Comprehensive Guide: Reliable Slotting Machining Services at SourcifyChina Factory

Explore the dependable slotting machining services offered by SourcifyChina factory, ensuring precision, quality, and efficiency for all your manufacturing needs. Discover how their expertise and state-of-the-art technology can enhance your production processes.

Why Choose “SourcifyChina” Factory for Buyer Purchasing Slotting Machining from China?

SourcifyChina offers high-quality slotting machining services, ensuring precision and reliability in every product. Their advanced machinery and skilled workforce guarantee top-notch results, tailored to meet specific buyer requirements.

Additionally, SourcifyChina provides competitive pricing without compromising on quality, making them an ideal choice for cost-conscious buyers. Their transparent pricing model eliminates hidden costs, fostering trust and long-term partnerships.

Customer service is a top priority at SourcifyChina. They offer responsive communication, timely updates, and comprehensive support throughout the purchasing process, ensuring a smooth and efficient experience for buyers.

Furthermore, SourcifyChina adheres to stringent quality control measures, ensuring each product meets international standards. Their commitment to excellence is reflected in their consistent delivery of superior slotting machining solutions.

In conclusion, choosing SourcifyChina means investing in quality, reliability, and exceptional customer service, making them a preferred partner for buyers seeking top-tier slotting machining from China.

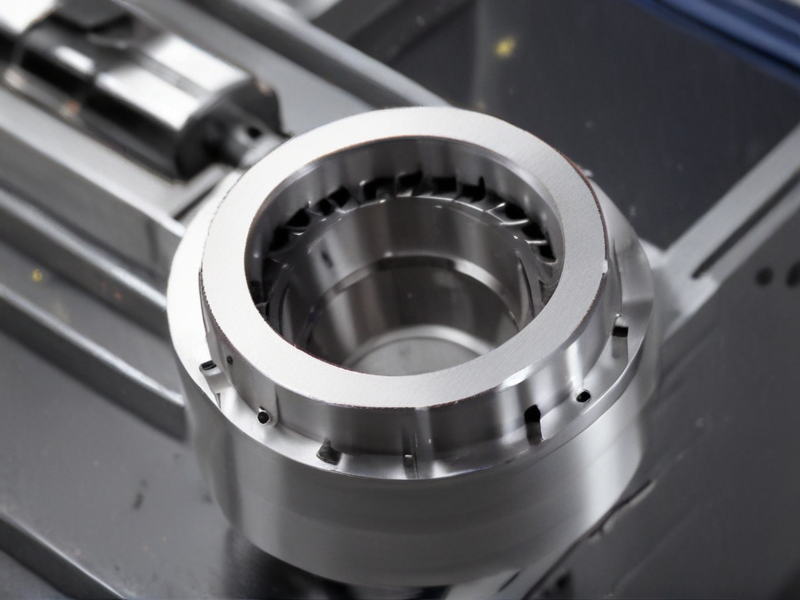

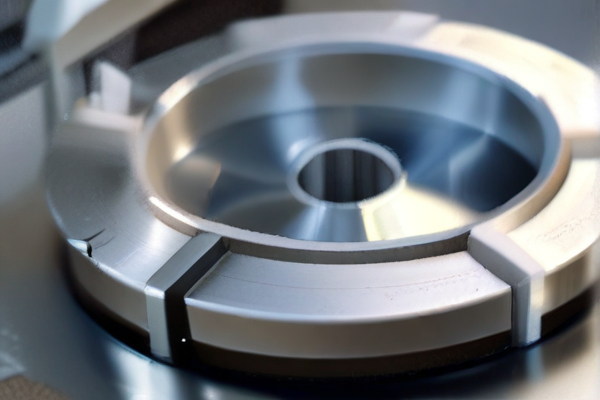

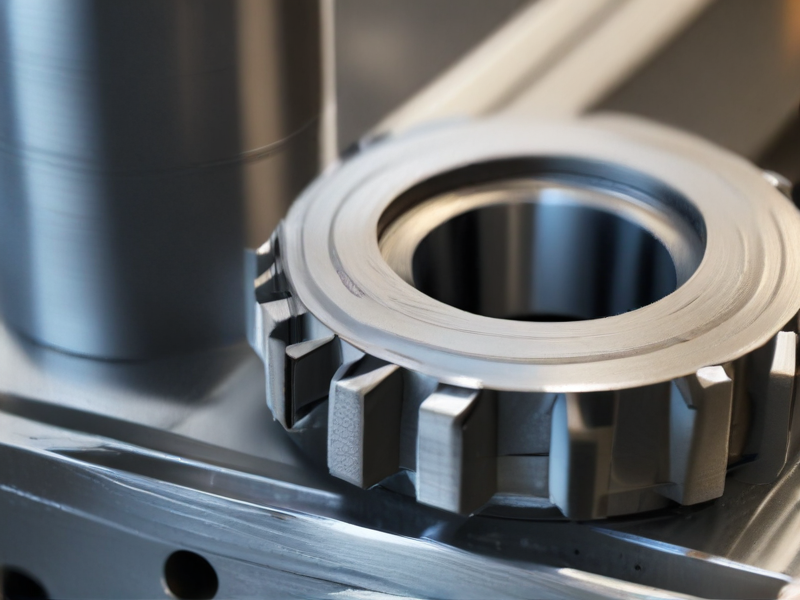

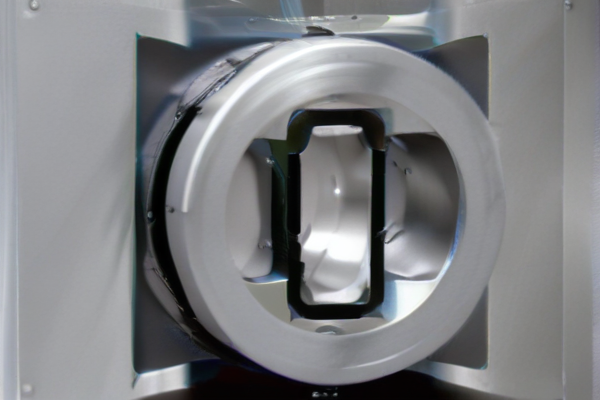

Slotting machining involves cutting slots or grooves into a workpiece, often used in creating keyways, splines, or intricate internal features. This process is vital in manufacturing and can be accomplished using various methods.

