Reliable Phenolic Machining Solutions by SourcifyChina: Your Trusted Factory Partner

Looking for top-notch phenolic machining? SourcifyChina is your reliable factory partner, offering precision and quality in phenolic machining solutions. Discover dependable manufacturing services that meet your exact specifications with superb accuracy and efficiency.

Choosing “SourcifyChina” Factory for purchasing phenolic machining from China ensures high-quality products. Their experienced team provides precision manufacturing, meeting international standards and specific requirements to optimize product performance and durability.

“SourcifyChina” offers competitive pricing without compromising quality. Leveraging cost-effective labor and advanced technology, they deliver exceptional value, which makes them an attractive choice for budget-conscious buyers.

They boast a robust quality control system, ensuring consistent product excellence. Frequent inspections and adherence to stringent guidelines guarantee that each phenolic machining piece meets your exact specifications.

Efficient supply chain management is another benefit of choosing “SourcifyChina.” Their well-established logistics network ensures timely delivery, minimizing downtime and ensuring your production schedules remain on track.

Customer support at “SourcifyChina” is outstanding. Their responsive service team addresses inquiries promptly, ensuring a smooth purchasing experience from initial contact to final delivery.

Innovative manufacturing solutions are a hallmark of “SourcifyChina.” They continually invest in advanced machinery and technology, enabling them to produce complex phenolic machining components with precision.

Environmental responsibility is embedded in their operations. “SourcifyChina” employs eco-friendly practices and sustainable resource management, making them a responsible choice for environmentally-conscious buyers.

Their vast industry experience and expertise enable them to offer insightful guidance on material selection and engineering, ensuring optimized performance of your phenolic machined components.

“SourcifyChina” Factory builds strong, long-term relationships with clients. Their dedication to understanding client needs and delivering consistently high-quality products fosters trust and reliability.

Overall, “SourcifyChina” Factory is the ideal partner for buyers seeking high-quality, cost-effective phenolic machining solutions in China. With their commitment to excellence, robust quality control, and superior customer service, you can be assured of a seamless, reliable purchasing experience.

Phenolic machining involves shaping phenolic resin-based materials into desired forms. This versatile process applies to electrical components, insulators, and mechanical parts due to phenolic’s excellent insulating properties and mechanical strength.

Key types and options in phenolic machining include:

– Routing: Ideal for intricate shapes and details.

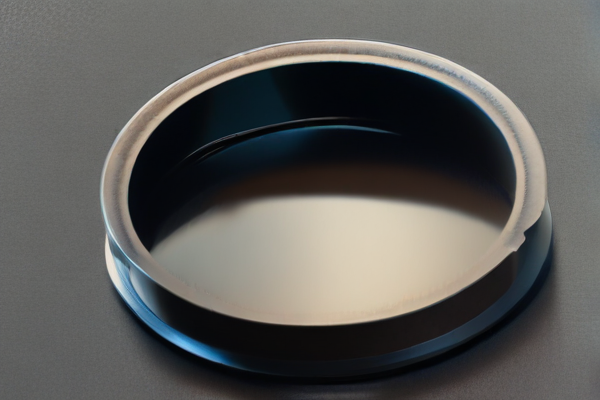

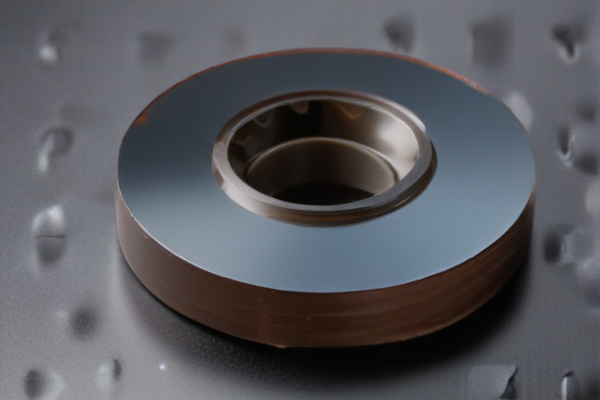

– Turning: Used for cylindrical and rounded components.

