Discover

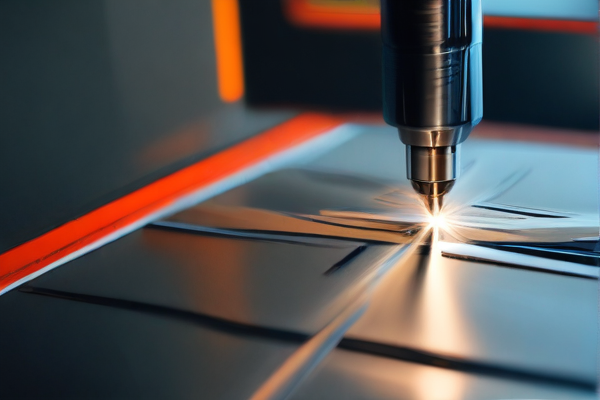

the Reliable “SourcifyChina Factory Laser Cutting Machine for Steel”: Precision Engineering for Your Industrial Needs

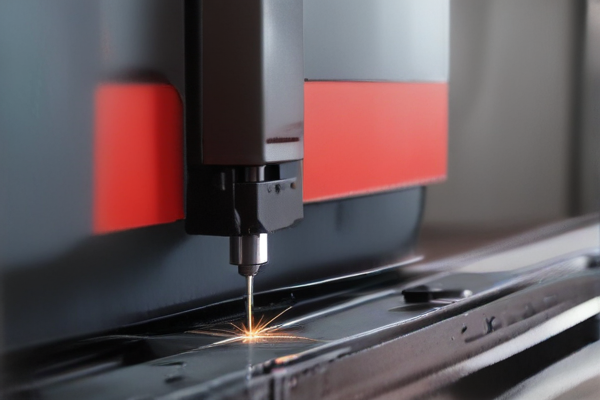

When it comes to precision and reliability, the “SourcifyChina factory laser cutting machine for steel” stands out as a top-tier choice for industrial applications. Known for its exceptional cutting accuracy and robust build, this machine ensures that your steel cutting tasks are handled with utmost efficiency and minimal waste.

Designed by SourcifyChina, a trusted name in the manufacturing industry, this laser cutting machine integrates advanced technology to deliver high-speed operations without compromising on quality. Its user-friendly interface and customizable settings make it an ideal solution for both small-scale workshops and large-scale production facilities.

One of the key features of the SourcifyChina laser cutting machine is its ability to maintain consistent performance even under heavy-duty conditions. This reliability reduces downtime and enhances productivity, making it a cost-effective investment for your business. Additionally, the machine’s precision in cutting complex shapes and intricate designs ensures that your products meet the highest standards of quality.

Furthermore, the laser cutting machine is equipped with safety features that protect operators, ensuring a secure working environment. SourcifyChina’s commitment to excellence is evident in their rigorous testing and quality assurance processes, which guarantee that each machine meets international standards.

In conclusion, the “SourcifyChina factory laser cutting machine for steel” offers unparalleled precision, reliability, and efficiency. Whether you are looking to improve your production capabilities or seeking a dependable machine for intricate steel cutting tasks, SourcifyChina’s laser cutting machine is the perfect choice to meet your industrial needs.

Choosing SourcifyChina Factory for purchasing laser cutting machines for steel offers distinct advantages. They provide state-of-the-art technology, ensuring top-notch precision and efficiency in metal fabrication processes. Their competitive pricing guarantees value without compromising quality, making them an ideal choice for cost-effective solutions.

SourcifyChina also places a high emphasis on customer satisfaction, offering comprehensive after-sales support and training. This ensures that buyers can make the most of their investment, minimizing downtime and maximizing productivity. With a strong focus on innovation, they continually update their machines to cater to evolving industrial needs.

Moreover, the factory has a proven track record of reliability, with numerous positive testimonials from global clients. Their transparent business practices and excellent communication further instill confidence in buyers. They offer customizable machine options to cater to specific requirements, enhancing operational flexibility for various business scales.

In summary, SourcifyChina Factory stands out for its advanced technology, exceptional customer service, and customization prowess, making it the preferred choice for acquiring high-quality laser cutting machines for steel from China.

Laser cutting machines for steel come in various types such as fiber lasers, CO2 lasers, and Nd:YAG lasers. These machines offer precision, high speed, and versatility for cutting different steel thicknesses and types.

– Fiber Lasers:

– Efficient and fast for cutting thin to medium-thickness steel

– Low maintenance with a long lifespan

– High energy efficiency and precision

– CO2 Lasers:

– Versatile for cutting various materials, including steel

– Ideal for thicker steel sheets

– Higher maintenance but provides smooth cut edges

– Nd:YAG Lasers:

– Suitable for high-speed drilling and cutting

– Less common for general steel cutting

– High initial cost but specialized for specific applications

– Options to Consider:

– Power Levels: Machines offer different power ranges (e.g., 500W to 10kW) affecting cutting speed and thickness capabilities.

