Streamline Your Production with Reliable Factory Manufacturing Machines from SourcifyChina

Discover high-quality, reliable manufacturing machines for your factory needs with SourcifyChina. Our extensive selection ensures efficient production, cost-effectiveness, and superior performance, enhancing your manufacturing capabilities with trusted, durable equipment.

Choosing SourcifyChina Factory for purchasing manufacturing machines from China ensures quality and reliability. With extensive experience, SourcifyChina offers expert guidance in selecting the right machinery to meet specific needs, ensuring efficient and cost-effective production solutions.

SourcifyChina’s comprehensive quality control processes guarantee that every machine meets international standards. This dedication to quality reduces risks associated with purchasing machinery from overseas, providing peace of mind for buyers.

SourcifyChina also offers exceptional after-sales support. Their team of experts is available to assist with installation, maintenance, and troubleshooting, ensuring that your machinery operates smoothly and efficiently.

Moreover, SourcifyChina provides competitive pricing without compromising on quality. Their strong relationships with reputable manufacturers in China enable them to offer the best deals, maximizing your investment.

In conclusion, choosing SourcifyChina Factory means access to high-quality manufacturing machines, expert support, and competitive pricing, making it the ideal choice for buyers seeking reliable and efficient production solutions from China.

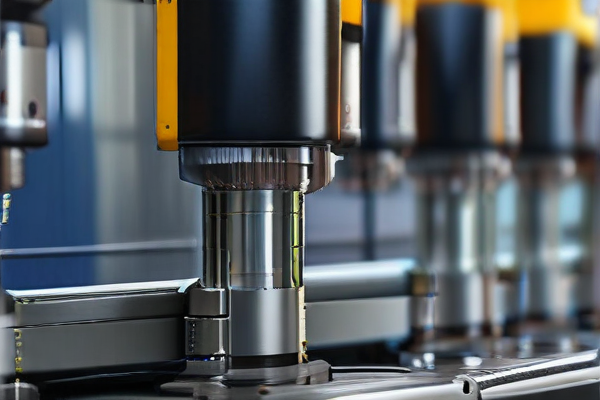

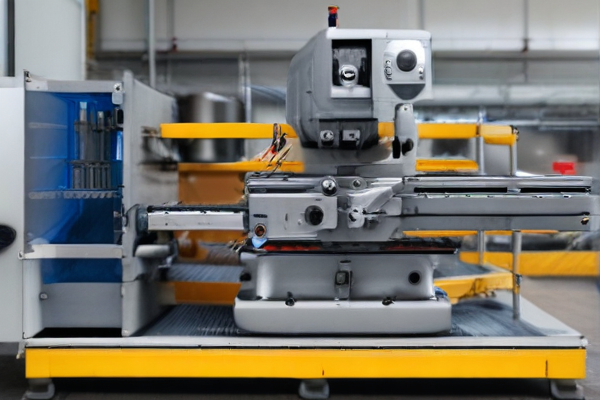

Manufacturing machines are crucial for production efficiency, enabling the automation of processes across various industries. These machines range from simple hand tools to complex computer-controlled systems. Key types include CNC machines, injection molding machines, and industrial robots, each offering unique capabilities and applications.

– CNC Machines: Computer Numerical Control (CNC) machines automate the control of machine tools through a computer. They include lathes, mills, and routers, providing precision in cutting, drilling, and machining tasks.

– Injection Molding Machines: These machines are used for producing plastic parts by injecting molten plastic into molds. They are essential in the automotive, consumer goods, and medical device industries.

– 3D Printers: Additive manufacturing machines that create objects by layering material based on digital models. They are versatile and used in prototyping, custom manufacturing, and even bioprinting.

– Industrial Robots: Robots designed for manufacturing applications such as welding, painting, assembly, and material handling. They enhance productivity, precision, and safety in manufacturing environments.

– Laser Cutting Machines: Use lasers to cut materials with high precision. They are used in various industries, including metalworking, automotive, and aerospace, for cutting, engraving, and marking tasks.

– Packaging Machines: Automate the packaging process, including filling, sealing, labeling, and wrapping. They are essential in the food and beverage, pharmaceuticals, and consumer goods industries.

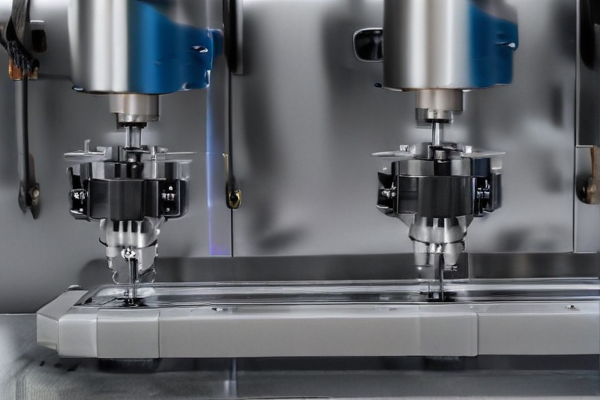

– Assembly Machines: Used to assemble components into finished products. They can be highly automated and integrated into production lines, improving speed and consistency in manufacturing.