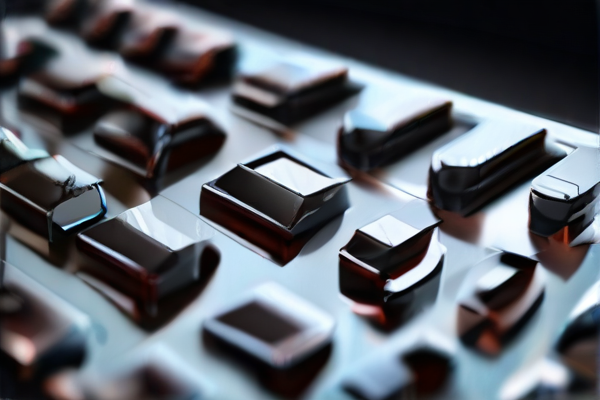

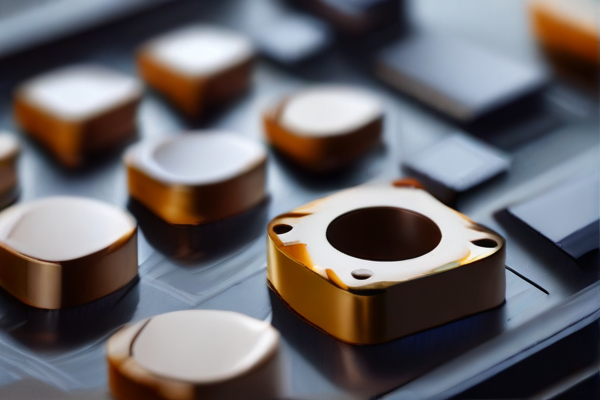

– Milling: Suitable for complex and multi-axis machining applications.

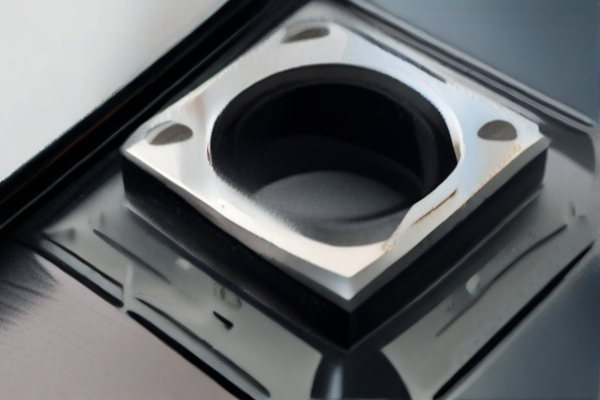

– Drilling: Essential for creating precise holes and aperture.

– Sawing: Common for cutting large phenolic sheets into manageable sizes.

– Grinding: Provides a smooth finish and precise thickness control.

– Laser Cutting: Offers high precision for intricate patterns and minimized material wastage.

Material options and factors:

– Grades: Various grades like CE (Canvas/Phenolic), LE (Linen/Phenolic), and G-10 (Glass Cloth/Phenolic) for different mechanical, electrical, and thermal properties.

– Thickness: Options range from thin sheets to thick blocks to accommodate diverse applications.

– Color: Phenolic materials come in different colors for aesthetic or functional purposes, such as improved visibility or UV resistance.

Application considerations:

– Tolerances: Phenolic machining must account for material expansion or contraction.

– Tooling: Specialized carbide or diamond-tipped tools offer enhanced durability and precision.

– Coolants: Certain coolants optimize tool life and material finish by reducing heat buildup.

Pros and cons:

– Pros: High precision, excellent electrical insulation, and strong chemical resistance.

– Cons: Material brittleness and potential for dust generation during machining, necessitating proper safety measures.

Understanding these aspects ensures that phenolic machining meets the specific needs of various industrial applications effectively. Adjustments in techniques and materials can tailor the process to produce high-quality, customized phenolic components.

Phenolic machining involves the precise shaping and forming of phenolic resins into various industrial components due to its excellent thermal, electrical, and mechanical properties.