– Automation Features: Automated loading, unloading, and cutting processes can increase efficiency.

– Cooling Systems: Proper cooling systems prevent overheating and ensure continuous operation.

– Software Integration: Advanced software options for design and real-time monitoring.

– Safety Features: Comprehensive safety measures like enclosure and fume extraction systems.

– Table Size: Varying table sizes to accommodate different steel sheet dimensions.

– Cost: Options from entry-level to high-end machines based on performance and features.

These variables help in selecting the right laser cutting machine for your specific steel cutting needs.

Laser cutting machines for steel are essential in various industries, offering precision and efficiency. They are used for custom fabrications, automotive parts, and intricate designs in architecture.

– Custom Fabrications: Create bespoke metal components with high precision.

– Automotive Parts: Manufacture parts with exact specifications quickly.

– Architecture: Produce intricate and decorative steel elements.

– Shipbuilding: Cut steel plates and components for ships and submarines.

– Aerospace: Fabricate lightweight yet durable aviation parts.

– Manufacturing: High-speed production of components and machinery parts.

– Medical Devices: Develop innovative and precise medical instruments.

– Electronics: Cut casings and components for electronic devices.

– Construction: Shape structural elements like beams and panels.

– Art and Sculpture: Craft detailed and intricate steel artworks.

– Agricultural Equipment: Manufacture robust and durable farming machinery parts.

– Heavy Machinery: Produce large components with complex shapes.

– Signage: Create precise and polished metal signs and displays.

– Prototyping: Rapidly develop and test new designs and concepts.

– Renewable Energy: Manufacture components for wind turbines and solar panels.

– Military and Defense: Produce parts for vehicles, weapons, and protective gear.

– Tool and Die Making: Precision cutting for molds and dies.

– Metal Furniture: Design and produce unique and robust pieces.

– HVAC Systems: Create components for heating, ventilation, and air conditioning.

– Jewelry: Craft fine and detailed steel jewelry pieces.

– Research and Development: Facilitate advanced material studies and prototypes.

– Electromechanical Assemblies: Produce complex and precise parts for assemblies.

– Railway Industry: Manufacture components for trains and railway infrastructure.

– Robotics: Create parts and frames for robotic systems.

– Plumbing and Pipework: Fabricate intricate pipe fittings and connectors.

– Kitchen Equipment: Produce durable and hygienic kitchen appliances.

– Pipelines: Cut segments with high precision for oil and gas transport.

– Telecommunications: Manufacture enclosures and brackets for telecom equipment.

– Furniture Hardware: Produce hinges, brackets, and other metal fittings.

– Mining Equipment: Create robust parts for mining machinery and tools.

– Instrumentation: Fabricate precision parts for measuring and control instruments.

– Food Processing: Manufacture sanitary and durable equipment.

– Automated Machines: Produce components for automated and robotic systems.

– Outdoor Equipment: Create durable and weather-resistant components.

– Fashion Accessories: Fabricate designer steel accessories.

– Traffic Signs: Cut and shape steel for durable road signs.

Laser cutting machines for steel are revolutionizing the Aerospace, Defense, and Marine industries by offering unmatched precision and efficiency. In aerospace, the demand for intricate and lightweight components is high, and laser cutting technologies cater to this by producing parts with exceptional accuracy and minimal material wastage. High-powered lasers can cut through various thicknesses of steel, enabling the production of complex geometries that would be impossible with traditional cutting methods. This precision is crucial for ensuring the aerodynamic performance and structural integrity of aircraft, where even minor deviations can have significant consequences.

In the Defense and Marine sectors, laser cutting machines provide a robust solution for manufacturing durable and reliable components essential for mission-critical applications. The ability to produce high-quality cuts at remarkable speeds enhances production efficiency, meeting the stringent timelines often associated with defense contracts. Furthermore, laser cutting is a non-contact process, reducing the risk of material contamination and ensuring consistent quality. For marine applications, where corrosive environments are a major concern, the precision cutting of stainless steel and other specialized alloys contributes to the longevity and performance of vessels. Overall, the adaptability, precision, and efficiency of laser cutting machines make them indispensable assets across these high-stakes industries.

Laser cutting machines for steel have revolutionized the manufacturing processes in both the automotive and electronics industries. In automotive manufacturing, precision, speed, and efficiency are paramount. Laser cutting machines provide all these by enabling the production of highly precise components with minimal material waste. Whether cutting intricate designs or larger structural components, these machines ensure that each piece meets exact specifications, which is crucial for the automotive industry’s demand for high-quality and safety-compliant parts. Additionally, laser cutting technology enhances production flexibility, allowing manufacturers to quickly adapt to design changes or new production requirements without significant downtime, thus optimizing the manufacturing workflow and reducing lead times.