– Press Machines: Apply pressure to form or shape materials. Types include hydraulic presses, mechanical presses, and pneumatic presses, used in metal forming, plastic molding, and other applications.

– Extrusion Machines: Force material through a die to create long shapes with a fixed cross-section, such as pipes, sheets, and profiles. Commonly used in plastics and metal industries.

– Grinding Machines: Use abrasive wheels to remove material and achieve precise dimensions and surface finishes. Essential in metalworking, toolmaking, and other precision machining tasks.

Each of these machines plays a vital role in modern manufacturing, enabling higher efficiency, precision, and versatility in producing a wide range of products.

Manufacturing machines are essential for modern production processes, significantly enhancing efficiency, precision, and scalability across various industries. These machines streamline operations, reduce manual labor, and ensure high-quality output.

Applications for manufacturing machines include:

– Automotive Industry: Assembly lines, welding robots, and CNC machines.

– Electronics: PCB manufacturing, soldering, and surface mount technology (SMT) machines.

– Food and Beverage: Packaging, bottling, and labeling machines.

– Textiles: Automated knitting, weaving, and dyeing machines.

– Pharmaceuticals: Tablet pressing, capsule filling, and blister packaging machines.

– Aerospace: CNC machining, composite material fabrication, and inspection systems.

– Medical Devices: Precision molding, assembly, and sterilization equipment.

– Construction: Prefabrication, concrete batching, and brick manufacturing machines.

– Metalworking: Lathes, milling machines, and laser cutters.

– Furniture: Woodworking CNC routers, sanding, and finishing machines.

– Plastics: Injection molding, extrusion, and blow molding machines.

– Energy: Wind turbine blade manufacturing, solar panel assembly, and battery production equipment.

– Consumer Goods: 3D printing, automated assembly, and quality control systems.

– Printing: Digital printing, offset printing, and binding machines.

– Textile Recycling: Fiber shredding, sorting, and reprocessing machines.

– Chemical Processing: Mixing, separation, and distillation equipment.

– Agriculture: Automated harvesting, sorting, and packaging machines.

– Mining: Drilling, crushing, and material handling equipment.

– Marine: Shipbuilding, welding, and cutting machines.

– Railway: Track laying, maintenance, and inspection machines.

– Defense: Ammunition assembly, vehicle manufacturing, and maintenance equipment.

– Jewelry: Precision casting, engraving, and polishing machines.

These applications highlight the versatility and critical role of manufacturing machines in driving industry advancements and productivity.

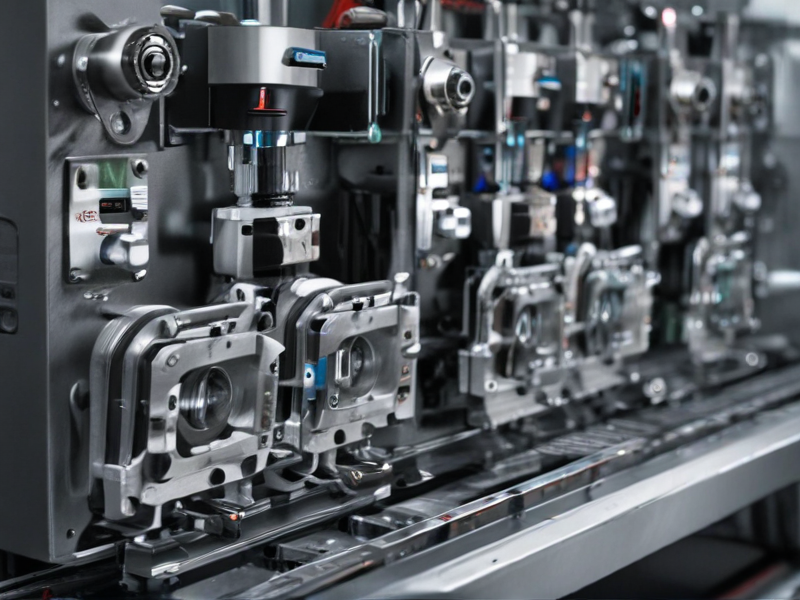

Manufacturing machines are integral components in the modern industrial landscape, driving efficiency and precision in production processes. These machines, ranging from simple automated tools to complex robotics, are designed to handle various tasks such as cutting, molding, assembling, and packaging materials. The automation of these processes not only speeds up production but also enhances the quality and consistency of products. By minimizing human intervention, manufacturing machines reduce the likelihood of errors and improve workplace safety. As technology advances, these machines become more sophisticated, incorporating artificial intelligence and machine learning to optimize operations and predict maintenance needs.

The impact of manufacturing machines extends beyond productivity and quality. They play a crucial role in the economic development of industries by lowering production costs and enabling mass production. This cost-effectiveness allows companies to offer competitive pricing and improve market reach. Additionally, the precision and capability of modern manufacturing machines facilitate innovation by allowing the creation of complex designs and new products that were previously unattainable. As the manufacturing sector continues to evolve, these machines will likely integrate more advanced technologies, such as the Internet of Things (IoT) and advanced analytics, further revolutionizing the way products are made and contributing to sustainable manufacturing practices.