– Electrical Insulation Parts: Widely used in transformers, circuit breakers, and other electrical equipment.

– Mechanical Components: Bearings, gears, and wear-resistant parts in machinery.

– Aerospace: Lightweight, durable components in aircraft interiors and systems.

– Automotive Industry: High-performance brake and clutch systems.

– Chemical Industry: Corrosion-resistant pump and valve components.

– Medical Devices: Sterilizable and chemical-resistant components for medical equipment.

– Textile Machinery: Wear-resistant parts like bobbins and shuttles.

– Oil & Gas: High-temperature, corrosion-resistant parts for drilling and processing.

– Food Processing Equipment: FDA-approved phenolics for food-safe applications.

– Custom Prototyping: Precise and durable prototypes for various applications.

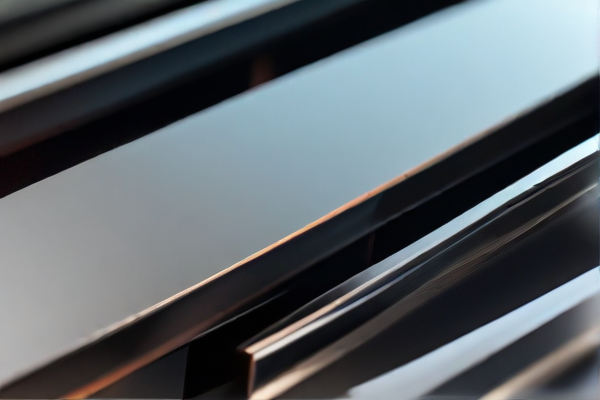

SourcifyChina offers high-quality phenolic machining materials known for their durability and resistance to various chemicals. These materials are ideal for applications requiring high thermal and electrical insulation.

The phenolic materials provided are crafted to meet stringent industry standards. They exhibit excellent mechanical properties, making them suitable for producing complex components and parts used in different sectors, such as automotive and electrical industries.

Clients are guaranteed consistency and precision in every order. SourcifyChina’s phenolic machining materials are engineered to maintain stability under extreme conditions, ensuring longevity and reliability of the manufactured parts.

SourcifyChina emphasizes sustainability, utilizing eco-friendly practices in the production of phenolic materials. This commitment helps in minimizing waste and environmental impact while delivering top-notch products to customers worldwide.

In summary, SourcifyChina’s phenolic machining materials offer unmatched durability, precision, and sustainability, making them the preferred choice for industrial applications. With a focus on quality and eco-friendly practices, the company ensures that every product not only meets but exceeds customer expectations.

SourcifyChina excel in phenolic machining, emphasizing stringent quality control measures throughout the manufacturing process. Each step is meticulously monitored to ensure precision, consistency, and compliance with industry standards.

Raw materials are carefully sourced and inspected to maintain high quality. Through advanced testing methodologies, SourcifyChina verifies the integrity and performance characteristics of each phenolic component before machining begins.

State-of-the-art machinery and skilled technicians are utilized to execute precise machining operations. SourcifyChina employs CNC technology for intricate shapes and tolerances, ensuring uniformity across all products.

Post-machining inspections involve rigorous checks to verify dimensional accuracy and surface finish. This layer of quality control helps minimize defects and uphold product reliability.

Customer feedback is continually incorporated into the quality control loop. By analyzing performance data and client input, SourcifyChina refines its processes to achieve exceptional standards of phenolic machining.

Overall, SourcifyChina’s phenolic machining quality control process is a comprehensive system designed to deliver superior products. From raw material procurement to final inspection, every phase is executed with meticulous attention to detail, ensuring optimal performance and customer satisfaction.

SourcifyChina excels in precision phenolic machining, translating intricate designs into high-performance components. Utilizing state-of-the-art equipment, they ensure precise cuts and superior finishes, tailored to meet diverse industrial needs.

Their expertise spans both large-scale productions and customized projects, harnessing advanced techniques to maintain consistent quality. High tolerance levels are achieved, critical for sectors demanding stringent specifications.

