Comprehensive

Guide to SourcifyChina Factory Sheet Metal Fabrication: Reliable Services and Quality Assurance

This article explores SourcifyChina’s factory sheet metal fabrication, highlighting their reliable services, quality assurance processes, and the benefits of partnering with them for all your sheet metal fabrication needs. Learn about their advanced techniques, skilled workforce, and commitment to excellence in the industry.

Choosing SourcifyChina for sheet metal fabrication from China ensures high-quality products due to their stringent quality control measures. Their advanced machinery and experienced workforce guarantee precision and durability, meeting international standards.

Additionally, SourcifyChina offers competitive pricing, providing excellent value for your investment. Their efficient production processes and strategic location enable cost savings, making them a cost-effective choice.

Furthermore, SourcifyChina provides comprehensive support throughout the purchasing process. From initial consultation to final delivery, their dedicated team ensures seamless communication, timely updates, and reliable logistics.

In conclusion, SourcifyChina is a top choice for sheet metal fabrication due to its commitment to quality, competitive pricing, and exceptional customer service. By partnering with SourcifyChina, buyers can confidently expect superior products and a hassle-free purchasing experience.

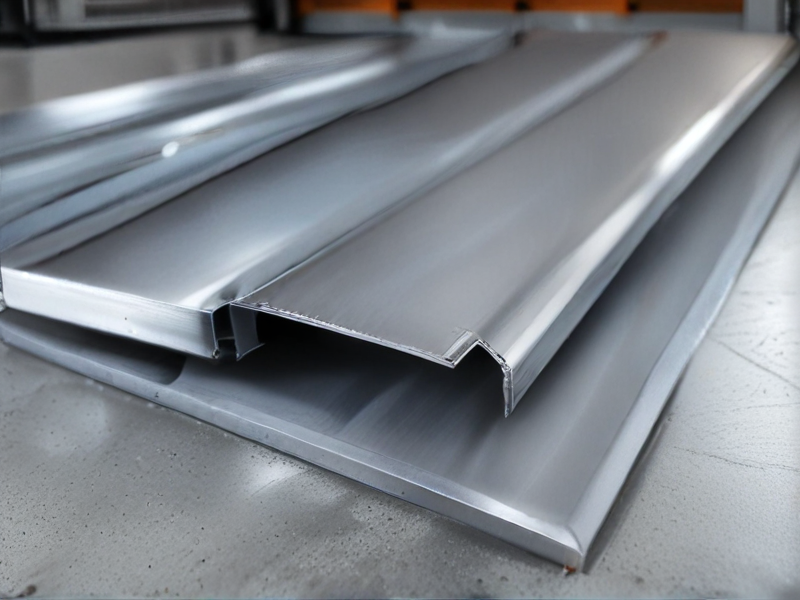

Sheet metal fabrication involves various processes used to shape, cut, and assemble metal sheets into desired forms. It’s essential in industries such as automotive, aerospace, and construction.

– Cutting: Laser cutting, water jet cutting, and plasma cutting.

– Bending: Press brake bending and roll forming.

– Punching: CNC punching for creating holes and shapes.

– Welding: MIG, TIG, and spot welding for joining metal pieces.

– Finishing: Powder coating, anodizing, and galvanizing for surface treatment.

– Assembling: Using fasteners, adhesives, and welding to put parts together.

– Stamping: High-speed presses for creating complex shapes.

– Rolling: Forming cylinders and curved shapes.

– Shearing: Cutting straight lines on metal sheets.

– Deep Drawing: Forming deeper parts from metal sheets.

Each process has unique advantages and is chosen based on material type, desired precision, and production volume.

Sheet metal fabrication is a versatile process used across various industries for creating parts and structures from thin metal sheets. Its applications range from simple brackets to complex enclosures, making it essential in manufacturing, construction, and many other fields.

– Automotive Industry: Creating car bodies, chassis, and other components.

– Construction: Producing roofing, gutters, and ductwork for HVAC systems.

– Aerospace: Fabricating parts for aircraft and spacecraft.

– Electronics: Making enclosures, brackets, and frames for electronic devices.

– Medical Equipment: Manufacturing parts for medical devices and machinery.

– Furniture: Producing metal frames and supports for furniture.

– Agriculture: Creating machinery parts and equipment used in farming.

