Choosing SourcifyChina Factory for purchasing a 3D wood sculpture machine from China ensures quality and reliability. Their extensive experience in the industry guarantees top-notch products. SourcifyChina Factory is renowned for its state-of-the-art technology and precise manufacturing processes. They offer competitive pricing, ensuring buyers receive excellent value for their investment.

Moreover, SourcifyChina Factory prioritizes customer satisfaction, providing exceptional after-sales service and support. Their team of experts is always ready to assist with any technical issues or inquiries. The factory adheres to strict quality control measures, ensuring each machine meets international standards and performs efficiently.

SourcifyChina Factory’s efficient supply chain management minimizes lead times, ensuring timely delivery of products. They have a robust logistics network, facilitating smooth and hassle-free shipping to various global destinations. Buyers can trust SourcifyChina Factory for a seamless purchasing experience.

In conclusion, choosing SourcifyChina Factory means partnering with a reliable and customer-focused supplier. Their dedication to quality, competitive pricing, and excellent customer service make them an ideal choice for purchasing 3D wood sculpture machines from China.

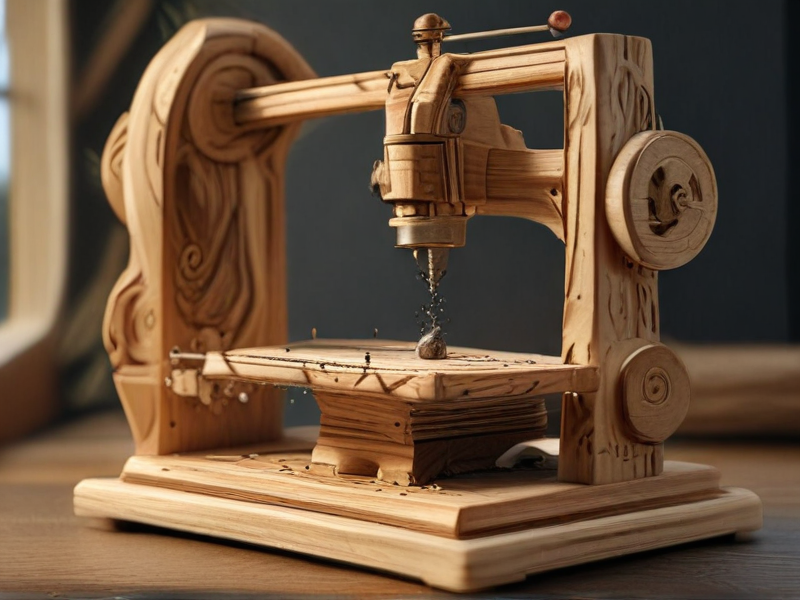

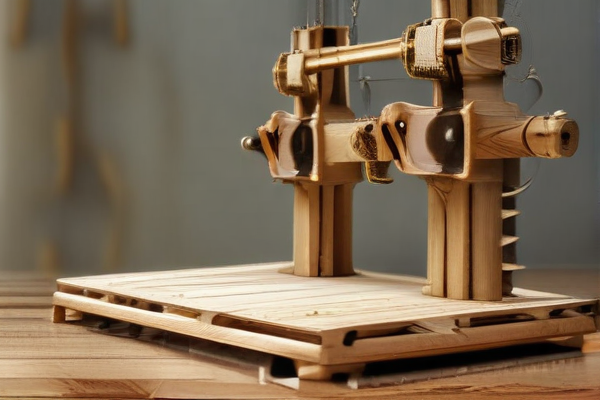

A 3D wood sculpture machine, or CNC router, offers precise and efficient wood carving. These machines vary in size, capability, and price, catering to both hobbyists and professionals.

– Desktop CNC Routers: Compact, ideal for small projects and hobbyists.

– Industrial CNC Routers: Large, powerful, suited for high-volume and complex tasks.

– Laser Cutters/Engravers: Utilize lasers for fine detail and intricate designs.

– 5-Axis CNC Routers: Offer extensive flexibility for complex, multi-dimensional carvings.

– Hybrid Machines: Combine features of CNC routers and laser engravers.

– DIY CNC Kits: Affordable, customizable options for tech-savvy users.

– Pre-Assembled Machines: Ready-to-use models requiring minimal setup.

A 3D wood sculpture machine revolutionizes wood crafting by enabling precise, intricate designs that are difficult to achieve manually. These machines serve various industries, enhancing both artistic and functional woodwork.