SourcifyChina prioritizes innovation and continuous improvement. Employing a team of skilled engineers, they develop solutions that enhance product durability and efficiency, addressing evolving market demands.

Client satisfaction is paramount, reflected in their seamless service delivery. From initial consultation to the final product, SourcifyChina ensures uncompromised excellence and reliability.

Phenolic

Machining: Key Benefits

Phenolic machining offers numerous advantages due to its unique properties, including high strength, moisture resistance, and electrical insulation.

#### Key Benefits:

– High Strength and Durability: Phenolic materials are known for their exceptional mechanical strength, making them ideal for heavy-duty applications.

– Moisture Resistance: These materials exhibit excellent resistance to moisture, ensuring long-term dimensional stability.

– Electrical Insulation: Phenolic resins provide superior electrical insulating properties, essential for electrical and electronic applications.

– Thermal Resistance: Phenolic materials can withstand high temperatures, adding another layer of safety and reliability.

– Chemical Resistance: Resistance to a variety of chemicals makes phenolic machining suitable for harsh environments.

– Ease of Machining: Phenolic materials are relatively easy to machine, allowing for high precision and intricate designs.

– Cost-Effective: The durability and long lifespan of phenolic parts make them a cost-effective choice in the long run.

– Wide Range of Applications: From automotive to aerospace, phenolic machining serves diverse industries due to its versatile properties.

In summary, phenolic machining offers numerous benefits, including high mechanical strength, excellent thermal and electrical properties, and resistance to moisture and chemicals, making it a versatile and cost-effective solution for many industrial applications.

Phenolic machining involves working with phenolic resins, a type of plastic known for its durability, chemical resistance, and thermal stability. This material’s unique properties make it suitable for various industrial applications.

– Durability: Phenolic materials offer high mechanical strength, maintaining structural integrity under stress.

– Chemical Resistance: These resins resist many chemicals, including acids and solvents, making them ideal for harsh environments.

– Thermal Stability: Phenolics can withstand high temperatures without degrading, suitable for applications with significant heat exposure.

– Electrical Insulation: Providing excellent electrical insulation properties, phenolic materials are commonly used in electrical and electronic components.

– Lightweight: Despite their strength, phenolic materials are relatively lightweight, offering ease of handling and installation.

– Dimensional Stability: They maintain their shape and size over time, even under varying environmental conditions.

– Machinability: Phenolic resins can be precisely machined using standard cutting tools, ensuring accurate and clean finishes.

– Moisture Resistance: They possess low moisture absorption, maintaining performance in humid conditions.

– Versatility: Phenolic materials come in various grades and forms, catering to diverse industrial needs.

At SourcifyChina, we specialize in phenolic machining, providing custom products tailored to suit a wide variety of industries. Phenolic materials are known for their excellent thermal, electrical insulation, and mechanical strength properties, making them a versatile choice for numerous applications.

Our skilled team leverages state-of-the-art equipment and innovative techniques to achieve precision and quality in every project. Whether you require intricate components or large-scale fabrications, we are equipped to meet your specifications and tight tolerances. Our dedication ensures consistent performance and reliability for your end-use scenarios.

SourcifyChina’s phenolic machining services are comprehensive, encompassing design consultation, material selection, prototyping, and full-scale production. We prioritize client collaboration to ensure the final product meets all technical and functional requirements. Our robust quality control processes further cement our commitment to delivering top-notch products.

Choose SourcifyChina for your phenolic machining needs and experience unparalleled excellence and innovation. We pride ourselves on transforming complex projects into success stories, ensuring optimal outcomes and client satisfaction. Let us help you take your project from concept to completion seamlessly and efficiently.

SourcifyChina Phenolic Machining is a pioneering manufacturer specializing in the precision machining of phenolic and composite materials for diverse industrial applications. With a reputation built on quality and innovation, the company leverages state-of-the-art technology and highly skilled craftsmanship to deliver superior machining solutions tailored to customers’ specific needs. Their extensive product range includes machined components for electrical insulation, automotive, aerospace, and heavy machinery industries, underscoring their versatility and expertise within the sector. By maintaining stringent quality control processes and ensuring compliance with international standards, SourcifyChina consistently meets and exceeds client expectations. The company prides itself on its commitment to sustainability, utilizing environmentally responsible practices across all stages of production. With a customer-centric approach, fast turnaround times, and competitive pricing, SourcifyChina Phenolic Machining stands as a trusted partner for businesses seeking reliable and high-quality phenolic machining services.

