SourcifyChina stands out for its rigorous selection of manufacturers, guaranteeing top-notch CNC wire cutting machinery. Their extensive vetting process ensures buyers receive high-quality products backed by robust engineering and reliability.

Second, SourcifyChina offers personalized customer service, assisting buyers at every step. Their expert team guides clients through specifications, requirements, and procurement, ensuring a seamless purchasing experience and addressing any concerns.

Moreover, SourcifyChina provides competitive pricing, leveraging their network to secure the best deals. This cost efficiency doesn’t compromise quality, allowing buyers to benefit from high-value, durable machinery without breaking the bank.

Additionally, their focus on transparent communication builds trust. Regular updates and prompt responses foster a smooth transactional environment, making sure clients are well-informed and confident throughout the purchasing journey.

Finally, SourcifyChina’s comprehensive logistics support ensures timely delivery. From order placement to shipment, their streamlined processes minimize delays and mitigate risks associated with international trade, facilitating a hassle-free procurement experience.

In conclusion, choosing SourcifyChina for purchasing CNC wire-cutting machines from China means accessing high-quality products, excellent customer service, cost efficiency, transparent communication, and reliable logistics. This holistic approach simplifies the procurement process and ensures complete buyer satisfaction.

CNC wire cut machines are vital in precision manufacturing, offering various options like high-speed, medium-speed, and low-speed machines, catering to different cutting needs and material types. These machines utilize a thin, electrically charged wire to cut intricate shapes with high accuracy.

Types and options:

– High-Speed CNC Wire Cut Machines: Ideal for rapid cutting with moderate precision; typically used for soft materials.

– Medium-Speed CNC Wire Cut Machines: A balanced option offering a good mix of speed and precision for various materials.

– Low-Speed CNC Wire Cut Machines: Provides the highest precision and accuracy for hard and intricate materials, often used in tool and die making.

– Brass Wire: Common wire type offering good conductivity and versatility.

– Molybdenum Wire: Suitable for high-precision and high-wear applications due to its durability.

– Coated Wires: Features special coatings to reduce wear and increase cutting efficiency and accuracy.

– Multi-Axis Capability: Advanced systems offering cutting in multiple axes for complex geometries.

– Adaptive Control Systems: Automatically adjust parameters for optimized cutting based on real-time conditions.

– Automatic Wire Threading: Enhances productivity by reducing manual intervention.

– Water Jet Assisted Wire Cut: Combines the precision of wire EDM with the cutting force of water jets for challenging materials.

– Remote Monitoring: Allows operators to oversee cutting processes remotely, improving efficiency.

– Software Integration: Advanced software solutions for designing and programming cuts, offering greater precision and user-friendliness.

– Eco-Friendly Options: Machines designed to minimize energy consumption and reduce environmental impact.

– Cost-efficiency Options: Machines offering basic functionalities for small-scale operations, balancing performance and cost.

CNC wire cut machines thus provide varied options to suit different industrial requirements, ranging from high-speed operations to extremely precise cuts for specialized applications.

CNC wire cut machines are essential in manufacturing for their precision and efficiency. They excel in creating complex shapes and intricate designs used in various industries from aerospace to medical devices. These machines enhance productivity, accuracy, and are vital in producing components with tight tolerances.

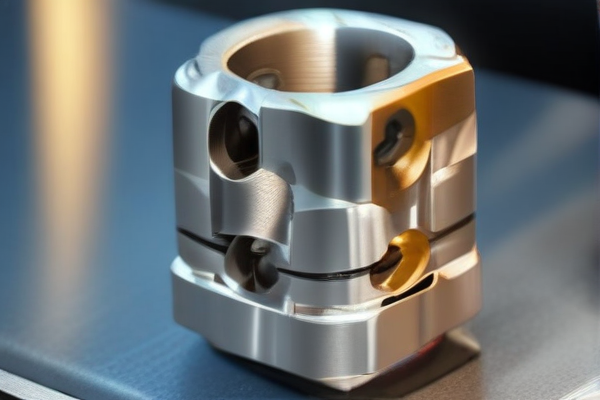

– Aerospace Industry: CNC wire cut machines are used to manufacture turbine blades, engine components, and structural parts with high precision and reliability.

– Medical Devices: Essential for producing surgical instruments, implants, and intricate parts required in medical equipment.

