Choosing SourcifyChina Factory for purchasing CNC blocks from China ensures high quality, affordability, and efficient service. Their team offers extensive industry experience, guaranteeing precision in every product.

In addition, SourcifyChina provides thorough quality control, ensuring each CNC block meets international standards. Their commitment to excellence shines through detailed inspections and rigorous testing.

Moreover, SourcifyChina prides itself on reliable customer service, providing quick responses and comprehensive support throughout the purchasing process. Their transparency and dedication build trust with buyers.

Lastly, SourcifyChina leverages strong relationships with logistics providers, ensuring timely and efficient delivery of CNC blocks worldwide. This comprehensive approach makes them an ideal partner for global buyers.

Computer Numerical Control (CNC) blocks are essential components in precision machining industries. They offer various options such as steel, aluminum, and titanium, each tailored for specific applications and performance standards.

– Steel Blocks: Known for durability, resistance to wear and tear, ideal for high-stress applications.

– Aluminum Blocks: Lightweight, good thermal conductivity, suitable for aerospace and automotive industries.

– Titanium Blocks: Exceptional strength-to-weight ratio, corrosion resistance, often used in medical and aerospace fields.

– Cast Iron Blocks: Excellent machinability, vibration dampening properties, commonly found in automotive and industrial machinery.

– Plastic Blocks: Lightweight, resistant to corrosion, used in custom prototyping and low-stress applications.

– Composite Blocks: Made from a combination of materials to achieve specific properties like enhanced strength and reduced weight.

– Tool Steel Blocks: High hardness and heat resistance, preferred for cutting tools and dies.

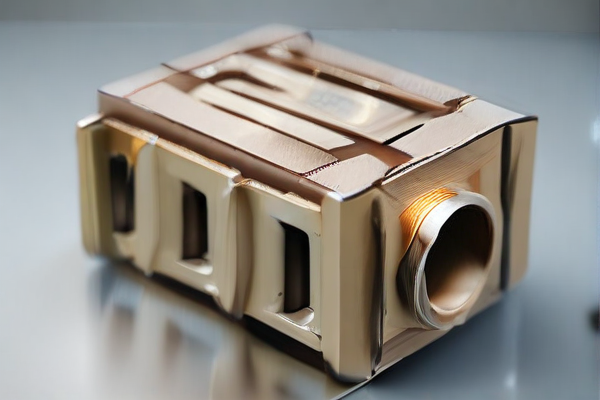

– Brass Blocks: Good machinability, low friction, typically used in decorative and precision instrument applications.

– Copper Blocks: Excellent electrical conductivity, utilized in electronic components and heat exchangers.

CNC users choose blocks based on factors like mechanical properties, weight, cost, and the specific requirements of the application at hand.

Computer Numerical Control (CNC) blocks are essential in manufacturing for precision and efficiency, transforming raw materials into precise components. They find applications in various industries and tasks, enhancing productivity and quality.

– Automotive Industry: Creating engine blocks, gears, and other critical components.

– Aerospace Industry: Crafting high-precision parts for aircraft, ensuring safety and performance.

– Medical Devices: Producing surgical instruments and implants with exact specifications.

– Electronics: Manufacturing precise parts for circuit boards and housings.

– Tool and Die Making: Crafting molds and dies used in mass production.

– Custom Fabrication: Tailoring bespoke parts for specific user needs.

– Woodworking: Shaping intricate designs and components.

– Prototyping: Rapid creation of prototypes for testing and development.

– Jewelry Making: Producing detailed and complex designs.

– Military and Defense: Fabricating high-precision equipment and components.

– Maritime Industry: Creating parts for ships and underwater equipment.

– Renewable Energy: Manufacturing parts for wind turbines and solar panels.

– Textile Manufacturing: Developing machinery components for textile production.

– Agricultural Machinery: Producing parts for farming equipment.

– Construction Equipment: Crafting durable components for heavy machinery.

– Home Appliances: Forming precise parts for various household devices.

– Furniture Making: Ensuring accuracy in the production of furniture parts.

– Sporting Goods: Creating specialized parts for equipment.