– Food Processing: Fabricating sanitary equipment and components for food production.

– Renewable Energy: Building components for solar panels and wind turbines.

– Custom Fabrication: Creating tailored parts for specific applications and prototypes.

– Tooling and Machinery: Producing tools and machine parts for industrial use.

– Signage: Making durable and weather-resistant signs.

– Military and Defense: Manufacturing parts for vehicles, equipment, and infrastructure.

– Marine Industry: Creating parts for boats and ships, including hulls and structural components.

– Public Infrastructure: Fabricating components for bridges, tunnels, and public transport.

Sheet metal fabrication’s adaptability and precision make it indispensable in producing reliable and high-quality components for a wide range of applications, driving innovation and efficiency across numerous sectors.

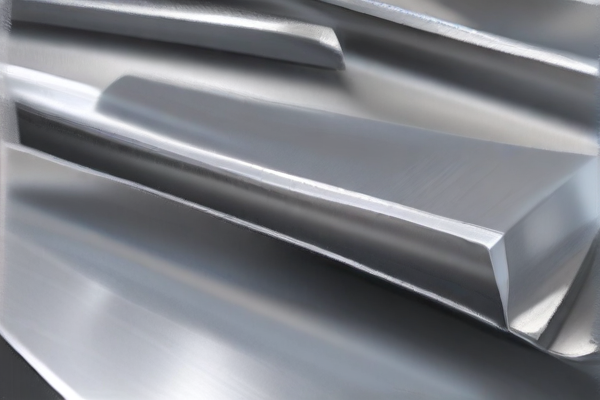

SourcifyChina specializes in sheet metal fabrication, utilizing high-quality materials to ensure durable and precise products. They work with various metals including aluminum, stainless steel, and carbon steel, each chosen for its specific properties and suitability for different applications.

Aluminum is lightweight, corrosion-resistant, and easy to form, making it ideal for aerospace, automotive, and consumer electronics. Stainless steel offers excellent strength, durability, and resistance to rust and staining, perfect for kitchen equipment, medical devices, and architectural applications.

Carbon steel, known for its hardness and high tensile strength, is used in construction, heavy machinery, and industrial tools. SourcifyChina ensures all materials meet rigorous industry standards to provide reliable and high-performance products.

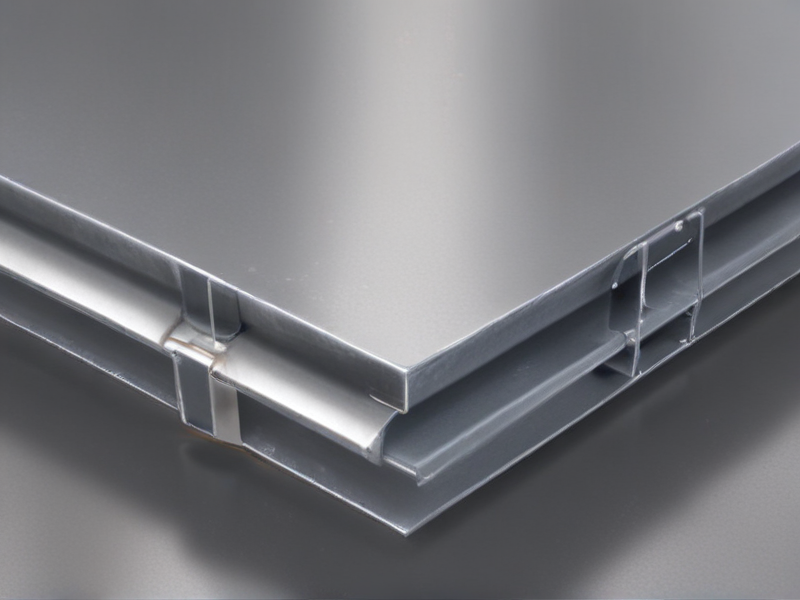

Their advanced fabrication processes, including laser cutting, bending, and welding, ensure precision and quality. By combining expert craftsmanship with top-grade materials, SourcifyChina delivers custom solutions tailored to meet diverse client needs across various industries.

SourcifyChina’s sheet metal fabrication quality control process ensures precision and reliability in manufacturing. Initial inspections assess raw material quality, confirming compliance with specifications and standards. This step ensures the foundational integrity of all subsequent processes.