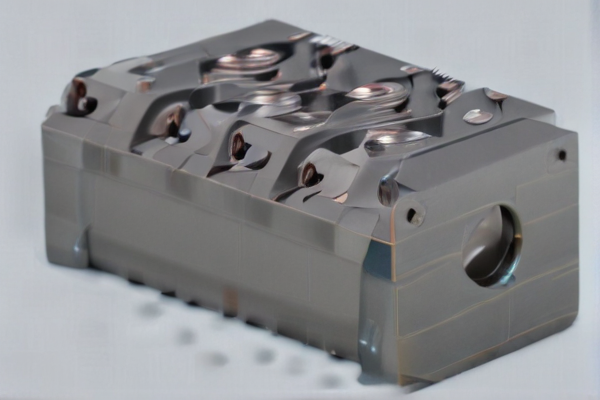

– Automotive: Utilized to create precision moulds, dies, and complex automotive components ensuring high performance and safety.

– Electronics: Produces parts for circuit boards, connectors, and miniaturized electronic components with fine tolerances.

– Tool and Die Making: Key in manufacturing punches, dies, and tool components, achieving intricate shapes and sharp angles.

– Jewelry Making: Allows for detailed and delicate designs, enhancing the aesthetic and maintaining consistency in pieces.

– Military and Defense: Used for producing components that require high precision and durability, such as weapon parts and communication device components.

– Consumer Products: Helps in the creation of precise and complex parts in products like appliances and gadgets.

– Prototyping: Crucial for developing prototypes with exact specifications, aiding in the design and testing phase of new products.

– Custom Manufacturing: Allows creation of bespoke parts tailored to specific industry needs or unique applications.

CNC wire cut technology not only increases efficiency and reduces waste but also allows for the production of complex geometries unachievable by traditional methods, solidifying its indispensability in modern manufacturing processes across multiple sectors.

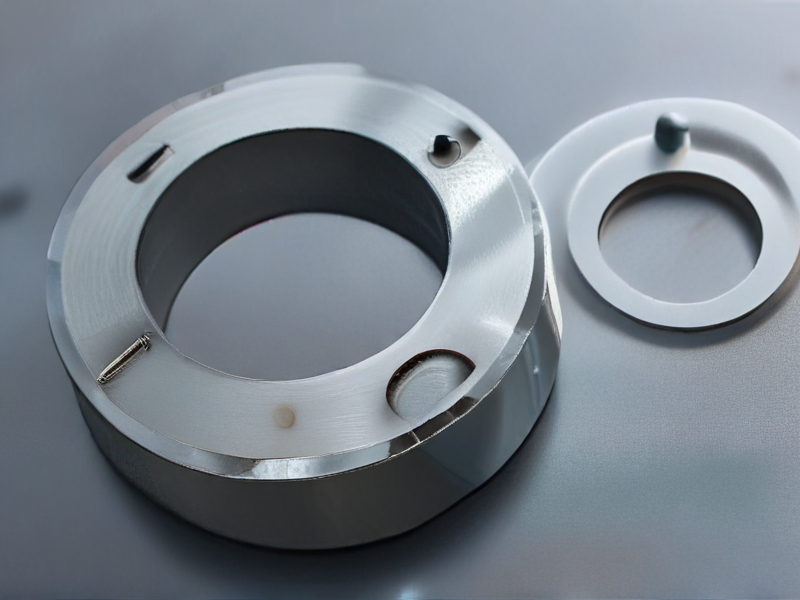

“SourcifyChina CNC Wire Cut” machines are constructed from high-quality materials selected for durability and precision. The framework often utilizes robust steel alloys to ensure stability and minimize vibrations during operation, enhancing overall performance.

The wire used in these CNC machines is typically made from brass or molybdenum. Brass wires are favored for their electrical conductivity and cost efficiency, while molybdenum wires offer superior strength and longevity, essential for more demanding cutting tasks.

These machines also feature advanced composite materials in their insulation components, ensuring electrical safety and integrity even under prolonged use. Such materials contribute to the efficient and reliable functioning of the CNC wire cut machinery.

To further enhance performance, precision-engineered ceramic guides are employed. These guides offer wear resistance and maintain alignment accuracy, critical for achieving fine tolerances. The combination of these advanced materials results in a machine capable of exceptional precision and reliability.