– Art and Sculptures: Fabricating precise and detailed artwork components.

– Packaging Industry: Developing machinery parts for packaging lines.

CNC blocks thus play a pivotal role across multiple industries, driving innovation and efficiency by producing highly accurate and consistent parts.

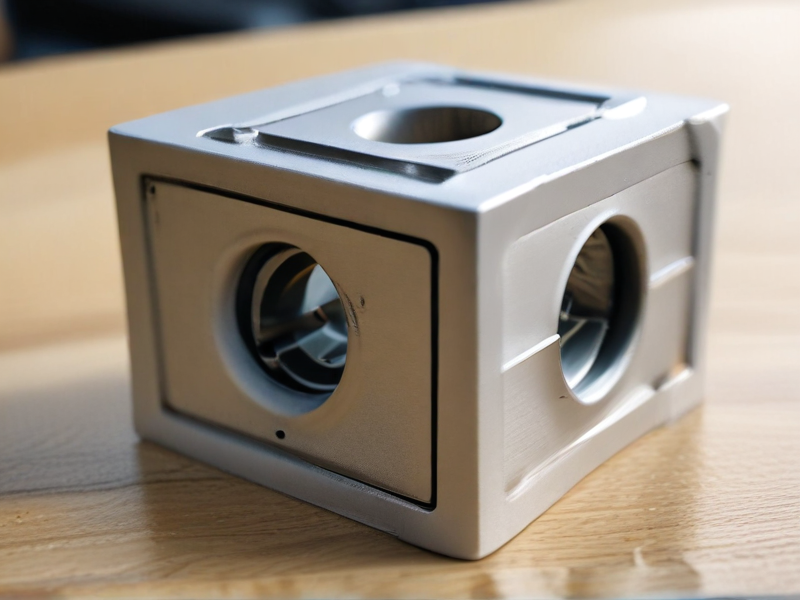

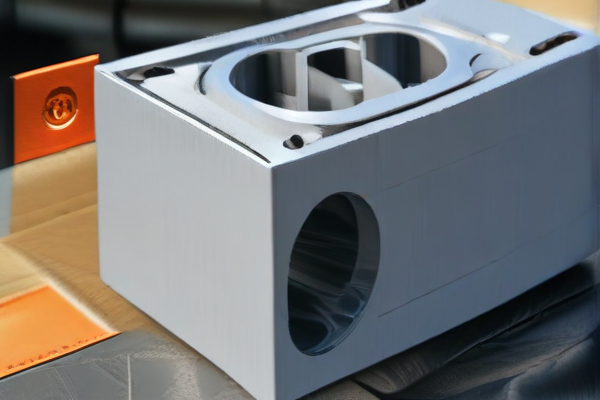

The “SourcifyChina CNC block” is crafted with high-grade aluminum alloy, known for its lightweight and robust properties. Aluminum alloys provide excellent resistance to corrosion, making them suitable for long-term usage in various environmental conditions.

Precision is a hallmark of the CNC block, achieved through advanced Computer Numerical Control (CNC) machining techniques. This meticulous process ensures that every piece meets strict dimensional tolerances, enhancing performance and reliability.

Durability is a key feature, with the aluminum alloy offering both mechanical strength and thermal stability. This makes the CNC block ideal for demanding industrial applications where precision and longevity are crucial.

Surface treatments further optimize the material’s characteristics. Anodizing, for instance, can enhance corrosion resistance and provide a hardened surface, extending the block’s service life significantly.

Overall, SourcifyChina’s CNC block is a well-engineered solution constructed from top-tier aluminum alloy. Its advanced machining, durability, and protective treatments make it a versatile and reliable choice for various industries.

