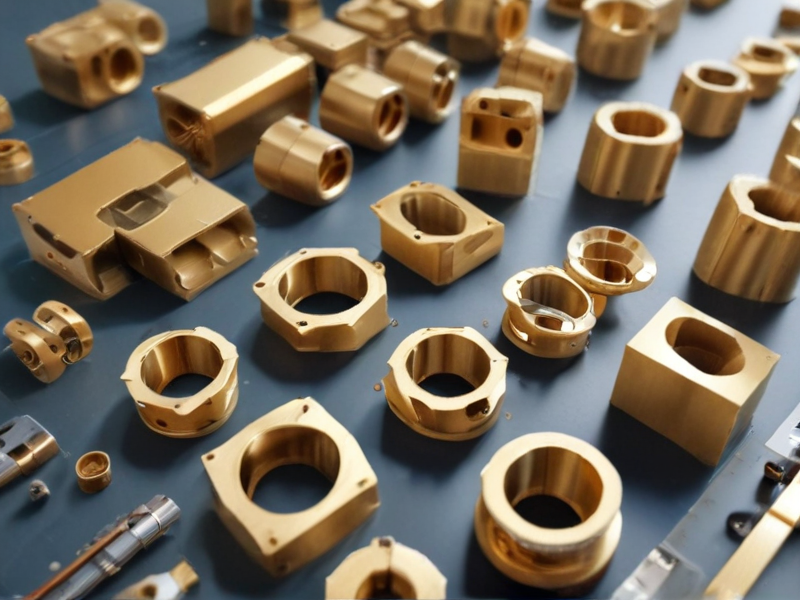

“SourcifyChina: Your Reliable Source for High-Quality CNC Brass Parts Factory Direct”

Looking for dependable CNC brass parts? Trust SourcifyChina, your reliable partner for precision-engineered brass components, directly from the factory. Explore our quality guarantees and competitive pricing today.

Choosing SourcifyChina Factory for purchasing CNC brass parts guarantees quality and precision. Our state-of-the-art machinery ensures consistent, reliable production. We maintain stringent quality control standards to exceed customer expectations.

Additionally, SourcifyChina offers competitive pricing without compromising on quality. Our experienced engineers work meticulously to meet your specifications, providing value and efficiency in every piece produced.

Exceptional customer service is a cornerstone at SourcifyChina. Our dedicated support team assists you throughout the purchasing process, from initial inquiry to final delivery, ensuring a seamless experience.

Moreover, we prioritize timely delivery, understanding the critical nature of your production schedules. Our logistics network ensures your orders arrive promptly, helping you stay on track with your projects.

In conclusion, choosing SourcifyChina Factory for CNC brass parts means entrusting your needs to a provider committed to quality, affordability, and exceptional service. We strive to build lasting partnerships by delivering excellence in every order.

CNC brass parts are precision components manufactured using computer numerical control machines, known for their superior mechanical properties and conductivity. These parts serve various industries including automotive, electronics, and plumbing due to their corrosion resistance and machinability.

– Turned Parts: Utilized for components requiring cylindrical shapes, like rods and shafts.

– Milled Parts: Perfect for intricate designs, including slots, holes, and complex surface geometries.

– Bushings: Common in devices needing reduced friction between parts, such as engines.

– Connectors: Used in electronic applications for their excellent conductivity and ease of attachment.

– Valve Components: Ideal in plumbing and gas systems, providing durability and tight seals.

– Precision Gears: Suitable for high-precision applications like in robotics or clocks.

– Fittings and Fasteners: Standard components in construction and assembly due to their strength.

– Custom Machined Parts: Tailored to specific requirements for unique industrial applications.

– Electrical Contacts: Employed in switches and relays for reliable electrical performance.

– Automotive Components: Essential in vehicle manufacturing for parts like fuel injectors and brake systems.

– Sensor Housings: Utilized in protective casings for sensors, ensuring durability and environmental resistance.

– Couplings: Common in mechanical systems needing the connection of two rotating shafts.

– Hydraulic Components: Integral in hydraulic systems for their resistance to wear and pressure.

