Description

cnc lathe metal Safety Certifications

CNC lathe metalworking operations require adherence to stringent safety standards to ensure the well-being of operators and the efficiency of production processes. Key safety certifications and standards relevant to CNC lathe operations include:

1. OSHA (Occupational Safety and Health Administration): In the United States, OSHA provides guidelines for machine safety, including CNC lathes. Compliance with OSHA standards helps prevent workplace injuries and ensures that machines are properly safeguarded.

2. ISO 23125: This international standard specifies safety requirements for turning machines, including CNC lathes. It covers various aspects such as risk assessment, safety control systems, and operator protection.

3. ANSI B11.22: This American National Standard addresses safety requirements for CNC turning centers and lathes. It provides guidelines for safeguarding, safety control systems, and proper training of operators.

4. CE Marking: In Europe, CNC lathes must comply with the Machinery Directive 2006/42/EC, which requires CE marking. This ensures the machine meets essential health and safety requirements before it can be sold in the European Economic Area (EEA).

5. NFPA 79: This standard from the National Fire Protection Association (NFPA) pertains to electrical standards for industrial machinery, including CNC lathes. It ensures electrical safety and reduces the risk of fire hazards.

6. CSA Z432: In Canada, this standard outlines the safeguarding of machinery, providing guidelines to prevent accidents and ensure the safe operation of CNC lathes.

7. RoboCrib Certification: This is specific to automated tool handling and storage systems integrated with CNC machines. It ensures that these systems meet safety and operational standards.

Adherence to these certifications ensures CNC lathe operations are conducted safely, minimizing risks of injury and enhancing overall productivity. Regular training and audits are also essential to maintain compliance and update safety practices in line with evolving standards.

List Reference Technical Parameters of “cnc lathe metal”

When discussing CNC lathes for metalworking, several technical parameters are crucial to consider:

1. Swing Over Bed:

– The maximum diameter of the workpiece that can be rotated over the lathe bed. This parameter dictates the largest size of the workpiece that the lathe can handle.

2. Distance Between Centers:

– The maximum length of the workpiece that can be mounted between the headstock and tailstock centers. It affects the length of the workpiece that can be machined.

3. Spindle Speed Range:

– The range of speeds at which the spindle can rotate, usually measured in RPM (revolutions per minute). This influences the cutting speed and surface finish of the workpiece.

4. Spindle Bore Diameter:

– The diameter of the hole through the spindle, determining the maximum diameter of the bar stock that can be fed through the spindle.

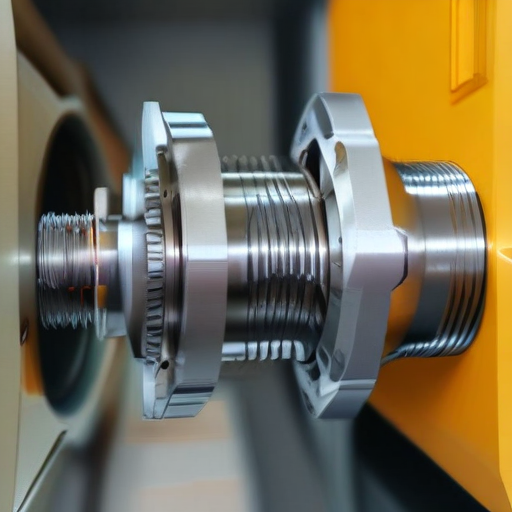

5. Chuck Size:

– The diameter of the chuck, which grips the workpiece. Larger chucks can hold bigger workpieces more securely.

6. Tool Turret Capacity:

– The number of tools the turret can hold and index. More tool positions allow for more complex machining operations without manual tool changes.

7. X and Z Axis Travel:

– The movement range of the cutting tool in the X-axis (cross-slide) and Z-axis (longitudinal slide). This defines the machining envelope.

8. Control System:

– The type of CNC control system used (e.g., Fanuc, Siemens). It affects programming flexibility, user interface, and compatibility with CAM software.

9. Feed Rate:

– The speed at which the cutting tool and the workpiece move relative to each other, typically measured in inches per minute (IPM) or millimeters per minute (mm/min).

10. Motor Power:

– The power of the main spindle motor, usually measured in horsepower (HP) or kilowatts (kW). Higher power is needed for heavy-duty machining.

11. Repeatability and Accuracy:

– The precision with which the machine can return to a specific position, often measured in microns. Higher accuracy is crucial for precision machining.