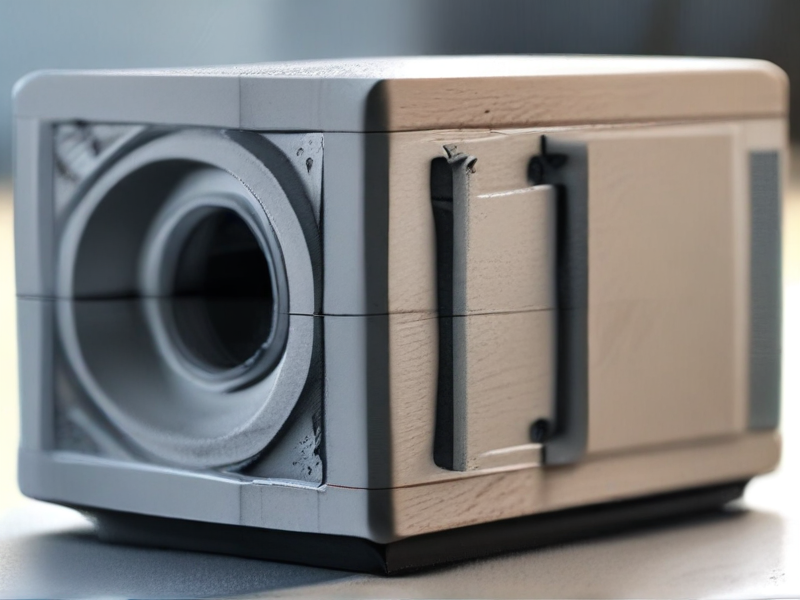

SourcifyChina ensures top-quality CNC blocks through a stringent quality control process. The selection of raw materials is of utmost importance, guaranteeing durability and performance.

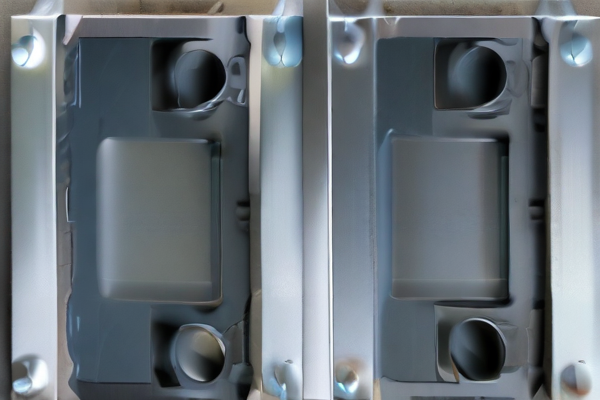

Detailed inspection protocols are followed at each production stage to maintain conformity with design specifications. State-of-the-art machinery and technology are employed to enhance precision.

Skilled technicians conduct various tests, including dimensional accuracy and stress analysis, to certify that each block meets industry standards. Real-time monitoring systems enable immediate detection of any anomalies.

Final checks involve rigorous validation, ensuring that the finished CNC blocks are flawless and ready for delivery. SourcifyChina’s comprehensive approach guarantees unmatched quality and reliability.

SourcifyChina specializes in delivering high-precision CNC machining services, making it an industry leader in the creation of complex parts. Their technological prowess ensures accurate and efficient production workflows.

Utilizing state-of-the-art CNC machines, SourcifyChina excels in producing custom CNC blocks that meet exact specifications. This advanced machinery guarantees high tolerance levels, resulting in exceptionally accurate parts.

SourcifyChina’s team of skilled engineers ensures optimal performance during the CNC machining process. Their deep expertise allows them to troubleshoot issues quickly and maintain the quality of each CNC block.

Moreover, SourcifyChina prioritizes customer satisfaction by offering end-to-end support, from initial design to final production. They excel in managing projects of all sizes and complexities, ensuring timely delivery and adherence to specifications.

In addition to producing CNC blocks, SourcifyChina also provides additional services such as finishing and surface treatments. This holistic approach means clients receive fully finished products, ready for immediate use or further assembly.

Another key aspect of SourcifyChina’s service is its commitment to sustainable practices. They incorporate eco-friendly materials and processes wherever possible, contributing to a greener manufacturing industry.

By continuously investing in cutting-edge technology and staff training, SourcifyChina remains at the forefront of CNC machining innovation. Their ongoing efforts ensure that they can tackle even the most challenging projects with ease.

In conclusion, SourcifyChina stands out due to its precision, technological capabilities, and commitment to customer satisfaction. Their expertise in producing high-quality CNC blocks, combined with a comprehensive suite of services and sustainable practices, makes them a go-to choice for businesses seeking reliable CNC machining solutions.