Applications include:

– Custom furniture design

– Artistic sculptures and installations

– Architectural models

– Musical instrument crafting

– Prototyping and product development

– Signage and decorative panels

– Restoration and replication of historical pieces

– Detailed carvings for doors and cabinetry

– Educational tools and models

The “SourcifyChina 3D Wood Sculpture Machine” is engineered for precise and intricate wood carving, utilizing advanced CNC technology. It is capable of producing detailed sculptures and designs from various types of wood, including hardwoods and softwoods.

The machine’s frame is constructed from high-grade steel, ensuring durability and stability during operation. This robust construction minimizes vibrations, enhancing the accuracy and quality of the carvings.

Equipped with a powerful spindle motor, the machine can handle dense and complex wood materials, making it suitable for both artistic and industrial applications. The motor’s high speed ensures efficient and smooth cutting.

The software integration allows for seamless design input, supporting various file formats. This flexibility enables users to create custom designs or replicate intricate patterns with ease, enhancing creativity and productivity.

In addition to wood, the SourcifyChina 3D Wood Sculpture Machine can also work with certain composites, expanding its utility. This versatility makes it a valuable tool for artisans, furniture makers, and manufacturers alike.

SourcifyChina’s 3D wood sculpture machine undergoes rigorous quality control processes to ensure high standards. The raw materials are carefully selected, emphasizing sustainability and quality.

Each machine component is inspected for precision and durability, utilizing advanced testing equipment. This ensures that every part meets strict specifications before assembly.

The assembly process is monitored by skilled technicians, who adhere to stringent protocols. Automated systems assist in achieving consistent and accurate assembly.

Post-assembly, each machine undergoes thorough testing, including operational tests and performance evaluations, to verify functionality and reliability.

Finally, the machines are packaged securely to prevent damage during transportation, ensuring they reach customers in perfect condition.

The SourcifyChina 3D wood sculpture machine offers advanced precision, allowing artisans to create intricate designs with minimal effort. Its cutting-edge technology ensures high accuracy and detail in every piece, enhancing the quality of the final product.

This machine supports a wide range of wood types, making it versatile for various projects. Whether working with softwoods or hardwoods, it can handle different densities and textures effectively, ensuring consistent results.

User-friendly software interfaces simplify the design process, making it accessible even to beginners. The intuitive controls and programmable settings allow for customization, enabling users to achieve their desired artistic vision effortlessly.

The machine’s robust build and durable components ensure long-term reliability and reduced maintenance. Its efficient performance reduces production time, increasing overall productivity for professional workshops and hobbyists alike.

In addition to its technical capabilities, the SourcifyChina 3D wood sculpture machine is designed with safety in mind. Equipped with various safety features, it minimizes the risk of accidents, providing peace of mind during operation.

Ultimately, the SourcifyChina 3D wood sculpture machine represents a significant advancement in woodworking technology. It combines precision, versatility, ease of use, and safety, making it an indispensable tool for both seasoned artisans and newcomers to the craft.

3D wood sculpture machines revolutionize woodworking by offering precision, speed, and creativity. They enhance the quality and efficiency of crafting intricate designs.

– Precision: Achieve detailed and accurate carvings that are difficult to replicate by hand.

– Speed: Significantly reduce production time compared to traditional methods.

– Consistency: Produce uniform and identical pieces, ideal for mass production.

– Complex Designs: Create intricate patterns and shapes that are challenging with manual tools.

– Customization: Easily modify designs and prototypes for personalized projects.

– Waste Reduction: Optimize material use, minimizing waste.

– Skill Enhancement: Allow artisans to focus on design and finishing, enhancing their craft.

– Cost Efficiency: Lower labor costs and reduce material wastage.

– Safety: Minimize physical strain and risk of injury associated with manual carving.

A 3D wood sculpture machine revolutionizes woodworking by automating intricate carving tasks, enhancing precision and efficiency. These machines blend traditional craftsmanship with modern technology to create detailed wooden art pieces.

– Precision and Accuracy: Advanced CNC (Computer Numerical Control) systems enable precise carvings, ensuring consistent and intricate designs.

– Versatility: Capable of handling various wood types and designs, from small detailed pieces to large sculptures.

– Automation: Reduces manual labor by automating the carving process, which also minimizes human error.

– Design Flexibility: Compatible with various design software, allowing artists to create complex models digitally and reproduce them accurately.

