Reliable 5-Axis CNC Router from SourcifyChina: Factory-Direct Quality and Precision Engineering

Discover the precision and quality of SourcifyChina’s 5-axis CNC routers, directly from their factory. Learn about their reliable engineering, advanced features, and how they can enhance your manufacturing capabilities.

Choosing SourcifyChina Factory for buying a 5-axis CNC router from China ensures high-quality products. With a reputation for excellence, they offer state-of-the-art machinery tailored to your specific needs. Their commitment to quality and innovation makes them a reliable partner for your business.

SourcifyChina Factory provides competitive pricing without compromising on quality. By sourcing directly from the factory, you eliminate middleman costs, ensuring you get the best value for your investment. Their transparent pricing model helps you manage your budget effectively.

Their exceptional customer service sets SourcifyChina Factory apart. With dedicated support throughout the purchasing process, they ensure your experience is smooth and satisfactory. Their team is available to answer questions and provide technical assistance, enhancing your confidence in their products.

The factory’s adherence to international standards guarantees reliable performance and durability of the 5-axis CNC routers. SourcifyChina Factory’s stringent quality control measures ensure each machine meets rigorous standards, reducing the risk of defects and enhancing operational efficiency.

SourcifyChina Factory offers comprehensive after-sales support, including maintenance and training services. This holistic approach ensures that you can fully utilize your 5-axis CNC router, maximizing its potential and longevity. Their ongoing support fosters a long-term partnership, essential for business growth.

In conclusion, SourcifyChina Factory stands out as a premier choice for purchasing 5-axis CNC routers from China. Their blend of high-quality products, competitive pricing, exceptional customer service, adherence to international standards, and comprehensive after-sales support makes them an ideal partner for your manufacturing needs.

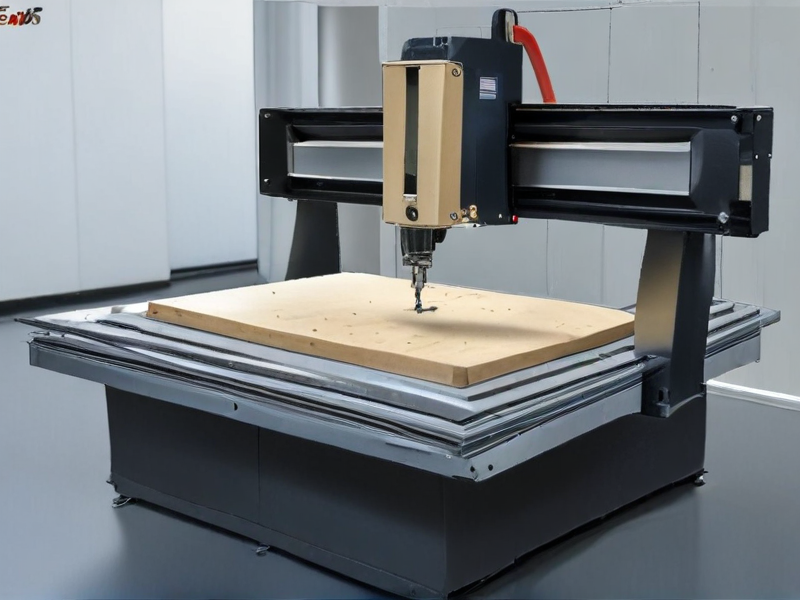

A 5-axis CNC router is a versatile machine that allows for precise and complex cutting, carving, and milling in multiple directions. It is ideal for intricate designs in various materials.

Types and Options for 5-axis CNC Routers:

– Gantry Style: Provides a large working area; suitable for big projects.

– Trunnion Table: Offers high precision; ideal for complex geometries.

– Head/Head Configuration: Ensures maximum flexibility; best for detailed tasks.

– Bridge Style: Ensures stability and accuracy; perfect for heavy-duty applications.

– Articulated Arm: Allows for intricate movements; best for sculptural and artistic works.

– Portable Units: Offers mobility; great for on-site projects.