These parameters collectively determine the capabilities and suitability of a CNC lathe for specific metalworking tasks.

List Product features of “cnc lathe metal”

A CNC lathe for metalworking is a sophisticated machine tool used for precise shaping and cutting of metal parts. Here are the primary product features of a CNC lathe metal:

1. Computer Numerical Control (CNC):

– Automates the control of the machine through programmed instructions.

– Enhances precision, repeatability, and complexity in metalworking tasks.

2. High Precision and Accuracy:

– Provides exceptional accuracy in dimensions and tolerances.

– Capable of producing intricate and complex shapes with high repeatability.

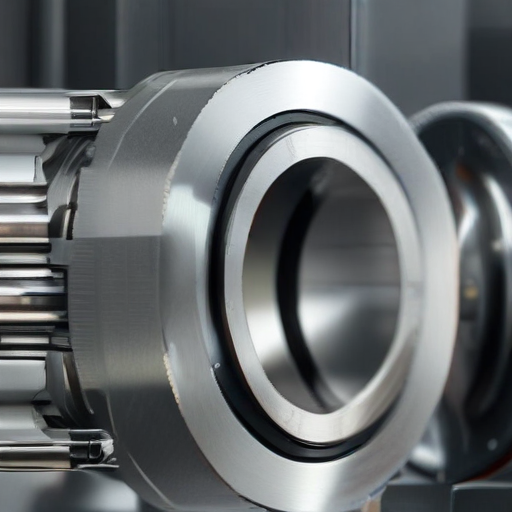

3. Robust Construction:

– Built with a sturdy frame to withstand heavy-duty machining.

– Ensures stability and minimizes vibrations during operation.

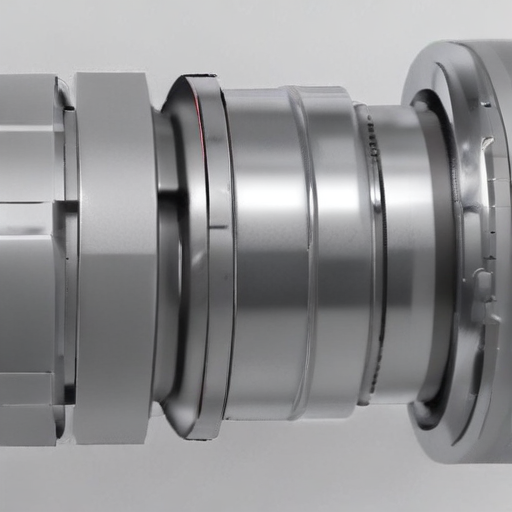

4. Spindle:

– High-speed spindles for efficient metal cutting.

– Variable speed control for different types of materials and operations.

5. Tool Turret:

– Equipped with multiple tool holders for various cutting tools.

– Enables quick tool changes to enhance productivity.

6. Control Panel:

– User-friendly interface for programming and monitoring.

– Typically includes an LCD screen and keyboard for ease of use.

7. Coolant System:

– Integrated coolant system to keep the workpiece and tools cool.

– Enhances tool life and maintains machining accuracy.

8. Chip Management:

– Efficient chip evacuation system to remove metal shavings.

– Helps maintain a clean working environment and prevents tool damage.

9. Tailstock:

– Provides additional support for long workpieces.

– Can be manually or automatically positioned.

10. Automatic Tool Changer (ATC):

– Facilitates the automatic switching of tools during machining.

– Reduces downtime and improves operational efficiency.

11. Safety Features:

– Emergency stop buttons and protective enclosures.

– Ensures operator safety and complies with industrial safety standards.

12. Software Compatibility:

– Compatible with various CAD/CAM software for easy programming.

– Supports G-code and M-code programming languages.

These features collectively make CNC lathes indispensable in modern metalworking industries, providing high precision, efficiency, and versatility in manufacturing processes.