– High Speed: Significantly faster than manual carving, increasing productivity and reducing production time.

– Durability: Constructed with robust materials to withstand continuous operation and heavy use.

– User-Friendly Interface: Intuitive controls and interfaces make it accessible for both beginners and experienced users.

– Customization: Allows for easy adjustments to design specifications and dimensions to cater to specific requirements.

– Safety Features: Equipped with safety mechanisms to protect users from accidents during operation.

– Cost-Effectiveness: Though initially expensive, it reduces long-term costs by cutting down on labor and material waste.

– Environmental Benefits: Optimizes wood use, reducing waste and promoting sustainable practices in woodworking.

These features make 3D wood sculpture machines indispensable tools for modern woodworking, blending efficiency with creativity to produce high-quality wooden sculptures.

SourcifyChina’s 3D wood sculpture machine is revolutionizing the custom products market. This advanced technology enables the creation of intricate wood sculptures with unparalleled precision and efficiency, catering to diverse client needs.

The machine’s versatility allows for the production of unique, bespoke designs, making it ideal for personalized gifts, corporate awards, and bespoke furniture. Its precision ensures each piece is a true work of art, reflecting detailed craftsmanship.

Clients can collaborate closely with designers to bring their visions to life, whether for artistic projects, architectural elements, or decorative items. The technology supports creativity without compromising on quality or detail.

In addition to custom products, SourcifyChina undertakes large-scale projects, including themed installations and public art pieces. The machine’s capabilities allow for seamless scaling from small items to grand sculptures, ensuring consistency and excellence.

Overall, SourcifyChina’s 3D wood sculpture machine empowers creators and clients alike to explore new dimensions in woodcraft, blending traditional artistry with cutting-edge technology to produce stunning, customized works.

SourcifyChina is a pioneering company specializing in 3D wood sculpture machines, renowned for integrating advanced technology with traditional craftsmanship. Their innovative machinery enables precision and efficiency in carving intricate wooden designs, catering to industries ranging from furniture manufacturing to bespoke art installations. By leveraging cutting-edge 3D modeling software and high-precision CNC (Computer Numerical Control) systems, SourcifyChina ensures that each piece produced is of exceptional quality and detail. The company is committed to sustainability, often utilizing responsibly sourced wood and promoting eco-friendly practices within their production processes. With a focus on customization, they provide tailored solutions to meet the unique needs of their diverse clientele, ensuring that each machine is optimized for specific project requirements. SourcifyChina’s dedication to excellence has positioned them as a leader in the 3D wood sculpture market, attracting a global customer base that values both innovation and traditional artistry.

The Aerospace, Defense, and Marine industries are increasingly integrating advanced manufacturing technologies like the 3D wood sculpture machine to enhance their production capabilities. In aerospace, this technology is utilized for creating lightweight, durable components and intricate models used in wind tunnel testing and design validation. The precise control over material and shape afforded by these machines ensures that prototypes and final products meet the stringent specifications required for flight safety and performance. Additionally, wood, being a sustainable and easily workable material, offers a cost-effective solution for producing complex shapes and structural elements in the early stages of product development.

In the Defense and Marine sectors, the 3D wood sculpture machine is pivotal in fabricating parts and models for vehicles, ships, and tactical equipment. For defense applications, these machines can produce accurate replicas of terrain and structures for strategic planning and training simulations. The ability to quickly produce detailed and robust parts allows for rapid prototyping and iterative design, enhancing the agility of defense manufacturing processes. In the marine industry, the technology is used to craft detailed hull models and custom components, contributing to optimized vessel design and hydrodynamic performance. The adoption of 3D wood sculpture machines thus supports these industries’ needs for innovation, efficiency, and precision in manufacturing processes.

A 3D wood sculpture machine has significant applications in the automotive industry, where it can be utilized to create detailed wooden prototypes and models of car parts. These machines enable precision carving and intricate designs that help in the early stages of vehicle design and testing. For instance, interior car components such as dashboards, gear knobs, and trim panels can be crafted with exacting detail to assess their aesthetic and ergonomic qualities. Additionally, wooden molds and fixtures for custom parts and limited edition models can be produced, allowing for a high degree of customization and rapid prototyping. The precision and repeatability of these machines ensure that automotive designers and engineers can create highly accurate models that reflect the final product’s quality.