Phenolic machining has become instrumental in the aerospace, defense, and marine industries due to the exceptional properties of phenolic materials, including high strength-to-weight ratios, excellent thermal resistance, and superior electrical insulation capabilities. In the aerospace sector, phenolic composites are extensively used for manufacturing critical components such as interior panels, ducting systems, and insulation parts in both commercial and military aircraft. The ability to precisely machine phenolic materials allows for the production of intricate shapes and designs that meet the stringent safety and performance standards required in aviation. This ensures not only the durability and reliability of aerospace components but also contributes to the overall efficiency of aircraft by reducing weight and improving aerodynamic performance.

In the defense industry, phenolic machining plays a key role in fabricating specialized parts for military vehicles, weapon systems, and electronic enclosures. Phenolic materials provide robust mechanical properties and chemical resistance, ensuring that components can withstand harsh operating environments and intense mechanical stress. For marine applications, phenolic machining is utilized to create durable and moisture-resistant parts, such as bulkheads, decking, and various structural elements of ships and submarines. The excellent water and corrosion resistance of phenolic composites make them ideal for withstanding prolonged exposure to seawater and other marine conditions. By leveraging phenolic machining, these industries achieve optimal performance, longevity, and safety in their critical applications, underscoring the material’s vital role in advancing technology and maintaining operational readiness.

Phenolic machining, which refers to the precision shaping and forming of phenolic materials, plays a crucial role in the automotive industry. Phenolic resins are engineered to withstand high temperatures and mechanical stress, making them ideal for under-the-hood applications such as brake pads, engine components, and transmission parts. These components often require intricate shapes and tight tolerances to ensure optimal performance and reliability. The machinability of phenolic materials allows manufacturers to create complex geometries with high precision, thus enhancing the durability and efficiency of automotive systems. Additionally, phenolic materials offer excellent wear resistance and low friction, contributing to the longevity and safety of automotive components.

In the realm of electronics, phenolic machining is equally significant. Phenolic laminates are widely used in the production of printed circuit boards (PCBs) due to their excellent insulating properties, thermal stability, and mechanical strength. The ability to machine phenolic materials accurately ensures that electrical components can be securely mounted and connected, minimizing the risk of circuit failures. Moreover, phenolic materials’ resistance to moisture and chemicals makes them suitable for use in a variety of electronic devices, ranging from consumer gadgets to industrial equipment. Through precise machining, phenolic-based insulating components, housings, and connectors can be produced, ensuring reliable performance in demanding electronic applications. The versatility and machinability of phenolic materials thus play an indispensable role in advancing both automotive and electronics industries.

Phenolic machining, a process involving the shaping and tooling of phenolic resins or composite materials based on phenolic resins, plays a critical role in modern construction applications. Due to its exceptional thermal stability, mechanical strength, and resistance to moisture and chemicals, phenolic materials are ideal for various construction components. These properties allow phenolic panels and parts to be used extensively in the creation of durable building exteriors, moisture-resistant bathroom partitions, and high-strength laminate flooring. The precision offered by phenolic machining ensures that components fit together seamlessly, enhancing both the aesthetic appeal and structural integrity of buildings. Moreover, phenolic machining facilitates the production of custom-designed elements, allowing architects and builders to achieve intricate designs and meet specific engineering requirements.

In the energy sector, phenolic machining is indispensable due to the material’s excellent electrical insulating properties and high strength-to-weight ratio. Phenolic components are widely used in electrical insulation systems, such as switchgear, transformers, and other critical power distribution equipment. By utilizing phenolic machining, manufacturers can produce precise and complex shapes necessary for insulating components that must withstand high voltages while maintaining mechanical stability under various operational stresses. Additionally, phenolic materials are employed in the production of turbine blades and other components within renewable energy systems, such as wind and hydroelectric power installations. Their robustness and resistance to environmental degradation ensure longevity and reliability in demanding energy applications, ultimately contributing to the efficiency and sustainability of power generation systems.