In the electronics sector, the precision of laser cutting machines is indispensable. As electronic devices become increasingly complex and miniaturized, the need for components with high precision and clean edges has grown. Laser cutters are capable of producing extremely fine cuts and detailed engravings on steel, which is essential for fabricating parts like metal enclosures, circuit boards, and other intricate components. Moreover, the ability to create detailed and complex patterns with tight tolerances means that manufacturers can continuously innovate, producing smaller, more efficient, and higher-performing electronic devices. This precision not only ensures the functionality and reliability of the end products but also streamlines the production process, reducing errors and enhancing overall efficiency.

In the realm of Construction and Energy sectors, the advent of laser cutting machines for steel has revolutionized the efficiency and precision of materials fabrication. These sophisticated machines employ high-powered lasers that can slice through steel with remarkable accuracy, allowing for intricate designs and minimized material wastage. The streamlined cutting process not only substantially reduces labor costs but also accelerates project timelines, providing construction companies with a crucial competitive edge. Furthermore, laser cutting ensures cleaner edges and reduces the need for additional finishing processes, thereby enhancing the overall quality and durability of steel components used in building frameworks, energy plants, and infrastructural projects.

The energy sector also greatly benefits from the utilization of laser cutting machines for steel. Renewable energy systems, such as wind turbines and solar panel installations, require precisely cut steel parts to ensure optimal performance and longevity. By employing laser cutting technology, energy firms can produce components that meet the stringent specifications necessary for efficient energy generation and distribution. Additionally, the high-speed and low-maintenance nature of laser cutters contribute to a more sustainable production environment by lowering energy consumption and minimizing the use of consumable materials. This results in a more eco-friendly manufacturing process, aligning with the sector’s growing commitment to sustainability and reducing environmental impact.

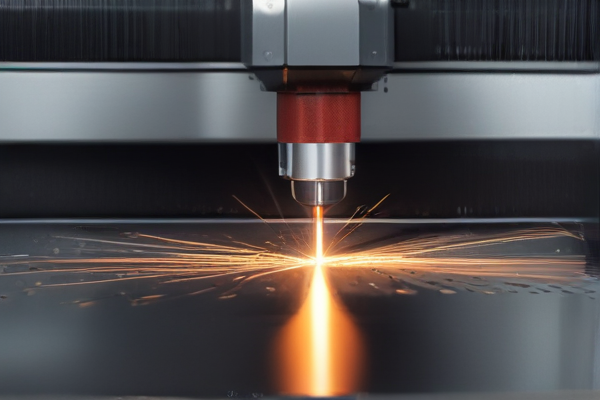

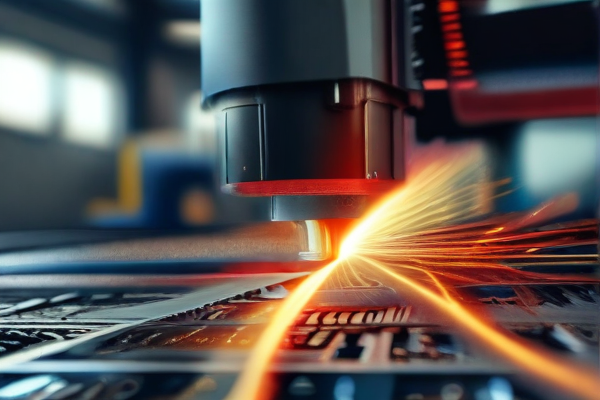

A laser cutting machine for steel is a highly efficient and precise industrial tool that leverages the power of focused laser beams to cut through steel sheets and plates of varying thickness. Unlike traditional mechanical cutting methods, which involve contact and can cause material distortion, laser cutting is a non-contact process. This means the laser beam interacts with the steel directly, melting, burning, or vaporizing material with pinpoint accuracy. The result is smooth, clean cuts with minimal kerf (material waste) and reduced need for post-processing. Industries such as automotive, aerospace, and heavy machinery manufacturing particularly benefit from the speed and precision offered by laser cutting machines, enabling them to produce high-quality components with complex geometries in a fraction of the time it would take using more conventional methods.

Moreover, modern laser cutting machines for steel are equipped with advanced features like CNC (Computer Numerical Control) integration, automated loading and unloading systems, and real-time monitoring capabilities. CNC allows for the automation of cutting processes, ensuring consistent, repeatable results with high precision. These machines are also designed to handle various grades and thicknesses of steel, from thin sheets used in detailed fabrication work to thicker plates needed for structural components. The integration of these technologies not only enhances production efficiency but also significantly reduces operational costs by minimizing material waste and energy consumption. In today’s competitive industrial landscape, investing in a laser cutting machine for steel is a strategic move that can greatly enhance the operational capabilities and output quality of any manufacturing or fabrication enterprise.