A CNC (Computer Numerical Control) block offers significant advantages in manufacturing, automating precision tasks and streamlining operations. Its accuracy and versatility boost productivity and enhance efficiency.

– Precision: CNC machines deliver extremely high precision, minimizing human error and ensuring consistent quality across multiple units.

– Cost-Effectiveness: Reduces material waste, labor costs, and time spent on manual adjustments, leading to overall cost savings.

– Versatility: Suitable for a variety of materials such as metals, plastics, and wood, allowing for diverse applications.

– Repeatability: Once programmed, CNC machines can replicate designs exactly, making them ideal for mass production.

– Efficiency: Increases production speed while maintaining quality, thereby improving overall throughput.

– Complex Geometries: Capable of producing intricate and complex designs that would be challenging or impossible via manual machining.

– Reduced Labor: Minimizes the need for skilled labor, thereby lowering labor costs and reducing potential human error.

– Safety: Keeps operators safe by minimizing direct interaction with the machine during operation.

– Ease of Use: With advanced software, programming and operating a CNC block can be learned relatively quickly.

– Maintenance: Modern CNC machines are built for durability and require less frequent maintenance.

– Flexibility: Easy to reprogram for new tasks or products, providing quick adaptability to changing production needs.

– Scalability: Facilitates scaling up production to meet increased demand without compromising quality.

– Resource Efficiency: Optimizes use of raw materials, lowering production costs and reducing environmental impact.

– Remote Operation: Many CNC machines support remote monitoring and control, allowing for more flexible and efficient operations.

– Integration: Easily integrates with other computer-aided design (CAD) and manufacturing (CAM) systems for a seamless production workflow.

Incorporating CNC blocks into manufacturing processes can significantly enhance productivity, quality, and cost-efficiency, making them indispensable tools in modern industries.

CNC blocks, or Computer Numerical Control blocks, are essential components in the machining industry, providing precise and efficient control over various cutting and shaping processes.

– Precision and Accuracy: CNC blocks ensure high levels of precision and accuracy in machining, minimizing errors.

– Repeatability: They offer consistent performance in repetitive tasks, ensuring uniformity in production.

– Flexibility: Suitable for various materials including metals, plastics, and composites.

– Automation: Reduces the need for manual intervention, increasing productivity.

– Complex Designs: Capable of producing intricate and complex geometries.

– Integration: Easily integrated with other CNC machinery and systems.

– Scalability: Ideal for both small-scale and large-scale manufacturing.

– User-Friendly: Often come with intuitive software for ease of programming and operation.

– Speed: Significantly boosts machining speed, reducing time-to-market.

– Tool Management: Advanced tool management features extend tool life and reduce downtime.

– Enhanced Safety: Comes with built-in safety features to protect operators and equipment.

– Cost-Efficiency: Despite initial investment, they lower operational costs in the long run through efficiency and precision.

– Environmentally Friendly: Minimized waste thanks to precise material usage.

CNC blocks are indispensable for modern manufacturing, offering unparalleled efficiency and precision.

SourcifyChina is renowned for its custom CNC block products, serving a wide range of industries with precision and efficiency. Utilizing advanced CNC machining techniques, they craft high-quality, bespoke components tailored to specific client needs. Their capabilities are complemented by rigorous quality control measures, ensuring each product meets exact specifications.

The company offers an extensive selection of custom CNC blocks, accommodating various materials such as aluminum, steel, and titanium. Their skilled engineers and technicians collaborate closely with clients to develop innovative solutions, providing prototype development and full-scale production services.

SourcifyChina prides itself on handling complex projects with ease, thanks to their state-of-the-art equipment and expertise. They support industries from automotive to aerospace, delivering components that enhance performance and reliability. Their dedication to precision and customer satisfaction distinguishes them as a leader in CNC machining.

Additionally, the company’s commitment to sustainability is evident through their use of eco-friendly practices and materials. They strive to minimize waste and optimize processes, making their operations environmentally responsible. SourcifyChina’s focus on sustainable practices reflects their holistic approach to business, balancing industry demands with environmental stewardship.