Types and options for slotting machining:

– Vertical Slotting Machine: Best for cutting internal keyways and splines.

– Horizontal Slotting Machine: Suitable for cutting external slots and flat surfaces.

– CNC Slotting Machine: Offers high precision and repeatability with computer control.

– Planer Slotting Machine: Ideal for heavy-duty slotting and large workpieces.

– Broaching: Effective for precision slots, especially in high-volume production.

– Shaping: Versatile for both internal and external slots, useful in small to medium batch production.

– Wire EDM (Electrical Discharge Machining): Excellent for intricate and hard-to-reach slots, providing high accuracy.

– Manual Slotting: Basic method for simple slots, used in small shops or for one-off projects.

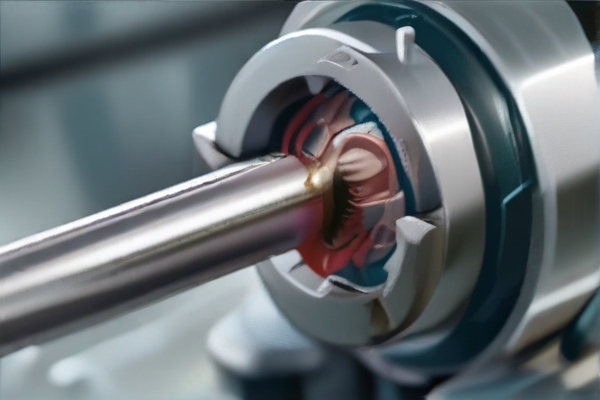

Slotting machining, also known as keyway cutting, is a versatile process used in various industries to produce precise internal slots or grooves. It’s essential for creating keyways, splines, and other internal profiles in components.

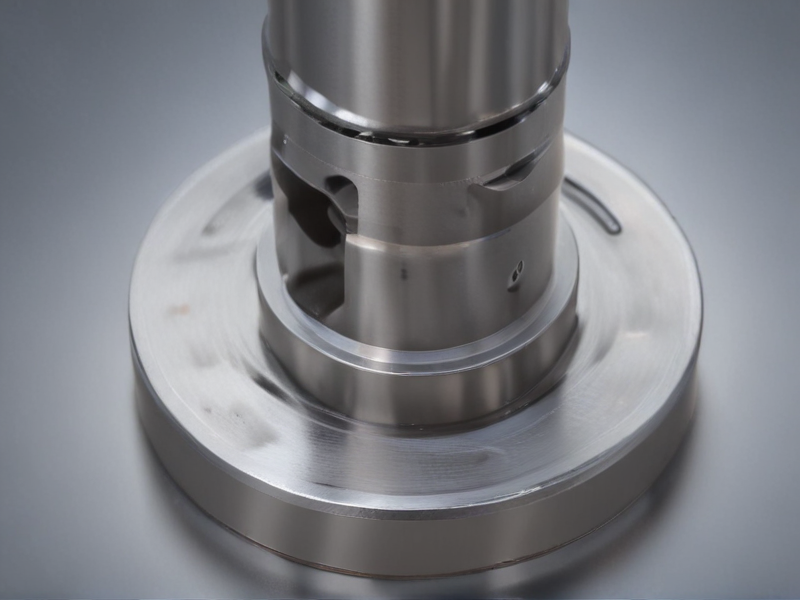

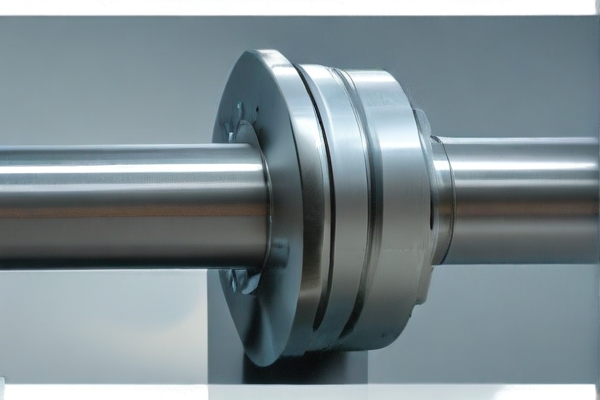

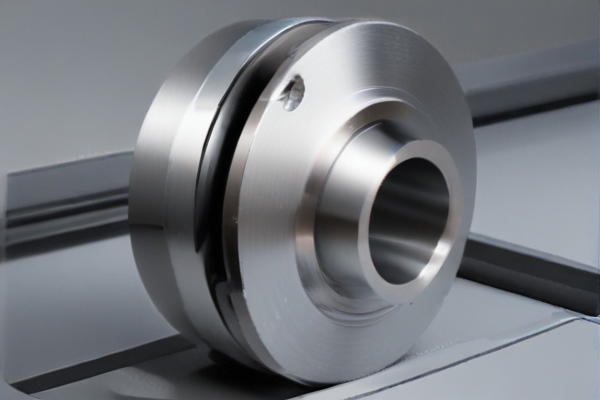

– Keyways and Splines: Critical for fitting gears and pulleys to shafts.