In conclusion, “SourcifyChina CNC Wire Cut” machines are built from an array of high-quality materials, such as steel alloys, brass, molybdenum, advanced composites, and ceramics. These materials collectively ensure durability, precision, and longevity, making the machines indispensable for high-precision cutting tasks.

SourcifyChina CNC wire cut machines undergo stringent quality control protocols to ensure precision and reliability. Each unit is meticulously inspected at various stages of the manufacturing process, ensuring compliance with top industry standards.

Beginning with the initial design phase, engineers use state-of-the-art technology to create blueprints that meet rigorous specifications. These designs are then subjected to detailed reviews to ensure they will deliver optimal performance.

Materials used in SourcifyChina machines are sourced from reputable suppliers and undergo rigorous testing for durability and strength. This helps in ensuring that the final product can withstand prolonged usage without compromising on efficiency.

During the assembly phase, skilled technicians employ advanced calibration tools to align machine components accurately. Any deviations are instantly corrected to avert potential performance issues later on.

Once assembly is complete, each CNC wire cut machine undergoes a series of comprehensive tests. These include functionality checks, operational simulations, and stress tests to verify their robustness and accuracy under various conditions.

Data gathered from these tests is meticulously documented. Any anomalies that arise undergo immediate analysis and rectification, guaranteeing that every unit delivered to customers meets the highest standards of quality.

Feedback loops are established to continually improve the manufacturing process. Customer feedback is actively sought and incorporated, ensuring ongoing enhancements to product quality.

Finally, SourcifyChina emphasizes rigorous training for its workforce. Regular workshops and updated training programs for technicians ensure they are well-versed with the latest industry practices and technological advancements.

The culmination of these meticulous steps ensures that every SourcifyChina CNC wire cut machine meets the benchmark of superior quality. These thorough quality control measures guarantee that customers receive equipment that exceeds expectations in performance and durability.

SourcifyChina’s CNC wire cut technology exemplifies precision and efficiency. Using top-tier machinery, the company ensures accurate cutting of intricate designs, essential for industries requiring high tolerances.

The machinery is equipped to handle a variety of materials, including metals and composites. This versatility makes it suitable for a wide range of applications, from automotive parts to mold-making.

Advanced software integration allows for seamless operation and quick adjustments. This ensures that production times are minimized, leading to faster turnaround rates and increased throughput without compromising quality.

Additionally, SourcifyChina employs a highly skilled team of engineers and operators. Their expertise guarantees that every project meets stringent quality standards and specific customer requirements.

Customer feedback underscores SourcifyChina’s commitment to excellence, particularly in delivering consistent, high-quality results. This has fostered long-term relationships and repeat business, solidifying their reputation in the CNC wire cut industry.

Investing in cutting-edge technology and employee training remains a priority. This continuous improvement approach not only enhances capabilities but also prepares the company to meet future industry challenges.

In conclusion, SourcifyChina’s CNC wire cut capabilities are unparalleled. Combining advanced machinery, versatile applications, skilled personnel, and a commitment to quality, they stand out as a leader in the precision cutting market. Whether for intricate designs or high-volume production, SourcifyChina delivers with exceptional precision and reliability.

CNC wire cut technology offers precision and efficiency in machining complex shapes and tight tolerances. This advanced manufacturing process is essential for various industries due to its numerous benefits.

– High Precision: CNC wire cut machines can achieve extremely tight tolerances and intricate detailing, making them ideal for high-precision parts and components.

– Versatility: Suitable for a variety of materials, including hard metals like titanium and carbide, as well as softer materials such as aluminum and plastics.

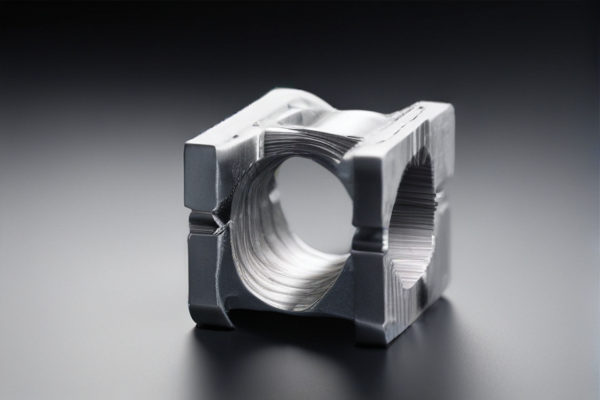

– Complex Shapes: Capable of producing complex geometries and intricate profiles that would be difficult or impossible to achieve with traditional machining methods.