Laser cutting machines for steel have revolutionized the manufacturing processes within the medical device industry, offering unparalleled precision and efficiency. Utilizing high-powered lasers, these machines can cut through steel with remarkable accuracy, creating intricate components required for medical devices such as surgical instruments, implants, and diagnostic tools. The precision of laser cutting ensures that each component adheres to stringent medical standards, minimizing the risk of defects or inaccuracies that could compromise patient safety. The ability to produce complex geometries with clean edges also reduces the need for secondary processing, streamlining the production workflow and reducing lead times.

Moreover, laser cutting machines enhance the scalability and customization capabilities of medical device manufacturing. They can handle a diverse range of steel types and thicknesses, allowing for the production of both standard and bespoke medical components. This versatility is crucial in a field where device specifications can vary widely depending on the application and individual patient needs. Additionally, the integration of computer-aided design (CAD) software with laser cutting technology ensures repeatability and consistency across multiple production runs. This combination of precision, efficiency, and adaptability makes laser cutting machines an indispensable tool in the advancement of medical device manufacturing, ultimately leading to the development of higher-quality medical products and improved patient outcomes.

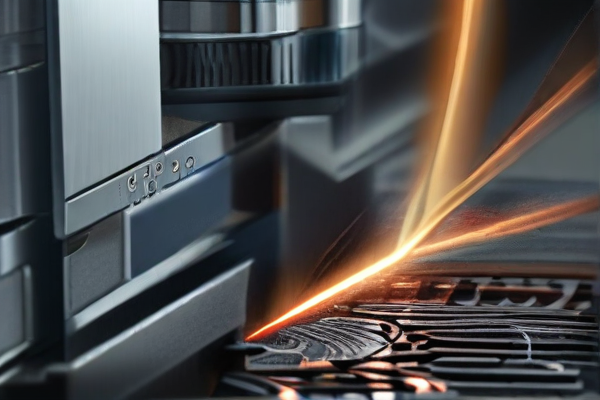

Laser cutting machines for steel have revolutionized the machining and manufacturing industries by offering unparalleled precision, speed, and versatility. Utilizing a high-powered laser beam controlled by computer numerical control (CNC) technology, these machines can cut through steel with incredible accuracy, creating intricate designs and patterns that would be impossible or extremely labor-intensive with traditional cutting methods. The laser cutting process can accommodate various thicknesses of steel, from thin sheets to thicker plates, making it highly adaptable for diverse industrial applications. One of the key advantages of laser cutting is its ability to produce clean, burr-free edges, which significantly reduces the need for secondary finishing processes. As a result, manufacturers can achieve higher productivity rates and reduce production timelines, thus improving overall operational efficiency.

In addition to precision and efficiency, laser cutting machines also contribute to material optimization and waste reduction, which are crucial in modern manufacturing practices. The focused laser beam ensures minimal material wastage by allowing tight nesting of parts on the steel sheet, leading to better utilization of raw materials. Furthermore, the automation and programmability of laser cutting machines enable the production of complex and customized components with consistent quality, even in high-volume productions. This capability is particularly beneficial for industries such as automotive, aerospace, and construction, where precision parts and components are essential. Additionally, the non-contact nature of the laser cutting process minimizes thermal distortion and mechanical stress on the steel, preserving the material’s integrity and mechanical properties. Overall, laser cutting machines for steel represent a significant advancement in machining technology, offering manufacturers a powerful tool to meet the demands of modern production standards efficiently and effectively.

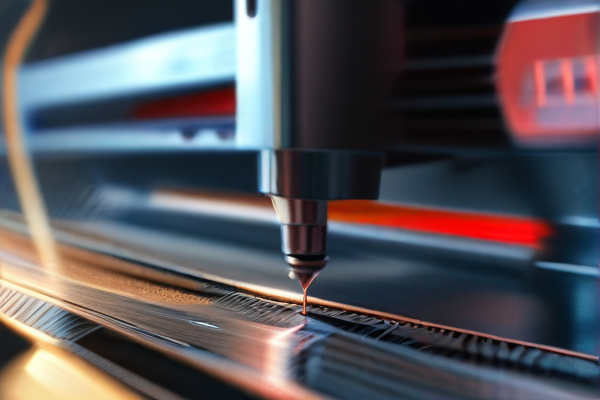

SourcifyChina’s laser cutting machines for steel utilize high-quality materials designed for precision and durability. The machines feature robust steel frames, providing stability and longevity in industrial environments. Each component, from the cutting head to the bed, is engineered for optimal performance and minimal maintenance. The laser source itself employs advanced technology for efficient energy utilization and consistent cutting results.

These machines are crafted to handle various steel thicknesses with precision, thanks to their sophisticated control systems and cutting-edge optics. The focus is on achieving smooth, clean cuts with minimal heat-affected zones, crucial for maintaining material integrity and dimensional accuracy. SourcifyChina integrates safety features to ensure operator protection during operation, adhering to international standards.

The choice of materials ensures reliability under heavy workloads, enhancing productivity and reducing downtime. SourcifyChina prioritizes user-friendly interfaces and software for seamless operation and efficient workflow integration. With a commitment to quality assurance, these machines undergo rigorous testing to meet stringent performance benchmarks and customer expectations.