List Application of “cnc lathe metal”

A CNC (Computer Numerical Control) lathe is a highly versatile machine used for metalworking. Here are several key applications of CNC lathe metal machining:

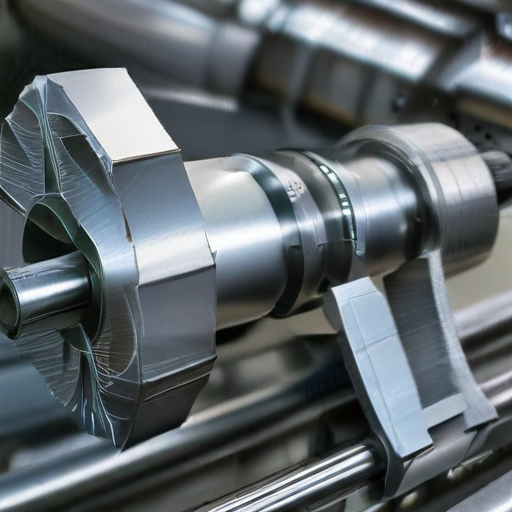

1. Automotive Industry:

– Engine Components: Producing precise parts such as camshafts, crankshafts, and cylinder heads.

– Drive Axles: Manufacturing axles with high accuracy to ensure proper fit and function.

2. Aerospace Industry:

– Turbine Components: Crafting intricate turbine blades and other critical engine parts.

– Structural Components: Fabricating lightweight yet strong parts for aircraft frames.

3. Medical Device Manufacturing:

– Implants: Creating custom implants like hip joints and dental fixtures.

– Surgical Instruments: Producing precise and reliable tools for surgery.

4. Defense and Firearms:

– Weapon Components: Making parts such as barrels and firing pins with tight tolerances.

– Ammunition: Manufacturing high-precision components for various types of ammunition.

5. Electronics Industry:

– Heat Sinks: Producing components that manage heat dissipation in electronic devices.

– Connectors and Housings: Crafting small, precise parts for electronic assemblies.

6. Oil and Gas Industry:

– Drill Components: Making durable parts for drilling operations, such as drill bits and valves.

– Pipelines: Producing connectors and joints used in pipeline systems.

7. Heavy Equipment:

– Construction Machinery: Manufacturing large parts for equipment like bulldozers and excavators.

– Agricultural Machinery: Creating durable components for tractors and harvesters.

8. Custom Manufacturing:

– Prototyping: Allowing rapid development and iteration of new designs.

– Custom Parts: Producing bespoke parts for specialized applications or small batch runs.

9. General Engineering:

– Tooling: Creating custom tools and dies for manufacturing processes.

– Fixtures: Producing precise jigs and fixtures for assembly lines and manufacturing.

In summary, CNC lathe metal machining is critical in producing a wide range of high-precision, complex parts across multiple industries, enhancing efficiency and enabling innovations in design and functionality.

List Various Types of “cnc lathe metal”

CNC (Computer Numerical Control) lathes for metalworking come in various types, each suited for different applications. Here are some of the primary types:

1. Horizontal CNC Lathe: This is the most common type, featuring a horizontally oriented spindle. It’s used for cylindrical parts, shafts, and other round components. These lathes can perform turning, threading, drilling, and facing operations.

2. Vertical CNC Lathe: In this type, the spindle is vertically oriented. It’s ideal for large, heavy, and asymmetrical parts that are difficult to mount on horizontal lathes. Common applications include large diameter rings, disks, and turbine components.

3. Multi-Spindle CNC Lathe: These lathes have multiple spindles allowing simultaneous machining of different parts or multiple operations on the same part, significantly improving productivity. They are often used in high-volume production environments.

4. Swiss-Type CNC Lathe: Designed for precision and high production rates, these lathes are ideal for small, complex parts such as those used in the medical and electronics industries. They use a sliding headstock and guide bushing to support long, slender workpieces.

5. CNC Turning Center: More advanced than standard lathes, turning centers can perform multiple operations like milling, drilling, and tapping in addition to turning. They often feature multiple turrets and live tooling for enhanced versatility.

6. CNC Mini Lathe: Smaller versions of standard CNC lathes, these are used for detailed and precise small part machining, making them suitable for hobbyists and small workshops.

7. Flat Bed CNC Lathe: This type offers a flat bed for stability and ease of handling large parts. It’s commonly used for heavy-duty applications and large workpieces.

8. Slant Bed CNC Lathe: Featuring a slanted bed, this design provides improved chip removal, ergonomics, and rigidity. It’s ideal for high-speed and precision applications.

Each type of CNC lathe has its own set of capabilities and is chosen based on the specific needs of the job, material, and production volume.

cnc lathe metal Accessories Upgrades and Custom Manufacturing Options

CNC lathes are vital for precision machining, and numerous accessories and upgrades can enhance their functionality. Here are key options for both standard upgrades and custom manufacturing:

Standard Accessories and Upgrades:

1. Tooling Systems: High-precision tool holders, live tooling, and quick-change tooling systems can significantly improve efficiency and accuracy.