– Automotive Industry: Manufacture of transmission parts and engine components.

– Aerospace Industry: Producing precise parts for turbines and structural components.

– Tool and Die Making: Creating accurate internal features for molds and dies.

– Heavy Machinery: Construction of parts for cranes, excavators, and other heavy equipment.

– Medical Devices: Fabrication of intricate parts for surgical instruments and implants.

– Electrical Engineering: Manufacturing components like switches and connectors.

– Defense Sector: Producing parts for firearms and military vehicles.

– Robotics: Fabricating components for precise motion control and actuation.

– Renewable Energy: Construction of parts for wind turbines and hydroelectric generators.

Slotting machining’s ability to produce precise internal geometries makes it invaluable across a wide range of industries, ensuring the reliable performance of complex machinery and components.

Slotting machining is a critical process in the aerospace, defense, and marine industries, where precision and durability are paramount. This machining technique involves the creation of elongated slots or grooves in metal or composite components, essential for various applications such as the assembly of intricate structures, weight reduction, and the accommodation of wiring or tubing. In aerospace, slotting machining is used to manufacture components like wing spars and fuselage frames, ensuring they meet stringent specifications for strength and lightweight properties. The precision of slotting ensures that parts fit together seamlessly, enhancing the overall structural integrity and performance of aircraft.

In the defense and marine sectors, slotting machining plays a vital role in producing parts for vehicles, ships, and submarines that must withstand harsh environments and operational stresses. For instance, in defense applications, slotting is used in the manufacturing of armored vehicle components and weapon systems, where precise fits and robust joints are crucial for reliability and safety. In marine engineering, slotting machining aids in creating watertight joints and streamlined components that reduce drag and improve fuel efficiency. The ability to produce complex geometries with high accuracy ensures that slotting machining meets the rigorous demands of these industries, contributing to the development of advanced, reliable, and efficient systems.

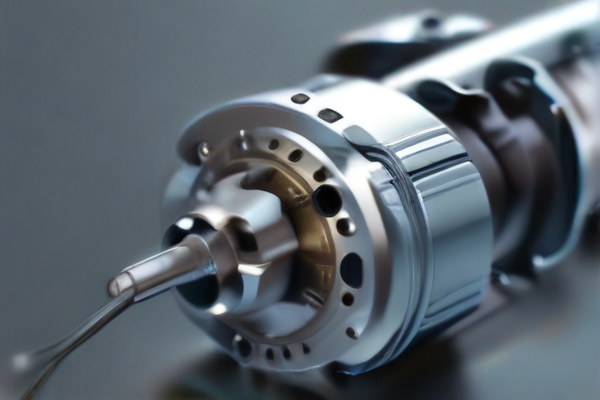

Slotting machining is a critical process in the automotive industry, primarily used to create precise slots and keyways in various engine components and mechanical parts. This technique enhances the performance and longevity of automotive components by ensuring accurate alignment and fit. For instance, the creation of keyways in crankshafts and camshafts is essential for the proper timing and operation of the engine. Additionally, slotting is used to produce slots in gears, which are vital for efficient power transmission. The precision offered by slotting machining ensures that these components operate smoothly under high stress and speed conditions, contributing to the overall reliability and efficiency of automotive systems.

In the electronics industry, slotting machining plays a pivotal role in manufacturing components that require high precision and miniaturization. This process is crucial for creating slots and grooves in printed circuit boards (PCBs) and semiconductor devices. Slotting allows for the integration of intricate designs and fine features necessary for the compact and high-performance requirements of modern electronic devices. For example, in PCB manufacturing, precise slots are needed for mounting components and ensuring electrical isolation. Additionally, slotting is used in the production of heat sinks and connectors, which are essential for thermal management and connectivity in electronic systems. The accuracy and precision of slotting machining help in maintaining the integrity and functionality of electronic components, thereby supporting the advancement of technology.

Slotting machining, a precise and versatile process, is pivotal in the construction and energy sectors for creating keyways, slots, and grooves in metal components. In construction, this technique is crucial for fabricating parts that require high precision and durability, such as structural supports, brackets, and machinery components. Slotting machines operate by moving a single-point cutting tool vertically, making them ideal for cutting internal shapes or intricate profiles that are challenging for other machines. This capability ensures that components fit together seamlessly, enhancing the overall integrity and stability of large structures.

In the energy sector, slotting machining plays a vital role in the manufacture of parts for turbines, generators, and other critical infrastructure. The precision offered by slotting is essential for components that must withstand extreme conditions and high-stress environments. For instance, the slots and keyways created are integral to the efficient operation of rotating machinery, ensuring secure fits and reliable performance. Additionally, slotting machining allows for the production of custom components that meet specific requirements, thus supporting innovation and the development of more efficient energy systems. Overall, the versatility and accuracy of slotting machining make it indispensable in these industries, contributing to both safety and efficiency.