Their customer-centric approach ensures that projects are delivered on time and within budget, addressing specific client requirements efficiently. SourcifyChina’s comprehensive service offerings and unwavering commitment to quality make them a trusted partner for CNC block products. As they continue to innovate and evolve, they remain positioned to meet the ever-changing demands of their diverse clientele.

SourcifyChina CNC Block is a prominent manufacturer and supplier in the precision engineering sector, renowned for its high-quality CNC machining solutions. Located in the industrial heartland of China, SourcifyChina specializes in the production of CNC blocks and components, serving diverse industries such as automotive, aerospace, medical, and electronics. The company’s cutting-edge manufacturing facility is equipped with state-of-the-art CNC machines and staffed by highly skilled engineers, ensuring the highest standards of accuracy and durability in their products. SourcifyChina prides itself on its commitment to excellence and innovation, continuously investing in advanced technologies and rigorous quality control processes. By emphasizing customer satisfaction and tailored solutions, SourcifyChina has established itself as a trusted partner in the global supply chain, delivering precision-engineered components that meet stringent international standards. With a focus on sustainable practices and efficiency, SourcifyChina CNC Block continues to push the boundaries of what’s possible in modern manufacturing.

Computer Numerically Controlled (CNC) block technology has become a cornerstone in the aerospace, defense, and marine industries due to its unparalleled precision and reliability. In aerospace applications, CNC machining is used to create complex components such as turbine blades, engine parts, and structural elements that require extreme accuracy and consistency. Aerospace components must withstand harsh environments and high pressures, and CNC technology provides the necessary precision to ensure that each part meets rigorous performance and safety standards. The ability to machine components to exact specifications reduces the risk of failure in critical aerospace systems, boosting the overall safety and efficiency of aircraft.

In the defense and marine sectors, CNC block technology is equally vital. Defense applications often require robust components for weapons systems, armor plating, and specialized equipment, where any flaw could have catastrophic consequences. CNC machining ensures that each piece is manufactured to exacting standards, providing reliability and durability in the field. Similarly, the marine industry benefits from CNC technology through the production of precision parts for ship engines, propulsion systems, and underwater vehicles. These components must endure corrosive saltwater environments and high mechanical stresses. By employing CNC machining, the marine industry can produce highly durable and efficient parts that enhance the longevity and performance of naval vessels, commercial ships, and underwater equipment. Overall, CNC block technology plays a critical role in advancing the capabilities and safety of aerospace, defense, and marine applications.

CNC blocks, or computer numerical control blocks, play a pivotal role in the automotive sector, significantly elevating the precision and efficiency of production processes. In engine manufacturing, CNC blocks are instrumental in the machining of engine blocks, cylinder heads, and various other critical components. These blocks enable the creation of highly intricate and complex geometries with exceptional accuracy, which is essential for enhancing engine performance, fuel efficiency, and reducing emissions. Their ability to automate repetitive tasks ensures consistency and speeds up production, allowing automakers to meet stringent production targets and maintain high-quality standards. Additionally, CNC blocks are vital in the prototyping phase, facilitating rapid development and iteration of new automotive designs, thereby shortening the time-to-market for innovative vehicle models.

In the electronics industry, CNC blocks are equally transformative, enabling the precise machining of components for a wide array of electronic devices. They are crucial in the production of circuit boards, where minute and meticulous cuts are necessary to create intricate pathways for electrical connections. This precision is essential for the functionality and reliability of devices ranging from smartphones to medical instruments. Furthermore, CNC blocks are used to create custom enclosures and housings for electronic components, ensuring that they fit perfectly and function effectively. As electronics continue to miniaturize, the demand for extremely precise and efficient manufacturing processes provided by CNC blocks has surged, contributing to advancements in consumer electronics, telecommunications, and sophisticated computing systems. Ultimately, CNC blocks are foundational in driving forward both the automotive and electronics industries through enhanced precision, efficiency, and innovation.