Options and Features:

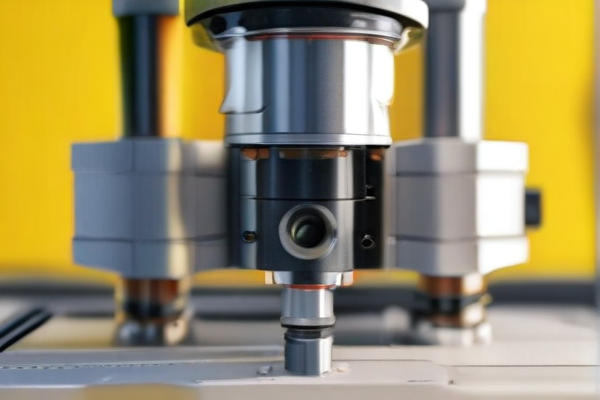

– Spindle Types: High-speed, high-torque, and multi-spindle options.

– Software: Advanced CAM software for optimized paths and efficiency.

– Tool Changers: Automatic tool changers for increased productivity.

– Vacuum Tables: For secure material holding.

– Dust Collection Systems: To maintain a clean working environment.

– Rotary Axes: For enhanced 3D capabilities.

– Probing Systems: For accurate measurements and quality control.

– Coolant Systems: For prolonged tool life and better finishes.

– Safety Enclosures: To protect operators from debris and noise.

A 5-axis CNC router is a versatile machine capable of creating complex and intricate parts. It is extensively used in various industries due to its precision and efficiency.

– Aerospace: crafting components with complex geometries

– Automotive: producing custom parts and prototypes

– Medical: manufacturing implants and surgical instruments

– Art and Sculpture: creating detailed artworks

– Woodworking: fabricating intricate furniture designs

– Metalworking: milling and drilling precise parts

– Electronics: producing circuit boards and enclosures

– Marine: crafting boat hulls and components

Its ability to move a tool or part in five different axes allows for high accuracy and efficiency in manufacturing, enhancing productivity and reducing manual labor.

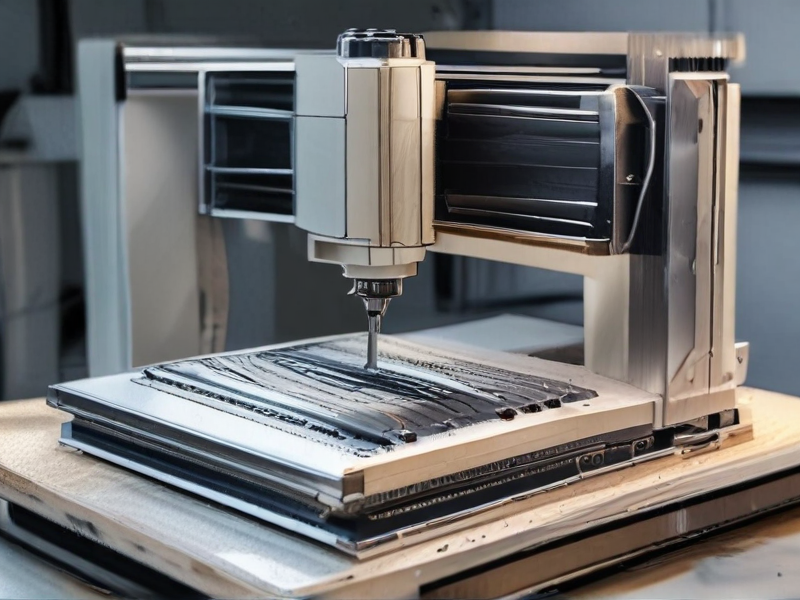

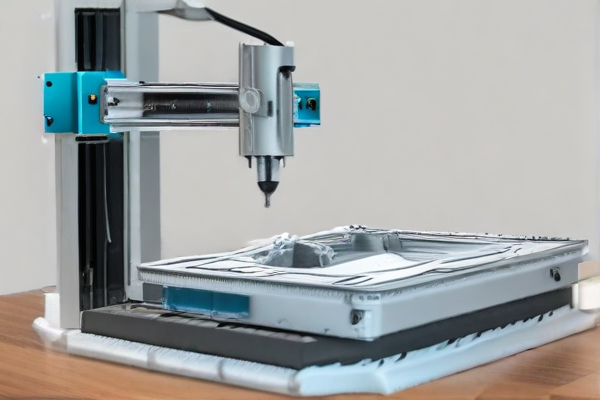

The SourcifyChina 5-axis CNC router is constructed using high-quality aluminum alloy, providing a lightweight yet robust frame. This material ensures durability and resistance to corrosion, ideal for high-precision machining.

