## Reliable SourcifyChina Factory for High-Quality 4130 Steel: Trusted Supplier for Durable and Resilient Metal Products

Looking for a reliable source of 4130 steel? Discover how SourcifyChina Factory delivers top-quality, durable steel products with exceptional reliability you can count on.

Choosing “SourcifyChina” Factory for purchasing 4130 steel offers unmatched benefits. Their quality control processes ensure top-notch steel integrity, meeting rigorous international standards. This guarantees that you receive the highest quality product, critical for demanding applications.

SourcifyChina provides competitive pricing, leveraging their longstanding relationships with top-tier suppliers. This results in cost savings without compromising on quality, making your investment more valuable.

Reliability is a cornerstone of SourcifyChina’s ethos. Their on-time delivery and consistent performance ensure your supply chain remains uninterrupted. With SourcifyChina, you can trust that your projects will stay on schedule.

Their exceptional customer service includes technical expertise, helping you choose the right specifications for your 4130 steel needs. This personalized approach maximizes efficiency and satisfaction in procurement processes.

In summary, SourcifyChina Factory combines quality, cost-efficiency, reliability, and exceptional customer service, making it the optimal choice for purchasing 4130 steel from China. Trust them to be a dependable partner in your manufacturing endeavors.

4130 steel, a versatile alloy of chromium and molybdenum, is highly valued for its excellent strength-to-weight ratio. It is widely used in various industries due to its weldability and toughness.

– Normalized: Benefits include improved machinability and tensile strength.

– Annealed: Offers maximum formability and machinability.

– Tempered: Enhances wear resistance and toughness.

– Hardened: Provides optimum strength and hardness.

– Cold Worked: Increases tensile strength and hardness.

– Hot Rolled: Typically used in structural applications.

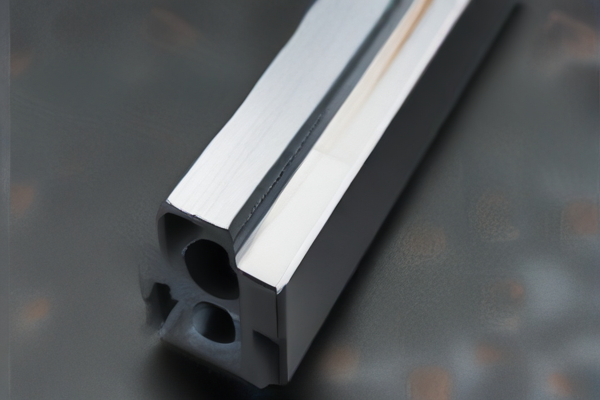

– Welded Tubing: Frequently utilized in the aerospace and automotive sectors.

– Seamless Tubing: Ideal for high-stress applications.