The construction industry has significantly benefited from the introduction of CNC (Computer Numerical Control) block technology, allowing for unprecedented precision and efficiency in building processes. These CNC blocks are often used to create complex building components, from structural elements to bespoke architectural designs. By integrating CNC machining technology, construction companies can fabricate consistent, high-quality parts while minimizing human error and material waste. The precision of CNC blocks ensures that elements fit together perfectly, streamlining the construction process and enhancing the overall structural integrity of buildings. This technology also supports the creation of intricate designs and customized solutions, enabling architects and builders to push the boundaries of modern architecture and deliver unique, aesthetically pleasing, and functional structures.

In the realm of energy applications, CNC blocks play a pivotal role in the manufacturing of components for various energy systems, including wind turbines, solar panels, and hydroelectric machinery. The high precision and repeatability of CNC machining are crucial for producing parts that must adhere to stringent tolerances and performance standards. For example, components of wind turbine gearboxes and solar panel frames require exact specifications to ensure maximum efficiency and longevity. By utilizing CNC blocks, manufacturers can produce parts that enhance the energy output and reliability of renewable energy systems. Additionally, the enhanced material efficiency and reduced waste associated with CNC machining contribute to the sustainability of the production process itself, aligning with the broader goals of reducing the environmental impact of energy generation.

The industrial equipment industry has significantly benefitted from the adoption of CNC (Computer Numerical Control) block technology, revolutionizing the way components are manufactured. CNC blocks serve as the foundational programming units in CNC machines, enabling high precision and automation in industrial operations. Utilizing CNC block technology allows for intricate designs and complex geometries to be manufactured with unparalleled accuracy, reducing human error and ensuring consistent quality in mass production. This level of precision is vital in sectors such as aerospace, automotive, and heavy machinery, where even minute discrepancies can lead to significant functional issues. Moreover, CNC blocks facilitate the rapid prototyping of equipment, allowing manufacturers to innovate and bring new products to market more swiftly.

The integration of CNC block technology into industrial equipment applications also enhances operational efficiency and reduces costs. By automating the production process, CNC machines minimize the need for manual labor, which not only cuts labor costs but also accelerates production timelines. Moreover, CNC blocks can be easily reprogrammed to adapt to different production needs, offering flexibility and reducing downtime. This adaptability is particularly advantageous in the industrial equipment sector, where the ability to quickly switch between manufacturing different components can lead to better resource utilization and faster response to market demands. Additionally, with the capability to perform multiple operations such as drilling, milling, and cutting in a single setup, CNC machines enhance throughput while maintaining high precision, which is a game-changer for industrial manufacturing efficiency.

Computer Numerical Control (CNC) block technology has revolutionized the medical device industry by enabling the precise and efficient manufacture of complex and customized components. One of the primary applications of CNC blocks is in the production of orthopedic implants, such as knee and hip replacements. These implants require exact specifications to fit accurately within the human body and function effectively. By leveraging CNC machining, manufacturers can ensure that each implant is machined with micron-level precision, which is crucial for the longevity and performance of the implants. Moreover, CNC technology allows for rapid prototyping and iterative design adjustments, significantly reducing the time required for development and improving the overall quality of medical devices.

In addition to orthopedic applications, CNC blocks are also used in the production of dental implants, surgical instruments, and even advanced diagnostic equipment. Dental implants, for instance, must be tailored to fit individual patients’ jaw structures. CNC machines enable the creation of these highly customized components by following digital design files with incredible accuracy. Similarly, surgical instruments such as scalpels, forceps, and retractors benefit from the precision of CNC machining. These tools need to be meticulously crafted to perform delicate and intricate procedures. Furthermore, advanced diagnostic devices, including MRI and CT scanners, incorporate numerous machined components that must meet stringent standards. CNC technology ensures that all parts meet these high standards, enhancing the reliability and safety of medical equipment, ultimately contributing to better patient outcomes.

Computer Numerical Control (CNC) blocks are a cornerstone of modern machining and manufacturing, offering precision, consistency, and efficiency. In machining applications, CNC blocks serve as the framework for creating intricate and complex parts by guiding cutting tools based on a pre-programmed set of instructions. The versatility of CNC technology allows it to process various materials such as metals, plastics, and composites with remarkable accuracy. The precision afforded by CNC blocks reduces the margin of error significantly, enabling the production of high-quality components essential in industries like aerospace, automotive, and medical device manufacturing. The automation provided by CNC systems not only enhances speed but also minimizes human intervention, thereby reducing labor costs and the likelihood of human error.

