“Reliable Brass CNC Parts from SourcifyChina: High-Quality Factory Solutions for Precision Manufacturing”

SourcifyChina is your dependable source for brass CNC parts, offering factory-direct solutions that ensure precision and quality. Trust us for reliable, high-performance components to meet all your manufacturing needs.

Choosing SourcifyChina Factory for buying brass CNC parts ensures high-quality materials and precision engineering, thanks to their robust quality control processes and cutting-edge technology. The factory’s experienced workforce delivers exceptional craftsmanship in every part produced.

For global buyers, SourcifyChina Factory streamlines the purchasing process by offering flexible and comprehensive supply chain solutions. Their efficient logistics management guarantees timely deliveries, minimizing delays and reducing costs.

SourcifyChina Factory is known for its competitive pricing without compromising quality. Their cost-effective production methods and direct sourcing strategies help buyers achieve significant savings on bulk orders.

Moreover, SourcifyChina Factory provides excellent customer support, with representatives available to assist with inquiries, customization requests, and any issues that may arise. Their commitment to customer satisfaction reflects their dedication to fostering strong client relationships.

In conclusion, SourcifyChina Factory stands out as a reliable partner for purchasing brass CNC parts, combining quality, cost efficiency, and unparalleled customer service. This makes them the ideal choice for buyers seeking to optimize their procurement processes while ensuring high standards.

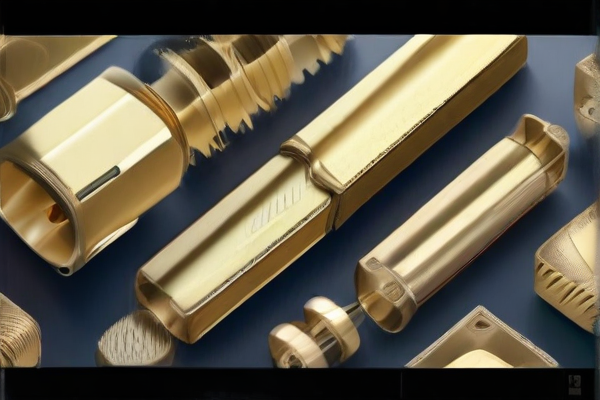

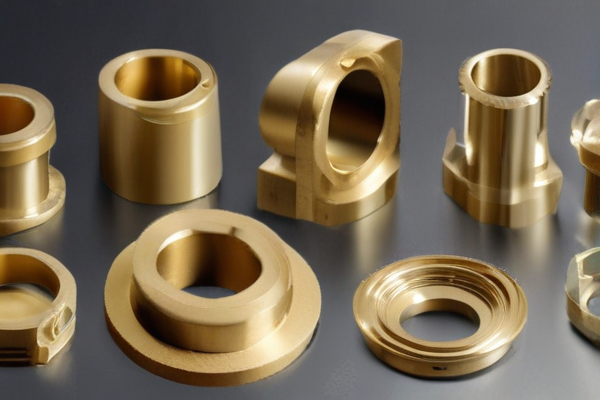

Brass CNC parts come in various shapes and sizes, offering precision and durability. CNC machining enables the production of intricate components used in different industries such as automotive, aerospace, and plumbing.

Options for brass CNC parts include:

– Connectors: Used in electrical and plumbing systems.

– Bushings: Reduce friction in mechanical applications.

– Valves: Control the flow of fluids or gases.

– Threaded Inserts: Enhance the strength of connections in softer materials.

– Fittings: Connect pipes and tubes reliably.

– Gears: Essential in automotive and industrial machinery.

– Fasteners: Bolts, screws, and nuts with enhanced corrosion resistance.

– Manifolds: Distribute fluid or gas from a single source to multiple destinations.

– Pins: Provide pivot points in mechanical assemblies.

– Spacers: Maintain proper distance between parts.

– Couplings: Connect rotating shafts and transfer torque.

– Turned Parts: Custom components made to specific dimensions.

– Custom Prototypes: Tailored to meet specific design requirements.