During production, continuous monitoring and in-process inspections are conducted to maintain adherence to design tolerances. Automated systems and skilled technicians check for dimensional accuracy, surface finish, and overall workmanship, promptly addressing any deviations.

Post-production, comprehensive testing evaluates the final products. Non-destructive tests, including ultrasonic and X-ray inspections, identify hidden defects. Physical tests, such as tensile and hardness testing, validate mechanical properties.

Final inspections and audits ensure that each item meets rigorous quality standards before packaging and shipment. Documentation of all stages maintains traceability and accountability, fostering trust and transparency with clients. The systematic approach to quality control at SourcifyChina guarantees high-quality, reliable sheet metal fabrication products.

SourcifyChina excels in sheet metal fabrication, offering a comprehensive range of services tailored to meet diverse industrial needs. With state-of-the-art technology and skilled craftsmanship, they ensure high precision and quality in every project.

Their capabilities include cutting-edge laser cutting, bending, and welding, which allow for the creation of complex and intricate designs. The use of advanced machinery ensures consistency and accuracy, minimizing errors and enhancing production efficiency.

SourcifyChina’s fabrication services extend to a variety of metals, including aluminum, steel, and stainless steel, providing flexibility to cater to different client requirements. Their expertise spans across various industries, from automotive to aerospace, ensuring versatile applications.

The company prides itself on delivering timely and cost-effective solutions, supported by a strong commitment to customer satisfaction. Their dedicated team works closely with clients to understand specific needs and deliver customized results that meet the highest standards.

In addition to fabrication, SourcifyChina offers value-added services such as finishing, assembly, and prototyping. These complementary services enable clients to streamline their production processes, saving time and resources while maintaining superior quality.

Their robust quality control measures and adherence to international standards guarantee reliable and durable products. This commitment to quality ensures that clients receive components that not only meet but exceed expectations.

SourcifyChina’s dedication to innovation and continuous improvement drives their ability to adapt to evolving market demands. By investing in the latest technologies and training, they stay ahead of industry trends and deliver cutting-edge solutions.

Overall, SourcifyChina’s sheet metal fabrication capabilities are marked by precision, versatility, and a customer-centric approach. Their comprehensive services, from initial design to final production, make them a trusted partner for businesses seeking top-tier fabrication solutions.

Sheet metal fabrication offers numerous benefits, making it a vital process in various industries. It allows for precise, durable, and cost-effective manufacturing of components.

– Durability: Sheet metal products are highly durable and can withstand harsh environments, reducing the need for frequent replacements.

– Versatility: It supports a wide range of materials and thicknesses, making it suitable for diverse applications.

– Precision: Advanced techniques ensure accurate and consistent production, crucial for high-quality outcomes.

– Cost-Effectiveness: Efficient processes and minimal waste lower production costs, benefiting both manufacturers and consumers.

– Customization: It enables tailored designs to meet specific requirements, enhancing functionality and aesthetics.

– Scalability: Ideal for both small and large-scale production, offering flexibility to scale operations as needed.

– Strength-to-Weight Ratio: Provides robust structural integrity without excessive weight, important for industries like automotive and aerospace.

– Quick Turnaround: Streamlined processes ensure rapid production times, meeting tight deadlines.

– Sustainability: Utilizes recyclable materials, contributing to eco-friendly manufacturing practices.

Overall, sheet metal fabrication is essential for producing high-quality, cost-efficient, and durable products across various sectors.

Sheet metal fabrication involves transforming flat sheets of metal into various structures and products using cutting, bending, and assembling processes. This versatile method is essential in numerous industries.

– Material Versatility: Works with metals like steel, aluminum, copper, and brass.

– Precision Cutting: Utilizes laser cutting, water jet cutting, and plasma cutting for accurate shapes.

– Bending and Forming: Achieved through press brakes and roll forming for various angles and curves.

– Joining Techniques: Includes welding, riveting, and adhesive bonding to assemble parts.

– Surface Treatments: Options like painting, powder coating, and anodizing enhance appearance and durability.

– Customizability: Allows for tailor-made designs to meet specific requirements.

– Cost-Effective: Suitable for both small and large production runs.

– Durability: Produces robust components that withstand high stress and harsh environments.