2. Chucks and Collets: Upgraded chucks and collets provide better grip and precision. Options include hydraulic, pneumatic, and quick-change chucks.

3. Bar Feeders: Automatic bar feeders increase productivity by enabling continuous machining without manual intervention.

4. Tailstocks: Hydraulic or servo-driven tailstocks enhance support for long workpieces, ensuring better stability and precision.

5. Coolant Systems: Advanced coolant systems, including high-pressure and mist coolant systems, improve tool life and workpiece finish by better managing heat and chips.

6. Chip Management: Upgraded chip conveyors and filtration systems help maintain a clean work environment and prevent machine damage.

Custom Manufacturing Options:

1. Custom Tooling: Tailored tooling solutions, including specialized inserts and tool holders, meet specific machining requirements and materials.

2. Fixture Design: Custom fixtures ensure optimal positioning and stability for complex or irregularly shaped workpieces, enhancing precision and repeatability.

3. Automation Integration: Adding robotic arms or custom automation systems can streamline operations, reduce labor costs, and increase throughput.

4. Software Upgrades: Custom software solutions, such as advanced CAM software, can optimize machining strategies and improve efficiency.

5. Specialized Workholding Solutions: Custom-designed workholding devices, including bespoke collets and chucks, cater to unique workpiece geometries and machining processes.

6. High-Speed Spindles: Upgrading to high-speed spindles tailored for specific materials or operations can significantly improve cutting speeds and surface finishes.

Conclusion:

Enhancing CNC lathes with the right accessories and custom solutions not only improves productivity but also extends the machine’s versatility. Tailoring upgrades to specific operational needs ensures optimal performance and precision, meeting diverse manufacturing challenges.

List Quality Control and The Manufacturing Process of “cnc lathe metal”

Quality Control and Manufacturing Process of CNC Lathe Metal

Manufacturing Process:

1. Design and Planning: Develop detailed CAD models and CNC programs for the metal part.

2. Material Selection: Choose appropriate metal (e.g., aluminum, steel) based on strength, durability, and application.

3. Setup: Install the CNC lathe with necessary tools and fixtures. Align and calibrate the machine.

4. Machining: Load the metal workpiece. The CNC lathe uses programmed instructions to perform cutting, drilling, and turning operations with high precision.

5. Finishing: Apply finishing processes such as deburring, polishing, or coating to achieve desired surface quality.

6. Inspection and Testing: Check dimensions and tolerances using instruments like calipers and micrometers.

Quality Control:

1. Initial Inspection: Verify raw materials for compliance with specifications.

2. In-process Inspection: Monitor machining parameters and tool conditions. Use real-time data to adjust processes.

3. Dimensional Checks: Measure parts at various stages using coordinate measuring machines (CMM) to ensure they meet design specifications.

4. Surface Quality: Inspect surface finish using profilometers or visual checks.

5. Functional Testing: Ensure parts function correctly in their intended applications through functional tests.

6. Final Inspection: Perform a comprehensive check of all dimensions, surface quality, and functional aspects before shipping.

7. Documentation and Traceability: Maintain records of all inspections, tests, and material certificates for traceability.

8. Continuous Improvement: Analyze data from quality control to identify and implement process improvements.

By integrating rigorous quality control measures at each stage of the manufacturing process, CNC lathe metal parts are produced with high precision and reliability, ensuring they meet the required standards and specifications.

Materials of “cnc lathe metal”

A CNC (Computer Numerical Control) lathe is a precision machine tool used for shaping and cutting various materials, predominantly metals, into precise components. The materials commonly machined on CNC lathes include:

1. Steel: Widely used due to its strength, durability, and versatility. Common types include mild steel, carbon steel, and stainless steel. Stainless steel is favored for its corrosion resistance.

2. Aluminum: Known for its lightweight, high machinability, and excellent thermal properties. It is often used in the aerospace, automotive, and electronics industries.

3. Brass: Appreciated for its ease of machining, corrosion resistance, and attractive appearance. Commonly used in plumbing, electrical components, and musical instruments.

4. Titanium: Valued for its high strength-to-weight ratio and corrosion resistance. Used extensively in aerospace, medical implants, and high-performance engineering applications.