In manufacturing, CNC blocks play a pivotal role in streamlining production processes. The repeatability of CNC machining ensures that each part produced meets stringent quality standards, which is crucial for mass production scenarios. These blocks are integral in the production of molds, dies, and fixtures used in various manufacturing operations. Their ability to effortlessly handle complex geometries and tight tolerances makes them indispensable in the production pipeline. Additionally, the use of CNC blocks in manufacturing aligns well with Just-In-Time (JIT) production methodologies, allowing for rapid turnaround and minimal waste. This combination of precision, reliability, and efficiency makes CNC blocks a fundamental component in the scalable and sustainable manufacturing of high-quality products.

Sure! Below is a list of frequently asked questions (FAQ) along with their answers regarding manufacturing CNC block quality work from SourcifyChina factory:

Q1: What types of CNC blocks can SourcifyChina manufacture?

A: SourcifyChina specializes in producing a wide range of CNC blocks, including aluminum, steel, titanium, and plastic blocks. Custom specifications can also be accommodated.

Q2: What is the typical lead time for an order?

A: The lead time varies based on the complexity and quantity of the order. Generally, it ranges from 2 to 6 weeks. Rush orders can be accommodated upon request.

Q3: How do you ensure the quality of CNC blocks?

A: Quality is assured through rigorous inspections, including dimensional checks, material verification, and surface finish assessments. Our factory is ISO 9001 certified, ensuring adherence to international quality standards.

Q4: Do you offer custom CNC block designs?

A: Yes, SourcifyChina provides custom CNC block designs tailored to your specific requirements. Our design team works closely with clients to ensure precision and compliance with their specifications.

Q5: What is your minimum order quantity (MOQ)?

A: The MOQ varies by material and design complexity but generally starts at 50 pieces. For precise information, it’s best to contact our sales team with your requirements.

Q6: What type of machinery is used for manufacturing?

A: Our factory is equipped with state-of-the-art CNC machining centers, lathes, mills, and grinding machines that ensure high precision and consistency.

Q7: Can you handle bulk orders?

A: Yes, SourcifyChina is well-equipped to handle bulk orders efficiently while maintaining high quality standards.

Q8: What materials can be used for CNC block manufacturing?

A: We work with various materials, including but not limited to, aluminum, stainless steel, titanium, brass, and different types of plastics.

Q9: How do I request a quote?

A: You can request a quote by contacting us through our website or emailing our sales team with your project details, specifications, and quantity needed.

Q10: Do you provide samples before full production?

A: Yes, we offer sample production runs to ensure the final product meets your expectations before proceeding with full-scale manufacturing.

When considering CNC block manufacturing from a facility like SourcifyChina, it’s essential to maximize efficiency and ensure quality. Here are key tips to help you navigate the process:

1. Define Specifications: Clearly outline your requirements, including dimensions, tolerances, and materials. Detailed specifications prevent misunderstandings and ensure the factory can accurately meet your needs.

2. Prototype First: Request a prototype to assess the factory’s capabilities and the quality of the output. This step is crucial for identifying any issues early and refining the design before mass production.

3. Material Quality: Verify the quality of materials used. Different applications require varying grades of metals or plastics, so confirm that the factory can source and work with your specified materials.

4. Communicate Clearly: Maintain clear and constant communication with the factory. Language barriers can exist, so using clear, concise instructions and visual aids (e.g., CAD drawings) can prevent misunderstandings.

5. Technology Check: Ensure the factory uses up-to-date CNC machinery and software. Advanced technology improves precision, reduces defects, and enhances efficiency.

6. Quality Control: Investigate the factory’s quality control processes. Consistent inspection and testing at various stages of production can help maintain high standards.

7. Production Times: Get a realistic estimate of production and lead times. Rush orders might compromise quality, so plan accordingly to allow ample time for each stage of manufacturing.