In the electronics sector, 3D wood sculpture machines are employed to create stylish and functional wooden casings for various devices, such as speakers, radios, and custom computer housings. These machines allow for the production of unique and aesthetically pleasing designs that cater to consumer preferences for natural and eco-friendly materials. Furthermore, they can be used to manufacture wooden components for electronic instruments, such as guitar bodies and synthesizer panels, where the unique acoustic properties of wood are desirable. The ability to produce intricate and precise wooden parts enhances the functionality and appeal of electronic products, providing both manufacturers and consumers with innovative solutions that combine traditional materials with modern technology.

A 3D wood sculpture machine is revolutionizing the construction industry by enabling the creation of intricate and bespoke wooden structures with unprecedented precision. In construction, this technology is utilized to fabricate complex wooden components that would be labor-intensive and time-consuming to produce manually. For instance, architects and builders can design custom wooden beams, trusses, and decorative elements with intricate patterns and geometries, enhancing both structural integrity and aesthetic appeal. The precision of 3D wood sculpting ensures perfect fits and finishes, reducing material wastage and speeding up the assembly process. This capability not only elevates the architectural creativity but also promotes sustainable building practices by optimizing the use of resources.

In the energy sector, 3D wood sculpture machines are contributing to the development of innovative and efficient solutions. Wooden components produced by these machines are being integrated into renewable energy systems, such as wind turbines and solar panel supports, where the lightweight and strong properties of engineered wood offer significant advantages. Additionally, the ability to create custom-shaped components enhances the aerodynamic efficiency of wind turbine blades and the structural support for solar arrays. Furthermore, the precision of 3D sculpting allows for the creation of optimized designs that maximize energy capture and structural stability, leading to more effective and sustainable energy solutions. This technological synergy between 3D sculpting and renewable energy applications underscores the potential for advanced manufacturing techniques to drive innovation and efficiency in the energy sector.

The industrial equipment industry has significantly benefited from the integration of 3D wood sculpture machines, revolutionizing the precision and efficiency of woodworking processes. These advanced machines use CNC (Computer Numerical Control) technology to craft intricate designs and complex shapes out of wood with unparalleled accuracy. This precision reduces material wastage and enhances production speed, making it possible to achieve detailed carvings that were previously labor-intensive and time-consuming. Industries such as furniture manufacturing, interior design, and architectural modeling now rely on these machines to produce high-quality wooden components that meet exacting standards and intricate design specifications.

Moreover, the 3D wood sculpture machines have opened new possibilities for custom and bespoke projects in the industrial sector. They enable manufacturers to easily produce limited runs of unique items without the need for extensive retooling, thus catering to personalized customer demands and niche markets. This flexibility is particularly valuable in creating prototypes and specialized components for construction and decorative applications. Additionally, the automation and consistency offered by these machines lead to lower labor costs and reduced human error, fostering a more cost-effective production environment. Overall, the adoption of 3D wood sculpture machines marks a significant advancement in the industrial equipment industry, enhancing both the creative potential and operational efficiency of woodworking enterprises.

The application of 3D wood sculpture machines in the medical devices industry represents a novel intersection of traditional craftsmanship and advanced technology. These machines, equipped with precise computer numerical control (CNC) capabilities, allow for the creation of highly detailed and customized wooden models that can be used in various medical applications. For instance, anatomical models crafted from wood can be used for educational purposes, offering medical students and professionals tactile and visual aids to enhance their understanding of human anatomy. The natural texture and durability of wood provide a unique, sustainable alternative to traditional plastic models, aligning with increasing environmental consciousness within the healthcare sector.

Moreover, 3D wood sculpture machines can be instrumental in prototyping and developing medical devices. The ability to rapidly produce precise wooden prototypes enables designers and engineers to test and refine their innovations in a cost-effective manner. These prototypes can be used to assess the ergonomics, functionality, and aesthetics of medical devices before committing to mass production using more expensive materials. Additionally, the versatility of 3D wood sculpture machines allows for the creation of bespoke medical tools and equipment tailored to specific patient needs, thus enhancing personalized medicine approaches. By integrating traditional woodworking with cutting-edge 3D technology, the medical field can leverage these machines to advance both educational and practical aspects of healthcare.