– Electrical Contacts: Ensure reliable electrical connections.

Brass offers advantages such as excellent machinability, corrosion resistance, and good thermal and electrical conductivity. These characteristics make it a preferred material for a wide range of applications.

Brass CNC parts are widely used in various industries due to their durability, corrosion resistance, and excellent machinability, making them ideal for precision components. Here are some key applications:

– Aerospace: Precision components for aircraft and spacecraft systems.

– Automotive: Fuel systems, engine components, and brake systems.

– Electronics: Connectors, terminals, and heat sinks.

– Plumbing: Fittings, valves, and water supply components.

– Medical: Surgical instruments, diagnostic equipment, and implants.

– Marine: Corrosion-resistant hardware for boats and ships.

– Industrial Machinery: Gears, bearings, and hydraulic components.

– Musical Instruments: Parts for brass wind instruments.

Brass CNC parts are essential in creating reliable and long-lasting products across these sectors, enhancing performance and safety.

SourcifyChina specializes in brass CNC parts, known for their excellent conductivity and corrosion resistance. Brass is particularly advantageous for components requiring a balance between durability and machinability. Modern CNC techniques at SourcifyChina ensure precision and adherence to stringent quality standards.

Brass is an alloy of copper and zinc, offering a combination of mechanical properties well-suited for diverse industrial applications. The material’s inherent machinability allows for intricate designs and fine detailing, making it highly desirable for custom components.

The brass used by SourcifyChina undergoes meticulous quality checks to ensure uniformity in its physical and mechanical properties. This rigorous inspection process guarantees that each CNC machined part meets rigorous performance expectations, contributing to the reliability and efficiency of the end applications.

Moreover, brass’s thermal and electrical conductivity make it ideal for components in electronic and electrical assemblies. SourcifyChina leverages these properties to produce parts that perform reliably in high-stress and precise requirements, proving their expertise and trustworthiness in delivering top-quality CNC brass parts.

By incorporating state-of-the-art CNC machining techniques, SourcifyChina ensures minimal waste and consistent output quality. This efficiency translates to cost benefits for clients while maintaining high standards. When combined with the exceptional attributes of brass, customers can expect parts that combine superior performance with economic value.

SourcifyChina specializes in producing high-quality brass CNC parts, adhering to stringent quality control standards. Their manufacturing begins with the selection of premium-grade brass, ensuring durability and precision for each component.

During production, CNC machines are meticulously calibrated, reducing any risk of deviation. Skilled technicians oversee the operations, regularly inspecting machine settings to maintain optimal precision throughout the process, all while ensuring compliance with industry standards.

Post-production, each brass CNC part undergoes rigorous quality checks, including dimensional accuracy, surface finish, and stress testing. This multi-layered inspection ensures that only the highest quality parts reach clients.

SourcifyChina also employs advanced statistical process control (SPC) software, allowing real-time monitoring and adjustments. This proactive approach minimizes defects and enhances overall efficiency in the manufacturing process, ensuring consistent product quality.

Finally, feedback from customers is integrated into the continuous improvement process. This customer-centric approach helps SourcifyChina to refine its quality control measures, fostering long-term client relationships and maintaining its reputation for excellence in the field of CNC machining.

SourcifyChina specializes in the precise manufacturing of brass CNC parts, leveraging advanced technology and equipment to produce high-quality components. Their capabilities include intricate machining, milling, and turning processes, which ensure excellent accuracy and reliability.

Their expertise in CNC machining allows them to deliver complex brass parts tailored to various industries, including automotive, electronics, and medical. SourcifyChina’s skilled engineers meticulously design and verify each piece to meet stringent industry standards and customer specifications.

Through state-of-the-art inspection techniques and comprehensive quality control, SourcifyChina guarantees superior craftsmanship. Each brass CNC part undergoes rigorous testing, ensuring durability, efficiency, and long-lasting performance for diverse applications.

