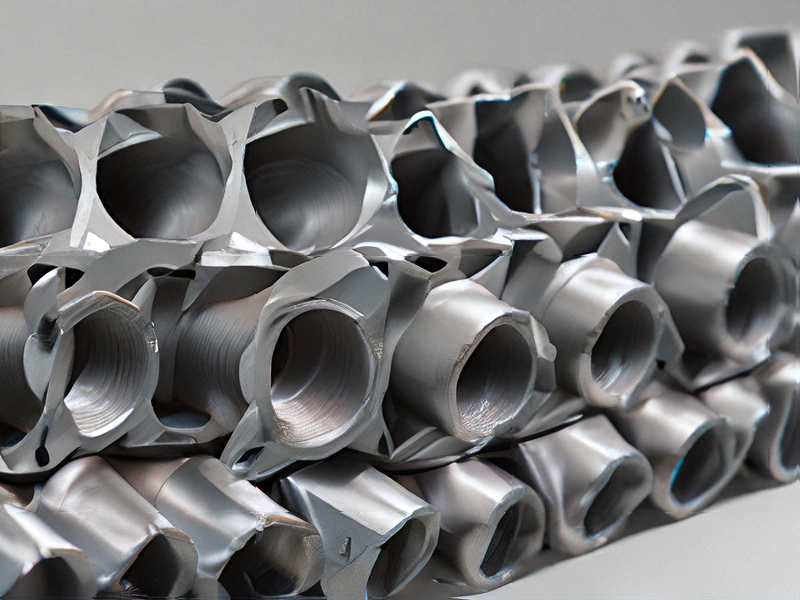

3D printing metal, also known as metal additive manufacturing, has revolutionized various industries by enabling the production of complex geometries that are often difficult or impossible to achieve with traditional manufacturing methods.

Key technologies in metal 3D printing include Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Direct Metal Laser Sintering (DMLS). These processes utilize high-energy sources like lasers or electron beams to melt and fuse metal powders layer by layer, allowing for precise control over the part’s microstructure.

Applications span multiple sectors, including aerospace, automotive, medical, and tooling. In aerospace, for instance, lightweight components can be produced, optimizing fuel efficiency and performance. The automotive industry benefits from rapid prototyping and the ability to manufacture custom parts, facilitating faster design iterations. In the medical field, personalized implants and prosthetics can be created to meet individual patient needs, enhancing functionality and comfort.

Additionally, metal 3D printing reduces material waste compared to subtractive manufacturing methods, as it only uses the necessary material required for the build. This aspect, alongside the ability to create complex designs, encourages sustainability and innovation.

Challenges remain, including material costs, production speed, and the need for post-processing to achieve desired surface finishes. However, advancements in technology and material science are continuously paving the way for broader adoption and new applications, such as in electronics and energy sectors.

In conclusion, metal 3D printing is a transformative technology with diverse applications that promises to enhance manufacturing capabilities and efficiency across industries while promoting sustainability.

Quality Testing Methods for 3d printing metal and how to control quality

Quality testing methods for metal 3D printing are vital to ensure the integrity and performance of printed components. Several key methods are commonly employed:

1. Visual Inspection: This initial check involves assessing the printed part for any visible defects such as surface irregularities, warping, or incomplete builds.

2. Dimensional Analysis: Precision is crucial, and tools like calipers or laser scanners evaluate the dimensions of the printed parts against the CAD models to ensure adherence to specifications.

3. Mechanical Testing: Tests like tensile, compression, and hardness tests assess the mechanical properties of printed parts. These tests help identify strength, ductility, and material performance under stress.

4. Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, X-ray computed tomography, and magnetic particle inspection identify internal defects or inconsistencies without harming the part.

5. Microstructural Analysis: Using techniques like scanning electron microscopy (SEM) or optical microscopy, the material’s microstructure is examined to evaluate grain structure and phase distribution, which influence mechanical performance.