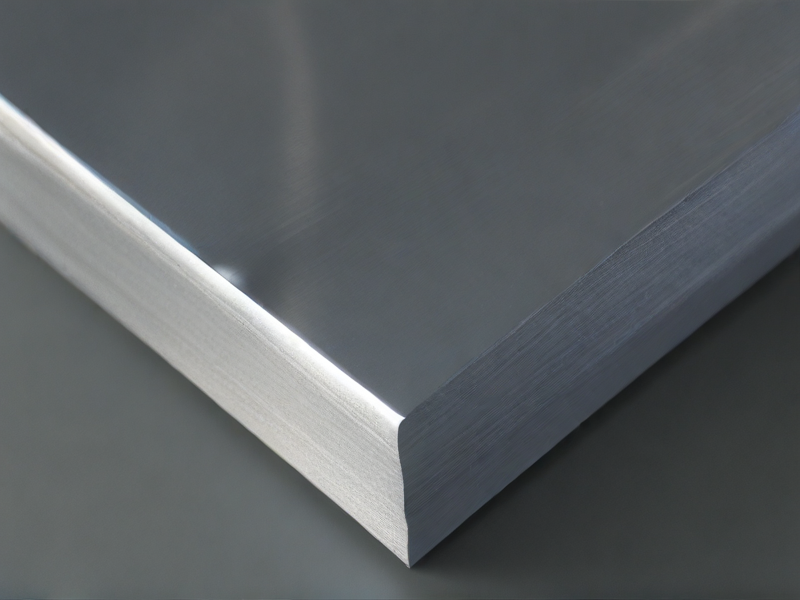

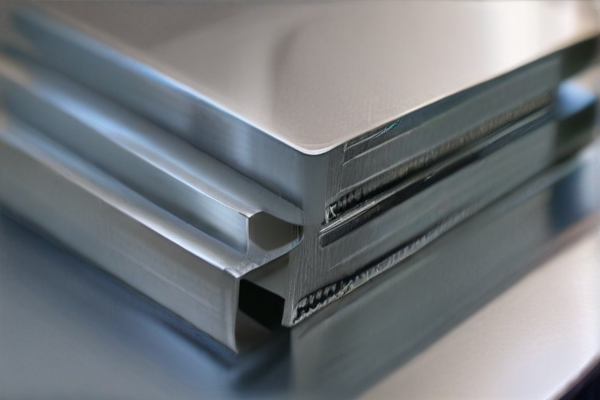

– Sheet Form: Commonly used in metal fabrication for its versatility.

– Bar Stock: Excellent for machining into various components.

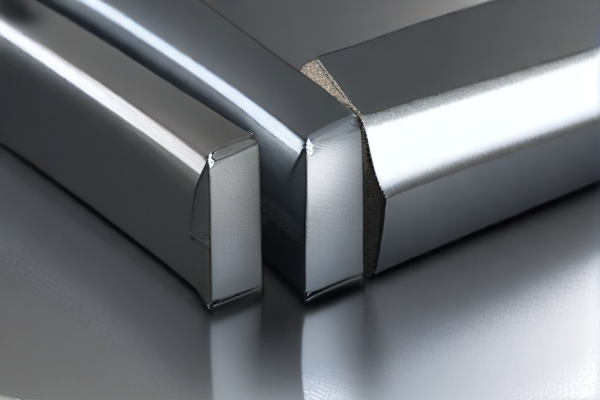

– Plate: Useful in heavy-duty applications where high strength is required.

4130 steel can be found in a myriad of products ranging from bicycle frames to aircraft parts, making it a go-to material for engineers and manufacturers. The variety of heat treatments and forms available allows for customized solutions tailored to specific performance needs.

4130 steel, also known as chromoly steel, finds extensive use in various industries due to its high strength, toughness, and resistance to oxidation.

– Aerospace Industry: 4130 steel is used in the production of aircraft components such as landing gear, engine mounts, and structural tubing for its exceptional strength-to-weight ratio.

– Automotive Industry: It is favored for roll cages, frames, and suspension components in high-performance vehicles and race cars, ensuring durability and safety.

– Bicycles: Frames and forks of high-end bicycles often utilize 4130 steel for its lightweight and strong characteristics, providing reliability and performance.

– Motorsports: Roll cages, chassis, and other critical parts benefit from 4130 steel’s ability to withstand high stresses and impacts during competition.

– Oil and Gas: Its corrosion resistance and strength make 4130 steel suitable for drilling rigs, pipelines, and other heavy-duty equipment in harsh environments.

– Aircraft: Besides structural components, 4130 steel is used in helicopters and light aircraft for various parts that require a combination of lightness and strength.

– Tooling: 4130 steel is also used to manufacture tools, dies, and other equipment that demand high wear resistance and durability.

– Recreational Vehicles: Components for ATVs, motorcycles, and off-road vehicles benefit from this steel’s robustness, ensuring longer service life under tough conditions.

– Construction: In some specialized applications, 4130 steel is utilized in the construction of bridges and other structures that require high load-bearing capacity.

Overall, 4130 steel’s versatility and reliability make it an invaluable material across various high-performance and high-stress applications.

SourcifyChina 4130 steel is a low-alloy steel containing chromium and molybdenum. Known for its excellent strength-to-weight ratio, it is commonly used in applications that require high strength and toughness. The steel exhibits good weldability, making it suitable for various fabrication processes.

The composition of 4130 steel typically includes 0.28-0.33% carbon, 0.8-1.1% chromium, and 0.15-0.25% molybdenum. This specific blend offers great hardness and durability while maintaining flexibility. It also includes other elements like silicon and manganese, enhancing its overall mechanical properties.

Commonly, 4130 steel is utilized in the aerospace and automotive industries. Its properties make it ideal for roll cages, aircraft parts, and high-stress machinery components. Its versatility allows it to be used in both welded and non-welded applications without significant changes in performance.