Phenolic machining plays an integral part in the industrial equipment industry due to the unique properties of phenolic materials, which include excellent mechanical strength, dimensional stability, and resistance to heat, chemical corrosion, and electrical conductivity. These attributes make phenolic components highly desirable for manufacturing parts in heavy machinery, electrical systems, and wear-resistant applications. The precision required in producing gears, bushings, insulators, and other complex parts is achieved through advanced phenolic machining techniques. Such techniques allow for the creation of components that are not only durable but also lightweight and cost-effective, enhancing the overall efficiency and longevity of industrial equipment. The versatility in machining phenolic materials ensures suitability across a broad spectrum of applications, from mining and construction machinery to high-precision aerospace and electronics equipment.

In the realm of industrial equipment, phenolic machining is particularly valuable due to its customization capabilities that cater to specific operational requirements. For example, custom-engineered phenolic parts are used in high-stress environments where metal components might fail due to friction or chemical exposure. The insulating properties of phenolics also make them indispensable in electrical equipment, providing reliable performance and reducing the risk of electrical failures. Furthermore, the ease with which phenolic materials can be machined into complex shapes and fine tolerances supports the trend towards more compact and efficient industrial designs. This adaptability not only maintains the integrity and functionality of the equipment but also contributes to advancements in automation and technological integration within the industry. Overall, phenolic machining stands out as a crucial process for enhancing the durability, performance, and customizability of industrial equipment.

Phenolic machining refers to the precision shaping and forming of materials made from phenolic compounds, which are known for their excellent mechanical strength, electrical insulation properties, and resistance to heat and chemicals. In the medical device industry, phenolic machining has become crucial for producing components that need to withstand rigorous conditions and maintain high levels of reliability and safety. Phenolic materials, such as Bakelite and glass-filled phenolic resins, can be machined into intricate shapes with fine tolerances, which is essential for developing complex medical devices like surgical instruments, imaging equipment, and diagnostic tools. These components often demand biocompatibility, durability, and minimal interference with electronic signals, making phenolic compounds an ideal choice for a myriad of medical applications.

Moreover, the sterilization and hygiene requirements within the medical field are substantial, and phenolic materials excel in environments where sterilization processes, such as autoclaving, are routine. The ability of phenolic machined parts to withstand high temperatures and exposure to disinfectants without degradation ensures that medical devices remain safe and effective over prolonged use. For instance, phenolic-based components are used in manufacturing housing and brackets for diagnostic sensors and imaging machines, where electrical insulation minimizes the risk of short circuits and signal distortion. Additionally, phenolic materials can be crafted to include custom features like grooves, threads, and slots, making them versatile for designing tailored solutions to meet specific medical needs, thereby advancing medical technology and healthcare delivery.

Phenolic machining pertains to the precise shaping, cutting, and finishing of phenolic materials, which are a type of synthetic polymer reinforced with phenolic resin. These materials, known for their excellent high-temperature stability, electrical insulation, and resistance to chemicals and water, are pivotal in various industrial applications. Machining phenolics requires specialized techniques and tools due to their abrasive nature, which can wear down conventional cutting tools. Utilizing diamond-tipped or carbide tools is common practice to ensure precision and maintain the integrity of the machined parts. The machining process itself must account for the material’s brittleness and potential for dust generation, necessitating adequate ventilation and dust management systems to maintain a safe working environment.

In the realm of manufacturing, phenolic machining is crucial for producing components used in aerospace, automotive, electrical, and marine industries. Commonly machined phenolic products include bearings, gears, insulators, and structural parts, which benefit from the material’s durability and thermal resistance. For instance, electrical insulators machined from phenolic materials are integral in electrical and electronic devices, providing both mechanical support and electrical isolation. Similarly, phenolic gears and bearings are chosen for applications where reduced friction and high load capacity are required, such as in heavy machinery and automotive components. By leveraging precision machining techniques, manufacturers can produce highly reliable and efficient phenolic parts, contributing significantly to the performance and longevity of industrial equipment and consumer products.