In conclusion, SourcifyChina’s laser cutting machines for steel combine advanced materials and cutting-edge technology to deliver precision, reliability, and safety in industrial cutting applications. They represent a robust solution for manufacturers seeking efficient and high-quality steel processing capabilities.

SourcifyChina’s laser cutting machines for steel undergo rigorous quality control at every manufacturing stage. Initially, raw materials are carefully selected and tested for durability and consistency.

In the assembly phase, precision engineering ensures each component fits perfectly, minimizing any operational discrepancies. Automated systems conduct real-time monitoring to detect and correct any defects during production.

Once assembled, the machines are subjected to multiple rounds of testing, including stress tests and performance evaluations, to ensure they meet stringent industry standards.

Final inspections involve thorough checks by expert technicians, verifying that each unit functions flawlessly.

These comprehensive quality control measures guarantee that SourcifyChina’s laser cutting machines deliver reliable, high-performance cutting solutions for steel applications, maintaining their commitment to excellence and customer satisfaction.

The SourcifyChina laser cutting machine for steel offers ultimate precision, ensuring accurate cuts on various steel thicknesses. Its high-power laser can penetrate even the hardest steel, producing clean and smooth edges. The machine’s advanced software allows for easy customization and complex design execution.

Equipped with the latest technology, the SourcifyChina laser cutting machine maximizes efficiency, reducing cutting time significantly. It also features automated settings to handle repetitive tasks, increasing productivity. Its robust build ensures durability and long-term reliability.

Safety is a priority with built-in protective features that safeguard operators from potential hazards. The machine is user-friendly, with an intuitive interface that simplifies operation even for beginners.

In addition to its cutting capabilities, the SourcifyChina machine supports various steel types, from stainless to carbon steel. Its versatility makes it an excellent choice for diverse industrial applications. The ultimate performance and adaptability of this machine make it an invaluable asset for any steel cutting requirement.

Laser cutting machines offer significant advantages for cutting steel, making them an essential tool in modern manufacturing.

– Precision: Laser cutting machines provide exceptional accuracy, allowing for precise cuts with tight tolerances.

– Speed: These machines operate at high speeds, significantly reducing production time compared to traditional methods.

– Versatility: Capable of cutting various steel thicknesses and types, laser cutters are highly adaptable to different projects.

– Minimal Waste: The precision of laser cutting reduces material waste, leading to cost savings.

– Quality: Laser cutting produces clean edges, eliminating the need for secondary finishing processes.

– Automation: Laser cutting machines can be easily automated, enhancing efficiency and reducing labor costs.

– Complex Designs: They can handle intricate and complex designs that are difficult to achieve with other cutting methods.

Laser cutting machines for steel are renowned for their precision and efficiency. These machines offer a range of features that enhance their performance and usability.

– Precision Cutting: Laser cutting machines deliver high precision cuts, maintaining tight tolerances and smooth edges, essential for intricate designs.

– High Speed: These machines can cut through steel quickly, increasing productivity and reducing lead times.

– Versatility: Capable of cutting various thicknesses and types of steel, from thin sheets to thick plates.

– Automation: Equipped with automated features such as CNC control, which allows for programmable and repeatable cuts.

– Quality Finish: Produces clean cuts with minimal burrs, reducing the need for secondary finishing processes.

– Energy Efficiency: Modern laser cutters are designed to be energy-efficient, lowering operational costs.

– Safety Features: Include enclosed cutting areas and safety interlocks to protect operators.

– Low Maintenance: Require minimal maintenance due to fewer moving parts compared to traditional cutting methods.

– Customizability: Users can easily adjust settings and configurations for different cutting needs.

– Software Integration: Compatible with CAD/CAM software, allowing for precise control over cutting patterns and designs.

These features make laser cutting machines an indispensable tool in industries requiring precise and efficient steel cutting.

SourcifyChina’s laser cutting machines for steel offer precise and efficient solutions for custom products and projects. These machines ensure high-quality cuts, ideal for intricate designs and complex shapes, making them perfect for various industries.

Utilizing advanced laser technology, SourcifyChina’s machines can handle different steel thicknesses with ease. Their versatility allows for customization to meet specific project requirements, ensuring optimal results and client satisfaction.

The durability and reliability of these machines make them a cost-effective choice for both small and large-scale productions. They minimize waste and reduce processing time, enhancing overall productivity and efficiency.

SourcifyChina also provides excellent customer support and maintenance services, ensuring the longevity and optimal performance of their laser cutting machines. Their commitment to quality and innovation makes them a leading provider in the industry.

Overall, SourcifyChina’s laser cutting machines for steel are a valuable investment for businesses looking to improve their production capabilities and achieve high-quality custom products.