5. Copper: Offers excellent thermal and electrical conductivity. Used in electrical components, heat exchangers, and plumbing fittings.

6. Plastics: Although less common, certain plastics like nylon, PEEK, and Delrin are machined on CNC lathes. These materials are used when specific properties such as low weight, chemical resistance, or electrical insulation are required.

7. Cast Iron: Known for its good machinability and vibration damping properties, it is used in heavy machinery and automotive components.

The choice of material depends on the application requirements such as strength, weight, corrosion resistance, machinability, and cost. CNC lathes are capable of handling a wide range of materials with high precision, making them essential in modern manufacturing across various industries.

“cnc lathe metal” Comparative Analysis

When comparing CNC lathes to traditional CNC turning centers and Swiss CNC lathes, several factors distinguish them in terms of functionality, precision, versatility, and cost.

CNC Lathes:

CNC lathes are known for their precision and ability to produce complex parts with high accuracy. They use computer programs to control operations, enabling automated, repetitive tasks with minimal human intervention. These machines are ideal for high-volume production due to their efficiency and consistency. Notable models like the Haas ST 10Y offer features like high thermal stability, a 6000 RPM spindle, and a 12-station turret, making them suitable for industrial settings. However, their high initial cost and operational expenses can be a barrier for smaller businesses (CNCSourced).

CNC Turning Centers:

CNC turning centers are more advanced, offering multi-axis capabilities (up to 5 axes) which provide greater versatility and efficiency. They can perform various tasks such as drilling, tapping, and milling in addition to turning. This multitasking ability makes them suitable for complex operations and higher production volumes. Although the initial investment for a turning center is higher, the operational costs can be lower over time due to reduced production times and higher output. These machines are particularly beneficial in industries requiring intricate designs and rapid production cycles (RapidDirect).

Swiss CNC Lathes:

Swiss CNC lathes, like the APSX-NANO, are specialized for producing small, intricate parts with tight tolerances. They utilize a guide bushing to support the workpiece, minimizing vibrations and allowing for the precise creation of long, slender components. This makes them ideal for industries such as medical device manufacturing and precision engineering. Swiss CNC lathes are generally more complex and expensive than regular CNC lathes, but their ability to handle detailed workpieces efficiently can justify the cost for certain applications (APSX).

Conventional Machining:

Traditional machining methods, while less automated, offer flexibility and adaptability, especially for custom or low-volume projects. Skilled machinists can make real-time adjustments, which can be advantageous in specific scenarios. However, these methods are more time-consuming and prone to human error compared to CNC machining. They are generally more cost-effective for small-scale operations but lack the efficiency and precision of CNC technologies (SigmaTechnik).

In summary, the choice between CNC lathes, CNC turning centers, and Swiss CNC lathes depends on the specific requirements of the project, including the complexity of parts, production volume, material variety, and budget. CNC turning centers offer the highest versatility and efficiency for complex, high-volume tasks, while Swiss CNC lathes excel in precision for small, intricate parts. Regular CNC lathes provide a balanced solution for various industrial applications, albeit at a higher initial cost.

“cnc lathe metal” Warranty and Support

When purchasing a CNC lathe for metalworking, warranty and support are critical factors to consider. Here’s a concise overview of what to expect:

Warranty

1. Duration: Most CNC lathe manufacturers offer a standard warranty period, typically ranging from 1 to 3 years. Extended warranties may be available for an additional cost.

2. Coverage: Warranties usually cover defects in materials and workmanship. This includes parts and labor required to repair the machine. It’s essential to understand what specific components are covered (e.g., spindle, control system, motors).

3. Exclusions: Regular wear and tear, consumables (like cutting tools and belts), and damage due to improper use or lack of maintenance are often excluded.

4. Claim Process: Understand the process for filing a warranty claim. This typically involves contacting the manufacturer or dealer, providing proof of purchase, and describing the issue in detail.

Support

1. Technical Support: Reliable technical support is crucial. Look for manufacturers that offer 24/7 phone or online support to help troubleshoot issues promptly.

2. Training: Many suppliers provide training sessions to help operators understand the machine’s functionalities, maintenance procedures, and troubleshooting techniques.

3. Spare Parts Availability: Ensure the manufacturer has a well-stocked inventory of spare parts and offers a quick turnaround on orders to minimize downtime.