The router’s work surface is made of hardened steel, designed to withstand extensive use without warping or damage. This material is crucial for maintaining accuracy and consistency in machining processes.

The spindles and cutting tools are crafted from tungsten carbide, known for its exceptional hardness and heat resistance. This choice of material allows for efficient cutting and longer tool life, even with challenging materials.

To enhance performance, the router incorporates advanced ball screws and linear guide rails made from tempered steel. These components ensure smooth, precise movements, reducing vibration and improving machining accuracy.

Overall, the combination of high-grade aluminum alloy, hardened steel, tungsten carbide, and tempered steel makes the SourcifyChina 5-axis CNC router a reliable and efficient machine for various industrial applications.

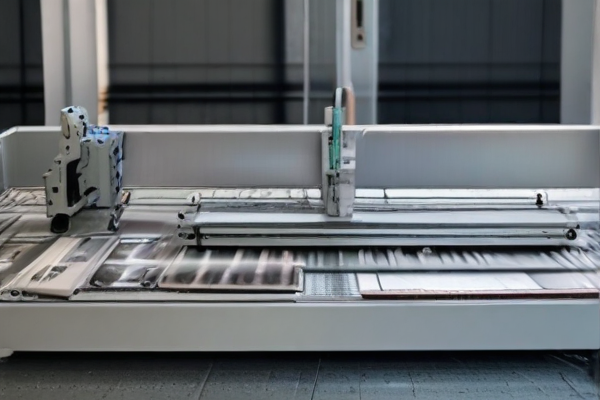

The quality control manufacturing process of SourcifyChina 5-axis CNC routers involves stringent standards to ensure precision and reliability. Each component undergoes rigorous inspection for material integrity and dimensional accuracy.

During assembly, precision alignment and calibration are performed using advanced metrology tools. This ensures all axes function with high precision and minimal deviation.

Every unit is subject to extensive testing, including full operational cycles and stress testing. This verifies performance under various conditions, ensuring robustness and durability.

Finally, a comprehensive quality assurance review is conducted. Each machine is certified to meet international standards, guaranteeing consistent quality and customer satisfaction.

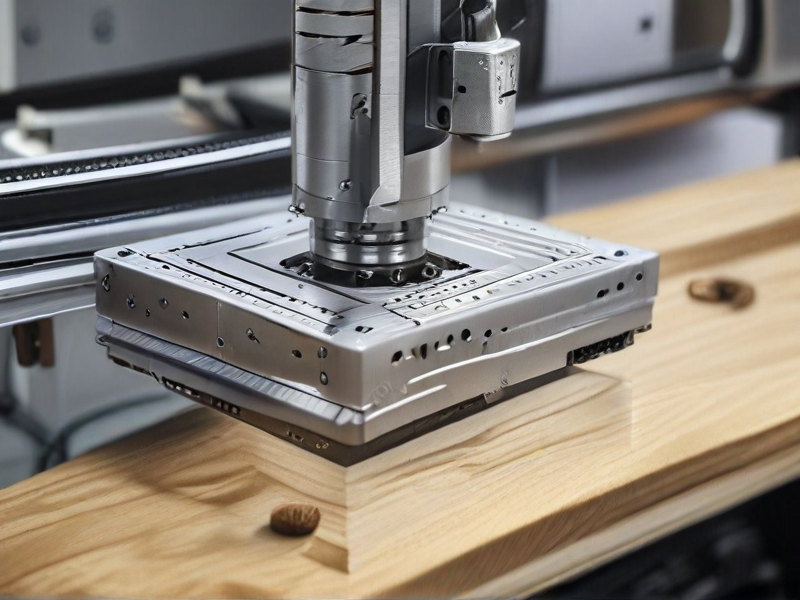

The SourcifyChina 5-axis CNC router is designed for intricate and precise machining. Its five-axis capability allows for complex cuts and detailed work on multiple surfaces in a single setup.