SourcifyChina is a leading manufacturer specializing in high-precision laser cutting machines for steel, catering to a global market with cutting-edge technology and exceptional service. The company’s laser cutting machines are renowned for their accuracy, efficiency, and ability to handle various thicknesses of steel, making them a preferred choice for industries ranging from automotive to construction. Equipped with advanced features such as automated loading and unloading systems, these machines ensure seamless and continuous operation, significantly boosting productivity. SourcifyChina’s commitment to innovation is reflected in their continuous investment in research and development, ensuring their products remain at the forefront of technological advancements. Additionally, their robust customer support network and comprehensive after-sales service provide clients with reliable and timely assistance, fostering long-term partnerships. With a strong emphasis on quality control and adherence to international standards, SourcifyChina stands out as a reliable and trusted supplier in the competitive field of laser cutting solutions for steel.

Laser cutting machines for steel are revolutionizing the Aerospace, Defense, and Marine industries by providing precision, speed, and efficiency in manufacturing and fabrication processes. In the aerospace sector, laser cutting is critical for producing complex, high-precision components required for aircraft and spacecraft. The ability to cut intricate shapes with minimal thermal distortion ensures that parts meet the stringent quality and safety standards of the industry. This precision also contributes to the lightweighting of components, which is essential for fuel efficiency and performance. Additionally, the flexibility of laser cutting machines allows for rapid prototyping and customization, accelerating the development cycle for new aerospace technologies.

In the defense and marine industries, the robust capabilities of laser cutting machines enhance both production and maintenance operations. For defense applications, steel components used in vehicles, weapon systems, and infrastructure benefit from the high precision and repeatability of laser cutting. This technology ensures that parts are manufactured to exact specifications, which is crucial for operational reliability and effectiveness. In the marine industry, laser cutting machines are employed to fabricate ship hulls, structural components, and intricate parts used in various marine systems. The precision and speed of laser cutting reduce production times and costs while improving the durability and performance of marine vessels. Overall, the integration of laser cutting technology in these industries not only enhances manufacturing efficiency but also contributes to the longevity and resilience of critical steel components.

Laser cutting machines for steel have significant applications in the automotive industry, where precision, efficiency, and production speed are paramount. These machines are utilized to fabricate intricate components such as chassis parts, engine mounts, and heat shields with high precision. The laser cutting process allows for the production of parts with complex geometries and tight tolerances, which is essential for ensuring the proper fit and function of automotive components. Additionally, laser cutting contributes to reducing material wastage and enhancing production speed, thus lowering manufacturing costs. The superior edge quality achieved through laser cutting also minimizes the need for additional finishing processes, streamlining the overall production workflow and improving the efficiency of automotive manufacturing operations.

Laser cutting machines have become a cornerstone in the construction industry, particularly for their ability to precisely cut steel components that form the backbone of modern architecture. Utilizing highly focused laser beams, these machines can slice through thick steel sheets with unmatched accuracy, reducing waste and ensuring that each piece fits seamlessly into its designated place. The precision offered by laser cutting technology allows for intricate designs and complex geometries that are often required in the construction of skyscrapers, bridges, and other large-scale infrastructure projects. Furthermore, the speed and efficiency of laser cutting expedite project timelines, enabling construction companies to meet tight deadlines while maintaining high standards of quality and safety.

In the energy sector, laser cutting machines for steel play a pivotal role in the production and maintenance of critical components for energy generation and distribution systems. For instance, in the manufacturing of wind turbines, laser cutting is used to create intricate parts such as turbine blades that require both high strength and aerodynamic efficiency. Similarly, in the oil and gas industry, laser cutting machines are used to produce precision-engineered components for pipelines and drilling rigs, where reliability and durability are paramount. Additionally, the renewable energy sector benefits from laser-cut steel parts in solar panels and battery storage systems, contributing to the overall efficiency and sustainability of energy solutions. By offering precision, speed, and flexibility, laser cutting technology enables the energy sector to meet evolving demands and innovate continuously, driving advancements in both traditional and renewable energy sources.

The industrial equipment industry has significantly evolved with the introduction of laser cutting machines for steel, bringing a transformative impact on manufacturing processes. Laser cutting technology leverages high-powered lasers to precisely cut through steel sheets and components, offering unparalleled accuracy and efficiency. This precision allows for the creation of complex geometries and intricate designs that would be challenging or impossible with traditional cutting methods. Industries such as automotive, aerospace, and construction have benefited from this technology by reducing waste, speeding up production times, and enhancing the overall quality of their products. The ability to produce custom steel parts rapidly and with tight tolerances helps companies remain competitive in a fast-paced market.

Moreover, laser cutting machines contribute to significant cost savings and operational efficiencies. Traditional cutting methods often involve considerable material wastage and require extensive post-processing, such as deburring and finishing. In contrast, laser cutting produces cleaner edges, minimizing the need for additional processing and reducing labor costs. Additionally, these machines can be easily automated and integrated into smart manufacturing systems, supporting Industry 4.0 initiatives. Automation not only boosts productivity but also alleviates human error, ensuring consistent output quality. As a result, businesses can achieve higher throughput and faster turnaround times while maintaining stringent quality standards, ultimately leading to improved customer satisfaction and market growth.