SourcifyChina is committed to sustainability and efficiency. They implement eco-friendly practices and resource-efficient methods, aligning with global environmental standards. This dedication not only benefits the planet but also enhances the overall value of their products.

Customer satisfaction is a cornerstone of SourcifyChina’s service. They offer customizable solutions, timely delivery, and responsive support. Their client-focused approach ensures that each project is seamlessly executed from concept to completion, consistently meeting or exceeding expectations.

In essence, SourcifyChina’s robust capabilities in brass CNC machining set them apart in the competitive manufacturing landscape. Their dedication to precision, quality, and customer-centricity makes them a reliable partner in delivering top-tier CNC parts for various industrial needs.

Brass CNC parts offer exceptional reliability and precision. They are highly durable and resistant to corrosion, making them ideal for various applications.

– Durability: Brass is known for its excellent durability, making it perfect for parts that require long-lasting performance.

– Corrosion Resistance: Brass does not rust, which makes it an excellent choice for environments exposed to moisture and certain chemicals.

– Excellent Machinability: Brass can be easily machined, enabling the creation of highly precise components with complex shapes.

– Thermal Conductivity: High thermal conductivity makes brass parts suitable for applications that require efficient heat transfer.

– Aesthetic Appeal: Brass has a distinguished appearance, adding a touch of elegance to parts that remain visible.

– Electrical Conductivity: Brass is a good conductor of electricity, which is beneficial for electrical and electronic components.

– Cost-Effective: While being premium in performance, brass remains cost-effective compared to some other metals like stainless steel.

– Non-Magnetic: Brass is non-magnetic, making it useful in applications that require non-magnetic materials.

– Recyclability: Brass is highly recyclable, aligning with sustainable and eco-friendly manufacturing practices.

Overall, using brass CNC parts combines performance, durability, and economic efficiency, making them a highly advantageous choice for a wide range of industrial and decorative applications.

Brass CNC parts are renowned for their excellent machinability, durability, and corrosion resistance, making them ideal for various industrial applications.

– Precision Machining: Brass is easy to machine, allowing for high-precision parts with tight tolerances.

– Corrosion Resistance: Brass resists corrosion, making it suitable for harsh environments and reducing maintenance costs.

– Thermal Conductivity: Excellent thermal conductivity ensures efficient heat dissipation in applications like radiators and heat exchangers.

– Electrical Conductivity: High electrical conductivity makes brass ideal for electrical components and connectors.

– Aesthetic Appeal: Brass offers a visually appealing finish, suitable for decorative and architectural applications.

– Biocompatibility: Non-toxic and bacteriostatic properties make brass suitable for medical and food industry applications.

– Wear Resistance: Exhibits good wear resistance, extending the lifespan of components in high-friction environments.

– Versatility: Compatible with various post-processing techniques, including plating, polishing, and coating.

– Cost-Effective: Lower material and machining costs compared to other metals, offering excellent value for performance.

– Customizable: Available in a wide range of alloys, meeting specific mechanical and environmental requirements.

SourcifyChina specializes in manufacturing high-quality brass CNC parts tailored to meet specific client needs. Their custom products are built with precision, ensuring strict adherence to design specifications and tolerances. These parts exhibit excellent durability and corrosion resistance, ideal for various applications.

Their advanced CNC machinery and skilled technicians facilitate the production of intricate designs. This combination ensures optimal performance and reliability of the custom brass components. SourcifyChina’s dedication to quality is evident in their rigorous inspection processes, guaranteeing that each piece meets stringent industry standards.

SourcifyChina’s custom projects range across multiple sectors, including automotive, aerospace, and electronics. They work closely with clients to understand project requirements, ensuring timely delivery and exceptional performance. Their commitment to innovation helps clients enhance product functionality and efficiency.

Customer satisfaction is a core value for SourcifyChina. They provide end-to-end support, from initial design consultation to final product delivery, facilitating seamless project execution. Clients benefit from their transparent communication and competitive pricing, ensuring value for money.

