Description

custom drive shaft Safety Certifications

When it comes to custom drive shafts, ensuring they meet relevant safety certifications is crucial for reliability and compliance with industry standards. Here are some key safety certifications and standards that custom drive shafts should adhere to:

1. SAE J2260: This standard by the Society of Automotive Engineers (SAE) specifies the requirements for drive shafts used in light-duty vehicles. It covers aspects such as design, manufacturing, testing, and quality assurance to ensure the drive shafts meet stringent safety and performance criteria.

2. ISO 9001: While not specific to drive shafts, ISO 9001 certification ensures that the manufacturer has a quality management system in place. This certification helps guarantee that the products are consistently high-quality and meet customer and regulatory requirements.

3. ISO/TS 16949: This is an industry-specific extension of ISO 9001 for the automotive sector. It focuses on continuous improvement, defect prevention, and reducing variation and waste in the automotive supply chain, including drive shafts.

4. TUV Certification: The Technischer Überwachungsverein (TUV) is a technical inspection association based in Germany that certifies products to meet European safety and quality standards. TUV certification for drive shafts ensures they comply with rigorous testing and performance standards.

5. DIN Standards: The Deutsches Institut für Normung (DIN) provides German national standards. DIN certifications related to drive shafts ensure they conform to high-quality engineering and safety practices.

6. CE Marking: For drive shafts used in machinery within the European Economic Area (EEA), CE marking indicates compliance with the EU’s safety, health, and environmental requirements.

Ensuring that a custom drive shaft adheres to these certifications guarantees its safety, reliability, and performance, aligning with both regulatory requirements and industry best practices.

List Reference Technical Parameters of “custom drive shaft”

When specifying a custom drive shaft, several technical parameters are essential to ensure proper functionality and performance:

1. Material:

– Steel (Commonly 4140 Chromoly or 1350 Carbon Steel)

– Aluminum (Typically 6061 or 7075 alloy)

– Carbon Fiber (for high-performance, lightweight applications)

2. Dimensions:

– Length: Measured from the center of one universal joint to the center of the other.

– Diameter: Varies based on torque requirements and space constraints.

3. Spline Count and Size: The number of splines and their dimensions on the yokes and slip joints, which must match the mating components.

4. U-Joints (Universal Joints):

– Size and Type: Determines the compatibility with yokes and the operating angle.

– Material: Typically high-strength steel for durability.

5. Operating Torque:

– The maximum torque the shaft needs to transmit, factoring in the engine’s power and the vehicle’s gear ratios.

6. Critical Speed:

– The rotational speed at which the shaft experiences resonance, potentially leading to failure. This is influenced by length, diameter, and material.

7. Balancing:

– Precision balancing to ensure smooth operation and minimize vibrations.

8. Slip Yoke and Tube Yoke Specifications:

– Size, spline count, and material of the yokes.

9. Welding and Assembly Quality:

– Ensures the structural integrity and alignment of the assembled drive shaft.

10. Coatings and Finishes:

– Corrosion resistance and surface treatment for longevity and performance.

11. Weight:

– Influences the overall vehicle dynamics and fuel efficiency.

12. Application Specific Requirements:

– Custom features based on the vehicle type, such as off-road vehicles, racing cars, or industrial machinery.

Considering these parameters helps in designing a custom drive shaft tailored to specific operational needs, ensuring reliability, performance, and safety.

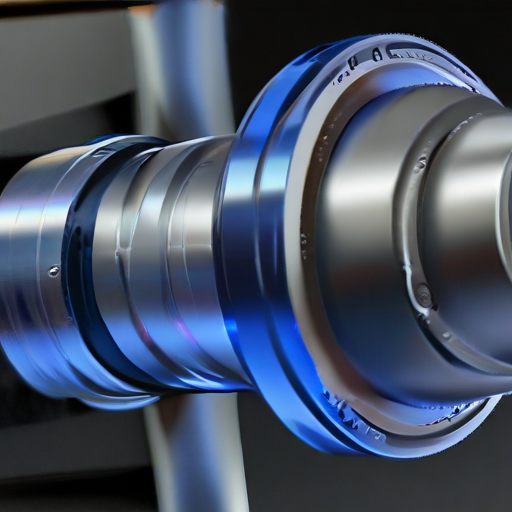

List Product features of “custom drive shaft”

A custom drive shaft is a critical component in various types of vehicles and machinery, designed to transmit torque and rotation. Here are the key features of a custom drive shaft:

1. Material Options: Custom drive shafts can be made from materials such as steel, aluminum, and carbon fiber, each offering different benefits in terms of strength, weight, and durability.