Laser cutting machines for steel are revolutionizing the medical device industry by providing unmatched precision and efficiency in the manufacturing of critical components. These advanced machines utilize high-powered lasers to cut through steel with extraordinary accuracy, allowing for the creation of intricate and delicate parts essential for medical tools and instruments. For instance, surgical instruments, which must adhere to stringent quality and precision standards, benefit significantly from laser cutting technology. The superior precision of laser cutting ensures that each instrument is crafted to exact specifications, reducing the risk of error and enhancing the efficacy and safety of medical procedures.

Moreover, the application of laser cutting machines extends beyond surgical instruments to include the production of various medical implants and devices. The clean and precise cuts offered by laser technology are crucial in creating components for stents, orthopedic implants, and dental devices, where even the slightest deviation can impact performance and patient outcomes. Laser cutting also allows for the efficient processing of biocompatible steel, ensuring that the materials meet the rigorous health standards required for medical applications. The technology’s ability to produce complex geometries without additional tooling contributes to faster production times and reduced costs, ultimately improving the accessibility and affordability of high-quality medical devices.

Laser cutting machines have revolutionized machining and manufacturing, particularly in the processing of steel. Using a focused laser beam, these systems can deliver precision cuts with minimal material wastage and exceptional accuracy. The technology works by directing the laser through optics, and it is controlled via CNC (computer numerical control) for intricate designs and patterns. This method is especially advantageous in steel fabrication because it reduces the need for secondary finishing processes such as deburring, as the laser produces a clean edge with minimal thermal distortion. Consequently, this enhances productivity and lowers costs, making it a highly efficient solution for both industrial and smaller-scale applications.

In the context of manufacturing, laser cutting machines have broad applications ranging from automotive and aerospace to electronics and construction. For instance, automotive industries utilize laser cutting for creating car body components and intricate parts that demand high precision and strength. Aerospace manufacturers leverage this technology for cutting high-strength steel alloys used in aircraft construction, ensuring both durability and lightweight properties. In electronics, laser cutting is indispensable for producing intricate components required for modern devices, maintaining both high precision and efficiency. The ability to quickly adapt to different types of steels and varying thicknesses further makes laser cutting a versatile tool in manufacturing, complementing the industry’s push towards smarter, more flexible production systems.

Sure, here are some frequently asked questions (FAQ) along with their answers for manufacturing a laser cutting machine for steel quality work from SourcifyChina Factory:

Q1: What types of laser cutting machines for steel does SourcifyChina manufacture?

A1: SourcifyChina offers a variety of laser cutting machines, including fiber laser cutting machines and CO2 laser cutting machines, designed specifically for high-quality steel cutting applications.

Q2: What is the maximum thickness of steel that SourcifyChina’s laser cutting machines can cut?

A2: Our laser cutting machines can cut steel up to 25mm in thickness, depending on the specific model and power configuration.

Q3: What kind of precision can I expect from SourcifyChina’s laser cutting machines?

A3: Our laser cutting machines offer high-precision cutting with tolerances as tight as ±0.1mm, ensuring high-quality results for intricate designs and applications.

Q4: What industries are your laser cutting machines suitable for?

A4: SourcifyChina’s laser cutting machines are ideal for various industries, including automotive, aerospace, construction, metal fabrication, and more, where high-quality steel cutting is required.

Q5: What are the power options available for your laser cutting machines?

A5: We provide laser cutting machines with power options ranging from 1000W to 12000W, allowing for flexibility and customization based on your specific cutting requirements.

Q6: Is there any after-sales support or warranty for the laser cutting machines?

A6: Yes, we offer comprehensive after-sales support, including installation, training, and technical assistance. Our machines also come with a warranty period that covers key components to ensure your investment is protected.

Q7: How can I get a quote or more information about purchasing a laser cutting machine from SourcifyChina?

A7: You can contact our sales team through our website, email, or phone. Provide details of your requirements, and we will get back to you with a customized quote and further information.

Q8: Are there any financing options available for purchasing a laser cutting machine?

A8: Yes, we offer flexible financing options to suit different budget needs. Please consult with our sales team to discuss the best financing plan for your purchase.

Q9: How long does it take to manufacture and deliver a laser cutting machine?

When considering a laser cutting machine for steel manufacturing from SourcifyChina factory, it’s essential to focus on several key aspects to ensure you make an informed decision:

1. Specifications: Verify the machine’s power and capabilities. For cutting steel, high-power CO2 or fiber lasers (e.g., 2kW to 6kW) are typical. Assess the maximum thickness it can handle smoothly.

2. Accuracy and Precision: Look for machines with high precision, typically measured in micrometers. Features like auto-focusing, and stable motion control systems will enhance cutting accuracy.