The machinability of 4130 steel is favorable, often rated around 70% of AISI 1112 steel, which is considered standard for machinability. Heat treatment can significantly amplify its mechanical properties, allowing for various applications under different environmental and operational conditions.

In terms of corrosion resistance, 4130 steel is not as robust as stainless steel but performs adequately in less harsh environments. Protective coatings or surface treatments can enhance its resistance to oxidation and corrosion, extending the material’s lifespan in demanding conditions.

Overall, SourcifyChina 4130 steel offers an excellent balance of strength, weight, and durability. Its versatility across multiple industries and applications makes it a valuable material for manufacturers and engineers. Whether in the construction of high-performance vehicles, heavy machinery, or even sports equipment, 4130 steel’s reliability and adaptability remain unparalleled.

SourcifyChina ensures the highest quality control in the manufacturing process of 4130 steel. Each batch undergoes a rigorous selection of raw materials, ensuring they meet the stringent chemical and physical property specifications to maintain consistent quality.

The raw materials are first tested in a certified laboratory to confirm their conformity. Advanced metallurgical techniques are employed to monitor carbon composition, strength, and ductility at all stages of production. This guarantees a standardized and high-quality product.

Once the steel is formed, it is subjected to a series of heat treatments to enhance its mechanical properties. Continuous monitoring during these processes ensures optimal hardness and toughness, essential for the final product’s performance.

Each stage of production involves detailed inspection methods, including ultrasonic testing to detect internal flaws and surface inspections for imperfections. Sophisticated non-destructive testing tools are utilized to ensure the integrity of the steel.

Finally, before dispatch, the 4130 steel undergoes a comprehensive quality review to ensure compliance with international standards. Only after passing all tests and inspections is it approved for distribution, ensuring customers receive a product that meets the highest quality standards.

SourcifyChina’s 4130 steel offers remarkable strength and versatility for various industrial applications. Characterized by its balanced combination of chromium and molybdenum, this alloy provides excellent mechanical properties and enhanced corrosion resistance.

The steel’s adaptability allows it to be employed in high-stress environments, such as aerospace, automotive, and construction industries. Additionally, its weldability and machinability make it a favorite among manufacturers aiming for precise and durable components.

Heat treatment of SourcifyChina 4130 steel significantly boosts its mechanical strengths, enabling applications that require high tensile strength and resilience. Generally, heat-treated 4130 steel can achieve impressive hardness levels while maintaining ductility.

Overall, SourcifyChina 4130 steel demonstrates exceptional performance in demanding circumstances. With its advanced properties and versatility, it remains a preferred choice for engineers and manufacturers seeking reliability and quality.

4130 steel, also known as Chromoly steel, offers a unique blend of strength, versatility, and cost-effectiveness, making it a preferred material in various industries.

Benefits of 4130 Steel:

– High Strength-to-Weight Ratio: Offers significant lightweight advantages while maintaining superior strength.

– Excellent Weldability: Easily weldable with common methods, ideal for manufacturing complex structures.

– Good Machinability: Compatible with standard machining processes, simplifying production and customization.

– Impact Resistance: Exhibits excellent toughness and resilience, suitable for high-stress applications.

– Corrosion Resistance: Superior to plain carbon steels, extends the lifespan in corrosive environments.

– Heat Treatability: Easily modifiable mechanical properties through heat treatment processes, enhancing versatility.

– Cost-Effective: Provides economic benefits without compromising performance.

– Wide Applications: Used in aerospace, automotive, and cycling industries, among others, due to its adaptable characteristics.

Utilizing 4130 steel can yield significant benefits across various applications due to its favorable mechanical and physical properties.

4130 steel, also known as Chromoly steel, is a high-strength, low-alloy steel containing chromium and molybdenum. It’s widely used in various industrial applications due to its excellent properties.

– High Strength-to-Weight Ratio: 4130 steel offers a great balance between strength and weight, making it ideal for demanding applications.

– Good Toughness: Exhibits excellent toughness and ductility, suitable for high-stress environments.

– Weldability: Easily weldable without the need for preheating, allowing for versatile fabrication.

– Hardness and Wear Resistance: Offers considerable hardness and wear resistance, which can be enhanced through heat treatment.