2. Precision Engineering: Tailored to meet specific performance requirements, custom drive shafts are engineered with exact specifications to ensure optimal functionality and reliability.

3. Length and Diameter Customization: Custom drive shafts can be designed in various lengths and diameters to fit unique applications, ensuring compatibility with the vehicle’s powertrain and chassis.

4. Balance and Vibration Control: These shafts are meticulously balanced to reduce vibrations and ensure smooth operation, which is crucial for maintaining vehicle stability and comfort.

5. High Torque Capacity: Designed to handle high torque loads, custom drive shafts are essential for high-performance and heavy-duty applications, such as in racing cars, trucks, and industrial machinery.

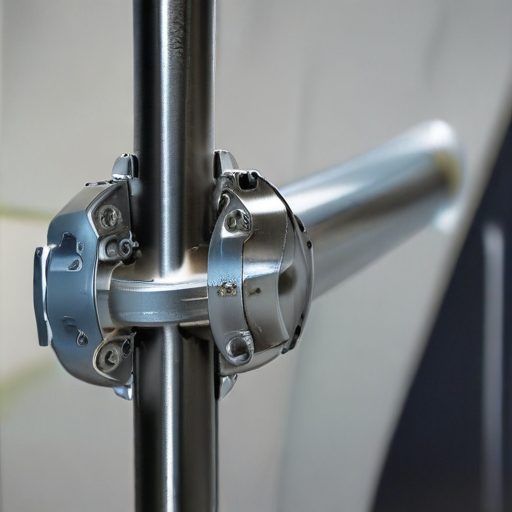

6. Universal Joint Options: Custom drive shafts can include different types of universal joints (U-joints) or constant velocity (CV) joints, allowing for flexibility in angular movement and accommodating various drivetrain configurations.

7. Spline Customization: The splines, or the ridges on the shaft that interlock with other components, can be customized to ensure a precise fit and smooth power transfer.

8. Corrosion Resistance: Custom drive shafts can be treated with coatings or made from corrosion-resistant materials to enhance longevity, especially in harsh environments.

9. Weight Optimization: Depending on the application, drive shafts can be designed to be lightweight, reducing the overall vehicle weight and improving performance and fuel efficiency.

10. Ease of Installation: Designed to fit seamlessly into the existing drivetrain system, custom drive shafts often come with easy-to-install features to minimize downtime and labor costs.

These features ensure that custom drive shafts meet the specific demands of various applications, providing reliability, efficiency, and enhanced performance.

List Application of “custom drive shaft”

Custom drive shafts are essential components in various applications where standard drive shafts do not meet specific performance requirements. Here are some key applications:

1. Automotive Performance:

– High-Performance Vehicles: Custom drive shafts are used in race cars, muscle cars, and other high-performance vehicles to handle increased horsepower and torque, reducing weight and increasing strength.

– Off-Road Vehicles: Custom drive shafts provide the necessary durability and flexibility for vehicles navigating rough terrains and extreme conditions.

2. Commercial Vehicles:

– Heavy-Duty Trucks: In trucks and commercial vehicles, custom drive shafts ensure reliable performance under heavy loads and extended operation.

– Buses: Custom solutions help manage the unique size and weight distribution of large passenger buses.

3. Industrial Equipment:

– Construction Machinery: Bulldozers, excavators, and cranes benefit from custom drive shafts designed to withstand high stress and variable loads.

– Agricultural Equipment: Tractors and harvesters require robust and reliable drive shafts for consistent operation in demanding field conditions.

4. Marine Applications:

– Boats and Yachts: Custom drive shafts in marine vessels are tailored to withstand the corrosive environment and specific power requirements.

– Commercial Shipping: They provide enhanced reliability and longevity for cargo ships and other large vessels.

5. Aerospace:

– Aircraft: Custom drive shafts are crucial for aircraft, where precision, weight, and strength are critical factors.

– Drones: High-performance drones use custom shafts for optimized power transmission and efficiency.

6. Motorcycles and ATVs:

– Custom and Racing Bikes: Custom drive shafts are designed to handle the specific needs of high-performance and custom-built motorcycles and all-terrain vehicles (ATVs).

7. Specialty Vehicles:

– Ambulances and Emergency Vehicles: These vehicles require custom drive shafts for reliability and performance under emergency conditions.

– Modified or Custom Builds: Custom-built or heavily modified vehicles often need drive shafts tailored to unique specifications.