– Decorative Elements: Used in luxury goods for their appealing finish and polishability.

– Threaded Inserts: Provide robust threading solutions in softer materials.

These various types of CNC brass parts cater to specific needs, making brass an irreplaceable material in many technological and industrial applications due to its unique blend of mechanical and physical properties.

CNC brass parts are essential in various industries due to their precision, durability, and conductivity. They are widely used in the automotive, electronics, plumbing, and aerospace sectors.

– Automotive: Utilized in fuel systems, electrical connectors, and engine components.

– Electronics: Ideal for electrical terminals, connectors, and precision components.

– Plumbing: Commonly used for valves, fittings, and fasteners due to their corrosion resistance.

– Aerospace: Essential for high-precision parts such as fuel nozzles and landing gear components.

– Medical Devices: Used in surgical instruments and diagnostic equipment for their biocompatibility.

– Manufacturing: Deployed for creating intricate parts for machinery and robotics.

– Telecommunications: Applied in the production of connectors, switches, and relay components.

– Musical Instruments: Critical for parts in brass wind instruments and other precision components.

– Marine: Used in boat fittings, propellers, and navigation equipment due to their resistance to seawater.

– Jewelry Making: Ideal for clasps, fasteners, and decorative elements, leveraging the metal’s aesthetic appeal.

– Optical Equipment: Employed in lens holders and adjustment mechanisms for cameras and telescopes.

SourcifyChina CNC brass parts are manufactured using high-quality brass material known for its excellent machinability properties. Brass, an alloy of copper and zinc, offers superior electrical conductivity and corrosion resistance. This makes it ideal for precision components.

Brass’s inherent durability and strength ensure that the parts can withstand substantial wear and tear, maintaining their functionality over extended periods. This robustness is essential in various industrial applications, where reliability is paramount.

The material’s workability allows for detailed and intricate designs, catering to custom specifications. This flexibility is vital for producing specialized CNC brass parts for different sectors, including automotive, electronics, and aerospace.

The lustrous finish of brass not only contributes to the aesthetic appeal of the parts but also adds a protective layer, enhancing longevity. Furthermore, brass is recyclable, making it an eco-friendly option for modern manufacturing needs.

In conclusion, the use of brass in SourcifyChina CNC parts combines durability, versatility, and sustainability, making it a preferred material in many high-precision industries. The exceptional qualities of brass ensure that the parts meet rigorous performance standards and offer reliable service across various applications.

SourcifyChina employs a meticulous quality control manufacturing process for CNC brass parts, ensuring exemplary precision and durability. Each stage, from material selection to final inspection, is carefully managed to uphold high standards.

Material selection is the foundation of quality. SourcifyChina prioritizes premium-grade brass to ensure the parts exhibit optimal strength, corrosion resistance, and a flawless finish. This initial step guarantees that the end product will meet the stringent industry specifications.

The CNC machining process involves cutting-edge technology and skilled technicians. SourcifyChina utilizes advanced CNC machines to deliver parts with precise tolerances, adhering to exact customer specifications. Each part is crafted with meticulous attention to detail.

Mid-process quality checks are integral to the workflow. Skilled inspectors monitor dimensions, surface finishes, and other critical parameters at various stages. These frequent inspections allow immediate adjustments to maintain consistent quality throughout production.

Post-machining treatments enhance the functionality and lifespan of the brass parts. Processes like deburring, polishing, and surface coating are meticulously performed. These treatments not only improve aesthetics but also add to the durability and reliability of the final parts.

Final inspection is thorough and exhaustive. Each CNC brass part undergoes a rigorous review, utilizing high-precision measuring instruments to verify compliance with design specifications. This comprehensive inspection ensures only defect-free parts reach customers.

SourcifyChina’s commitment to quality control extends beyond manufacturing. They provide robust documentation and traceability for every batch of parts produced. This transparency builds trust and confidence with their clients, reaffirming their commitment to delivering top-notch CNC brass parts.

Thanks to these stringent quality control measures, SourcifyChina stands as a reliable partner for customers seeking high-quality CNC brass parts. Their methodical approach ensures that every piece meets or exceeds expectations, providing unparalleled satisfaction and performance in various applications.