This machine is ideal for industries requiring high precision, such as aerospace, automotive, and mold-making. It handles a variety of materials including metals, plastics, and composites with ease.

Advanced software integration ensures seamless operation and accurate reproductions of CAD models. This makes the SourcifyChina 5-axis CNC router a versatile tool for prototyping and production.

Enhanced automation features reduce the need for manual intervention, improving efficiency and consistency. Operators benefit from intuitive controls and robust safety features, ensuring a smooth workflow.

Overall, the SourcifyChina 5-axis CNC router combines advanced technology with user-friendly operation, making it an excellent investment for businesses aiming to improve precision and productivity.

A 5-axis CNC router offers unparalleled precision and versatility, enabling the production of complex and detailed parts with high efficiency.

– Enhanced Precision and Accuracy: Allows for intricate designs and tight tolerances, reducing the need for manual finishing.

– Greater Flexibility: Capable of machining complex shapes and geometries that are impossible with traditional 3-axis machines.

– Improved Surface Finish: Provides smoother finishes by minimizing the number of setups required, reducing potential for errors.

– Increased Productivity: Faster production times and reduced material waste due to optimized machining processes.

– Cost Efficiency: Lower labor costs and reduced material wastage lead to significant cost savings in the long run.

– Wide Range of Applications: Ideal for industries such as aerospace, automotive, medical devices, and custom manufacturing.

– Reduced Tool Wear: Optimal tool paths and angles prolong the life of cutting tools, decreasing the need for frequent replacements.

A 5-axis CNC router offers advanced capabilities for precise and complex machining tasks, enhancing efficiency and versatility in manufacturing processes.

Key features of a 5-axis CNC router include:

– Simultaneous Movement: Allows for the simultaneous movement along five different axes, enabling complex shapes and detailed work.

– Improved Accuracy: Provides high precision and accuracy, essential for intricate designs and detailed parts.

– Reduced Setup Time: Minimizes the need for multiple setups and repositioning, saving time and increasing productivity.

– Enhanced Flexibility: Capable of machining a wide variety of materials, including wood, metal, and composites.

– Better Surface Finish: Produces smoother finishes due to the continuous and simultaneous movement of the cutting tool.

– Complex Geometries: Facilitates the creation of complex geometries that are impossible or very difficult with 3-axis machines.

– Optimized Tool Paths: Allows for optimized tool paths, reducing wear and tear on tools and extending their life.

– Integration with CAD/CAM: Seamlessly integrates with CAD/CAM software, ensuring precise and efficient design-to-production processes.

– Versatility: Suitable for a wide range of industries, from aerospace to automotive, due to its ability to handle diverse projects.

– Automated Operation: Often equipped with automated features, reducing the need for manual intervention and allowing for continuous operation.

Overall, a 5-axis CNC router is a powerful tool that enhances the manufacturing process by providing greater precision, flexibility, and efficiency.

SourcifyChina specializes in custom products and projects using their advanced 5-axis CNC router technology. This allows for high precision in crafting complex designs across various materials.

Their expertise spans multiple industries, from aerospace to furniture, ensuring that every custom product meets specific requirements with exceptional accuracy and quality. The 5-axis CNC router’s flexibility allows for intricate carvings and detailed machining.

SourcifyChina’s commitment to innovation is evident in their approach to each project, leveraging state-of-the-art technology to push the boundaries of what’s possible in custom manufacturing.

Their clients benefit from reduced production times and increased efficiency, leading to cost-effective solutions without compromising on quality.

Overall, SourcifyChina’s 5-axis CNC router services offer unparalleled customization, precision, and efficiency, making them a leader in the field of advanced manufacturing.