Custom drive shafts are critical in ensuring optimal performance, durability, and efficiency across a wide range of applications where standard components fall short.

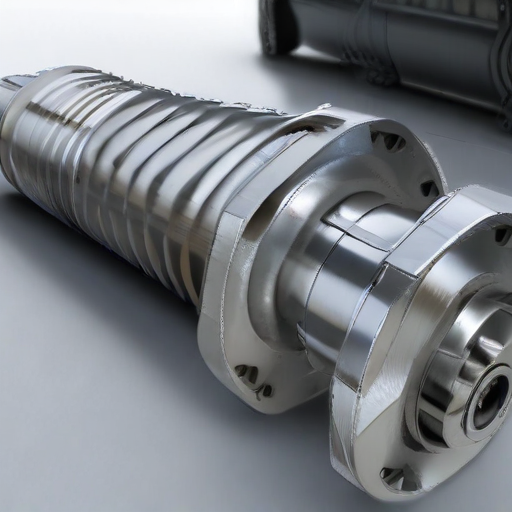

List Various Types of “custom drive shaft”

Custom drive shafts are designed to meet specific requirements for various vehicles and applications. Here are the primary types:

1. Steel Drive Shafts:

– Mild Steel: Commonly used for its durability and cost-effectiveness. Suitable for most standard applications.

– Chromoly Steel: Stronger and lighter than mild steel. Ideal for high-performance and racing applications.

2. Aluminum Drive Shafts:

– Lightweight and corrosion-resistant. They reduce rotational mass, improving acceleration and fuel efficiency. Commonly used in high-performance and racing vehicles.

3. Carbon Fiber Drive Shafts:

– Extremely lightweight and strong. They offer superior vibration damping and are used in high-end performance and racing vehicles. They also have high fatigue resistance.

4. Composite Drive Shafts:

– Made from a mix of materials like carbon fiber and fiberglass. They combine the benefits of both, offering strength, light weight, and improved performance characteristics.

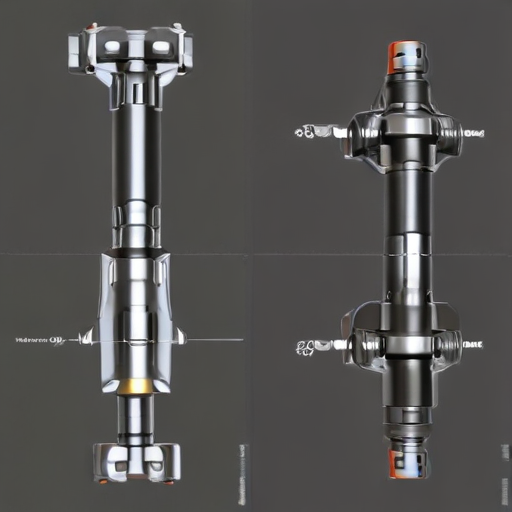

5. Two-Piece Drive Shafts:

– Used in vehicles with longer wheelbases to reduce vibrations and improve stability. They consist of two connected shafts with a center support bearing.

6. Custom Length Drive Shafts:

– Specifically tailored to fit vehicles with altered ride heights or modified frames. Ensures proper fitment and optimal performance.

7. High Torque Drive Shafts:

– Designed to handle high torque outputs from powerful engines. Made from reinforced materials to prevent twisting and breakage under stress.

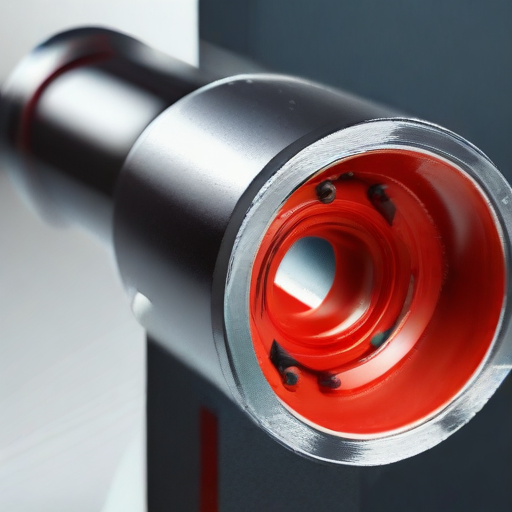

8. CV (Constant Velocity) Drive Shafts:

– Used in front-wheel-drive and all-wheel-drive vehicles. Allow for smooth power transfer even when the angle between the drive shaft and the wheels changes.