SourcifyChina specializes in the precision manufacturing of CNC brass parts, leveraging state-of-the-art technology to ensure high-quality and intricate components. Their advanced CNC machines enable the production of complex geometries with exceptional accuracy, meeting stringent industry standards.

The company offers a wide range of brass parts, customized to meet specific client requirements across various sectors, including automotive, electronics, and medical equipment. Their capabilities extend to both small-scale prototypes and large-scale production runs, demonstrating remarkable flexibility and scalability in operations.

Material selection and quality control are paramount at SourcifyChina. Brass is chosen for its excellent machinability, corrosion resistance, and thermal conductivity. Each part undergoes rigorous inspection processes, including dimensional checks and surface finish evaluations, to ensure it meets exacting specifications and functions reliably in its intended application.

SourcifyChina prides itself on its customer-centric approach, providing end-to-end support from initial consultation through to final delivery. Their experienced team works closely with clients to understand their needs, offering expert guidance on design optimization and cost-efficiency.

In conclusion, SourcifyChina’s CNC brass parts capabilities stand out due to their precision engineering, customization options, strict quality controls, and comprehensive customer service. These strengths enable them to deliver reliable and high-performance brass components that cater to various industry needs. By continually investing in advanced technology and skilled personnel, SourcifyChina ensures consistent excellence and innovation in their offerings.

Using CNC machining to produce brass parts offers numerous benefits, including precision, durability, and cost efficiency. This reliable method ensures consistent quality, making it ideal for various applications.

– Precision: CNC machines produce highly precise parts with tight tolerances, important for technical or intricate components.

– Durability: Brass parts crafted with CNC machining exhibit excellent durability and resistance to wear and corrosion.

– Cost Efficiency: Despite the initial investment, mass production lowers costs over time owing to reduced waste and minimal need for post-processing.

– Customizability: CNC machining allows for easy customization, fitting diverse specifications without the need for major readjustments.

– Speed: The process is faster than traditional methods, speeding up production cycles.

– Minimal Waste: The precision of CNC machining reduces material wastage, promoting sustainable manufacturing practices.

– Consistency: Achieves uniformity across multiple parts, ensuring each meets the required standards.

– Versatility: Suitable for producing components for industries ranging from automotive to electronics.

Each of these benefits underscores why CNC brass parts are increasingly used in modern manufacturing processes.

CNC brass parts are essential components in various industries due to their precision, durability, and conductivity. These parts exhibit numerous beneficial features.

– High Precision: CNC machining offers exceptional accuracy, ensuring each brass part meets exact specifications.

– Excellent Conductivity: Brass has outstanding electrical and thermal conductivity, making it ideal for electronic components.

– Corrosion Resistance: Brass resists corrosion and tarnishing, prolonging the lifespan of parts.

– Strength and Malleability: Brass is both strong and malleable, allowing for complex shapes and robust parts.

– Aesthetic Appeal: The golden hue of brass is visually appealing for decorative applications.

– Cost-Effective: CNC machining of brass is cost-efficient due to the material’s ease of machining and longevity.

– Versatility: Suitable for diverse applications from plumbing to musical instruments.

– Sustainability: Brass is recyclable, making it an environmentally friendly choice.

SourcifyChina is a renowned player in the CNC brass parts manufacturing sector, providing bespoke, high-precision solutions tailored to specific client needs. Their commitment to quality and meticulous attention to detail sets them apart in the competitive landscape.

With years of industry experience, SourcifyChina excels in producing custom brass components that adhere to the strictest standards. Their advanced CNC machinery enables the production of intricate parts with unfaltering accuracy, ensuring that every project meets the required specifications.

The company’s robust project management framework ensures timely delivery, enabling clients to maintain their production schedules without disruption. From initial design consultation through to final delivery, SourcifyChina offers comprehensive support.

SourcifyChina’s versatility in handling projects of various scales makes them a preferred partner for numerous industries. Whether it’s automotive, medical, or consumer electronics, their expertise spans multiple applications, guaranteeing optimum performance.