SourcifyChina is a prominent manufacturer specializing in 5-axis CNC routers, a critical technology for precision machining and complex part manufacturing. The company has established a strong reputation in the industry by delivering high-performance machines that cater to various sectors, including aerospace, automotive, and mold making. SourcifyChina’s 5-axis CNC routers are renowned for their advanced capabilities, allowing simultaneous movement along five different axes, which enhances flexibility and precision in cutting intricate geometries. The company prides itself on integrating cutting-edge technology and robust engineering in its products, ensuring that each machine meets rigorous quality and performance standards. With a commitment to innovation and customer satisfaction, SourcifyChina continually evolves its product offerings, providing tailored solutions that help businesses enhance productivity and maintain competitive edges in their respective markets. The firm’s dedication to excellence is reflected in its comprehensive support services, from installation and training to maintenance, ensuring clients can fully leverage the capabilities of their CNC routers.

The aerospace, defense, and marine industries significantly benefit from the precision and versatility of 5-axis CNC routers. These advanced machining tools allow for the creation of complex and high-precision components that are essential in these sectors. In aerospace, the 5-axis CNC routers are instrumental in manufacturing intricate parts like turbine blades, structural components, and airframe elements. The ability to machine components from a single setup reduces the margin for error and enhances the integrity and performance of aerospace parts, which is critical for maintaining safety and efficiency in aircraft operations.

In the defense sector, 5-axis CNC routers contribute to the production of complex parts for weapons systems, armored vehicles, and other military equipment. These routers enable the machining of sophisticated geometries and tight tolerances required for the reliable and effective performance of defense hardware. Similarly, in the marine industry, the 5-axis CNC routers are used to create intricate propellers, hull components, and other critical maritime parts. The routers’ capability to handle large and complex shapes ensures that marine vessels achieve optimal hydrodynamics and durability, enhancing performance and safety in harsh marine environments. Across these industries, the adoption of 5-axis CNC routers leads to improved manufacturing efficiency, higher quality products, and innovation in design and functionality.

The 5-axis CNC router has revolutionized the automotive industry by enabling the precise and efficient production of complex components. This advanced machinery allows for the creation of intricate parts that are essential for modern vehicles, such as engine components, transmission parts, and custom bodywork. The router’s ability to move along five different axes provides unparalleled accuracy and flexibility, reducing the need for multiple setups and manual adjustments. This capability not only enhances production speed but also ensures high-quality finishes, which are critical for both performance and aesthetics in automotive manufacturing. Additionally, the 5-axis CNC router supports rapid prototyping, allowing engineers to quickly iterate designs and bring innovative automotive solutions to market faster.

In the electronics sector, 5-axis CNC routers play a crucial role in manufacturing complex electronic components and enclosures. These routers enable the precise machining of intricate circuit boards, heat sinks, and other critical parts that require tight tolerances and complex geometries. The versatility of 5-axis machining ensures that even the most challenging designs can be accurately produced, facilitating the development of compact and efficient electronic devices. Furthermore, the high precision of 5-axis CNC routers enhances the reliability and performance of electronic products by ensuring consistent quality across production runs. This technology is also instrumental in creating prototypes for new electronic devices, allowing for thorough testing and refinement before mass production.

Construction Applications of 5-Axis CNC Routers

In the construction industry, 5-axis CNC routers are revolutionizing the way complex architectural components are fabricated. These advanced machines allow for the precise cutting and shaping of materials such as wood, metal, and composites, facilitating the creation of intricate designs and custom components that would be difficult or impossible to achieve with traditional tools. For instance, intricate moldings, complex joinery, and bespoke structural elements can be manufactured with exceptional accuracy, enhancing both the aesthetic and structural integrity of buildings. Moreover, the ability of 5-axis CNC routers to operate on multiple planes simultaneously reduces the need for multiple setups and manual adjustments, significantly speeding up production times and reducing labor costs. This technological advancement is particularly beneficial for large-scale projects and bespoke architectural designs where precision and efficiency are paramount.