Each type of custom drive shaft is designed to meet specific needs, whether for enhanced performance, durability, weight reduction, or application-specific requirements.

custom drive shaft Accessories Upgrades and Custom Manufacturing Options

Custom drive shaft accessories and upgrades offer significant enhancements to vehicle performance and durability. Key accessories and upgrades include:

1. High-Performance Universal Joints: Upgrading to high-quality, greaseable universal joints can improve durability and reduce maintenance needs.

2. Slip Yokes: These allow for better handling of axle movement and reduce the risk of drive shaft damage, particularly in lifted vehicles.

3. Balanced Drive Shafts: Custom balancing reduces vibrations, improving ride quality and extending the life of drivetrain components.

4. Heavy-Duty Tubing: Using stronger materials, such as DOM (Drawn Over Mandrel) tubing, increases the drive shaft’s strength and torsional capacity, which is crucial for off-road and high-torque applications.

5. Flange Yokes and Adapters: Custom flange yokes and adapters can be designed to fit specific vehicle models, ensuring optimal compatibility and performance.

6. Upgraded CV Joints: Constant Velocity (CV) joints are ideal for vehicles requiring smooth power delivery over varying angles, such as those with independent suspension systems.

Custom manufacturing options include:

1. Material Selection: Options range from steel, aluminum, and carbon fiber, each offering different benefits like weight reduction (aluminum, carbon fiber) or increased strength (steel).

2. Length and Diameter Customization: Tailoring the length and diameter ensures the drive shaft meets the specific needs of the vehicle, whether it’s for a compact sports car or a heavy-duty truck.

3. Spline and Yoke Customization: Custom splines and yokes can be designed to match unique transmission and differential setups, enhancing compatibility and performance.

4. Special Coatings and Treatments: Protective coatings, such as powder coating or anodizing, can be applied to resist corrosion and wear, extending the drive shaft’s lifespan.

Investing in these accessories and custom manufacturing options can significantly enhance a vehicle’s performance, durability, and reliability, especially in demanding conditions.

List Quality Control and The Manufacturing Process of “custom drive shaft”

Manufacturing Process of Custom Drive Shafts

1. Design and Specifications: The process begins with obtaining detailed specifications from the customer, including length, diameter, material, and performance requirements.

2. Material Selection: High-quality metals such as steel or aluminum are selected based on strength, weight, and durability requirements.

3. Cutting and Shaping: Raw materials are cut to size and machined to the desired shape using lathes and CNC machines, ensuring precision.

4. Heat Treatment: The machined shafts undergo heat treatment processes like quenching and tempering to enhance hardness and strength.

5. Balancing: Shafts are dynamically balanced to prevent vibrations during operation. This involves adding or removing small amounts of material to achieve optimal balance.

6. Welding and Assembly: Components such as yokes and flanges are welded or assembled onto the shaft. High-precision welding ensures strong and durable joints.

7. Surface Treatment: Shafts may undergo processes like polishing, coating, or plating to enhance corrosion resistance and appearance.

Quality Control in Custom Drive Shaft Manufacturing

1. Material Inspection: Raw materials are inspected for defects and compliance with specifications.

2. Dimensional Checks: During and after machining, dimensional checks ensure that the parts meet the exact design specifications using tools like calipers and micrometers.

3. Non-Destructive Testing (NDT): Methods like ultrasonic testing and magnetic particle inspection detect internal or surface defects without damaging the shafts.

4. Balancing Tests: Precision balancing equipment is used to ensure that the drive shaft rotates smoothly at high speeds.

5. Weld Quality Inspection: Visual inspection, x-rays, and ultrasonic testing verify the integrity of welds.

6. Performance Testing: Finished shafts undergo testing for strength, durability, and performance under simulated operating conditions.

7. Final Inspection: A comprehensive final inspection ensures that the shaft meets all customer specifications and industry standards before shipment.

By integrating meticulous manufacturing processes and rigorous quality control, custom drive shafts are produced to meet high performance and reliability standards.

Materials of “custom drive shaft”

A custom drive shaft is a critical component in a vehicle’s drivetrain, responsible for transmitting torque and rotation from the engine to the wheels. The materials used in its construction are selected based on strength, weight, durability, and cost considerations. Here are the primary materials used in custom drive shafts:

1. Steel:

– Carbon Steel: Widely used due to its high strength and durability. It can be alloyed with other elements to enhance its properties.