In summary, SourcifyChina’s dedication to precision, quality, and customer satisfaction makes them an invaluable asset in the world of custom CNC brass parts. Their comprehensive services and robust project execution ensure that clients receive top-notch products tailored to their unique requirements.

SourcifyChina is a renowned company specializing in the production of high-quality CNC brass parts. With a commitment to precision engineering and advanced manufacturing techniques, the company caters to a wide range of industries, including automotive, electronics, and machinery. SourcifyChina prides itself on utilizing state-of-the-art CNC technology to deliver brass components that meet stringent international standards. Their experienced team of engineers and machinists ensure each part achieves optimal performance and durability. By leveraging cutting-edge equipment and stringent quality control measures, SourcifyChina is able to provide customized solutions that meet the specific needs of their diverse clientele. The company also emphasizes efficient production timelines and competitive pricing, making it a preferred partner for businesses seeking reliable and high-performance brass parts. With a strong focus on innovation and customer satisfaction, SourcifyChina continues to establish itself as a leader in the CNC brass manufacturing industry.

CNC brass parts are pivotal in the Aerospace, Defense, and Marine sectors owing to their exceptional machinability, durability, and corrosion resistance. In aerospace, the precision and reliability of brass components are essential for critical systems such as fuel delivery, navigation, and hydraulic assemblies. Brass’s thermal conductivity and resistance to wear and fatigue ensure optimal performance in the high-stress environments encountered by aircraft. The precision offered by CNC machining guarantees that parts meet stringent aerospace standards, enabling seamless integration and superior performance, which are vital for the safety and efficiency of contemporary aircraft.

In the Defense and Marine sectors, CNC brass parts are equally indispensable. In defense, brass is commonly used for ammunition casings, connectors, and various tactical equipment due to its robustness and resistance to environmental factors. Its properties make it ideal for use in harsh conditions where durability and reliability are of utmost importance. Similarly, in marine applications, brass’s excellent resistance to corrosion from saltwater makes it ideal for manufacturing components for boats, ships, and submarines, such as valves, propeller shafts, and navigational instruments. The precision machining capabilities of CNC technology ensure that these parts operate seamlessly within complex marine systems, contributing to both performance and safety in these critical applications.

Computer Numerical Control (CNC) brass parts have become integral in the automotive industry due to their reliability, precision, and durability. Brass components in vehicles are frequently used for essential parts like connectors, fittings, and various other engine components because of their excellent corrosion resistance and electrical conductivity. For instance, brass CNC-machined parts are often found in fuel systems where they contribute to the accurate flow and measurement of fluids. Additionally, brass’s inherent thermal stability ensures these components can withstand the harsh conditions of an engine environment, maintaining performance even under high temperature and pressure. The precise nature of CNC machining allows for the creation of complex geometries and tight tolerances necessary for modern automotive applications, ensuring that every part fits and functions perfectly.

In the realm of electronics, CNC brass parts are equally essential, commonly used in connectors, terminals, and switches. The superior electrical conductivity and thermal properties of brass make it an excellent choice for these components, which are critical for ensuring reliable and efficient electronic circuits. For example, CNC-machined brass terminals are employed in a variety of electronic devices, from household appliances to telecommunications equipment, maintaining a secure and stable connection due to brass’s excellent alloy properties. The precision offered by CNC machining also ensures that these small, intricate components maintain consistency across large production runs, which is crucial for the mass production of electronic devices. Additionally, brass parts are often coated or plated to enhance their performance further, making them versatile elements in the rapidly advancing electronics industry.

CNC brass parts play a pivotal role in the construction industry due to their precision, durability, and suitability for a wide range of applications. Brass, an alloy of copper and zinc, is known for its excellent corrosion resistance, making it ideal for components exposed to harsh environmental conditions often found on construction sites. These parts are used in various building infrastructure elements, including plumbing fixtures, valves, and fittings, which require tight tolerances and reliable performance. The precision machining capabilities of CNC technology ensure that each brass component adheres to stringent specifications, enhancing the overall quality and safety of construction projects. Additionally, the malleability of brass makes it easy to machine into complex shapes, catering to custom architectural features and decorative elements that demand both functionality and aesthetic appeal.