– Rapid Prototyping: Facilitates quick production of prototypes for testing and refinement.

– Automated Processes: Integration of CNC machines for increased efficiency and repeatability.

– Scalability: Easily adapts to changing production volumes without significant investment.

SourcifyChina specializes in sheet metal fabrication, offering custom products tailored to meet specific client requirements. Their expertise ensures high-quality and precision in every project, catering to various industries.

Their state-of-the-art facilities and advanced machinery enable them to handle complex designs and large-scale production efficiently. This ensures timely delivery without compromising on quality.

Clients benefit from their comprehensive services, including design consultation, prototyping, and mass production. This holistic approach streamlines the manufacturing process, reducing costs and time.

SourcifyChina is committed to innovation and excellence, continuously improving their processes to meet evolving market demands. Their dedication to customer satisfaction makes them a trusted partner for sheet metal fabrication needs.

SourcifyChina is a leading company specializing in sheet metal fabrication, catering to a wide array of industries with precision and efficiency. Leveraging advanced technology and a skilled workforce, SourcifyChina offers comprehensive fabrication services, including laser cutting, bending, welding, and finishing. Their commitment to quality and customer satisfaction is evident through their rigorous quality control processes and adherence to international standards. With a focus on innovation and sustainability, SourcifyChina not only meets the demands of high-volume production but also excels in delivering custom solutions tailored to specific client requirements. This combination of expertise, advanced machinery, and a customer-centric approach positions SourcifyChina as a preferred partner in the global sheet metal fabrication market.

FAQ for Sheet Metal Fabrication Quality Work from SourcifyChina Factory

1. What services does SourcifyChina offer for sheet metal fabrication?

SourcifyChina provides comprehensive sheet metal fabrication services, including cutting, bending, welding, punching, and assembly. We handle both small and large production runs, ensuring high precision and quality.

2. What materials can you work with?

We work with a wide range of materials, including stainless steel, aluminum, carbon steel, and various alloys. Our team can help you select the best material for your specific application.

3. How do you ensure the quality of your sheet metal fabrication?

Quality is ensured through strict adherence to ISO 9001 standards, regular quality checks, and the use of advanced machinery. We also employ experienced technicians and engineers to oversee the entire production process.

4. Can you provide custom designs?

Yes, we offer custom design services. Our engineers collaborate with clients to create designs that meet their exact specifications. We use CAD/CAM software to ensure precision and efficiency.

5. What is your lead time for production?

Lead times vary depending on the complexity and volume of the order. Typically, we can complete orders within 2-4 weeks. Rush orders can be accommodated upon request.

6. Do you offer prototyping services?

Yes, we offer prototyping services to help you test and refine your designs before committing to full-scale production. This ensures the final product meets all your requirements.

7. How do you handle shipping and logistics?

We provide comprehensive shipping and logistics solutions, including packaging, labeling, and documentation. We can ship globally and work with various carriers to ensure timely delivery.

8. What are your payment terms?

Our payment terms are flexible. We typically require a deposit upfront, with the balance due upon completion of the order. We accept various payment methods, including wire transfer and PayPal.

9. Can you provide references or case studies?

Yes, we can provide references and case studies upon request. These showcase our expertise and the quality of work we deliver.

10. How can I get a quote for my project?

You can get a quote by contacting us through our website, providing details about your project, including material, dimensions, and quantity. We will respond promptly with a detailed quote.

Sheet metal fabrication manufacturing is a specialized process that involves cutting, bending, and assembling metal sheets to create various products. SourcifyChina factory is known for providing high-quality fabrication services. Here are some tips for optimizing your experience with sheet metal fabrication from this factory:

1. Specify Requirements Clearly: Ensure you provide detailed specifications, including material type, thickness, dimensions, and any special treatments or coatings needed. Clear communication helps avoid misunderstandings and ensures the final product meets your expectations.

2. Material Selection: Choose the right material for your application. Common materials include stainless steel, aluminum, and carbon steel, each offering different properties such as corrosion resistance, strength, and weight.

3. Design for Manufacturability (DFM): Work with the factory’s engineers to optimize your design for manufacturing. This can reduce production costs and improve the quality of the final product. Simplify complex designs where possible to make the fabrication process more efficient.