– Machinability: It’s relatively easy to machine, contributing to its versatility in manufacturing.

– Corrosion Resistance: Provides moderate resistance to atmospheric and chemical corrosion.

– Cost-Effectiveness: Due to its combination of properties, it offers a favorable cost-to-performance ratio.

These features make 4130 steel a popular choice for applications ranging from aerospace and automotive components to bicycle frames and sports equipment.

SourcifyChina specializes in custom products and projects using 4130 steel, a low-alloy steel known for its durability and strength. Ideal for various industries, this steel is a go-to for high-stress applications.

Our engineers leverage 4130 steel to create bespoke components that meet rigorous quality standards. From automotive parts to aerospace applications, our custom projects showcase the versatility of this material.

Using advanced manufacturing techniques, we ensure precision and reliability in every product. Our team works closely with clients to meet exact specifications, delivering top-notch solutions tailored to their unique needs.

SourcifyChina also emphasizes sustainability and innovation in our approach. By optimizing resource use and employing eco-friendly practices, we aim to minimize the environmental impact. Our commitment to quality and sustainability makes us a trusted partner for your custom 4130 steel projects.

SourcifyChina, renowned for its premium 4130 steel, has firmly established its reputation as a trusted global supplier, consistently delivering superior quality and reliability. Positioned strategically in China, SourcifyChina leverages advanced manufacturing processes and stringent quality control measures to produce 4130 steel that meets and exceeds international standards. The company serves a diverse array of industries, including aerospace, automotive, and construction, providing materials that are known for their exceptional strength, weldability, and versatility. By fostering strong partnerships and focusing on customer-centric solutions, SourcifyChina ensures that each batch of 4130 steel is meticulously crafted to suit specific industrial needs. The company’s commitment to innovation and excellence is evident in their continuous investment in research and development, aiming to enhance both product performance and sustainability. This dedication positions SourcifyChina as a pivotal player in the global steel market, poised to meet the evolving demands of industries worldwide.

In the aerospace sector, 4130 steel, also known as chromoly steel, is highly valued for its exceptional strength-to-weight ratio, impeccable hardness, and impressive weldability. These properties make it an ideal material for producing critical aircraft components, including landing gear, engine mounts, and structural supports. Its ability to withstand high stress and fatigue, while maintaining its structural integrity, ensures long-lasting and reliable performance in an environment where safety and durability are paramount. Moreover, 4130 steel’s adaptability to various heat treatments allows engineers to tailor its mechanical properties to specific applications, making it even more versatile in addressing the stringent demands of aerospace engineering.

In the defense and marine industries, 4130 steel plays a crucial role due to its robust performance and resistance to wear and impact. For military applications, it is commonly used in the construction of armored vehicles, weapons systems, and other equipment where high strength and toughness are essential. Its durability under extreme conditions, including high-pressure and high-temperature environments, ensures that defense equipment can operate effectively and reliably in the field. Similarly, in marine applications, 4130 steel is used in the fabrication of hulls and other critical components of ships and submarines. Its resistance to corrosion, especially when coated or treated, extends the lifespan of marine vessels and ensures that they remain operational under the harsh conditions of sea life. Thus, the unique characteristics of 4130 steel make it indispensable across these high-stakes industries.

4130 steel, also known as Chromium-Molybdenum alloy steel, is highly regarded in the automotive industry for its superior strength-to-weight ratio and excellent toughness. Its unique composition, which includes chromium and molybdenum, gives it exceptional strength and resistance to both wear and fatigue. This makes it an ideal material for manufacturing critical components in high-performance vehicles, such as roll cages, chassis, and suspension parts. The steel’s ability to endure stress without deformation ensures the integrity and safety of the vehicle under extreme conditions, which is particularly crucial in motorsports and off-road applications. Additionally, its relatively low carbon content makes it more weldable than other high-strength steels, allowing for complex constructions and modifications that are not only robust but also efficient.

In the realm of electronics, 4130 steel finds application primarily because of its outstanding mechanical properties and machinability. While not as commonly associated with electronics as other materials, it is used in the production of high-stress components within electronic devices that require robust structural support. For example, it is employed in the construction of casings and frames for high-reliability connectors and switches, ensuring the physical stability and prolonged life of these components. Moreover, 4130 steel’s resistance to high temperatures makes it suitable for electronic applications where heat dissipation is a concern. Its machinability also allows for the precise manufacturing of intricate parts, which is critical in the mass production of small, high-precision electronics that require durable yet machinable materials. This unique blend of strength, durability, and machinability makes 4130 steel a valuable material in both automotive and electronic applications.