Manufacturing machines are the backbone of modern production industries, transforming raw materials into finished goods through various processes. These machines range from simple tools like lathes and drills to complex automated systems that incorporate robotics and computer-aided manufacturing (CAM). They increase efficiency, consistency, and precision in production, enabling industries to meet high demands and maintain quality standards. Innovations in manufacturing technology, such as additive manufacturing (3D printing) and advanced CNC (Computer Numerical Control) machinery, have further revolutionized production capabilities, allowing for more complex designs and reducing waste.

The integration of manufacturing machines into production lines has also significantly impacted labor dynamics. Automation and robotics have taken over repetitive and hazardous tasks, reducing the risk of workplace injuries and freeing human workers to focus on more skilled and creative roles. This shift has necessitated a workforce skilled in operating, programming, and maintaining these sophisticated machines. As technology continues to advance, the role of manufacturing machines will likely expand, incorporating artificial intelligence and the Internet of Things (IoT) to create smart factories that are even more efficient, adaptable, and interconnected. These advancements promise to enhance productivity and innovation across various sectors, from automotive to electronics and beyond.

Manufacturing machines are the backbone of modern industrial production, enabling the mass production of goods with precision and efficiency. These machines range from simple hand-operated devices to highly sophisticated automated systems integrated with advanced robotics and artificial intelligence. Their primary purpose is to enhance productivity by performing repetitive tasks with high accuracy, reducing the need for manual labor and minimizing human error. For instance, CNC (Computer Numerical Control) machines can cut, shape, and finish materials with exact specifications, ensuring uniformity and quality in the final products. Moreover, the integration of IoT (Internet of Things) in manufacturing machines allows for real-time monitoring and maintenance, which reduces downtime and enhances overall operational efficiency.

The evolution of manufacturing machines has revolutionized various industries, from automotive to electronics and consumer goods. The introduction of 3D printing machines, for example, has opened new avenues for rapid prototyping and small-scale production, allowing companies to innovate and customize products quickly. Additionally, these machines contribute significantly to sustainability efforts by optimizing material usage and energy consumption. Automated assembly lines reduce waste and improve safety by minimizing the exposure of workers to hazardous environments. As technology continues to advance, the future of manufacturing machines promises further enhancements in speed, precision, and adaptability, driving the next wave of industrial innovation and economic growth.

Manufacturing machines are integral components of modern industrial processes, designed to enhance efficiency, precision, and scalability in production. These machines encompass a wide range of equipment, including CNC (Computer Numerical Control) machines, assembly line robots, and specialized tools for tasks such as welding, cutting, and molding. CNC machines, for example, allow for the automation of precise movements and operations, producing complex parts with high accuracy and minimal human intervention. Robots on assembly lines streamline the production process by performing repetitive tasks quickly and consistently, reducing the likelihood of errors and increasing output. The integration of these machines into manufacturing processes not only speeds up production but also ensures a higher standard of quality and uniformity in the final products.

The evolution of manufacturing machines has been driven by advancements in technology, including the development of IoT (Internet of Things), artificial intelligence, and machine learning. These innovations have led to the creation of smart factories where machines communicate with each other and with central control systems to optimize production processes in real-time. Predictive maintenance is another significant advancement, where sensors and AI analyze data to predict when a machine might fail, allowing for preemptive maintenance and reducing downtime. This technological progress has also enabled greater customization in manufacturing, allowing for the efficient production of small batches tailored to specific customer requirements. Ultimately, manufacturing machines represent the backbone of industrial productivity, continuously evolving to meet the demands of modern production needs.

Manufacturing machines are the backbone of modern industry, playing a crucial role in producing goods efficiently and consistently. These machines range from simple tools like lathes and drills to highly sophisticated, computer-controlled systems known as CNC (Computer Numerical Control) machines. They are designed to handle various tasks such as cutting, shaping, assembling, and finishing materials into final products. The automation and precision offered by these machines significantly reduce the time and labor required for production, leading to higher output and lower costs. Additionally, manufacturing machines ensure uniformity and quality in products, which is essential in industries like automotive, aerospace, and electronics.

The evolution of manufacturing machines has been marked by technological advancements that have revolutionized the production process. Early manufacturing relied heavily on manual labor and simple mechanical tools, but the advent of the Industrial Revolution introduced powered machinery, significantly boosting productivity. Today, the integration of robotics, artificial intelligence, and IoT (Internet of Things) in manufacturing machines has further enhanced their capabilities. These smart machines can communicate with each other, monitor their own performance, and even predict maintenance needs, thereby minimizing downtime and maximizing efficiency. The continuous improvement in manufacturing technology not only meets the growing demand for high-quality products but also drives innovation and competitiveness in the global market.