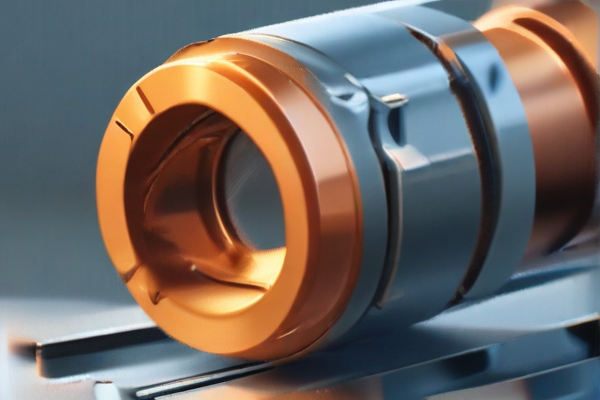

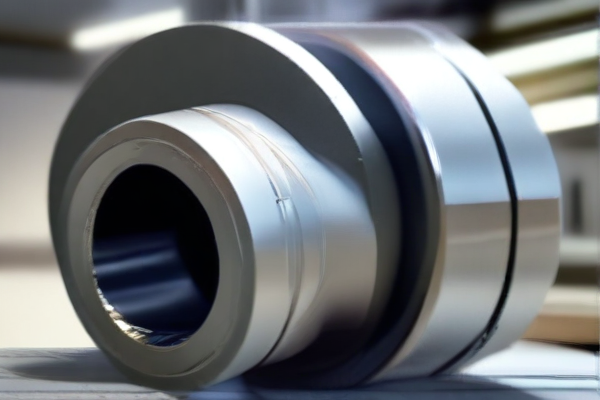

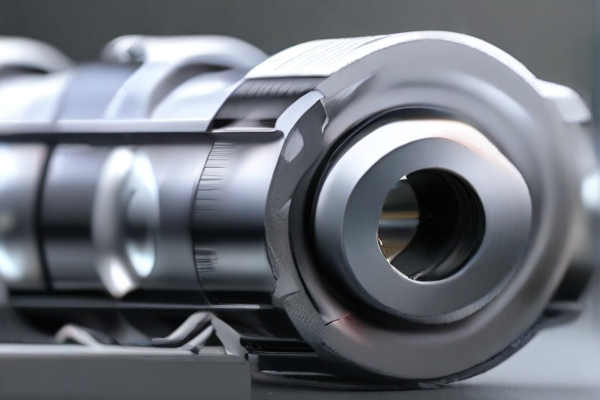

Slotting machining is a specialized process in the realm of industrial equipment, primarily used to create precise slots, grooves, and keyways in various materials. This method is essential for manufacturing components that require exact dimensions and intricate profiles. The slotting machine operates by employing a vertically reciprocating tool, which meticulously carves out the desired shape from the workpiece. This process is particularly advantageous for producing internal features that are difficult to achieve with other machining techniques. It can handle a wide range of materials, from metals like steel and aluminum to more resilient alloys, making it a versatile tool in industrial settings.

One of the key benefits of slotting machining is its ability to produce highly accurate and uniform slots, essential for parts that must fit together with tight tolerances. This precision ensures the reliability and performance of mechanical assemblies, especially in applications where exact alignment and fit are crucial. Furthermore, slotting machines can be adapted for both small-scale production and large-scale manufacturing, offering flexibility to manufacturers. The advancement in CNC (Computer Numerical Control) technology has further enhanced the capabilities of slotting machines, allowing for more complex and automated operations, thereby increasing efficiency and reducing human error. Overall, slotting machining remains a cornerstone process in the industrial equipment sector, valued for its precision, versatility, and reliability.

Slotting machining, a precision cutting process, plays a crucial role in the manufacture of medical devices. It involves creating slots or grooves in a workpiece using a tool with a single cutting edge. This method is particularly valued in the medical field for its ability to produce intricate and precise features necessary for devices like surgical instruments, implants, and components of diagnostic equipment. The accuracy of slotting machining ensures tight tolerances and clean finishes, which are vital for the functionality and safety of medical devices. Moreover, the process can be adapted to work with various materials, including metals, plastics, and composites, making it versatile for different types of medical device manufacturing.

In the context of medical devices, slotting machining offers significant advantages in terms of customization and consistency. Each device often requires specific features tailored to its application, and slotting allows for these precise adjustments. For example, the creation of custom slots in orthopedic implants can enhance their integration and performance within the human body. Additionally, the method’s consistency ensures that each device meets stringent regulatory standards, reducing the risk of defects and improving patient outcomes. The ability to produce complex geometries with high repeatability makes slotting machining an indispensable technique in the medical device industry, contributing to innovations and advancements in healthcare technology.

Slotting machining is a precision metalworking process used to create vertical slots, grooves, and keyways in a workpiece. The process involves the use of a slotting machine or slotter, which operates with a vertically reciprocating single-point cutting tool. This tool moves up and down to progressively remove material, creating precise and uniform slots. Slotting is particularly advantageous for applications requiring internal keyways or irregular shapes within a confined area, which are challenging to achieve with other machining processes. This method is widely used in the production of machine parts, automotive components, and various other industrial applications, where precise slot dimensions and finishes are critical.

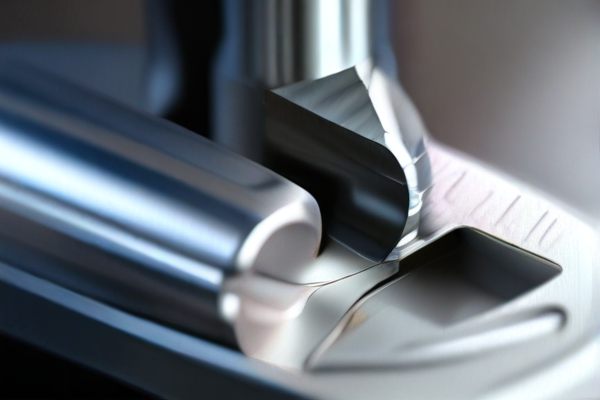

One of the key benefits of slotting machining is its ability to produce accurate and repeatable slots with tight tolerances. The process allows for excellent control over the depth and width of the cut, making it ideal for creating complex geometries in hard-to-machine materials like hardened steel and alloys. Additionally, slotting machines can be equipped with different types of cutting tools, such as form tools and slotting tools, to accommodate various design requirements. Despite its advantages, slotting machining can be time-consuming compared to other processes like milling or broaching, particularly for large-scale production runs. However, its precision and versatility often outweigh the longer cycle times, making it a valuable technique in many high-precision manufacturing environments.