4. Service Network: A robust service network ensures that certified technicians can reach your location quickly if on-site repairs are necessary.

5. Software Updates: Periodic updates to the CNC software are essential for maintaining optimal performance and security. Check if the manufacturer provides free or discounted software updates.

In summary, a comprehensive warranty and robust support infrastructure are vital when investing in a CNC lathe for metalworking. They ensure reliability, minimize downtime, and maximize the lifespan of your equipment. Always review the specific terms and conditions of warranty and support services offered by the manufacturer before making a purchase.

List “cnc lathe metal” FAQ

CNC Lathe Metal FAQ

1. What is a CNC lathe?

A CNC lathe is a computerized machine tool used for shaping metal parts. It uses computer numerical control (CNC) to automate the turning process, which involves rotating the workpiece while cutting tools shape it.

2. What types of metals can be machined on a CNC lathe?

CNC lathes can machine a variety of metals, including aluminum, steel, brass, copper, titanium, and various alloys. The choice depends on the specific application and material properties required.

3. How does a CNC lathe work?

A CNC lathe operates by spinning the workpiece on a spindle while stationary cutting tools remove material to form the desired shape. The CNC system precisely controls the movement and positioning of the tools.

4. What are the advantages of using a CNC lathe for metalworking?

– Precision: High accuracy and repeatability.

– Efficiency: Faster production and reduced human error.

– Versatility: Capable of producing complex shapes and designs.

– Consistency: Ensures uniformity in batch production.

5. What is the difference between a CNC lathe and a CNC mill?

A CNC lathe primarily rotates the workpiece against fixed cutting tools, suitable for cylindrical or symmetrical shapes. In contrast, a CNC mill uses rotating cutting tools to remove material from a stationary workpiece, ideal for more complex and irregular shapes.

6. What factors should be considered when selecting a CNC lathe?

Consider the material type, desired precision, production volume, machine size, and available budget. Features like spindle speed, tool capacity, and control software are also important.

7. What maintenance is required for a CNC lathe?

Regular maintenance includes cleaning, lubricating moving parts, checking for wear and tear, calibrating the CNC system, and ensuring proper tool alignment.

8. How do CNC lathes enhance production processes?

They increase productivity by allowing for continuous, unattended operation, minimize waste through precise material removal, and reduce the need for manual adjustments and interventions.

Top 10 FAQ with answer about cnc lathe metal for Buyer Sourcing from China

Top 10 FAQs About CNC Lathe Metal Sourcing from China

1. What types of CNC lathes are available in China?

Chinese manufacturers offer various types, including horizontal, vertical, multi-axis, and Swiss-type CNC lathes, suitable for different applications.

2. How can I ensure the quality of CNC lathes from China?

Verify the manufacturer’s certifications (ISO, CE), request samples, and review customer feedback. Visiting the factory or hiring third-party inspection services can also help ensure quality.

3. What are the common materials used in Chinese CNC lathes?

CNC lathes from China typically use high-quality materials like cast iron, steel, and aluminum, which ensure durability and precision.

4. What is the typical lead time for CNC lathes from China?

Lead times vary but generally range from 4 to 12 weeks, depending on the complexity of the machine and the manufacturer’s capacity.

5. Can Chinese manufacturers provide customized CNC lathes?

Yes, many Chinese manufacturers offer customization services to meet specific requirements, including bespoke designs, tooling, and software configurations.

6. What is the price range for CNC lathes from China?

Prices vary widely based on specifications and features, typically ranging from $10,000 to $100,000. It’s important to get multiple quotes and consider total cost, including shipping and tariffs.

7. How do I handle shipping and logistics?

Work with a reliable freight forwarder experienced in handling machinery. Consider both sea and air freight options, and ensure all necessary import documentation is in order.

8. Are there after-sales services available?

Many Chinese manufacturers offer after-sales services, including installation, training, and maintenance. Confirm the availability and terms of these services before purchasing.

9. What payment terms are commonly accepted by Chinese manufacturers?

Common terms include 30% deposit upfront and 70% balance before shipment. Letters of credit and escrow services are also used for additional security.

10. How do I communicate effectively with Chinese suppliers?

Clear and concise communication is key. Use English or hire a translator if needed. Video calls and factory visits can also enhance understanding and build trust.

These FAQs provide a concise overview for buyers looking to source CNC lathes from China, addressing essential concerns and offering practical advice.