In the energy sector, CNC brass parts are indispensable, particularly in oil, gas, and renewable energy systems. Brass components are used extensively in the manufacturing of connectors, terminals, and other critical parts for electrical systems due to their excellent electrical conductivity and thermal properties. This makes them perfect for use in high-voltage applications, where reliability and performance are paramount. Furthermore, the corrosion resistance of brass ensures longevity and minimal maintenance in challenging environments such as offshore oil rigs and wind turbine installations. In renewable energy systems, precision CNC-machined brass parts contribute to the efficiency and reliability of solar panels, wind turbines, and hydroelectric generators. This adaptability facilitates the seamless integration of brass components into cutting-edge energy solutions, supporting the transition towards more sustainable energy sources.

The industrial equipment sector extensively utilizes CNC brass parts owing to their durability, precision, and excellent anti-corrosive properties. Computer Numerical Control (CNC) machining allows for the production of brass components with highly intricate designs and tight tolerances, which is vital in industrial applications. Brass, being an alloy of copper and zinc, exhibits excellent thermal and electrical conductivity, making it ideal for components in machinery that require efficient heat dissipation and electrical conduction. Examples include gears, bearings, valves, and electrical connectors. The precision offered by CNC machining ensures that these parts operate seamlessly within intricate machinery, reducing wear and the need for frequent replacements, thereby contributing to overall equipment reliability and efficiency.

Moreover, the machinability of brass using CNC technology also leads to economic benefits in the industrial equipment industry. CNC machining enables the production of complex, high-quality parts with minimal waste, reducing material costs and adhering to strict budget constraints. The repeatability of CNC processes ensures each part matches exact specifications consistently, which is crucial for large-scale industrial applications where uniformity is key. Additionally, CNC machining of brass is relatively fast and requires less finishing work compared to other materials, translating to shorter production times and quicker turnaround for industrial equipment manufacturers. The cost-effectiveness and precision make CNC brass parts indispensable in sectors such as automotive, aerospace, and heavy machinery, where high performance and longevity are non-negotiable.

CNC (Computer Numerical Control) brass parts play an indispensable role in the medical devices industry, primarily because of the unique properties that brass offers, such as excellent resistance to corrosion, high malleability, and a natural antimicrobial surface. Brass components manufactured through CNC machining are integral in producing highly precise and reliable parts for medical instruments and equipment. For instance, brass fittings, valves, and connectors are commonly used in medical devices such as diagnostic machinery, ventilators, and surgical instruments. The ability of CNC machining to produce parts with high precision and tight tolerances ensures that these medical devices function reliably and safely, which is paramount in critical healthcare settings.

Moreover, the inherent qualities of brass, combined with the precision of CNC machining, contribute significantly to the safety and longevity of medical devices. The natural antimicrobial properties of brass help in minimizing the risk of infections, a critical consideration in medical environments where sterility is paramount. Additionally, the versatility of CNC machining makes it possible to create complex geometries and custom parts that adhere to stringent regulatory standards. This adaptability is particularly beneficial when producing components for bespoke medical devices or prototypes for new innovations in medical technology. Consequently, the application of CNC brass parts in the medical field not only enhances the reliability and functionality of medical devices but also plays a crucial role in improving patient safety and outcomes.

CNC (Computer Numerical Control) machining plays a pivotal role in the manufacturing of brass parts, delivering precision, consistency, and efficiency. Brass, an alloy of copper and zinc, is highly favored in machining due to its corrosion resistance, machinability, and aesthetic appeal. CNC brass parts are widely used across various industries such as automotive, aerospace, electronics, and plumbing. The versatility of CNC machines allows them to produce complex geometries and intricate designs with high accuracy, meeting stringent industry standards. This capability is particularly advantageous for applications requiring fine details and tight tolerances, ensuring that each part performs optimally within its designated context. Furthermore, the automation and repeatability of CNC machining significantly reduce human error, thereby enhancing the overall quality and uniformity of the produced components.