SourcifyChina specializes in slotting machining, utilizing high-quality materials to ensure precision and durability. Their material choices include various grades of steel, aluminum, and alloys, which are selected based on the specific requirements of the machining process. These materials are known for their excellent machinability, strength, and resistance to wear and tear.

The steel used in SourcifyChina’s slotting machining is often high-carbon or alloy steel, providing exceptional hardness and stability. This ensures the final product can withstand significant stress and maintain its shape and performance over time, even in demanding applications.

Aluminum is another preferred material, valued for its lightweight nature and excellent thermal conductivity. It is particularly suitable for applications where weight reduction is crucial without compromising strength. SourcifyChina uses high-grade aluminum to achieve precise and smooth slots.

For specialized applications, SourcifyChina employs various alloys that offer a balance of properties such as corrosion resistance, high tensile strength, and durability. These alloys are tailored to meet the specific needs of complex and high-performance slotting projects.

SourcifyChina’s commitment to using top-tier materials in slotting machining ensures that their products meet rigorous quality standards. By selecting the right materials, they can produce components that deliver superior performance, longevity, and reliability in a wide range of industrial applications. This meticulous approach to material selection underscores SourcifyChina’s dedication to excellence in slotting machining.

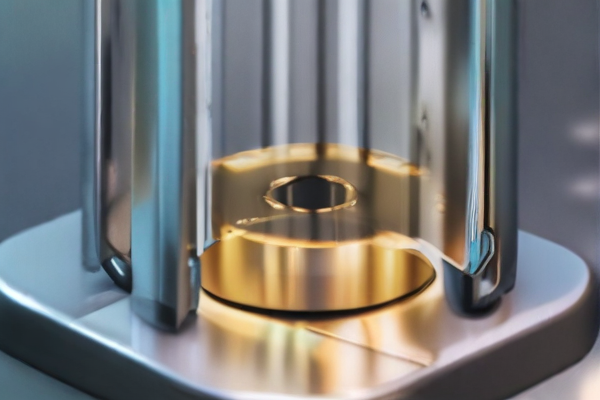

SourcifyChina’s slotting machining process adheres to stringent quality control measures to ensure high precision and consistency. The process begins with the careful selection of raw materials, ensuring they meet industry standards for strength and durability.

Advanced CNC machines are used, programmed with precise specifications to achieve exact slot dimensions. This minimizes errors and enhances the uniformity of the final product. Regular machine maintenance and calibration are integral to maintaining optimal performance and accuracy.

During production, in-process inspections are conducted to detect any deviations or defects. These inspections include dimensional checks, surface finish evaluations, and material integrity assessments, ensuring that each component meets the required tolerances.

Post-machining, all parts undergo a thorough quality assurance review. This involves comprehensive testing, including hardness testing and stress analysis, to confirm the parts’ ability to withstand operational demands. Non-conforming parts are rejected and analyzed to identify the root cause of the issue.

SourcifyChina employs continuous improvement methodologies, such as Six Sigma and Lean Manufacturing, to refine the slotting machining process. Feedback from these practices is used to enhance process efficiency and product quality, ensuring that customers receive components that meet or exceed their expectations.

To maintain high standards, SourcifyChina invests in employee training programs. Skilled operators and quality control inspectors are trained to use the latest technologies and techniques, ensuring a high level of craftsmanship and attention to detail in every part produced.

In summary, SourcifyChina’s quality control in slotting machining encompasses meticulous material selection, advanced machinery, rigorous inspections, and continuous improvement. This comprehensive approach guarantees that each product adheres to the highest standards of precision and reliability, solidifying SourcifyChina’s reputation as a leader in manufacturing excellence.

SourcifyChina specializes in slotting machining, offering precise and efficient solutions for complex slotting needs. They utilize advanced CNC technology to achieve high accuracy and repeatability in their machining processes.

Their capabilities include creating intricate slots in various materials, such as metals, plastics, and composites. This versatility makes them a preferred partner for industries ranging from automotive to aerospace.

SourcifyChina’s slotting machining ensures tight tolerances and smooth finishes, enhancing the performance and reliability of the final product. Their skilled technicians and engineers are adept at handling both small and large production runs.

In addition to standard slotting, they provide custom machining solutions tailored to specific client requirements. This customization is supported by their robust quality control processes, ensuring each piece meets stringent industry standards.

Overall, SourcifyChina’s slotting machining capabilities offer a comprehensive solution for businesses seeking precision, quality, and flexibility in their manufacturing processes. Their commitment to excellence and customer satisfaction sets them apart in the competitive machining industry.

Slotting machining offers significant advantages in precision and efficiency, making it essential for creating internal keyways, slots, and grooves.

– Precision and Accuracy: Slotting machines deliver high accuracy, crucial for tight tolerance applications.

– Versatility: They can handle various materials, including metals and plastics.

– Complex Geometries: Capable of producing intricate internal shapes that other machining processes might struggle with.

– Cost-Effective: Reduces the need for multiple setups and machines, saving time and cost.

– Surface Finish: Produces a superior surface finish, reducing the need for secondary operations.

– Customization: Easily adaptable for custom and short-run production.

– Automation: Modern slotting machines can be automated, improving consistency and reducing manual labor.

Overall, slotting machining is a versatile and efficient method that enhances manufacturing capabilities.