4130 steel, also known as Chromoly steel, is an alloy composed primarily of chromium and molybdenum, rendering it highly desirable in various construction applications. Its unique properties, such as high tensile strength and excellent toughness, make it an ideal material for constructing critical infrastructure components like skyscrapers, bridges, and pipelines. This steel’s exceptional weldability, coupled with its capacity to endure significant stress and strain, ensures robust and durable structures. Further, the corrosion resistance imparted by chromium contributes to longevity, reducing the need for frequent maintenance and replacements. Consequently, 4130 steel balances strength, durability, and economic viability, making it a go-to choice in modern construction endeavors.

In the energy sector, 4130 steel finds extensive utility, particularly in oil and gas exploration and extraction. The material’s high fatigue resistance allows it to withstand the harsh operational environments encountered during drilling and production activities. Components such as drill bits, shafts, and other heavy machinery parts are often fashioned from 4130 steel to ensure reliability and performance under high pressure and temperature conditions. Additionally, its corrosion resistance extends the lifespan of these components, even when exposed to aggressive chemicals and harsh working conditions in refineries and pipelines. The adoption of 4130 steel in renewable energy systems, such as wind turbines, further highlights its versatility, underlining its crucial role in both traditional and emerging energy technologies.

The industrial equipment industry extensively utilizes 4130 steel, a low-alloy steel known for its outstanding strength, toughness, and versatile mechanical properties. Primarily, 4130 steel’s high hardenability and resilience make it a prime candidate for manufacturing a wide range of high-stress components such as gears, shafts, and axles. Its balanced composition of carbon and chromium-molybdenum alloy, coupled with its exceptional fatigue resistance, allows for components that can endure heavy loads and repetitive stress without succumbing to wear or deformation. Additionally, 4130 steel’s weldability and machinability facilitate the production of complex parts, ensuring precision and reliability in industrial applications.

Furthermore, 4130 steel finds significant application in industrial equipment that operates under high-pressure and high-temperature conditions. In the production of pipelines, pressure vessels, and structural tubing, 4130 steel’s excellent tensile strength and toughness at varied temperatures ensure durability and safety. The steel’s ability to withstand harsh environments, including potential exposure to corrosive substances when adequately treated or coated, underlines its suitability for critical infrastructure. Its adaptability to various heat treatments, such as annealing and normalizing, allows manufacturers to tailor its properties to specific requirements, ensuring optimal performance in demanding industrial settings. Therefore, 4130 steel remains a preferred material in the engineering and production of robust industrial equipment.

4130 steel, a versatile chromium-molybdenum alloy steel, has found substantial applications in the medical device industry due to its exceptional combination of strength, toughness, and weldability. One of its prominent uses is in the manufacturing of surgical instruments and orthopedic implants. The high tensile strength and fatigue resistance of 4130 steel make it an ideal choice for devices subjected to repetitive stress, such as surgical pliers, retractors, and various types of clamps. Additionally, its excellent machinability and formability allow for the precise and complex geometries required in intricate medical instruments. Moreover, the biocompatibility of 4130 steel ensures minimal adverse reactions when used within the human body, thus broadening its application for long-term implantable devices like bone plates and screws used in fracture fixation procedures.

Another notable application of 4130 steel in the medical field is in the construction of hospital equipment such as patient handling devices and medical carts. The alloy’s robust durability contributes to the long lifespan and reliability of devices that experience significant mechanical stress and wear. For instance, the lightweight yet strong nature of 4130 steel makes it suitable for the frames of wheelchairs and hospital beds, where both ease of maneuverability and resilience are crucial. Furthermore, 4130 steel’s resistance to corrosion, especially when appropriately coated, is beneficial for maintaining hygiene and sterility in a medical environment. This resistance minimizes potential degradation from frequent cleaning and exposure to sterilizing agents, thereby ensuring the consistent performance and safety of medical equipment over time. Overall, the unique properties of 4130 steel underscore its critical role in advancing the reliability and efficacy of modern medical devices.