Q1: What types of phenolic materials are available for machining at SourcifyChina factory?

A1: SourcifyChina offers a variety of phenolic materials, including paper-based, fabric-based, and glass-based phenolics. These materials are chosen based on the specific requirements of your application, such as mechanical strength, thermal stability, and electrical insulation properties.

Q2: What are the typical applications of phenolic machined parts?

A2: Phenolic machined parts are widely used in electrical and electronic equipment, automotive components, aerospace applications, and industrial machinery. They are valued for their excellent thermal insulation, high mechanical strength, and resistance to chemicals.

Q3: Can SourcifyChina provide custom machining services for phenolic materials?

A3: Yes, SourcifyChina specializes in custom machining services tailored to meet your specific requirements. They use advanced CNC machinery and precision tools to ensure high-quality, accurate parts according to your design specifications.

Q4: How does SourcifyChina ensure quality in phenolic machined parts?

A4: SourcifyChina adheres to strict quality control protocols, including material inspection, precision machining, and final product testing. They also comply with industry standards and certifications to guarantee the highest quality in every machined part.

Q5: What is the typical lead time for an order of phenolic machined parts?

A5: Lead times vary based on the complexity and volume of the order. However, SourcifyChina generally offers competitive lead times and strives to accommodate urgent requests whenever possible. Contacting their customer service for specific timelines is recommended.

Q6: Can SourcifyChina provide prototypes before full-scale production?

A6: Yes, SourcifyChina can provide prototypes to help you validate your design before commencing full-scale production. This allows for any necessary adjustments and ensures that the final product meets your expectations.

Q7: What is the cost structure for phenolic machining services at SourcifyChina?

A7: The cost structure depends on factors such as material type, complexity of the design, quantity, and specific machining requirements. SourcifyChina provides competitive pricing and can offer detailed quotations upon request.

Q8: How do I place an order or request a quote from SourcifyChina for phenolic machined parts?

When considering phenolic machining manufacturing from SourcifyChina factory, there are several tips to optimize quality, efficiency, and cost-effectiveness:

1. Understand Material Properties: Phenolic compounds are known for their durability, thermal resistance, and electrical insulating properties. Familiarize yourself with these characteristics to ensure they align with your project’s requirements.

2. Choose the Right Grade: Phenolic comes in various grades (e.g., paper, fabric, and glass reinforced). Select the appropriate grade based on your application’s mechanical and electrical demands.

3. Precision Machining: Phenolic material can be abrasive; hence, using carbide or diamond-coated tools can enhance machining efficiency and tool longevity. Ensure that the factory employs CNC machinery with adequate cooling systems to maintain precision.

4. Quality Control: Verify that SourcifyChina follows stringent quality control protocols. Request detailed inspection reports and testing data to ensure compliance with your standards, particularly for tolerance and surface finish.

5. Customization Capabilities: Discuss customization options upfront. SourcifyChina should be capable of handling bespoke designs, complex geometries, and specific tolerances. Provide comprehensive CAD files and detailed specifications to avoid miscommunication.

6. Volume and Lead Time: Clarify production volumes and lead times. Understand SourcifyChina’s capacity for scaling production to meet your requirements. Early engagement can prevent potential delays.

7. Competitive Pricing: Obtain a detailed quote outlining all costs, including material, machining, and shipping. Compare this with other suppliers to ensure competitive pricing without compromising quality.

8. Communication and Support: Maintain clear and ongoing communication channels with your contact at SourcifyChina. A responsive support team can be invaluable for addressing issues promptly and ensuring a smooth manufacturing process.

9. Post-Machining Processes: Ensure that the factory can handle post-machining processes like deburring, cleaning, and finishing treatments, which are crucial for the final product’s performance and aesthetics.