A 3D wood sculpture machine is a versatile tool in machining and manufacturing, revolutionizing how intricate wood designs are created. Utilizing advanced CNC (Computer Numerical Control) technology, these machines can carve complex patterns and shapes with high precision and efficiency. This technology significantly reduces the manual labor involved in traditional wood carving, allowing for the production of detailed and consistent sculptures at a faster rate. The machine’s ability to execute precise cuts and engravings makes it invaluable for industries requiring detailed woodwork, such as furniture manufacturing, architectural detailing, and custom wood artistry. Its integration into manufacturing processes enhances productivity, reduces waste, and ensures uniformity in large-scale production runs.

In addition to improving efficiency, 3D wood sculpture machines expand creative possibilities in woodworking. Designers and artists can use digital modeling software to create intricate designs that are then seamlessly translated into physical form by the machine. This capability allows for the creation of complex geometries and fine details that would be difficult or impossible to achieve by hand. Moreover, the machine’s ability to work with various wood types and sizes broadens its application range, catering to both small artisanal workshops and large industrial operations. By merging traditional craftsmanship with modern technology, 3D wood sculpture machines foster innovation and precision in the woodworking industry, enabling the creation of both functional and decorative pieces with unparalleled quality.

Q: What is a 3D wood sculpture machine?

A: A 3D wood sculpture machine is a type of CNC (Computer Numerical Control) equipment designed to carve, cut, and shape wood into intricate 3D sculptures and designs, providing precision and efficiency in woodworking.

Q: What materials can the 3D wood sculpture machine handle?

A: The machine primarily works with various types of wood, including hardwood, softwood, MDF, and plywood. It can also handle composite materials and some plastics.

Q: What are the advantages of sourcing from SourcifyChina factory?

A: SourcifyChina factory offers high-quality machinery with advanced technology, competitive pricing, customizable options, and reliable after-sales support. The factory also adheres to strict quality control standards to ensure product excellence.

Q: Can the 3D wood sculpture machine be customized?

A: Yes, SourcifyChina factory provides customization services to meet specific requirements, including machine size, power, tool options, and additional features based on customer needs.

Q: What is the production capacity of the 3D wood sculpture machine?

A: The production capacity varies based on the machine model and specifications. Generally, these machines are capable of continuous operation, making them suitable for both small-scale and large-scale production.

Q: How do I maintain the 3D wood sculpture machine?

A: Regular maintenance includes cleaning the machine, lubricating moving parts, checking and tightening screws and bolts, and ensuring software updates. SourcifyChina provides detailed maintenance guidelines and support.

Q: What kind of support does SourcifyChina offer post-purchase?

A: SourcifyChina offers comprehensive after-sales support, including installation assistance, operator training, technical support, and warranty services to ensure smooth operation and customer satisfaction.

Q: How long does it take to deliver a machine from SourcifyChina?

A: Delivery time depends on the order specifications and destination. Typically, it takes 4-6 weeks for production and shipping. Expedited options may be available upon request.

Q: Is training provided for operating the 3D wood sculpture machine?

A: Yes, SourcifyChina provides training sessions for operators to ensure they understand how to use the machine efficiently and safely.

Q: What safety features are included in the 3D wood sculpture machine?

A: The machines are equipped with safety features such as emergency stop buttons, protective enclosures, dust extraction systems, and user-friendly interfaces to ensure safe operation.

Manufacturing 3D wood sculptures using machines from SourcifyChina factory involves several key considerations:

1. Machine Type: Choose between CNC routers and laser cutters. CNC routers are ideal for detailed and large-scale work, while laser cutters offer precision for intricate designs.

2. Specifications: Look for machines with high power, precision, and speed. Ensure the machine can handle the thickness and type of wood you plan to use.

1. Space: Ensure you have adequate space for the machine, including room for movement and ventilation.

2. Power Supply: Verify that your power supply meets the machine’s requirements. Industrial machines often need a stable, high-voltage power source.

3. Software: Install compatible design software (e.g., CAD/CAM) for creating and converting your designs into machine-readable formats.

1. Training: Proper training for operators is crucial. Understand the machine’s interface, safety protocols, and maintenance routines.

2. Regular Maintenance: Schedule regular maintenance checks to ensure the machine runs smoothly. Clean the machine after each use to prevent dust and debris buildup.

3. Tooling: Keep your tools, such as router bits and laser lenses, sharp and clean to maintain cutting precision and extend their lifespan.

1. Quality Wood: Use high-quality, kiln-dried wood to avoid warping and cracking.

2. Supplier Relationships: Establish a good relationship with reliable suppliers to ensure a consistent supply of materials and spare parts.