4. Prototyping: Before mass production, request a prototype to validate the design and functionality. This allows you to make necessary adjustments and ensures the final product aligns with your requirements.

5. Quality Control: SourcifyChina factory implements stringent quality control measures. Regularly review the quality control process and request inspection reports to ensure products meet your standards.

6. Lead Time and Scheduling: Discuss lead times and production schedules upfront. This helps manage expectations and ensures timely delivery of your products.

7. Cost Considerations: Understand the pricing structure, including costs for materials, labor, tooling, and any additional treatments or coatings. Bulk orders often benefit from reduced unit costs.

8. Communication: Maintain open and consistent communication with the factory. Regular updates and feedback loops can prevent potential issues and streamline the production process.

By following these tips, you can leverage SourcifyChina factory’s capabilities to achieve high-quality sheet metal fabricated products efficiently and cost-effectively.

FAQ for Sourcing Sheet Metal Fabrication from SourcifyChina Factory

Q: What types of sheet metal fabrication services does SourcifyChina offer?

A: SourcifyChina provides a comprehensive range of sheet metal fabrication services, including cutting, bending, welding, stamping, and assembly.

Q: What materials can SourcifyChina handle for sheet metal fabrication?

A: SourcifyChina works with a variety of materials such as steel, aluminum, stainless steel, copper, and brass.

Q: What are the production capabilities of SourcifyChina?

A: SourcifyChina can handle both small and large production runs with a focus on precision and efficiency, catering to custom orders and bulk manufacturing.

Q: How does SourcifyChina ensure the quality of its sheet metal products?

A: SourcifyChina employs stringent quality control measures, including thorough inspections, testing, and adherence to international standards like ISO 9001.

Q: Can SourcifyChina assist with the design and prototyping of sheet metal parts?

A: Yes, SourcifyChina offers design assistance and rapid prototyping services to help clients refine their product designs before mass production.

Q: What is the lead time for orders placed with SourcifyChina?

A: Lead times vary based on order complexity and volume, but SourcifyChina typically provides competitive turnaround times and efficient delivery schedules.

Q: What are the payment terms for sourcing from SourcifyChina?

A: Payment terms are flexible and can be negotiated based on the client’s needs, usually including options like T/T, L/C, and more.

Q: Does SourcifyChina provide shipping and logistics support?

A: Yes, SourcifyChina offers comprehensive shipping and logistics support to ensure timely and safe delivery of products to clients worldwide.

Q: How can I get a quote for my sheet metal fabrication project?

A: You can request a quote by contacting SourcifyChina through their website, providing detailed specifications and requirements for your project.

Q: What sets SourcifyChina apart from other sheet metal fabrication suppliers?

A: SourcifyChina stands out due to its high-quality workmanship, competitive pricing, advanced technology, and excellent customer service.

Sourcing sheet metal fabrication from SourcifyChina factory can be streamlined with the following tips:

1. Understand Your Requirements: Clearly define your sheet metal fabrication needs, including material type, thickness, and design specifications. This helps in precise communication and ensures you receive accurate quotations and prototypes.

2. Research the Factory: Verify the credentials and reputation of SourcifyChina. Check their experience in sheet metal fabrication, client reviews, and any certifications such as ISO 9001 that indicate quality assurance.

3. Sample and Prototype: Request samples or prototypes to assess the quality of their work. This will help you evaluate the factory’s capability to meet your specifications and quality standards.

4. Negotiate Terms: Discuss and negotiate key terms such as pricing, lead times, minimum order quantities, and payment terms. Ensure there are clear agreements to avoid misunderstandings.

5. Quality Control: Establish a quality control process, including inspections and testing procedures. Ensure the factory adheres to these standards to maintain consistency and quality in production.

6. Communication: Maintain clear and open communication channels with the factory. Use tools like email, video calls, and instant messaging for regular updates on production progress.

7. Visit the Factory: If possible, visit SourcifyChina to inspect their facilities, meet the team, and understand their manufacturing processes. This can provide insights into their operational capabilities and quality management.

8. Contract Agreement: Draft a detailed contract outlining all terms and conditions, including quality standards, delivery schedules, and penalties for non-compliance. This protects both parties and provides a clear framework for the partnership.

By following these tips, you can effectively source sheet metal fabrication from SourcifyChina, ensuring high-quality production and a reliable supply chain.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.