In addition to product manufacturing, SourcifyChina offers comprehensive project management services. They ensure that every project phase, from concept to completion, aligns with client goals and timelines. Their ability to adapt to evolving requirements underscores their flexibility and commitment to excellence.

By choosing SourcifyChina for brass CNC parts, clients gain access to top-tier engineering and manufacturing capabilities. Their focus on quality and customer-centric approach makes them a trusted partner for both small-scale and large-scale projects. Whether you need a single prototype or mass production, SourcifyChina delivers unparalleled results.

SourcifyChina is a distinguished company specializing in the production and supply of high-precision brass CNC parts. With a robust reputation in the industry, the company excels in delivering custom-manufactured components that meet rigorous standards and specifications. Utilizing state-of-the-art CNC machinery, SourcifyChina ensures exceptional accuracy and quality in every piece they produce, catering to a wide array of industries including electronics, automotive, and telecommunications. Their unparalleled commitment to innovation and customer satisfaction has propelled them to the forefront of the market. Beyond just manufacturing, SourcifyChina stands out with its comprehensive service offerings, from initial design consultation to final product distribution, ensuring a seamless, hassle-free experience for clients worldwide. Through their team of highly skilled engineers and technicians, they continuously strive to enhance production processes and integrate cutting-edge technologies, thereby setting new benchmarks in the field of precision brass CNC machining.

Brass CNC parts find extensive applications in the aerospace, defense, and marine industries due to their remarkable properties, which include excellent machinability, corrosion resistance, and superior electrical conductivity. In aerospace, these parts are crucial for manufacturing precision components such as hydraulic fittings, fuel system parts, and intricate instruments that demand high reliability under extreme conditions. The resilience of brass to stress and its ability to retain strength at varying temperatures make it an optimal choice for aircraft systems that ensure safety and performance. Moreover, the CNC machining process facilitates the production of highly complex and custom brass components with tight tolerances, imperative for the aerospace sector’s exacting standards.

In the defense industry, brass CNC parts are integral in the production of critical equipment such as ammunition casings, communication devices, and radar systems. The alloy’s inherent toughness and resistance to corrosion under harsh environmental conditions ensure the durability and longevity of defense hardware. Brass’s non-sparking characteristic is particularly advantageous in environments where flammable materials are present, thus enhancing safety. The marine industry also leverages brass CNC components for their exceptional resistance to seawater corrosion, making them ideal for maritime applications like shipbuilding, underwater equipment, and marine engines. The durability and reliability of brass parts, combined with precision CNC machining, ensure that vessels and marine apparatus operate efficiently and safely in challenging marine environments.

In the automotive industry, brass CNC parts have become increasingly significant due to their excellent mechanical properties and ease of machinability. Brass offers an optimal balance of strength, corrosion resistance, and thermal stability, making it suitable for various automotive components. For instance, brass bushings, valves, and connectors are extensively used in fuel systems, brake lines, and HVAC systems to enhance performance and reliability. The precision offered by CNC machining ensures that these parts meet stringent automotive standards, contributing to vehicle safety and efficiency. With the advancement of electric vehicles, the demand for brass CNC components continues to rise, given their superior conductivity and durability, especially in the drivetrain and battery management systems.

In the realm of electronics, brass CNC parts play a crucial role due to their exceptional electrical conductivity and thermal management capabilities. Components such as connectors, terminals, and heatsinks are often machined from brass to ensure optimal performance of electronic devices. Brass’s ability to resist tarnishing and maintain electrical conductivity over time makes it ideal for use in high-frequency and high-reliability applications, including communication devices, computer hardware, and consumer electronics. The precision afforded by CNC machining allows for the production of intricate and complex geometries required in miniaturized electronic components, ensuring consistent quality and improved device functionality. As electronics continue to become more sophisticated and compact, brass CNC parts remain indispensable for their contribution to durability and improved electrical performance.