Energy Applications of 5-Axis CNC Routers

In the energy sector, 5-axis CNC routers play a crucial role in the production of components for renewable energy systems, such as wind turbines and solar panels. These routers can accurately machine the complex geometries required for turbine blades, ensuring optimal aerodynamic performance and structural strength. The precision afforded by 5-axis machining is essential for maintaining the tight tolerances needed for efficient energy generation. Additionally, 5-axis CNC routers are used to create custom fixtures and housings for solar panels, contributing to more effective and durable energy solutions. The ability to work with a wide range of materials, including advanced composites and high-strength alloys, makes these routers indispensable for producing high-performance components that meet the rigorous demands of the energy industry. By enhancing the manufacturing capabilities and reducing production times, 5-axis CNC routers help drive innovation and efficiency in the quest for sustainable energy solutions.

The industrial equipment industry has seen significant advancements with the introduction of 5-axis CNC routers, which offer unparalleled precision and versatility. These machines allow for simultaneous movement along five different axes, enabling the creation of complex and intricate components that would be difficult or impossible to produce with traditional 3-axis routers. In industries such as aerospace, automotive, and medical device manufacturing, 5-axis CNC routers are essential for producing parts with intricate geometries and tight tolerances. This capability reduces the need for multiple setups and human intervention, leading to higher efficiency, reduced production time, and lower costs. Moreover, the ability to machine parts from multiple angles without repositioning enhances accuracy and consistency, which is critical in high-stakes industrial applications.

Beyond precision, 5-axis CNC routers also provide substantial benefits in terms of material usage and overall production flexibility. They are capable of machining a wide variety of materials, including metals, plastics, and composites, making them suitable for diverse applications across different sectors. This versatility allows manufacturers to optimize material selection for specific requirements, improving product performance and durability. Additionally, the advanced software integration with 5-axis CNC routers supports complex design and simulation, facilitating innovation and customization in product development. As industries increasingly demand high-quality, bespoke components, the role of 5-axis CNC routers becomes even more pivotal, driving advancements in manufacturing technology and fostering competitive advantage in the global market.

The use of 5-axis CNC routers in medical device manufacturing represents a significant advancement in precision engineering and production efficiency. These machines are capable of moving the cutting tool or workpiece along five different axes simultaneously, allowing for the creation of complex, three-dimensional geometries essential for medical devices. This capability is crucial in producing intricate components such as prosthetics, implants, and surgical instruments that must adhere to stringent dimensional tolerances and surface finishes. For example, creating customized implants that perfectly match a patient’s anatomy is possible with 5-axis CNC routers, leading to better fitting and more effective medical solutions. The precision and versatility of these machines ensure that even the most complex shapes can be manufactured with high repeatability, reducing the risk of errors that could compromise the functionality of medical devices.

Moreover, 5-axis CNC routers contribute to the rapid prototyping and iterative development processes in medical device innovation. Medical device manufacturers can quickly produce and test prototypes, shortening development cycles and accelerating time-to-market for new products. The flexibility of these routers enables the machining of a wide variety of materials, including biocompatible metals and advanced polymers, which are commonly used in medical devices. This adaptability is particularly beneficial in developing patient-specific solutions, such as custom dental implants or orthopedic components, tailored to individual anatomical requirements. Additionally, the automation and precision offered by 5-axis CNC technology improve overall production efficiency, reduce labor costs, and minimize material waste, making the manufacturing process more sustainable and cost-effective for the healthcare industry.

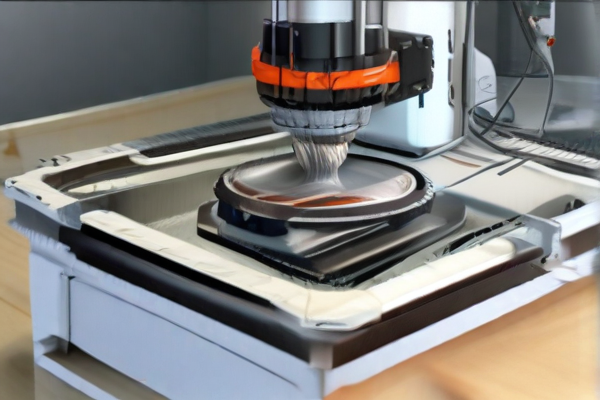

The 5-axis CNC router is a sophisticated machine tool that has revolutionized machining and manufacturing by allowing for the precise and efficient production of complex parts. Unlike traditional 3-axis machines, which can only move along the X, Y, and Z axes, 5-axis CNC routers also rotate on two additional axes, providing unparalleled flexibility and accuracy. This capability enables the router to machine intricate geometries and complex contours in a single setup, reducing the need for multiple fixtures and minimizing handling errors. Industries such as aerospace, automotive, and medical device manufacturing particularly benefit from this technology, as it allows for the production of highly detailed components with tight tolerances, enhancing overall product quality and performance.