In the realm of manufacturing, the application of CNC-machined brass parts extends to both mass production and custom, small-scale fabrication. Manufacturers benefit from the efficiency of CNC machinery as it minimizes material waste and optimizes production time. For instance, in the electronics industry, CNC brass parts are indispensable in the creation of connectors, terminals, and other conductive components. Similarly, the plumbing sector relies on these parts for producing durable and reliable fixtures and fittings. The ease of adaptability in CNC programming allows for rapid prototyping and adjustments to designs without the need for extensive retooling, making it an ideal solution for short runs and iterative development processes. The integration of CNC machining in producing brass parts underscores the advancement in manufacturing techniques, enabling businesses to meet the demands of modern engineering and design with heightened precision and efficiency.

Here is a list of FAQs regarding manufacturing CNC brass parts quality work from SourcifyChina factory:

1. What is SourcifyChina’s experience in manufacturing CNC brass parts?

SourcifyChina has over a decade of experience specializing in high-precision CNC machining. Our skilled technicians and advanced machinery ensure top-quality brass parts for various industries.

2. How do you ensure the quality of CNC brass parts?

We adhere to strict quality control procedures, including material verification, in-process inspections, and final product testing. We are ISO 9001 certified and utilize state-of-the-art inspection equipment to meet industry standards.

3. What types of CNC brass parts can SourcifyChina manufacture?

We can manufacture a wide range of CNC brass parts, including but not limited to fittings, connectors, fasteners, and custom-designed components. Our capabilities cover a broad spectrum of industries like automotive, electronics, and plumbing.

4. What is the minimum order quantity (MOQ) for CNC brass parts?

Our MOQ varies depending on the complexity and size of the project. For specific details, please contact our sales team with your project requirements.

5. Can you provide custom designs for CNC brass parts?

Yes, we offer custom design services. Our engineering team can work with you to transform your concepts into high-precision brass components. We use CAD/CAM software to ensure accuracy and efficiency.

6. What is the typical lead time for an order?

Lead times depend on the complexity and quantity of the order. Typically, it ranges from 2 to 6 weeks. Please provide your project details for a more accurate timeline.

7. Do you offer prototyping services?

Yes, SourcifyChina provides prototyping services to help you refine designs and verify performance before mass production. We ensure rapid turnaround for prototypes to expedite the development process.

8. How do you handle shipping and logistics?

We offer comprehensive shipping solutions, including international shipping. We collaborate with reliable logistics partners to ensure timely delivery of your CNC brass parts.

9. What are your payment terms?

Our standard payment terms are usually T/T (Telegraphic Transfer) with a 30% deposit and 70% balance before shipment. We can discuss other payment options based on your needs.

10. How can I get a quote for my project?

To obtain a quote, please contact us with your project specifications, including design files, material requirements, and quantity. Our sales team will provide a detailed quotation promptly.

When considering CNC brass parts manufacturing from SourcifyChina factory, here are some crucial tips to ensure a smooth and successful collaboration:

1. Understand Capabilities: SourcifyChina offers a range of CNC machining services. Make sure their capabilities align with your project requirements by reviewing their equipment and technical expertise.

2. Material Quality: Brass comes in various grades. Communicate your specific material requirements clearly to ensure the use of the right brass alloy for your application.

3. Design Precision: CNC machining thrives on detailed designs. Provide accurate CAD models and detailed drawings, including tolerances and surface finish specifications.

4. Volume and Lead Time: Discuss your production volume and lead time expectations upfront. SourcifyChina should be able to provide a realistic production schedule and accommodate your timelines.

5. Communication: Maintain clear and consistent communication. Use platforms that allow real-time updates and track production progress to avoid potential misunderstandings.

6. Quality Control: Inquire about their quality control processes. Reliable manufacturers will have stringent QC measures, such as inspections at various production stages and final quality checks.

7. Prototypes and Samples: If possible, request prototypes or initial samples to validate the quality and precision before proceeding with full-scale production.

8. Cost Transparency: Ensure there is a clear understanding of pricing, including all potential additional costs like shipping, handling, and post-processing services.