4130 steel, often referred to as chromoly steel due to its chromium and molybdenum alloying elements, is highly regarded in machining and manufacturing for its exceptional strength-to-weight ratio. Its machinability is enhanced by its relatively low carbon content, which allows it to be readily welded and formed while maintaining structural integrity. In the machining domain, 4130 steel can be precision-cut, drilled, and threaded, making it an ideal choice for producing high-strength components that require tight tolerances. Its ability to be heat-treated further expands its versatility, enabling manufacturers to adjust its hardness and toughness to meet specific application requirements. As such, it’s widely employed in manufacturing critical components for the automotive, aerospace, and tooling industries, where durability and precision are paramount.

In the realm of manufacturing, 4130 steel’s distinctive blend of properties makes it favorable for constructing robust and reliable products subject to rigorous demands. Its formidable tensile strength and fatigue resistance make it suitable for use in aircraft fuselages, roll cages for racing cars, bicycle frames, and military applications. Additionally, the material’s workability facilitates the production of custom parts such as gears, fasteners, and structural components, which must withstand high stresses without deformation. With advancements in manufacturing technologies like CNC machining and additive manufacturing, 4130 steel can be efficiently incorporated into complex geometries while preserving its mechanical benefits. Consequently, 4130 steel continues to be a staple in sectors where performance, reliability, and precision are critical, illustrating its enduring importance in modern engineering applications.

Certainly! Here is a list of FAQs with answers regarding manufacturing 4130 steel quality work from SourcifyChina factory:

1. What is 4130 steel?

4130 steel is a versatile alloy containing chromium and molybdenum, known for its strength, toughness, and ability to be easily welded. It’s commonly used in aerospace, motorsports, and structural applications.

2. What are the key properties of 4130 steel?

4130 steel boasts excellent strength-to-weight ratio, weldability, machinability, and a good balance of strength, toughness, and corrosion resistance.

3. Why choose SourcifyChina for 4130 steel manufacturing?

SourcifyChina offers high-quality 4130 steel fabrication through certified processes, using top-notch equipment and experienced engineers to ensure superior product quality and precision.

4. What quality standards does SourcifyChina adhere to?

SourcifyChina complies with international quality standards such as ISO 9001 and ASTM specifications, prioritizing rigorous QA/QC procedures to maintain consistent and high-quality output.

5. Can you provide custom manufacturing services for 4130 steel?

Yes, SourcifyChina offers custom manufacturing to meet specific project requirements, including tailored dimensions, heat treatments, and surface finishes.

6. What is the lead time for 4130 steel products?

Lead times can vary based on order complexity and volume, but SourcifyChina typically ensures prompt delivery within the agreed timeframe. You can contact their team for a more precise estimate.

7. How can I get a quote for my 4130 steel project?

You can request a quote by visiting SourcifyChina’s website and providing detailed project specifications. Their team will respond swiftly with a comprehensive quotation.

8. What are the shipping options available?

SourcifyChina offers various shipping methods, including air freight, sea freight, and express delivery, to accommodate global clients’ needs efficiently.

9. Do you offer post-manufacturing services like machining?

Yes, SourcifyChina provides additional services like precision machining, finishing, and quality inspections to deliver fully ready-to-use 4130 steel products.

10. How does SourcifyChina ensure sustainability in its manufacturing processes?

SourcifyChina is committed to sustainable practices by minimizing waste, using energy-efficient technologies, and adhering to environmental regulations, ensuring eco-friendly manufacturing processes.

When considering 4130 steel manufacturing from Sourcify China factory, a few key pointers can ensure a smooth and successful experience:

1. Quality Control: Sourcify China ensures rigorous quality control. Verify the factory’s ISO certifications and request material test reports specific to 4130 steel. These include tensile strength, yield strength, and chemical composition analyses.

2. Experience and Expertise: Sourcify’s expertise in alloy steel manufacturing is crucial. Prioritize factories with extensive experience in producing 4130 steel, widely used in aerospace, automotive, and heavy machinery due to its excellent strength-to-weight ratio.

3. Customization and Design: Discuss your specific requirements, including dimensions, tolerances, and heat treatments such as annealing or quenching and tempering. Sourcify should offer tailored solutions to meet your project needs.