Manufacturing machines have revolutionized the industrial landscape, significantly enhancing productivity and precision in various sectors. These machines range from simple tools like lathes and drills to highly sophisticated automated systems like CNC (Computer Numerical Control) machines and robotic arms. The primary function of these machines is to facilitate the mass production of goods by automating repetitive tasks, which not only speeds up the manufacturing process but also ensures consistent quality and reduces human error. As technology advances, these machines are becoming more intelligent and interconnected, forming the backbone of smart factories in the era of Industry 4.0, where real-time data and analytics drive efficiency and innovation.

Moreover, the impact of manufacturing machines extends beyond mere production speed and quality. They play a crucial role in enabling manufacturers to remain competitive in a global market by reducing labor costs and minimizing waste through precise material usage. Additionally, the versatility of modern manufacturing machines allows for greater flexibility in production lines, enabling quick adaptation to new products and changing market demands. This adaptability is particularly vital in industries such as automotive, aerospace, and electronics, where the ability to swiftly pivot to new designs and technologies can be a significant competitive advantage. Overall, manufacturing machines are indispensable in the modern industrial ecosystem, driving progress and enabling the creation of complex, high-quality products at scale.

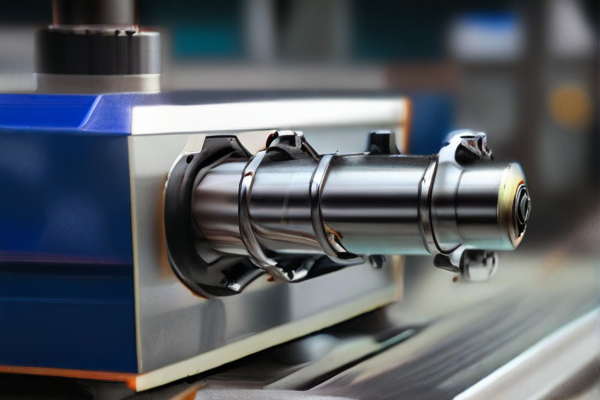

SourcifyChina specializes in manufacturing machines that are designed for high efficiency and precision. Their equipment is constructed from premium materials, ensuring durability and consistent performance. This focus on quality materials reduces maintenance needs and extends machine lifespan.

The company uses stainless steel and high-grade alloys, known for their resistance to corrosion and wear. This choice of materials is crucial for machines that operate in demanding environments, providing reliability and safety in production processes.

Advanced composites are also utilized, enhancing the structural integrity and reducing the overall weight of the machines. These composites offer excellent thermal stability, which is essential for maintaining accuracy during high-speed operations.

SourcifyChina integrates state-of-the-art electronic components into their machines. These components are sourced from reputable suppliers, ensuring high functionality and compatibility with various industrial applications. The use of robust electronics enhances machine control and efficiency.

To meet diverse manufacturing needs, SourcifyChina employs cutting-edge technologies in their machine design. This includes CNC machining, laser cutting, and precision welding, which are performed using top-tier materials. These methods ensure that each machine is crafted to the highest standards, delivering superior performance.

In summary, SourcifyChina’s commitment to using high-quality materials and advanced technologies results in manufacturing machines that are robust, reliable, and efficient. This dedication to excellence supports their reputation as a leading provider in the manufacturing industry.

SourcifyChina employs a rigorous quality control process for its manufacturing machines to ensure high standards. The process begins with the selection of top-grade materials, followed by meticulous design and engineering to meet industry specifications.

Each machine undergoes multiple stages of testing during production. This includes precision measurements, functionality assessments, and endurance tests to ensure reliability and performance under various conditions.

Quality control teams perform regular inspections throughout the assembly line, identifying and rectifying any defects promptly. This proactive approach minimizes errors and maintains consistent product quality.

Finished machines are subjected to final comprehensive tests, simulating real-world operating conditions. This ensures that each unit meets SourcifyChina’s stringent quality criteria before shipment.

Feedback from customers and in-field performance data are continuously reviewed. This information is used to refine the manufacturing process, implement improvements, and ensure ongoing product excellence.

SourcifyChina’s commitment to quality control extends to after-sales support, providing maintenance and addressing any issues that arise, ensuring customer satisfaction and long-term reliability of their machines.

SourcifyChina excels in manufacturing machines, offering cutting-edge technology for diverse industrial needs. Their machines are known for precision and efficiency, ensuring top-notch quality in every production line.

These machines incorporate advanced automation, significantly reducing manual labor and increasing production speed. This results in higher output and consistent product quality, meeting the demands of various industries.

SourcifyChina’s manufacturing machines are built with robust materials, ensuring durability and longevity. This reliability minimizes downtime and maintenance costs, enhancing overall productivity.

The company provides customizable solutions tailored to specific manufacturing requirements. This flexibility allows businesses to optimize their processes and achieve their unique production goals.

In addition to high performance, SourcifyChina prioritizes sustainability, integrating energy-efficient technologies that reduce environmental impact. This commitment to eco-friendly practices aligns with global standards and regulations.