– Chromoly Steel (4130 Steel): Contains chromium and molybdenum, providing higher tensile strength and resistance to wear compared to carbon steel. Commonly used in high-performance applications.

2. Aluminum:

– 6061-T6 Aluminum: Known for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Ideal for applications where weight reduction is crucial, such as in racing.

3. Carbon Fiber:

– Carbon Fiber Reinforced Polymer (CFRP): Combines high strength and low weight with excellent fatigue resistance. Carbon fiber drive shafts are used in high-performance and racing vehicles due to their ability to handle high torque loads and reduce rotational mass, leading to better acceleration and responsiveness.

4. Composite Materials:

– Glass Fiber Reinforced Polymer (GFRP): While not as strong as carbon fiber, it is more cost-effective and provides good strength and flexibility. Often used in applications where moderate performance and cost savings are needed.

5. Titanium:

– Rarely used due to high cost, titanium offers an excellent strength-to-weight ratio, corrosion resistance, and the ability to withstand extreme temperatures. It is reserved for specialized applications where these properties are critical.

The choice of material depends on the specific requirements of the vehicle and the intended use of the drive shaft. Factors such as the desired balance between weight and strength, cost constraints, and the level of performance demanded all influence the material selection for custom drive shafts.

“custom drive shaft” Comparative Analysis

When evaluating custom drive shafts, key factors include material, manufacturing processes, and intended applications.

Materials:

1. Steel: Steel drive shafts, particularly those made from chromoly, are known for their strength and durability. They are ideal for high-torque applications but are heavier than other materials.

2. Aluminum: Aluminum drive shafts are lighter, reducing rotational mass and improving vehicle performance. However, they might not handle high torque as well as steel.

3. Carbon Fiber: These offer the best strength-to-weight ratio. They are incredibly light and strong, ideal for high-performance applications, but are typically the most expensive.

Manufacturing Processes:

1. Welding: This traditional method involves welding the components together. It is reliable but can introduce weak points at the weld seams.

2. Tubular Construction: This method involves creating a seamless tube, which provides uniform strength and can be lighter than welded shafts.

3. Composite Wrapping: For carbon fiber shafts, layers of composite material are wrapped and cured to form the shaft, ensuring high strength and low weight.

Applications:

1. Performance Vehicles: Lightweight materials like aluminum or carbon fiber are preferred for their performance benefits.

2. Off-Road and Heavy-Duty: Steel is often used due to its durability and ability to withstand extreme conditions.

3. Custom Builds: The choice depends on the balance between performance needs and budget constraints.

Comparative Analysis:

– Cost: Steel is the most affordable, followed by aluminum, with carbon fiber being the most expensive.

– Weight: Carbon fiber is the lightest, followed by aluminum, and then steel.

– Strength: Steel offers the highest torque capacity, while carbon fiber provides excellent strength-to-weight ratio, and aluminum is a balanced option for moderate performance needs.

– Durability: Steel is the most durable, especially in harsh conditions. Carbon fiber is durable but can be prone to damage from impacts. Aluminum is less durable than steel but more resistant to corrosion.

Choosing the right custom drive shaft involves assessing the specific needs of the application, balancing factors such as cost, performance, and durability.

“custom drive shaft” Warranty and Support

Warranty and Support for Custom Drive Shafts

When purchasing a custom drive shaft, it is crucial to understand the warranty and support options provided by the manufacturer or supplier.

Warranty Coverage:

1. Duration: Most reputable manufacturers offer a warranty period ranging from 1 to 3 years, depending on the type of drive shaft and its intended use.

2. Scope: Warranties typically cover defects in materials and workmanship. This includes issues such as faulty welds, imbalanced shafts, or improper assembly.

3. Exclusions: Common exclusions include damage caused by improper installation, misuse, accidents, or modifications made by the user. Regular wear and tear are also usually not covered.

Support Services:

1. Technical Assistance: Manufacturers often provide technical support to help with installation, maintenance, and troubleshooting. This can include phone support, email assistance, and detailed manuals or guides.

2. Replacement and Repairs: If a defect is identified within the warranty period, the manufacturer may offer repair or replacement services at no additional cost. Some companies also provide loaner shafts to minimize downtime.

3. Customer Service: Reliable customer service is essential. Look for manufacturers with responsive support teams who can quickly address any concerns or issues.

Additional Considerations:

– Installation Guidance: Some companies offer professional installation services or can recommend certified installers to ensure the drive shaft is correctly fitted.

– Extended Warranties: Optional extended warranties may be available for an additional fee, providing longer-term protection.