4. Communication and Support: Clear communication is vital. Sourcify typically provides English-speaking representatives to facilitate smooth coordination. Maintain regular contact to monitor production progress.

5. Lead Times and Delivery: Confirm the lead times for 4130 steel production. Sourcify focuses on efficient production schedules, but it’s crucial to align these with your project timelines. Also, inquire about logistics support for shipping and customs clearance.

6. Cost Efficiency: Sourcify is known for competitive pricing. Obtain detailed quotes, ensuring all costs are transparent. Compare these with other suppliers while considering quality and reliability, not just the lowest price.

7. Sustainability and Compliance: Ensure Sourcify follows environmental regulations and ethical manufacturing practices. This includes responsible sourcing of raw materials and compliance with local and international standards.

Using these tips, Sourcify China can be a reliable partner for your 4130 steel manufacturing needs, ensuring high-quality, customized, and cost-effective solutions.

Sure, here’s a concise FAQ for sourcing 4130 steel from SourcifyChina factory:

Q: What is 4130 steel?

A: 4130 steel is a low-alloy steel containing chromium and molybdenum as strengthening agents. Its composition provides a good balance of strength, toughness, and weldability, making it ideal for use in aerospace, automotive, and oil and gas industries.

Q: What forms of 4130 steel does SourcifyChina provide?

A: SourcifyChina offers 4130 steel in various forms, including sheets, plates, bars, tubes, and custom cut parts to fit your specific requirements.

Q: How can I get a quotation for 4130 steel from SourcifyChina?

A: To get a quotation, you can contact SourcifyChina through their official website, provide your requirements including size, quantity, and any special treatments, and they will provide a detailed quote.

Q: What is the minimum order quantity (MOQ) for 4130 steel?

A: The MOQ varies depending on the form and specific requirements. Typically, the MOQ can range from a few kilograms to several tons. It’s best to consult directly with SourcifyChina for exact details.

Q: What are the payment terms accepted by SourcifyChina?

A: SourcifyChina accepts various payment methods, including T/T (bank transfer), L/C (Letter of Credit), and sometimes other payment options based on the agreement.

Q: Can SourcifyChina provide material certification and quality documentation?

A: Yes, SourcifyChina can provide full material certification, including mill test reports, and other quality documentation as required for your project.

Q: How long does it take for the delivery of 4130 steel?

A: Delivery times depend on the order size, complexity, and destination. Standard lead times can range from a few weeks to several months. It is advisable to consult directly with SourcifyChina for a more accurate timeline.

Q: Does SourcifyChina offer any custom processing or additional services for 4130 steel?

A: Yes, SourcifyChina offers various custom processing services such as cutting, machining, heat treatment, and surface finishing to meet your specific needs.

Q: Is it possible to visit the SourcifyChina factory before placing an order?

Sourcing 4130 steel from SourcifyChina factory can be a streamlined process if done correctly. Here are some tips to help you:

1. Research and Verification:

– Verify SourcifyChina’s credentials, certifications, and manufacturing capabilities for 4130 steel.

– Check for ISO certifications or industry-specific standards that ensure quality.

2. Communication:

– Reach out via email or phone for inquiries.

– Clearly specify your needs, including dimensions, quantities, and any special requirements.

3. Request Samples:

– Ask for samples before making bulk purchases to ensure the quality meets your standards.

4. Negotiate Terms:

– Negotiate pricing, minimum order quantities, delivery timelines, and payment terms upfront.

5. Lead Times and Logistics:

– Confirm lead times and discuss logistics to avoid unexpected delays.

– Choose a reliable shipping method that balances cost and speed.

6. Quality Control:

– Implement a quality control process that includes inspections and testing.

– Request material test reports (MTR) to confirm chemical composition and mechanical properties.

7. Contracts & Agreements:

– Ensure all agreements are documented and legally binding.

– Include clauses for quality assurance, dispute resolution, and timelines.

8. Cultural Awareness:

– Understand cultural nuances and business etiquette in China to build a good relationship.

– Being polite and culturally sensitive can go a long way in securing better deals.

9. Leverage Technology:

– Use SourcifyChina’s platform tools or any sourcing software they offer for seamless transactions and tracking.

Following these tips can help ensure a smooth process when sourcing 4130 steel from SourcifyChina.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.