Furthermore, their comprehensive after-sales service ensures continuous support and maintenance, helping clients maximize the lifespan and efficiency of their machines. This service includes regular check-ups, quick response times, and expert technical assistance.

Overall, SourcifyChina’s manufacturing machines represent a blend of innovation, reliability, and sustainability, making them a preferred choice for businesses aiming to enhance their production capabilities. With a focus on customer satisfaction and technological advancement, SourcifyChina continues to lead the market in manufacturing solutions.

Manufacturing machines have revolutionized production processes, offering numerous benefits that enhance efficiency and productivity.

– Increased Efficiency: Machines can operate continuously without breaks, significantly increasing the speed of production.

– Consistency and Precision: Automated machines ensure uniformity and high precision in manufacturing, reducing human error.

– Cost Reduction: While initial investments are high, machines lower long-term operational costs through reduced labor and wastage.

– Scalability: Machines can easily be scaled to meet varying production demands, facilitating quick adjustments to market needs.

– Enhanced Safety: Machines can handle hazardous tasks, reducing the risk of workplace injuries.

– Better Quality Control: Automated systems provide real-time monitoring and quality checks, ensuring superior product quality.

– Labor Savings: Machines perform repetitive and strenuous tasks, allowing human workers to focus on more complex and creative aspects of production.

– Innovation Facilitation: Advanced machinery enables the implementation of new technologies and processes, fostering innovation.

– Resource Efficiency: Machines optimize the use of materials and energy, contributing to sustainable manufacturing practices.

– Faster Time-to-Market: Automated production lines shorten the time required to bring products to market, enhancing competitiveness.

In conclusion, manufacturing machines play a crucial role in modern production by boosting efficiency, ensuring consistency, and enabling scalability. They not only reduce costs and improve safety but also promote innovation and resource efficiency, making them indispensable in today’s industrial landscape.

Manufacturing machines are essential in modern production, offering a variety of features that enhance efficiency, precision, and scalability.

Key features of manufacturing machines include:

– Automation: Machines can perform repetitive tasks with minimal human intervention, increasing productivity and reducing errors.

– Precision: Advanced control systems allow for high accuracy in measurements and operations, ensuring consistent quality.

– Flexibility: Modern machines can be easily reprogrammed or adjusted to produce different products or accommodate changes in production processes.

– Durability: Built with robust materials and components, these machines are designed to withstand continuous operation and harsh industrial environments.

– Integration: They can be integrated with other systems, such as ERP and supply chain management, to streamline operations and improve data flow.

– Safety Features: Equipped with sensors, emergency stop functions, and protective enclosures to ensure the safety of operators.

– Energy Efficiency: Designed to minimize energy consumption and reduce operational costs while maintaining high performance.

– Scalability: Machines can be scaled up or down to meet varying production demands without significant reconfiguration.

– Connectivity: IoT-enabled machines can communicate with each other and with central control systems, allowing for real-time monitoring and maintenance.

– Maintenance and Diagnostics: Built-in diagnostics and easy access to components facilitate routine maintenance and quick troubleshooting.

These features collectively contribute to the effectiveness and competitiveness of manufacturing operations, enabling businesses to meet market demands efficiently.

SourcifyChina specializes in manufacturing machines designed for custom products and projects. Their advanced machinery ensures high precision and efficiency, tailored to meet unique client specifications.

The company’s state-of-the-art technology allows for the production of a wide range of custom products, from small components to large assemblies. Each machine is built to handle specific manufacturing challenges, ensuring quality and consistency.

SourcifyChina’s machines are engineered to support diverse industries, including automotive, electronics, and consumer goods. Their flexible design makes them adaptable to various production needs, enabling companies to innovate and stay competitive.

Clients benefit from SourcifyChina’s comprehensive service, which includes initial consultation, machine customization, and ongoing technical support. This holistic approach ensures that each project is executed seamlessly from start to finish.

The company is committed to sustainability, incorporating eco-friendly practices into their manufacturing processes. By optimizing resource use and reducing waste, SourcifyChina contributes to a greener future while maintaining high production standards.

SourcifyChina’s dedication to quality and customer satisfaction has earned them a reputation as a reliable partner in the manufacturing industry. Their machines are known for durability, efficiency, and exceptional performance.

In conclusion, SourcifyChina offers innovative manufacturing machines for custom products and projects, providing tailored solutions to meet diverse industry needs. Their commitment to quality, sustainability, and customer service ensures they remain at the forefront of the manufacturing sector.

SourcifyChina is a prominent company specializing in the manufacturing of high-quality machines tailored for various industrial needs. With a strong commitment to innovation and precision engineering, SourcifyChina offers an extensive range of machinery that caters to sectors such as automotive, electronics, textiles, and heavy industries. The company prides itself on its state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians dedicated to producing reliable and efficient machines. SourcifyChina’s products are known for their durability, cutting-edge technology, and compliance with international standards, ensuring that clients receive the best solutions to enhance their production processes. Furthermore, the company places a significant emphasis on customer satisfaction, providing comprehensive after-sales support and maintenance services to ensure optimal performance of their machines. Through continuous research and development, SourcifyChina remains at the forefront of the manufacturing industry, delivering innovative solutions that drive industrial growth and efficiency.