8. Cost Analysis: Compare costs comprehensively. While lower prices are attractive, they shouldn’t compromise quality or lead to hidden costs (e.g., rework, delays).

9. Building Relationships: Establish a strong working relationship with the factory. Building trust can lead to better cooperation, improved problem-solving, and potentially favorable terms over time.

10. Risk Management: Identify potential risks, such as supply chain disruptions or quality issues, and have contingency plans in place.

By following these tips, you can enhance the effectiveness of your collaboration with SourcifyChina for CNC block manufacturing, ensuring high-quality outcomes and smooth operations.

Q1: What materials are used for CNC blocks at SourcifyChina Factory?

A1: SourcifyChina Factory uses a variety of materials including aluminum, stainless steel, brass, and plastic for manufacturing CNC blocks. They also accommodate custom material requests based on client needs.

Q2: What are the MOQ (Minimum Order Quantity) requirements?

A2: The standard MOQ at SourcifyChina Factory is generally 50 pieces. However, smaller orders can be accommodated, but may incur higher costs per unit.

Q3: Can I get a custom design for my CNC block?

A3: Yes, SourcifyChina Factory offers custom CNC machining services. Customers can provide CAD drawings or specific requirements to create a custom design.

Q4: What is the lead time for production and delivery?

A4: The lead time depends on the complexity and quantity of the order. Generally, it takes about 2-4 weeks for production and an additional 1-2 weeks for shipping.

Q5: Are there quality control measures in place?

A5: Yes, SourcifyChina Factory follows strict quality control procedures. Each CNC block undergoes rigorous inspection including dimensional accuracy, material integrity, and surface finish tests.

Q6: What payment methods are accepted?

A6: SourcifyChina Factory accepts various payment methods including wire transfer (T/T), PayPal, and credit cards. Payment terms are usually 50% upfront and the balance before shipping.

Q7: How can I request a quote?

A7: You can request a quote by emailing the factory with your specifications, including material type, dimensions, quantity, and any special requirements. Their team will respond within 24-48 hours.

Q8: Do you provide samples before full production?

A8: Yes, sample production is available. Depending on the material and complexity, there may be a nominal charge for sample creation and shipping.

Q9: What kind of post-sales support do you offer?

A9: SourcifyChina Factory offers post-sales support including technical assistance, replacement of defected parts, and general customer service for any issues that may arise.

Q10: Can SourcifyChina Factory handle large-scale production runs?

Sourcing CNC blocks from SourcifyChina factory involves a structured approach to ensure quality, efficiency, and cost-effectiveness. Here are some concise tips:

1. Research and Verification: Start by gathering detailed information about SourcifyChina. Check their credentials, certifications, and client reviews to ensure reliability and high standards.

2. Specify Requirements: Clearly define your CNC block specifications, including dimensions, materials, tolerances, and finishing requirements. Detailed drawings or CAD files can be very helpful.

3. Request for Quote (RFQ): Send a detailed RFQ to SourcifyChina. Include all your specifications, desired quantity, and delivery deadlines to get an accurate quote.

4. Sample Order: Before committing to a large order, request a sample CNC block. This helps verify the quality and adherence to your specifications.

5. Quality Inspection: Ensure the factory has robust quality control processes. Request documentation of these processes and possibly arrange for third-party inspection services.

6. Negotiate Terms: Discuss pricing, payment terms, and delivery schedules comprehensively. Ensure there are clear agreements on lead times and penalties for delays.

7. Track Production: Maintain open communication with the factory during the production phase. Ask for regular updates and progress reports.

8. Logistics and Shipping: Plan for shipping logistics. Determine if SourcifyChina handles shipping or if you need to arrange it. Factor in both cost and time for reliable delivery.

9. After-sales Support: Clarify post-delivery support policies, such as handling defective products or issues that may arise after receiving the CNC blocks.

10. Build Relationships: Cultivate a strong relationship with the factory. Good communication and a solid partnership can lead to better outcomes for future orders.

By following these steps, you can effectively source high-quality CNC blocks from SourcifyChina factory, ensuring that your manufacturing needs are met efficiently.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.