Brass CNC parts find extensive application in the construction industry due to their excellent mechanical properties and corrosion resistance. These parts are often employed in the manufacturing of architectural hardware, fixtures, and fittings including door handles, hinges, and valves. Their durability and aesthetic appeal make brass fixtures a popular choice in modern construction projects. Additionally, the precision offered by CNC machining ensures that each component meets the exact specifications required for complex construction designs, enhancing structural integrity and operational reliability. The versatility of brass allows it to be used in both contemporary and traditional construction settings, providing unmatched adaptability in various architectural projects.

In the energy sector, brass CNC parts are crucial in the fabrication of components for oil and gas extraction, renewable energy systems, and power generation equipment. The material’s excellent conductivity, combined with its resistance to corrosion and high-temperature stability, makes it ideal for use in connectors, fittings, and other critical components in pipelines, solar panels, and wind turbines. CNC machining enables the production of intricate parts with tight tolerances, vital for ensuring the efficiency and safety of energy systems. The reliability of brass components plays a key role in minimizing downtime and maintenance costs, thereby enhancing the overall performance and sustainability of energy infrastructures.

The industrial equipment industry extensively utilizes brass CNC parts due to brass’s unique combination of mechanical properties and workability. Brass, an alloy primarily composed of copper and zinc, demonstrates excellent resistance to corrosion, which is vital for industrial environments frequently exposed to moisture and various chemicals. Moreover, brass’s inherent machinability allows CNC (Computer Numerical Control) machines to fabricate highly precise and intricate parts with minimal wear on the cutting tools. Components such as bushings, gears, and valves, made from brass using CNC techniques, find critical applications in industrial machinery due to their durability and high performance under stress. Additionally, the superior thermal and electrical conductivity of brass makes it indispensable for parts that require efficient conduction, enhancing the overall efficiency and reliability of industrial systems.

Beyond durability and precision, brass CNC parts contribute significantly to the operational cost-effectiveness and longevity of industrial equipment. The manufacturing of custom brass parts through CNC machining ensures that the components can cater to specific requirements, thus improving compatibility and reducing installation issues in industrial machinery. This customizability is particularly significant in sectors such as automotive, aerospace, and heavy machinery, where tailor-made solutions are often necessary to meet stringent operational standards. Furthermore, the recyclability of brass makes it an environmentally sustainable choice, aligning with the growing emphasis on sustainable manufacturing practices in the industry. By integrating brass CNC parts, industrial equipment manufacturers can enhance the performance, durability, and cost-efficiency of their products, thereby offering superior solutions to meet the evolving demands of various industrial sectors.

The use of brass CNC parts in the medical device industry is increasingly prevalent due to the material’s unique properties and the precision offered by CNC machining. Brass, an alloy primarily composed of copper and zinc, is renowned for its excellent machinability, durability, and non-magnetic properties. These characteristics are essential for creating intricate components needed in medical devices. CNC (Computer Numerical Control) machining allows for the production of highly precise and complex parts with tight tolerances, which is critical in the medical field. Devices such as MRI machines, medical pumps, and surgical instruments often integrate brass components because they provide reliable performance and are resistant to corrosion, a crucial factor for ensuring the longevity and sterility of medical equipment.

Moreover, brass CNC parts are favored for their biocompatibility, meaning they are less likely to cause adverse reactions when used in contact with human tissues. This makes them suitable for implants, catheter fittings, and connectors within medical apparatus. The high precision of CNC machining also ensures the interoperable fit and function of these parts, reducing the risk of malfunctions and increasing the safety of medical procedures. As medical technology advances, the demand for miniaturized and highly accurate components grows, further solidifying the role of brass CNC parts in the medical device industry. Their reliability and adaptability contribute significantly to the development of innovative and effective medical solutions, enhancing patient outcomes and supporting the healthcare system’s overall efficiency.