Manufacturing machines play a pivotal role in modern industrial processes, offering significant advancements in efficiency, precision, and scalability. These machines, ranging from CNC (Computer Numerical Control) machines to automated assembly lines, enable manufacturers to produce complex parts with high accuracy and repeatability. For instance, CNC machines are widely used in industries such as aerospace, automotive, and electronics, where precision and reliability are paramount. By utilizing advanced software and robotics, these machines can produce intricate designs and components that would be difficult, if not impossible, to achieve manually. This automation not only improves product quality but also reduces waste, minimizes errors, and shortens production cycles, thereby enhancing overall productivity.

In addition to improving precision and efficiency, manufacturing machines also facilitate mass production and customization. Automated systems such as robotic arms, conveyors, and 3D printers allow for high-speed production of large volumes of goods while maintaining consistent quality. Moreover, the integration of IoT (Internet of Things) technologies enables real-time monitoring and optimization of manufacturing processes, leading to predictive maintenance and reduced downtime. Customization has also become more feasible with advanced manufacturing machines, as they can easily be reprogrammed to produce different products or variants in response to market demands. This flexibility is particularly valuable in industries like consumer electronics and fashion, where trends and consumer preferences change rapidly. Overall, manufacturing machines are indispensable in driving innovation, competitiveness, and sustainability in the industrial sector.

Manufacturing machines play a crucial role in modern production processes, significantly enhancing efficiency, precision, and scalability. These machines encompass a wide range of equipment, including CNC (Computer Numerical Control) machines, robotic arms, 3D printers, and assembly line automation systems. CNC machines, for example, allow for the precise cutting, shaping, and finishing of materials, from metals to plastics, enabling the production of complex and intricate parts that meet exact specifications. Robotic arms, integrated with AI and advanced sensors, can perform repetitive tasks with high accuracy and speed, reducing human error and increasing output. 3D printers have revolutionized prototyping and custom manufacturing, allowing for the rapid production of parts and products with complex geometries that would be challenging or impossible to create using traditional methods.

The application of manufacturing machines extends across various industries, from automotive and aerospace to electronics and healthcare. In the automotive industry, robotic assembly lines are pivotal in the mass production of vehicles, ensuring consistency and quality while significantly reducing production times. In aerospace, CNC machines are vital for creating precise and reliable components that meet stringent safety and performance standards. The electronics industry benefits from surface-mount technology (SMT) machines, which place components onto circuit boards with remarkable speed and accuracy. In healthcare, manufacturing machines enable the production of medical devices, implants, and even personalized prosthetics, enhancing patient care and treatment outcomes. By integrating these machines into their operations, companies can achieve higher productivity, maintain competitive advantages, and respond more swiftly to market demands.

Manufacturing machines play a crucial role in modern industrial processes, enabling the mass production of goods with high precision and efficiency. These machines range from simple, single-function devices to complex, computer-controlled systems known as CNC (Computer Numerical Control) machines. They automate tasks such as cutting, welding, assembling, and packaging, which significantly reduces human labor and increases production speed. The precision of manufacturing machines ensures consistent quality in products, minimizing defects and waste. This reliability is essential in industries like automotive, aerospace, and electronics, where exact specifications are critical for safety and functionality.

Moreover, the integration of advanced technologies such as robotics and IoT (Internet of Things) has further enhanced the capabilities of manufacturing machines. Robots can perform repetitive and hazardous tasks with greater accuracy and safety, while IoT devices enable real-time monitoring and predictive maintenance, reducing downtime and operational costs. These advancements support the implementation of smart manufacturing, where data-driven insights optimize the entire production process. As a result, manufacturers can respond more quickly to market demands, customize products to individual specifications, and maintain a competitive edge in a rapidly evolving global market.

Manufacturing machines have revolutionized various industries by significantly enhancing production efficiency and product quality. In the automotive sector, these machines enable precise assembly and fabrication of vehicle components, from engine parts to body panels. Automation in manufacturing processes reduces human error, increases speed, and ensures consistent quality, which is critical in producing reliable and safe vehicles. Robotics and computer-controlled machines in car manufacturing streamline the production line, reducing labor costs and minimizing waste. The ability to quickly adapt to different models and customizations also allows manufacturers to meet diverse market demands with agility.

In the electronics industry, manufacturing machines play a crucial role in producing high-precision components and assemblies for devices such as smartphones, computers, and medical equipment. Surface-mount technology (SMT) machines place tiny electronic components onto circuit boards with extreme accuracy, enabling the production of complex and compact devices. Automated testing equipment ensures that each product meets stringent quality standards before it reaches the market. This automation not only accelerates production but also supports innovation by allowing rapid prototyping and iteration. Overall, the integration of manufacturing machines across industries leads to higher productivity, cost-effectiveness, and the ability to maintain competitiveness in a global market.