To control quality, manufacturers can implement a robust quality management system (QMS) that includes:

– Process Monitoring: Real-time monitoring of key parameters during printing (temperature, feed rate, etc.) to prevent defects.

– Material Traceability: Keeping records of material batches ensures the consistency of material properties.

– Post-processing Inspection: After printing, employing processes like heat treatment or surface finishing should be followed by testing to confirm improvements in properties.

– Standards and Certifications: Adopting international standards (e.g., ISO 9011 for quality management) and seeking relevant certifications can ensure consistent quality in production.

By combining these testing methods and controls, manufacturers can significantly enhance the quality assurance of metal 3D printed components.

Tips for Procurement and Considerations when Purchasing from 3d printing metal

When procuring metal 3D printing services or products, consider these essential tips to ensure a successful purchase:

1. Material Selection: Different metals have unique properties. Consider the application requirements (e.g., titanium for lightweight strength, stainless steel for corrosion resistance) and request material certifications.

2. Technological Capabilities: Evaluate the supplier’s 3D printing technology (e.g., DMLS, SLM). Ensure they utilize suitable methods for your project’s precision and detail needs.

3. Supplier Experience: Choose vendors with proven expertise in metal 3D printing. Review their portfolio, client testimonials, and case studies to gauge their capabilities and reliability.

4. Quality Assurance: Inquire about their quality control processes. Certification to standards like ISO 9001 or AS9100 can indicate a commitment to quality management systems.

5. Lead Time and Production Volume: Clarify lead times for prototyping and production. Ensure they can handle the scale of your order—whether it’s a single part or bulk manufacturing.

6. Post-Processing Options: Understand the post-processing services offered (e.g., machining, heat treatment) for finishing parts, as these can significantly affect the final product quality.

7. Cost Transparency: Request detailed quotes and ensure you understand all associated costs, including materials, labor, and post-processing fees.

8. Intellectual Property (IP) Protection: Discuss IP rights and ensure that your designs are protected throughout the production process.

9. After-Sales Support: Assess the availability of support for revisions, troubleshooting, or reorders after the initial purchase.

By taking these factors into consideration, you can make informed decisions that will enhance the success and efficiency of your metal 3D printing procurement.

FAQs on Sourcing and Manufacturing from 3d printing metal in China

FAQs on Sourcing and Manufacturing 3D Printed Metal Parts in China

Q1: What materials are commonly used in metal 3D printing?

A1: Common metals include stainless steel, titanium, aluminum, and cobalt-chrome. Each has unique properties suited for different applications.

Q2: How does the metal 3D printing process work?

A2: Metal 3D printing typically involves powder bed fusion or binder jetting, where layers of metal powder are selectively fused or bonded to form parts.

Q3: What are the advantages of sourcing 3D printed metal parts from China?

A3: China offers competitive pricing, extensive manufacturing capabilities, and access to advanced technologies. This can significantly reduce lead times and costs.

Q4: What certifications should I look for?

A4: Ensure the manufacturer complies with international standards like ISO 9001 for quality management, as well as specific industry certifications such as ASTM for metal parts.

Q5: How do I ensure quality control?

A5: Request detailed quality assurance processes, including inspections, testing, and certification. Consider third-party audits or working with manufacturers that have established quality control measures.

Q6: What is the typical lead time for production?

A6: Lead times can vary based on complexity and volume but generally range from 2 to 6 weeks. Prototyping may take additional time.

Q7: Can I ask for custom designs?

A7: Yes, most manufacturers can accommodate custom designs. Providing detailed CAD files and specifications will help ensure the best results.

Q8: What are the shipping options?

A8: Common shipping methods include air freight for faster delivery or sea freight for larger volumes. Discuss logistics options with your manufacturer.

Q9: Are there language barriers when sourcing?

A9: While many manufacturers have English-speaking staff, it’s advisable to communicate clearly and possibly use translation services if needed.