Slotting machining, also known as keyway cutting or slotting, involves cutting keyways, splines, or slots in workpieces using a slotting machine. This process is essential for creating internal features in gears, pulleys, and similar components.

Key features of slotting machining include:

– Vertical Cutting Motion: Uses a vertically reciprocating single-point cutting tool.

– Precision: High accuracy in producing internal slots and grooves.

– Versatility: Suitable for various materials like metals and plastics.

– Tooling: Utilizes different tools for specific shapes and sizes of slots.

– Complex Geometries: Capable of machining intricate internal profiles.

– Automation: Modern machines often feature CNC capabilities for increased efficiency.

– Surface Finish: Provides a good surface finish with proper tooling and parameters.

– Customization: Can be adapted for custom applications and unique slot shapes.

SourcifyChina specializes in precision slotting machining, offering custom products tailored to meet specific industry needs. Their expertise ensures high-quality, accurate results for various applications.

Using advanced technology, SourcifyChina creates bespoke components, enhancing performance and durability. This precision is critical for sectors requiring exact tolerances and reliable parts.

Their slotting machining services cater to industries such as automotive, aerospace, and manufacturing. SourcifyChina’s ability to handle complex projects sets them apart from competitors.

Committed to client satisfaction, SourcifyChina offers comprehensive support throughout the project lifecycle. Their dedication to excellence ensures each custom product meets stringent quality standards.

By integrating innovative techniques and rigorous quality control, SourcifyChina consistently delivers superior slotting machining solutions. Their focus on precision and customization drives industry advancements.

With a team of skilled engineers, SourcifyChina tackles challenging machining tasks, producing components that meet the highest specifications. Their dedication to continuous improvement fosters client trust and long-term partnerships.

Overall, SourcifyChina’s slotting machining services are essential for clients seeking top-tier custom products. Their blend of technology, expertise, and client focus ensures successful project outcomes.

SourcifyChina is a leading company specializing in slotting machining services, providing precision engineering solutions to a diverse range of industries. Renowned for its high-quality craftsmanship, SourcifyChina leverages advanced CNC technology and state-of-the-art equipment to deliver intricate slotting tasks with unparalleled accuracy. The company prides itself on a customer-centric approach, offering customized machining solutions that meet the specific requirements of each client. With a team of experienced engineers and technicians, SourcifyChina ensures that every project is executed to the highest standards, adhering to stringent quality control processes. Their expertise extends to various materials, including metals and plastics, making them a versatile partner for manufacturing needs. Committed to innovation and efficiency, SourcifyChina continues to expand its capabilities, investing in new technologies and continuous training for its workforce. This dedication to excellence has established SourcifyChina as a trusted name in the slotting machining industry, known for its reliability, precision, and exceptional customer service.

Slotting machining is crucial in aerospace applications due to its precision and ability to produce complex geometries. This machining process involves creating slots, grooves, or keyways in metal or composite components, essential for manufacturing aircraft structures and engine parts. In aerospace, slotting is used to create tight tolerance slots in turbine blades, which are vital for enhancing aerodynamic performance and fuel efficiency. The precision and reliability of slotting machining ensure that the components meet the stringent safety and performance standards required in the aerospace industry.

In the defense and marine sectors, slotting machining is equally significant. In defense, it is used to manufacture parts for vehicles, weapons systems, and communication equipment, where precision and durability are paramount. Slotting allows for the creation of intricate components like locking mechanisms and housings that must withstand harsh conditions and extreme stress. In the marine industry, slotting machining is employed to produce parts for engines, propellers, and hull structures. These components require robust construction to endure corrosive marine environments and heavy loads. The versatility and accuracy of slotting machining make it indispensable across these industries, ensuring the production of high-quality, reliable components.

Slotting machining is a crucial process in the automotive industry, primarily used for creating internal keyways and slots within components such as gears, pulleys, and shafts. This precision machining technique enables the production of parts with tight tolerances and specific geometric requirements, essential for the high performance and reliability of automotive systems. For instance, in transmission systems, slotting ensures the proper fitting of gears and other components, facilitating smooth and efficient power transfer. Additionally, the ability to produce complex profiles and internal shapes enhances the overall functionality and durability of automotive parts, which is critical for safety and longevity in vehicles.

In the electronics industry, slotting machining is employed to manufacture intricate components that are fundamental to various devices and systems. It is particularly useful in the production of enclosures, connectors, and heat sinks, where precision slots and keyways are necessary for proper assembly and functionality. For example, slotting allows for the precise alignment and securing of circuit boards within enclosures, ensuring optimal performance and protection of electronic components. Furthermore, the technique is pivotal in the creation of cooling solutions, such as heat sinks, where precise slots improve heat dissipation and maintain the operational efficiency of electronic devices. The versatility and precision of slotting machining make it indispensable in the production of high-quality, reliable electronic products.

Slotting machining plays a pivotal role in the construction industry by enabling the precise cutting of slots and keyways in materials used for structural and architectural purposes. This technique is essential for creating intricate and accurate slots in steel beams, columns, and other structural elements, ensuring that components fit together seamlessly during assembly. The precision of slotting machining enhances the integrity and stability of construction frameworks, which is critical in high-rise buildings and bridges. Additionally, slotting is utilized in the fabrication of custom doors, windows, and other architectural details, allowing for unique design features while maintaining structural reliability.