In the realm of manufacturing, the 5-axis CNC router’s ability to perform multiple operations without repositioning the workpiece significantly boosts productivity. It reduces cycle times by streamlining the production process, enabling manufacturers to meet tight deadlines and high-volume demands more efficiently. Additionally, this machine’s advanced software integration facilitates better toolpath optimization and collision avoidance, leading to increased tool life and reduced material waste. By leveraging these advantages, manufacturers can achieve cost savings and improve their competitive edge in the market. Overall, the 5-axis CNC router is an indispensable tool that drives innovation and efficiency in modern machining and manufacturing processes.

Sure, here is a concise FAQ for the quality of 5-axis CNC router work from the SourcifyChina factory:

What is a 5-axis CNC router?

A 5-axis CNC router is a machine that moves a cutting tool or part along five different axes simultaneously. This allows for more complex shapes and higher precision in manufacturing.

What makes SourcifyChina’s 5-axis CNC routers superior?

SourcifyChina’s 5-axis CNC routers are known for their precision, reliability, and advanced technology. They use high-quality components and undergo rigorous quality control to ensure optimal performance.

What materials can SourcifyChina’s 5-axis CNC routers work with?

These routers can handle a variety of materials including metals, plastics, wood, and composites. Their versatility makes them suitable for diverse manufacturing needs.

How does SourcifyChina ensure the quality of their CNC router work?

Quality is ensured through stringent testing procedures, use of high-grade materials, and adherence to international manufacturing standards. Additionally, each machine is inspected before shipment.

What industries benefit from SourcifyChina’s 5-axis CNC routers?

Industries such as aerospace, automotive, medical devices, and furniture manufacturing benefit from the precision and versatility of these machines.

Can SourcifyChina customize their CNC routers?

Yes, SourcifyChina offers customization to meet specific manufacturing requirements. They work closely with clients to tailor the machine specifications.

What is the lead time for delivery?

The lead time varies depending on the complexity of the order and customization requirements. Typically, it ranges from a few weeks to a couple of months.

Does SourcifyChina provide after-sales support?

Yes, SourcifyChina offers comprehensive after-sales support including installation, training, maintenance, and technical assistance to ensure smooth operation.

How can I request a quote or more information?

You can visit SourcifyChina’s website or contact their customer service team directly through email or phone for quotes and detailed information.

What are the payment terms?

Payment terms typically include an initial deposit followed by the balance payment upon delivery or as per the agreed schedule. Detailed terms are provided during the quotation process.

Manufacturing with a 5-axis CNC router at SourcifyChina factory offers numerous advantages. Here are some key tips for optimizing your experience:

1. Understand the Capabilities: A 5-axis CNC router allows for complex shapes and designs with high precision, enabling the production of intricate parts that would be difficult or impossible with a 3-axis machine.

2. Material Selection: Ensure the material chosen for your project is compatible with 5-axis machining. SourcifyChina provides a range of materials, including metals, plastics, and composites. Consult with their experts to select the best material for your application.

3. Design for Manufacturability: Work closely with SourcifyChina’s engineers during the design phase to ensure your design is optimized for 5-axis machining. This collaboration can help reduce machining time and costs while improving part quality.

4. Toolpath Optimization: Efficient toolpath strategies are crucial. Leveraging SourcifyChina’s advanced CAD/CAM software can optimize toolpaths, reducing cycle times and improving surface finish.

5. Precision and Quality Control: SourcifyChina employs rigorous quality control measures. Make use of their in-house inspection services to ensure your parts meet the required specifications and tolerances.

6. Batch Production: Consider batch production to take advantage of cost efficiencies. SourcifyChina offers scalable solutions, from prototypes to full-scale production runs, providing flexibility and cost savings.