Brass CNC parts have become pivotal in modern machining and manufacturing due to their excellent machinability, corrosion resistance, and electrical conductivity. The use of CNC (Computer Numerical Control) technology allows for the precision machining of brass components to exacting tolerances, which is essential in various industrial applications. Brass, an alloy primarily composed of copper and zinc, is favored in CNC machining for its ease of cutting, reduced tool wear, and ability to produce smooth finishes. This makes it an ideal material for parts used in plumbing, electrical systems, and decorative applications where detail and accuracy are crucial. Furthermore, the recyclability of brass aligns with growing trends towards sustainable manufacturing practices.

In the realm of manufacturing, CNC machining of brass parts plays a significant role in producing components for sectors such as automotive, aerospace, and consumer electronics. Brass’s inherent properties, such as low friction and acoustic qualities, make it suitable for intricate parts like gears, valves, and musical instruments. The precision offered by CNC machines ensures that these parts meet stringent industry standards and performance requirements. Additionally, the versatility of CNC machining enables the production of both simple and complex brass components in large volumes, facilitating efficient mass production. As a result, brass CNC parts are integral to advancing technological innovation and maintaining high-quality standards in manufacturing processes.

Q1: What materials are used for brass CNC parts?

A: Brass, an alloy primarily composed of copper and zinc, is the primary material used. It offers excellent machinability, corrosion resistance, and electrical conductivity.

Q2: What industries can benefit from brass CNC parts?

A: Industries such as automotive, electronics, plumbing, and telecommunications widely utilize brass CNC parts due to their durability and precision.

Q3: How does SourcifyChina ensure quality in CNC manufacturing?

A: SourcifyChina employs strict quality control measures, including use of high-precision CNC machines, comprehensive inspections, and adherence to international standards.

Q4: Can SourcifyChina produce custom brass CNC parts according to specifications?

A: Yes, SourcifyChina specializes in creating custom CNC parts based on detailed customer specifications, blueprints, and CAD files.

Q5: What is the typical lead time for manufacturing and delivery?

A: Lead times vary based on order complexity and quantity, but typical production and delivery range from 2 to 6 weeks.

Q6: What is the minimum order quantity (MOQ) for brass CNC parts?

A: The MOQ depends on the specifications and manufacturing requirements but is generally flexible to accommodate various customer needs.

Q7: Are prototype services available?

A: Yes, SourcifyChina offers prototyping services, allowing clients to test and validate design concepts before full-scale production.

Q8: What are the advantages of using CNC machining for brass parts?

A: CNC machining offers enhanced precision, repeatability, reduced material waste, and the ability to produce complex geometries.

Q9: How does SourcifyChina handle international shipping and logistics?

A: SourcifyChina collaborates with reliable shipping partners to ensure timely and cost-effective delivery worldwide, handling all customs and documentation processes.

Q10: How can I request a quote for my project?

A: You can request a quote by visiting SourcifyChina’s website, filling out the contact form, or reaching out via email with detailed project requirements.

When considering “brass CNC parts manufacturing from SourcifyChina factory,” keep the following tips in mind to ensure a seamless experience and high-quality results:

1. Material Specification: Clearly specify the type of brass needed for your parts. Brass alloys come in various grades, each with unique properties suited for different applications.

2. Design Precision: Provide detailed CAD designs with precise measurements. This ensures the CNC machines can produce parts with exact specifications, minimizing errors and material waste.

3. Prototype Development: Request prototypes before full-scale production. This helps you verify the quality and design accuracy, allowing for adjustments if necessary.

4. Quality Control: Inquire about SourcifyChina’s quality control processes. Ensure they have stringent QC measures, including inspections and testing, to guarantee consistency and reliability.

5. Communication: Maintain clear and open communication with the factory. Regular updates on the production process can help address any issues promptly and keep the project on track.

6. Volume Requirements: Discuss your volume requirements upfront. Whether you need small batches or large-scale production, align with the factory’s capabilities to meet your demands.

7. Lead Times: Understand the lead times for production and delivery. This helps in planning your project timeline effectively and avoiding delays.

8. Cost Efficiency: Get a detailed quote that includes material, manufacturing, and shipping costs. Compare this with other vendors to ensure competitive pricing without compromising quality.