3. Software Compatibility: Ensure the machine is compatible with popular CAD/CAM software for ease of integration into your existing workflow.

4. Build Quality: Solid construction is vital for durability and consistent performance. Check the material used in the machine’s frame and key components. Stainless steel and aluminum alloys are often preferable.

5. Speed and Efficiency: Cutting speed directly impacts productivity. Compare the speed rates for different thicknesses of steel to see if the machine meets your production needs.

6. Maintenance and Support: Investigate the availability of local support and ease of maintenance. SourcifyChina typically provides good after-sales service, but verify this for your specific purchase. Look for features that reduce maintenance time, like easily replaceable parts.

7. Safety Features: Ensure the machine has necessary safety features such as protective covers, emergency stops, and proper ventilation to deal with metal fumes.

8. Cost-Efficiency: Balance the machine’s upfront cost against its features, efficiency, and durability. Factor in operating costs, including power consumption and consumables.

9. Reviews and Testimonials: Seek reviews and testimonials from other users of SourcifyChina’s laser cutting machines. Positive feedback can provide assurance of the machine’s quality and reliability.

By considering these factors, you can make a well-rounded decision on the most suitable laser cutting machine from SourcifyChina that meets your steel manufacturing needs.

FAQ for Sourcing Laser Cutting Machine for Steel from SourcifyChina Factory

Q1: What types of laser cutting machines for steel does SourcifyChina offer?

A1: SourcifyChina offers various types of laser cutting machines such as fiber laser cutters, CO2 laser cutters, and hybrid models, suited for different steel thicknesses and industrial applications.

Q2: What is the lead time for delivery once an order is placed?

A2: The standard lead time for delivery ranges from 30 to 45 days, depending on the model and customization requirements. Expedited shipping options may be available upon request.

Q3: What materials can these laser cutting machines handle?

A3: Besides steel, these machines can cut a variety of metals including aluminum, stainless steel, copper, and titanium, depending on the machine’s power and specifications.

Q4: What support services are available post-purchase?

A4: SourcifyChina provides comprehensive post-purchase services, including installation support, operator training, and ongoing technical assistance. Warranty and maintenance packages are also available.

Q5: Can we customize the laser cutting machines for specific requirements?

A5: Yes, SourcifyChina offers customization options to fit specific industrial needs. You can discuss your requirements with their engineering team to tailor the machine’s specifications.

Q6: What are the payment terms for placing an order?

A6: Payment terms usually include a 30% deposit upon order confirmation, with the remaining 70% due before shipment. Flexible financing options may also be discussed.

Q7: Are there any quality certifications for SourcifyChina’s laser cutting machines?

A7: SourcifyChina’s laser cutting machines adhere to international quality standards and are certified with ISO, CE, and other relevant certifications ensuring reliability and safety.

Q8: How can I get a quotation for a laser cutting machine?

A8: To get a quotation, you can contact SourcifyChina through their official website or customer service email, providing details about your specific requirements and intended usage.

Q9: What distinguishes SourcifyChina’s laser cutting machines from competitors?

A9: SourcifyChina’s machines are known for their high precision, cutting-edge technology, robust build quality, and competitive pricing, backed by excellent customer service and support.

Q10: Do you offer any training or demos before purchase?

Sourcing a laser cutting machine for steel from SourcifyChina factory can be straightforward with these tips:

1. Research:

Begin by thoroughly researching the types of laser cutting machines available. Understand whether you need fiber or CO2 lasers based on your material and thickness requirements.

2. Define Requirements:

Clearly specify your requirements, including cutting thickness, power output, precision, and additional features like software compatibility or automation.

3. Visit SourcifyChina’s Platform:

Explore SourcifyChina’s website and look for their laser cutting machine category. Utilize filters to narrow down the options that meet your needs.

4. Check Manufacturer Credentials:

Evaluate the factory’s credentials. Look for certifications such as ISO, CE, and RoHS that indicate compliance with international standards.

5. Ask for Samples or Demonstrations:

Request samples or live demonstrations to assess the machine’s performance and quality.

6. Read Reviews and Testimonials:

Seek out reviews or testimonials from previous buyers to gauge the factory’s reliability and product quality.

7. Inquire about After-Sales Service:

Clarify the after-sales support, including warranty, maintenance services, and availability of spare parts.

8. Communicate Clearly:

Maintain clear and consistent communication with the supplier. Ask detailed questions and ensure there is mutual understanding regarding specifications and terms.

9. Negotiate Terms:

Discuss and negotiate terms of purchase, including price, payment terms, and delivery schedules.

10. Inspect Before Shipping:

If possible, conduct a pre-shipment inspection through a third party to ensure the machine meets your standards before it’s shipped.

By adhering to these tips, you can efficiently source a quality laser cutting machine for steel from SourcifyChina factory, ensuring it meets your business needs and standards.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.