In the energy sector, slotting machining is crucial for the production and maintenance of various energy systems, particularly in the manufacturing of components for turbines, generators, and engines. The ability to produce precise slots and keyways ensures that parts such as shafts, gears, and couplings operate efficiently and reliably, which is vital for the performance and longevity of energy-generating equipment. Slotting is also employed in the creation of heat exchangers and other complex machinery used in both fossil fuel and renewable energy plants. This machining process contributes to the overall efficiency and safety of energy systems by enabling the production of high-quality, durable components that can withstand the rigorous demands of energy generation and distribution.

Slotting machining, a precise and versatile technique, plays a crucial role in the industrial equipment industry. This method involves creating slots or keyways on the surface of metal or other materials, typically using a vertical shaper or slotting machine. Its ability to produce accurate, repeatable cuts makes it indispensable for manufacturing components that require precise dimensions and high-quality finishes. In the industrial equipment sector, slotting machining is often used to fabricate parts like gears, pulleys, and engine components, where exact alignment and fit are critical. The ability to produce complex shapes and internal profiles further extends its application, ensuring that intricate machinery parts can be manufactured to stringent specifications.

Moreover, slotting machining contributes significantly to the efficiency and reliability of industrial equipment. By facilitating the production of components with tight tolerances and smooth finishes, it enhances the overall performance and lifespan of machinery. This precision reduces the need for additional finishing processes, thereby streamlining production and reducing costs. Additionally, slotting machining supports the customization and prototyping of industrial equipment, allowing for rapid adjustments and innovations in design. The technique’s versatility means it can be adapted for a wide range of materials, from hardened steels to softer metals and plastics, making it a fundamental process in the production and maintenance of diverse industrial machinery.

Slotting machining plays a critical role in the manufacturing of medical devices, offering precise and efficient solutions for creating intricate components. This machining process involves the use of a slotting machine to cut slots or grooves into metal or plastic parts, which are essential for assembling and operating various medical instruments. For instance, surgical tools such as forceps, clamps, and scissors require finely machined slots to ensure proper alignment and function. Additionally, medical implants, including orthopedic devices and dental implants, often incorporate slots to accommodate screws or to enable secure attachment to bone structures. The precision offered by slotting machining ensures that these medical devices meet stringent regulatory standards and function reliably in critical healthcare environments.

Moreover, slotting machining enhances the production of advanced medical devices by enabling the creation of complex geometries that are difficult to achieve through other manufacturing methods. This capability is particularly beneficial in the fabrication of minimally invasive surgical instruments, where small, precise slots are necessary for the movement and control of tiny components. The ability to machine such detailed features with high accuracy reduces the risk of component failure and enhances the overall safety and effectiveness of the devices. Furthermore, slotting machining can be integrated with computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, allowing for the customization of medical devices to meet specific patient needs. This adaptability is crucial for the development of personalized medical solutions, advancing the field of medical technology and improving patient outcomes.

Slotting machining, a type of vertical shaper, is an essential technique in the machining and manufacturing industry. It involves a reciprocating cutting action, which is particularly effective for creating internal shapes and keyways within a workpiece. This method is used extensively for crafting complex geometries and intricate designs that are challenging to achieve with other machining processes. Slotting machines operate by moving a single-point cutting tool in a linear motion, producing precise cuts with high accuracy. This precision makes slotting particularly valuable for producing components that require tight tolerances and high surface finish quality, such as gears, pulleys, and various automotive parts.

In manufacturing, slotting machining is prized for its versatility and efficiency. It can handle a variety of materials, including metals, plastics, and composites, making it suitable for diverse applications across multiple industries. The ability to create internal profiles, such as square or irregularly shaped holes, enhances its utility in manufacturing custom and specialized parts. Moreover, slotting machines can be integrated into automated production lines, contributing to higher productivity and consistent quality. The adaptability of slotting machining to both small-scale custom jobs and large-scale production runs underscores its importance in modern manufacturing, driving innovation and supporting the development of advanced mechanical systems.

Q: What is slotting machining?

A: Slotting machining is a process used to create slots or grooves in a workpiece. It involves using a tool that moves linearly to cut material and produce the desired slot shape.

Q: Why choose SourcifyChina for slotting machining?

A: SourcifyChina offers high-quality slotting machining services with precision and accuracy. Our advanced machinery and experienced technicians ensure top-notch results for various applications.

Q: What materials can SourcifyChina handle for slotting machining?

A: We can work with a wide range of materials including metals (steel, aluminum, brass), plastics, and composites. Our equipment is capable of handling both hard and soft materials efficiently.

Q: How does SourcifyChina ensure the quality of slotting machining?

A: Quality is ensured through stringent quality control measures, regular inspections, and the use of advanced CNC machines. We follow international standards and provide detailed quality reports for each project.

Q: What industries do you serve with your slotting machining services?

A: We serve a variety of industries including automotive, aerospace, electronics, medical devices, and industrial machinery. Our services are tailored to meet the specific needs of each industry.

Q: Can SourcifyChina handle custom slotting machining projects?

A: Yes, we specialize in custom slotting machining projects. Our team works closely with clients to understand their requirements and deliver customized solutions that meet their exact specifications.

Q: What is the turnaround time for slotting machining projects?

A: Turnaround time varies depending on the complexity and size of the project. We strive to complete projects promptly without compromising on quality. Typical lead times range from a few days to several weeks.

Q: How can I get a quote for my slotting machining project?

A: You can get a quote by contacting us through our website, email, or phone. Provide detailed information about your project, including material, dimensions, and quantity, and we will offer a competitive quote.

Q: Does SourcifyChina offer post-machining services?

A: Yes, we offer a range of post-machining services such as surface finishing, heat treatment, and assembly to ensure your parts are ready for use.

Q: What payment methods do you accept?

A: We accept various payment methods including wire transfer, credit card, and PayPal. Payment terms can be discussed and agreed upon during the quotation process.