10. Sustainability and Compliance: Verify that SourcifyChina adheres to environmental and industry standards. Ethical manufacturing practices can impact your brand’s reputation and compliance with international regulations.

By integrating these tips into your collaboration with SourcifyChina, you can effectively navigate the complexities of phenolic machining manufacturing.

Sure, here are some frequently asked questions (FAQ) along with their answers:

1. What is phenolic machining?

Phenolic machining involves the process of shaping and fabricating components from phenolic resin-based materials. These materials are commonly used in high-performance applications due to their durability, heat resistance, and insulating properties.

2. Why should I choose SourcifyChina factory for phenolic machining?

SourcifyChina factory offers state-of-the-art machinery, experienced technicians, and rigorous quality control processes. We provide cost-effective solutions while maintaining high standards of precision and reliability.

3. What types of phenolic materials do you work with?

We machine a wide range of phenolic materials, including but not limited to Bakelite, canvas phenolic, and paper phenolic. Each type has specific properties suited for various applications.

4. What are the applications of machined phenolic parts?

Machined phenolic parts are used in various industries such as electrical, automotive, aerospace, and marine. They are commonly found in insulators, gaskets, bushings, and structural components.

5. Can you provide custom phenolic machining services?

Yes, we offer customized machining services tailored to meet your specific requirements. Provide us with your design specifications, and our team will work to deliver parts that match your needs.

6. How do you ensure the quality of machined phenolic parts?

We adhere to stringent quality control measures, including material inspection, dimensional accuracy verification, and surface finish checks. Our facility is equipped with advanced equipment to ensure high precision.

7. What is the lead time for phenolic machining orders?

Lead times can vary depending on the complexity and quantity of your order. Typically, it ranges from a few days to a few weeks. Contact us with your project details for a more accurate estimate.

8. Can you handle large volume orders?

Yes, we have the capacity to handle both small and large volume orders efficiently. Our scalable production processes ensure timely delivery regardless of order size.

9. What is your pricing structure for phenolic machining?

Pricing is determined based on several factors including material type, part complexity, volume, and additional services required. For precise quotes, please provide detailed specifications of your project.

10. How can I place an order or get a quote?

Sourcing phenolic machining services from a reputable factory like SourcifyChina requires a strategic approach to ensure quality, efficiency, and cost-effectiveness. Here are some key tips to guide you through the process:

1. Research and Validate: Begin by thoroughly researching SourcifyChina and other potential suppliers. Look for reviews, client testimonials, and their experience in phenolic machining. Ensure they have a solid track record of delivering high-quality products.

2. Specify Requirements: Clearly outline your project specifications, including material grades, dimensions, tolerances, and any special treatments or coatings required. Detailed requirements help avoid misunderstandings and ensure the product meets your standards.

3. Request Samples: Before committing to a large order, request samples of the phenolic machined parts. Inspect the samples for compliance with your specifications and quality expectations.

4. Factory Visit: If feasible, visit SourcifyChina’s factory to assess their manufacturing capabilities, quality control processes, and overall working environment. This can provide insights into their operational reliability.

5. Quality Assurance: Confirm that the factory adheres to international quality standards, such as ISO certifications. Ensure they have robust quality control measures and inspection processes in place.

6. Cost Estimates and Negotiation: Obtain detailed cost estimates, including material, machining, and shipping costs. Don’t hesitate to negotiate for better pricing, especially for bulk orders, while ensuring that quality is not compromised.

7. Lead Time and Logistics: Clarify the lead time required for production and shipping. Factor in any potential delays and plan your inventory accordingly.

8. Communication: Maintain clear and consistent communication with the factory. Designate a point of contact who can address any issues promptly and efficiently.

9. Pilot Run: For large orders, consider a pilot run to validate the production process and quality before full-scale manufacturing.

10. Contract and Terms: Draft a comprehensive contract detailing all terms, including payment schedules, delivery timelines, and quality standards. Ensure there’s a clause for resolving disputes amicably.

By following these tips, you can successfully source phenolic machining from SourcifyChina, ensuring a smooth and satisfactory partnership.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.