9. Customization Options: Explore customization options for finishes and treatments. Brass parts can be plated or coated for enhanced durability and aesthetic appeal.

10. Compliance and Certifications: Verify that SourcifyChina complies with relevant industry standards and certifications. This reassures the quality and safety of the manufactured parts.

By following these tips, you can maximize the efficiency, quality, and satisfaction of your brass CNC parts manufacturing project with SourcifyChina factory.

Q: What types of brass CNC parts can SourcifyChina factory produce?

A: SourcifyChina factory specializes in producing a wide range of brass CNC parts, including but not limited to fittings, connectors, bushings, valves, and custom components according to specific designs and requirements.

Q: How do I place an order for brass CNC parts from SourcifyChina factory?

A: You can place an order by contacting SourcifyChina directly through their official website or via email. You will need to provide detailed drawings or specifications of the parts you require for an accurate quotation.

Q: What is the minimum order quantity (MOQ) for brass CNC parts?

A: The MOQ may vary depending on the complexity and size of the parts. Generally, SourcifyChina is flexible with MOQs, but it’s advisable to discuss your specific needs with their sales team.

Q: Can SourcifyChina factory provide prototypes before mass production?

A: Yes, SourcifyChina can produce prototypes based on your designs to ensure that all specifications and quality requirements are met before proceeding with mass production.

Q: What quality control measures does SourcifyChina factory have in place for brass CNC parts?

A: SourcifyChina employs stringent quality control measures, including material inspection, precision measurement, and final product testing to ensure all parts meet required standards and customer specifications.

Q: How long does it take to receive an order of brass CNC parts?

A: Lead times can vary based on the complexity and quantity of the order. Typically, it ranges from 2 to 6 weeks from the time of order confirmation to delivery.

Q: What shipping options are available for brass CNC parts?

A: SourcifyChina offers various shipping options, including air freight, sea freight, and express courier services. The choice of shipping method will depend on the urgency and volume of the order.

Q: Does SourcifyChina provide after-sales support for brass CNC parts?

A: Yes, SourcifyChina offers comprehensive after-sales support, addressing any issues related to the quality and performance of the brass CNC parts, ensuring customer satisfaction.

Q: Are there any customization options available for brass CNC parts?

A: Absolutely. SourcifyChina offers extensive customization options, from material specifications to precise dimensions and finishes based on customer requirements.

Certainly! Here are some tips for sourcing brass CNC parts from SourcifyChina factory:

1. Research and Verification: Start by researching the credibility of SourcifyChina factory. Look for reviews, ratings, and any certifications that verify their manufacturing and exporting capabilities.

2. Detailed Requirements: Clearly outline your specifications for the brass CNC parts. Include dimensions, tolerances, material grade, finish, and any other specifics. Providing detailed drawings or CAD models can be highly beneficial.

3. Initial Communication: Reach out to SourcifyChina through their official contact channels. Inquire about their experience with brass CNC machining and ask for examples of similar projects they’ve completed.

4. Samples and Prototypes: Request samples or prototypes of your parts to assess the quality of their work. This step is crucial to ensure that they can meet your standards before committing to a larger order.

5. Quotation and Pricing: Get a detailed quotation that outlines all costs, including material, machining, finishing, and shipping. Ensure there are no hidden charges.

6. Lead Times: Confirm the lead times for production and shipping. Make sure they can meet your deadlines and inquire about their capacity to handle larger orders if needed.

7. Quality Assurance: Understand their quality control processes. Ask about inspection reports, tolerances checks, and certifications they follow.

8. Communication: Maintain clear and consistent communication. Use email, video calls, and instant messaging to stay updated on the progress of your order.

9. Payment Terms: Discuss and agree on payment terms. It’s common to negotiate a portion upfront with the balance due upon completion or delivery.

10. Logistics: Plan your logistics thoroughly. Decide on the shipping method and confirm who will handle import duties, taxes, and customs clearance.

Following these tips will help ensure a smooth and successful partnership with SourcifyChina for sourcing brass CNC parts.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.