Slotting machining is a precise and efficient method used in manufacturing to create slots or grooves in a variety of materials. SourcifyChina Factory offers specialized services in this area, ensuring high-quality results. Here are some tips for effective slotting machining:

1. Material Selection: Choose the right material for the slotting process. Common materials include metals like aluminum, steel, and alloys, as well as plastics. Each material requires specific tools and settings.

2. Tool Selection: Use appropriate slotting tools, such as single-point cutting tools or broaches. Ensure they are made of high-speed steel (HSS) or carbide for better durability and performance.

3. Machine Settings: Adjust the machine settings according to the material hardness and slot dimensions. This includes spindle speed, feed rate, and depth of cut. Proper settings reduce tool wear and improve finish quality.

4. Cooling and Lubrication: Implement adequate cooling and lubrication to minimize heat generation and prevent tool wear. Coolants also help in flushing away chips from the cutting area.

5. Precision and Accuracy: Ensure precise alignment of the workpiece and tool. Use fixtures and clamps to secure the workpiece and avoid movement during the process. Regularly check and calibrate the machine for maintaining accuracy.

6. Quality Control: Perform regular inspections of the slots to ensure they meet the required specifications. Use measuring tools like calipers and micrometers to check dimensions and tolerances.

7. Maintenance: Keep the slotting machine well-maintained by regularly cleaning and inspecting for any signs of wear or damage. Replace worn-out tools promptly to maintain quality.

8. Expertise and Training: Ensure operators are well-trained and experienced in slotting machining techniques. Continuous learning and staying updated with the latest advancements in machining technology can lead to better efficiency and outcomes.

By following these tips, SourcifyChina Factory can ensure efficient and high-quality slotting machining processes, meeting the diverse needs of their clients.

1. What is slotting machining?

Slotting machining is a process used to cut slots, grooves, and other shapes into materials using a vertical tool that reciprocates, or moves back and forth.

2. Why should I choose SourcifyChina for slotting machining?

SourcifyChina offers high-quality slotting machining services with advanced equipment, experienced technicians, and competitive pricing. Their commitment to precision and customer satisfaction makes them a reliable choice.

3. What materials can SourcifyChina machine?

SourcifyChina can machine a variety of materials, including metals (such as steel, aluminum, and brass) and plastics. They can accommodate specific material requirements based on your project needs.

4. What are the tolerances that SourcifyChina can achieve?

SourcifyChina can achieve tight tolerances, typically up to ±0.01mm, depending on the material and design specifications. Detailed tolerance capabilities should be discussed during the consultation phase.

5. How do I request a quote for slotting machining services?

To request a quote, provide your detailed drawings or specifications, material requirements, and quantity. You can submit this information through SourcifyChina’s website or contact their sales team directly.

6. What is the lead time for slotting machining orders?

Lead times vary depending on the complexity and quantity of the order. Typically, lead times range from 2 to 4 weeks. For urgent orders, expedited services may be available upon request.

7. Does SourcifyChina offer prototyping services?

Yes, SourcifyChina offers prototyping services to help you validate your designs before full-scale production. Prototyping ensures that the final product meets your specifications and functional requirements.

8. What quality control measures does SourcifyChina implement?

SourcifyChina employs rigorous quality control measures, including in-process inspections and final quality checks. They use advanced measurement tools and techniques to ensure all parts meet the specified tolerances and standards.

9. Can SourcifyChina handle large production runs?

Yes, SourcifyChina is equipped to handle both small and large production runs. Their scalable production capabilities allow them to meet the demands of various order sizes efficiently.

10. How can I contact SourcifyChina for more information?

You can contact SourcifyChina through their website, email, or phone. Their customer service team is ready to assist with any inquiries or provide additional information about their slotting machining services.

When sourcing slotting machining services from SourcifyChina factory, consider the following tips to ensure a successful partnership:

1. Research and Verification:

– Begin by researching SourcifyChina’s reputation. Look for reviews, testimonials, and case studies from previous clients.

– Verify the factory’s credentials, certifications, and compliance with industry standards.

2. Detailed Requirements:

– Provide detailed specifications for your slotting machining needs. Include material types, dimensions, tolerances, and any special requirements.

– Share drawings, CAD files, and other technical documents to avoid misunderstandings.

3. Communication:

– Establish clear lines of communication. Use email, video calls, and messaging apps for regular updates.

– Ensure there is no language barrier. Utilize translators if necessary to prevent miscommunication.

4. Quality Control:

– Request samples or prototypes before committing to large orders. Evaluate these samples thoroughly.

– Ask about the factory’s quality control processes. Ensure they have rigorous inspection and testing protocols in place.

5. Production Capabilities:

– Confirm that SourcifyChina has the necessary machinery and technology to handle your slotting machining requirements.

– Inquire about their production capacity to ensure they can meet your deadlines.

6. Pricing and Terms:

– Discuss pricing in detail. Make sure you understand the cost structure, including any additional fees.

– Negotiate payment terms and ensure they are favorable and clear.

7. Lead Times and Shipping:

– Clarify lead times for production and shipping. Ensure they align with your project timelines.

– Discuss shipping methods and costs. Confirm that SourcifyChina can handle international logistics efficiently.

8. Legal Considerations:

– Draft a detailed contract outlining all terms, conditions, and expectations.

– Protect your intellectual property by including confidentiality agreements if necessary.

9. After-Sales Support:

– Inquire about after-sales support and warranty policies. Ensure you have a clear understanding of how issues will be handled post-delivery.

By following these tips, you can effectively source slotting machining services from SourcifyChina, ensuring high-quality production and smooth collaboration.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.