Manufacturing machines play a pivotal role in modern production processes, significantly enhancing efficiency and precision. These machines encompass a wide range of equipment, including CNC (Computer Numerical Control) machines, automated assembly lines, and 3D printers. CNC machines, for instance, are integral in the production of complex components with high accuracy, making them indispensable in industries such as aerospace, automotive, and electronics. Automated assembly lines streamline the production of consumer goods, from smartphones to automobiles, by reducing manual labor and minimizing errors. This automation not only boosts productivity but also ensures consistency in quality, which is crucial for maintaining competitive advantage in the market.

Moreover, the advent of advanced manufacturing machines has facilitated innovation in various sectors. For example, 3D printing technology, also known as additive manufacturing, allows for rapid prototyping and customization of products. This capability is particularly beneficial in the medical field, where custom prosthetics and implants can be produced to meet individual patient needs. In the aerospace industry, 3D printing enables the creation of lightweight yet durable components, contributing to more efficient and sustainable designs. Overall, the application of manufacturing machines extends beyond mere production efficiency; it drives technological advancement and opens up new possibilities for customized and innovative solutions across diverse industries.

Manufacturing machines are integral to modern production processes, significantly enhancing efficiency, precision, and scalability across various industries. These machines, ranging from CNC (Computer Numerical Control) systems to robotic arms, automate complex tasks that were traditionally performed manually. By doing so, they reduce human error, ensure consistent quality, and speed up production times. For instance, in the automotive industry, manufacturing machines are used to assemble parts, weld components, and apply finishes with remarkable accuracy and repeatability. This automation not only increases output but also allows for more flexible production schedules, adapting quickly to changes in demand or product specifications.

Furthermore, the application of manufacturing machines extends beyond mere production efficiency to encompass innovations in product design and development. Advanced manufacturing technologies, such as 3D printing and additive manufacturing, enable the creation of complex geometries and customized components that were previously impossible or prohibitively expensive to produce. In the aerospace and medical device sectors, these capabilities are particularly valuable, allowing for the production of lightweight, high-strength components and patient-specific implants. Additionally, the integration of IoT (Internet of Things) and AI (Artificial Intelligence) in manufacturing machines facilitates real-time monitoring and predictive maintenance, ensuring machines operate at optimal performance levels and minimizing downtime. This blend of automation, precision, and smart technology underscores the transformative impact of manufacturing machines on modern industry.

FAQ:

Manufacturing Machines Quality Work from SourcifyChina Factory

What types of manufacturing machines does SourcifyChina Factory offer?

SourcifyChina Factory provides a wide range of manufacturing machines including CNC machines, injection molding machines, laser cutting machines, and more. These machines are designed for various industries such as automotive, electronics, and consumer goods.

How does SourcifyChina ensure the quality of their manufacturing machines?

SourcifyChina adheres to strict quality control processes, including rigorous testing and inspection at every stage of production. They use high-quality materials and components, and follow international standards like ISO 9001 to ensure top-notch quality.

Can SourcifyChina customize manufacturing machines to specific requirements?

Yes, SourcifyChina offers customization services to meet specific requirements. Their team of engineers works closely with clients to design and produce machines that match precise specifications and needs.

What kind of after-sales support does SourcifyChina provide?

SourcifyChina provides comprehensive after-sales support including installation, training, maintenance, and technical assistance. They offer a warranty period and have a dedicated customer service team to address any issues promptly.

How long is the lead time for ordering manufacturing machines from SourcifyChina?

The lead time varies depending on the type and complexity of the machine. Generally, standard machines can be delivered within 4-6 weeks, while customized machines may take longer. It’s best to contact SourcifyChina directly for specific lead time estimates.

Are there any certifications that SourcifyChina’s machines comply with?

Yes, SourcifyChina’s machines comply with various international certifications such as CE, UL, and ISO standards, ensuring they meet global safety and quality requirements.

Can I visit SourcifyChina’s factory before making a purchase?

Yes, potential clients are welcome to visit the factory to see the production process, meet the team, and inspect the machines firsthand. It’s recommended to schedule an appointment in advance.

What payment methods does SourcifyChina accept?

SourcifyChina accepts various payment methods including wire transfer, letter of credit, and other secure payment options. They work with clients to determine the most convenient and secure method for their transactions.

How does SourcifyChina handle shipping and logistics?

SourcifyChina has a dedicated logistics team that manages the shipping process, ensuring safe and timely delivery of machines. They offer various shipping options and work with reliable freight forwarders to handle international deliveries.

Who should I contact for more information or to place an order?

For more information or to place an order, you can contact SourcifyChina’s sales team via their website, email, or phone. They are ready to assist with inquiries, provide quotes, and guide you through the purchasing process.

When considering “manufacturing machines manufacturing from SourcifyChina factory,” here are some key tips to ensure a smooth and successful process:

1. Research and Selection:

– Assess Needs: Clearly define your manufacturing needs to select the appropriate machines.

– Supplier Reputation: Verify SourcifyChina’s credibility through reviews, certifications, and previous client testimonials.