7. Lead Time Management: Plan your production schedule in advance. Communicate with SourcifyChina about your deadlines to ensure timely delivery, especially for complex projects that may require longer machining times.

8. After-Sales Support: Utilize SourcifyChina’s after-sales support for maintenance, troubleshooting, and further machining needs. Their technical support can help resolve issues quickly, ensuring continuous production.

By following these tips and leveraging the capabilities of SourcifyChina’s 5-axis CNC router, you can achieve high-quality, precision-manufactured parts efficiently and cost-effectively.

FAQ for Sourcing a 5-Axis CNC Router from SourcifyChina Factory

1. What is a 5-axis CNC router?

A 5-axis CNC router is a machine that can move a tool or a part along five different axes simultaneously. This allows for complex and precise machining of parts with intricate shapes and contours.

2. Why should I source a 5-axis CNC router from SourcifyChina?

SourcifyChina offers high-quality 5-axis CNC routers with advanced technology and competitive pricing. The factory has a reputation for reliable products and excellent customer service.

3. What materials can a 5-axis CNC router machine?

A 5-axis CNC router can machine a variety of materials, including wood, metal, plastics, foam, and composites, making it versatile for different industries.

4. How do I request a quote from SourcifyChina?

You can request a quote by contacting SourcifyChina directly through their website or by emailing their sales team with your specific requirements.

5. What is the lead time for manufacturing and delivery?

The lead time varies depending on the complexity of the order and current demand. Generally, it takes around 4-6 weeks for manufacturing and additional time for shipping.

6. Are there customization options available?

Yes, SourcifyChina offers customization options to meet specific customer needs, including custom sizes, tool configurations, and additional features.

7. What are the payment terms?

Payment terms typically include a deposit upon order confirmation and the balance before shipment. Detailed terms can be discussed directly with SourcifyChina.

8. Is there a warranty provided?

Yes, SourcifyChina provides a warranty for their 5-axis CNC routers. The terms of the warranty can be clarified during the purchasing process.

9. What after-sales support is available?

SourcifyChina offers comprehensive after-sales support, including technical assistance, spare parts, and maintenance services to ensure smooth operation of the CNC router.

10. Can I visit the factory for an inspection?

Yes, factory visits can be arranged. It is advisable to schedule an appointment in advance to ensure availability and a thorough tour.

Sourcing a 5-axis CNC router from SourcifyChina factory requires a structured approach. Here are some tips to help streamline the process:

1. Research and Specifications:

– Clearly define your requirements (e.g., material types, precision level, size).

– Understand the technical specifications of the 5-axis CNC router you need.

2. Initial Contact:

– Reach out to SourcifyChina via their official website or contact information.

– Provide detailed specifications and inquire about available models.

3. Verification:

– Verify the factory’s credibility through reviews and references.

– Request certifications and quality assurance documentation.

4. Quotation and Comparison:

– Obtain a detailed quotation including costs, lead times, and shipping options.

– Compare quotes from multiple suppliers if possible to ensure competitive pricing.

5. Sample Order:

– If feasible, place a sample order to evaluate the quality of the CNC router.

– Assess the machine’s performance and reliability through practical tests.

6. Customization and After-Sales Support:

– Discuss any customization needs directly with the supplier.

– Ensure that they offer reliable after-sales support and warranty services.

7. Payment Terms and Contracts:

– Negotiate favorable payment terms.

– Draft a clear contract outlining all terms, including delivery schedules and penalties for non-compliance.

8. Shipping and Logistics:

– Plan the logistics for shipping, including customs clearance and insurance.

– Confirm the shipping timeline and ensure proper packaging to prevent damage.

9. Communication and Monitoring:

– Maintain regular communication with the supplier.

– Monitor the production process and address any issues promptly.

10. Feedback and Continuous Improvement:

– Provide feedback on the product quality and supplier performance.

– Build a long-term relationship with the supplier for future sourcing needs.

Following these steps will help ensure you source a high-quality 5-axis CNC router from SourcifyChina efficiently and effectively.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.

How can I help you? :)