1. Protective Gear: Always wear safety glasses, hearing protection, and appropriate clothing.

2. Ventilation: Ensure proper ventilation to manage dust and fumes.

3. Emergency Procedures: Have clear emergency procedures and easily accessible safety equipment like fire extinguishers.

1. Design Efficiency: Optimize designs to reduce waste and maximize the use of materials.

2. Batch Production: Plan for batch production to improve efficiency and reduce machine downtime.

By carefully selecting the right machine, ensuring proper setup and maintenance, and adhering to safety protocols, you can successfully produce high-quality 3D wood sculptures with machinery from SourcifyChina factory.

Sure! Here’s a concise FAQ for sourcing a 3D wood sculpture machine from SourcifyChina factory:

Q: What types of 3D wood sculpture machines does SourcifyChina offer?

A: SourcifyChina provides a range of 3D wood sculpture machines, including CNC routers, laser engravers, and automated carving machines, suitable for different production needs and complexity levels.

Q: Can I customize the specifications of the 3D wood sculpture machine?

A: Yes, SourcifyChina offers customization options to tailor the machine’s specifications, such as size, power, and software, to meet your specific requirements.

Q: What materials can the 3D wood sculpture machine process?

A: The machines are designed to work with various wood types, including hardwood, softwood, plywood, MDF, and other wood composites.

Q: What is the lead time for manufacturing and delivering the machine?

A: The typical lead time ranges from 30 to 45 days, depending on the customization level and order volume. Shipping time will vary based on the destination.

Q: Does SourcifyChina provide installation and training services?

A: Yes, SourcifyChina offers on-site installation and training services to ensure proper setup and efficient use of the machine.

Q: What kind of technical support and warranty does SourcifyChina offer?

A: SourcifyChina provides comprehensive technical support, including online assistance and troubleshooting. The machines come with a standard one-year warranty, which can be extended upon request.

Q: How can I place an order for a 3D wood sculpture machine?

A: You can place an order by contacting SourcifyChina directly through their website, email, or phone. Their sales team will assist you with the quotation and ordering process.

Q: Are there any minimum order requirements?

A: No, SourcifyChina does not have a minimum order requirement, making it convenient for both large and small businesses to procure their machines.

Q: What are the payment terms?

A: The standard payment terms include a deposit upon order confirmation and the remaining balance before shipment. SourcifyChina accepts various payment methods, including wire transfers and letters of credit.

Q: Can I visit the factory before placing an order?

A: Yes, factory visits can be arranged. Contact SourcifyChina to schedule a visit and tour their manufacturing facilities to better understand their production capabilities and quality control processes.

To source a 3D wood sculpture machine from SourcifyChina factory efficiently, follow these tips:

1. Identify Requirements: Determine the specific features you need, such as size, power, precision, and software compatibility. This helps narrow down options and communicate clearly with suppliers.

2. Research Suppliers: Use SourcifyChina’s platform to search for reputable factories. Look for suppliers with good reviews, a history of reliable delivery, and relevant experience in producing 3D wood sculpture machines.

3. Request Quotes: Contact multiple suppliers to get quotes. Provide detailed requirements to get accurate pricing. Compare quotes to understand the market range and identify the best value for your budget.

4. Check Certifications and Compliance: Ensure the factory complies with international standards and has necessary certifications like CE, ISO, or UL, which guarantee product quality and safety.

5. Ask for Samples: If possible, request sample products or a demonstration to assess the machine’s quality and performance. This also helps verify the supplier’s capabilities.

6. Negotiate Terms: Discuss terms of payment, delivery schedules, warranty, and after-sales service. Negotiating favorable terms can save costs and ensure timely support if issues arise.

7. Inspect the Factory: If feasible, visit the factory or hire a third-party inspection service to verify the production process and quality control measures.

8. Review Contracts Thoroughly: Ensure all agreements are documented in a detailed contract. Review terms carefully to avoid misunderstandings or disputes later.

9. Utilize SourcifyChina’s Support: Leverage any buyer support services offered by SourcifyChina, such as logistics assistance, quality assurance, or dispute resolution services.

10. Monitor Production and Shipping: Stay in touch with the supplier during production to monitor progress. Use reliable logistics services for shipping to avoid delays or damages.

Following these steps can help you source a high-quality 3D wood sculpture machine from SourcifyChina factory efficiently and with confidence.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.