– Technology and Compatibility: Ensure the machines’ technology aligns with your production requirements and is compatible with existing systems.

2. Quality and Compliance:

– Quality Standards: Check that the machines meet international quality standards and certifications (e.g., ISO).

– Compliance: Confirm compliance with safety and environmental regulations in your region.

3. Customization and Flexibility:

– Customization Options: Inquire about the possibility of customizing machines to fit specific production processes.

– Scalability: Ensure the machines can scale with your business growth and evolving production demands.

4. Cost and Investment:

– Transparent Pricing: Request detailed quotes, including all potential costs (shipping, installation, taxes).

– ROI Analysis: Conduct a return on investment (ROI) analysis to justify the purchase.

5. After-Sales Support:

– Technical Support: Confirm the availability of technical support and the responsiveness of the service team.

– Training: Ensure comprehensive training for your staff on machine operation and maintenance.

6. Warranty and Spare Parts:

– Warranty Coverage: Understand the warranty terms and what they cover.

– Spare Parts Availability: Ensure easy access to spare parts to minimize downtime.

7. Logistics and Delivery:

– Shipping Arrangements: Clarify shipping terms and delivery schedules.

– Customs and Duties: Be aware of any customs duties or import regulations that may apply.

8. Trial and Testing:

– Prototypes and Trials: If possible, request a prototype or trial run to evaluate machine performance before full-scale purchase.

By following these tips, you can make informed decisions and establish a successful partnership with SourcifyChina for your manufacturing machinery needs.

Frequently Asked Questions (FAQ) for Sourcing Manufacturing Machines from SourcifyChina Factory

Q: What types of manufacturing machines does SourcifyChina Factory offer?

A: SourcifyChina Factory offers a wide range of manufacturing machines including CNC machines, injection molding machines, packaging machines, and assembly line equipment.

Q: How can I place an order for manufacturing machines from SourcifyChina Factory?

A: You can place an order by visiting our website, selecting the desired machine, and filling out the inquiry form. Alternatively, you can contact our sales team directly via email or phone.

Q: What is the lead time for manufacturing machines from SourcifyChina Factory?

A: The lead time varies depending on the type of machine and order quantity. Typically, it ranges from 4 to 12 weeks. Please contact us for specific details.

Q: Does SourcifyChina Factory offer customization options for manufacturing machines?

A: Yes, we offer customization to meet specific requirements. Please provide detailed specifications, and our engineering team will work with you to tailor the machine to your needs.

Q: What are the payment terms for purchasing manufacturing machines?

A: Payment terms typically include a 30% deposit upon order confirmation and the remaining 70% before shipment. We accept various payment methods, including bank transfers and letters of credit.

Q: What kind of warranty and support does SourcifyChina Factory provide?

A: We offer a one-year warranty on all manufacturing machines. Our after-sales support includes technical assistance, spare parts, and maintenance services.

Q: How does SourcifyChina Factory ensure the quality of its manufacturing machines?

A: Our factory adheres to strict quality control procedures and international standards. Each machine undergoes thorough testing before shipment.

Q: Can SourcifyChina Factory assist with the installation and training for the machines?

A: Yes, we provide on-site installation and training services to ensure your team can operate the machines efficiently.

For further inquiries, please visit our website or contact our customer service team.

Sourcing manufacturing machines from SourcifyChina factory can be a streamlined and efficient process if you follow these tips:

1. Define Your Requirements: Clearly outline the specifications and requirements for the manufacturing machines you need. This includes size, capacity, functionality, and any specific features.

2. Research and Select the Right Supplier: Conduct thorough research on SourcifyChina factory. Review their product range, quality standards, certifications, and customer feedback to ensure they meet your needs.

3. Request a Quote: Contact SourcifyChina with detailed information about your requirements and request a comprehensive quote. Ensure that the quote includes all costs, such as shipping, taxes, and any additional fees.

4. Assess Quality and Compliance: Verify the quality of the machines by requesting samples or conducting a factory visit. Check for compliance with international standards and certifications relevant to your industry.

5. Negotiate Terms: Discuss and negotiate the terms of the purchase, including payment terms, delivery schedules, and warranty conditions. Ensure all agreements are documented in a written contract.

6. Order a Sample: If possible, order a sample machine to test its functionality and quality before making a bulk purchase. This helps to mitigate risks and ensure the machine meets your expectations.

7. Arrange Logistics and Shipping: Plan and arrange the logistics for shipping the machines. Ensure you understand the import regulations and duties in your country to avoid delays and additional costs.

8. Track and Inspect the Shipment: Once the machines are shipped, track the shipment and arrange for an inspection upon arrival to ensure there is no damage during transit.

9. Provide Feedback and Build Relationships: After receiving and using the machines, provide feedback to SourcifyChina. Building a good relationship with the supplier can lead to better terms and support for future orders.

By following these steps, you can effectively source high-quality manufacturing machines from SourcifyChina factory, ensuring a smooth and successful procurement process.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.