– Performance Guarantees: Certain high-performance drive shafts come with performance guarantees, ensuring they meet specific operational standards.

When selecting a custom drive shaft, carefully review the warranty terms and support services to ensure comprehensive coverage and reliable assistance throughout the product’s lifespan.

List “custom drive shaft” FAQ

Custom Drive Shaft FAQ

1. What is a custom drive shaft?

A custom drive shaft is a tailor-made component designed to connect the transmission to the differential in a vehicle, ensuring the transfer of power from the engine to the wheels. It is customized to meet specific requirements of length, material, and design to enhance performance and compatibility.

2. Why would I need a custom drive shaft?

Custom drive shafts are necessary when the stock drive shaft doesn’t meet the needs of a modified vehicle. This includes changes in vehicle height, engine swaps, enhanced performance demands, or unique vehicle builds.

3. How do I measure for a custom drive shaft?

To measure for a custom drive shaft, determine the distance from the transmission output shaft to the differential input yoke. Measurements should be taken at ride height to ensure accuracy.

4. What materials are used for custom drive shafts?

Custom drive shafts can be made from various materials including steel, aluminum, and carbon fiber. Steel is durable and affordable, aluminum is lighter with good strength, and carbon fiber offers the highest strength-to-weight ratio but is more expensive.

5. How long does it take to build a custom drive shaft?

The build time for a custom drive shaft typically ranges from a few days to a couple of weeks, depending on complexity and shop workload.

6. Can a custom drive shaft improve performance?

Yes, a custom drive shaft can improve performance by reducing weight, enhancing strength, and ensuring optimal power transfer, which can lead to better acceleration and handling.

7. How do I maintain a custom drive shaft?

Regular inspection for wear and tear, ensuring proper lubrication of U-joints, and checking for balance are key maintenance steps. Follow manufacturer guidelines for specific care instructions.

8. What are the signs that I need a new drive shaft?

Common signs include vibrations, clunking noises, difficulty turning, and visible damage or wear. If experiencing any of these, consult a specialist to evaluate the need for a replacement.

9. Are custom drive shafts covered by warranty?

Warranties vary by manufacturer. It’s important to check the specific terms of the warranty at the time of purchase to understand coverage and limitations.

10. How much does a custom drive shaft cost?

The cost of a custom drive shaft can vary widely based on materials, length, and specifications, typically ranging from $300 to over $1000. Always request a quote based on your specific needs.

Top 10 FAQ with answer about custom drive shaft for Buyer Sourcing from China

Top 10 FAQ for Sourcing Custom Drive Shafts from China

1. What is the typical lead time for custom drive shafts from China?

Lead times can vary, but typically range from 4 to 8 weeks, including production and shipping.

2. How do I ensure the quality of drive shafts from Chinese suppliers?

Look for ISO-certified manufacturers, request samples, and perform third-party inspections. Regular communication and detailed specifications also help ensure quality.

3. What information do I need to provide for a custom drive shaft order?

Provide detailed specifications including material type, dimensions, torque requirements, and any specific design features. CAD drawings are highly recommended.

4. Can Chinese manufacturers produce drive shafts with special materials or coatings?

Yes, many Chinese manufacturers can work with a variety of materials such as steel, aluminum, and carbon fiber, and can apply coatings like zinc, chrome, or powder coating.

5. What are the payment terms when ordering from China?

Common terms include a 30% deposit before production and 70% upon completion, often via T/T (telegraphic transfer). Some suppliers may accept L/C (letter of credit) for larger orders.

6. How can I handle shipping and customs for drive shafts from China?

Most suppliers offer FOB (Free on Board) terms. You can work with a freight forwarder to manage shipping and customs clearance.

7. Are there minimum order quantities (MOQs) for custom drive shafts?

MOQs vary by manufacturer, but typically range from 50 to 100 units. Some may be flexible, especially for first-time buyers or prototypes.

8. What is the cost range for custom drive shafts from China?

Costs depend on material, complexity, and quantity, but generally range from $50 to $500 per unit. Bulk orders usually receive discounted rates.

9. How do I verify the reliability of a Chinese supplier?

Check supplier references, review certifications, visit the factory if possible, and use platforms like Alibaba with verified suppliers.

10. What should I do if there are issues with my order?

Communicate directly with the supplier to resolve issues. If unresolved, you can seek mediation through trade platforms or consider third-party arbitration services.

These FAQs address common concerns and help streamline the process of sourcing custom drive shafts from China.