9. Intellectual Property: Protect your designs and intellectual property. Verify that SourcifyChina has policies in place to safeguard your proprietary information.

10. After-Sales Support: Assess their after-sales service, including warranty, support, and the ability to handle any necessary modifications or reworks.

By addressing these aspects, you can leverage SourcifyChina’s expertise in CNC brass parts manufacturing while ensuring your project’s success.

Sure! Below is a list of Frequently Asked Questions (FAQ) along with answers for sourcing CNC brass parts from SourcifyChina factory:

What are the lead times for CNC brass parts from SourcifyChina?

The lead times typically depend on the order volume and complexity but generally range from 2 to 6 weeks. Quick-turn options may be available for urgent orders.

What materials does SourcifyChina offer for CNC brass parts?

SourcifyChina primarily offers various grades of brass including C36000, C37700, C26000, C28000, and custom alloys based on specific requirements.

What is the minimum order quantity (MOQ) for CNC brass parts?

The MOQ varies depending on the part complexity and size but usually starts at 100 pieces. For specific orders, please contact SourcifyChina for details.

Can SourcifyChina produce custom designs?

Yes, SourcifyChina specializes in custom CNC brass parts. Customers need to provide detailed drawings or CAD files for accurate quotes.

What quality control measures are in place?

SourcifyChina utilizes rigorous quality control processes including material certification, dimensional inspection, and functionality testing to ensure high-quality parts.

What are the payment terms?

SourcifyChina typically requires a 30% deposit upfront with the balance due before shipment. Payment methods include wire transfer, PayPal, and credit card.

Does SourcifyChina offer finishing services?

Yes, SourcifyChina provides various finishing options including plating, anodizing, polishing, and powder coating to meet specific requirements.

How can I request a quote?

You can request a quote by contacting SourcifyChina via email, phone, or their online form. Provide detailed specifications, including drawings, materials, and quantities needed.

Are samples available before placing a bulk order?

Yes, SourcifyChina offers sample production for customer approval before commencing with the bulk order. This ensures the parts meet your exact specifications.

Does SourcifyChina provide shipping and logistics support?

Yes, SourcifyChina can handle global shipping and logistics, offering various delivery options like DHL, FedEx, sea freight, and air freight to meet your needs.

This should give a concise overview of the common inquiries related to sourcing CNC brass parts from SourcifyChina.

Sourcing CNC brass parts from SourcifyChina factory can be efficient and cost-effective if you follow these tips:

1. Identify Your Requirements: Clearly define the specifications, quantity, and quality standards of the CNC brass parts you need. Detailed requirements facilitate accurate quotes and quality production.

2. Research the Factory: Verify SourcifyChina’s reputation through online reviews, testimonials, and industry forums. Look for feedback on their capabilities and reliability in CNC brass manufacturing.

3. Request Samples: Before placing a large order, ask for samples to evaluate the quality of their CNC brass parts. This helps in ensuring they meet your standards.

4. Communicate Clearly: Keep open and clear communication with the factory. Discuss timelines, production processes, and any potential challenges upfront. Clear communication prevents misunderstandings.

5. Negotiate Pricing: Get detailed quotes and compare them with other suppliers. Negotiate to get the best deal without compromising on quality. Consider the total cost, including shipping and any potential tariffs.

6. Check Certifications: Ensure SourcifyChina factory has the necessary certifications (ISO, RoHS, etc.) that align with your quality and compliance standards. This confirms their adherence to industry standards.

7. Review Terms & Conditions: Carefully review the contract, focusing on payment terms, delivery timelines, and warranty. Ensure favorable terms that protect your interests.

8. Inspect Upon Arrival: Once the parts arrive, inspect them for conformity to specifications before finalizing payment. This step ensures you receive what was promised.

9. Build Relationship: Cultivate a strong relationship with the factory. Long-term relationships often result in better service and pricing.

10. Leverage Technology: Use digital tools for project management, QA processes, and real-time communication to streamline the sourcing process.

By following these tips, you can effectively source high-quality CNC brass parts from SourcifyChina factory, ensuring a smooth and profitable business transaction.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.