– Reduced Material Waste: Since the wire cut process is highly accurate, there’s minimal material wastage compared to other machining techniques, which improves cost efficiency.

– Automation and Efficiency: These machines can run autonomously once programmed, reducing the need for human intervention and significantly lowering production time.

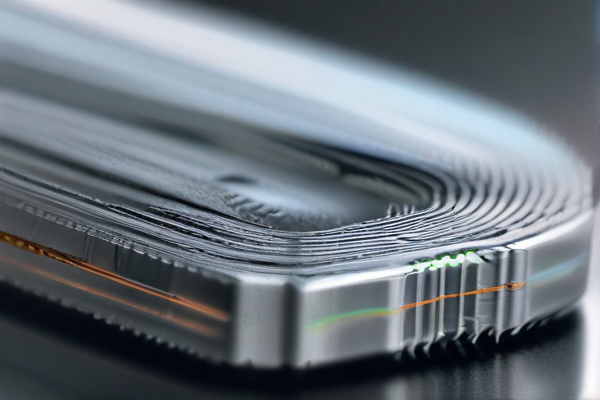

– Surface Finish Quality: Wire cut machining often results in superior surface finishes, reducing the need for additional finishing processes.

– Reduced Thermal Distortion: The wire cut process generates less heat, minimizing the risk of thermal distortion and ensuring dimensional stability of the machined parts.

– Consistency and Repeatability: CNC technology ensures consistent quality across large production runs, essential for industries that demand uniformity, such as aerospace and medical device manufacturing.

– Reduced Setup Times: Minimal setup times compared to traditional machining methods enhance overall productivity and turnaround times.

– Cost-Effective Prototyping: Ideal for rapid prototyping due to its accurate and fast machining capabilities, allowing for quicker iteration and time-to-market for new products.

In summary, CNC wire cut technology stands out for its precision, versatility, and efficiency, making it an indispensable tool in modern manufacturing.

CNC wire cut machines are advanced precision tools used for cutting complex shapes in hard materials. These machines utilize a thin, electrically charged wire to erode material with high accuracy.

Key Features of CNC Wire Cut:

– Precision Cutting: Achieves intricate details with tolerances in microns.

– Versatile Material Handling: Cuts hard materials like steel, titanium, and carbides.

– Complex Geometry: Ideal for producing complex shapes and detailed contours.

– Computer Control: Automated and programmable, ensuring consistency and repeatability.

– Minimal Material Waste: Efficient cutting process reduces scrap.

– Smooth Finishes: Results in fine surface finishes, often eliminating the need for additional machining.

– Cooling System: Integrated cooling to prevent overheating and maintain cutting accuracy.

– High Reliability: Consistent performance for both small- and large-scale production.

– Advanced Software: Utilizes CAD/CAM software for precise design execution.

– Low Maintenance: Robust design requiring minimal upkeep.

– Automated Wire Handling: Automatic threading and wire tension control.

– User-Friendly Interface: Intuitive controls for easier operation.

– Reduced Setup Time: Quick preparation and minimal manual intervention.

These features make CNC wire cut machines indispensable in industries like aerospace, medical devices, and mold making, where precision and efficiency are paramount.

SourcifyChina specializes in CNC wire cut services, tailoring solutions for diverse custom products and projects. Their precise cutting techniques enable intricate designs, ensuring high-quality results tailored to client needs.

These services are ideal for various industries, including automotive, electronics, and healthcare. By leveraging advanced technology, SourcifyChina meets stringent specifications, enhancing the functionality and aesthetics of the components.

Clients appreciate the flexibility in material selection, from metals to composites, guaranteeing that the final product meets all desired parameters. The company’s commitment to precision and quality sets it apart as a reliable partner for manufacturing.

With experienced engineers and state-of-the-art equipment, SourcifyChina ensures each project is executed flawlessly. Their expertise in CNC wire cut processes ensures that even the most complex designs are manufactured to perfection.

SourcifyChina’s dedication to customer satisfaction is evident through their comprehensive support, from the initial consultation to final delivery. Their transparent communication and meticulous attention to detail ensure a smooth and efficient production process.

In summary, SourcifyChina’s CNC wire cut services offer unparalleled precision and quality for custom products across various industries. Their expertise, innovative technology, and customer-centric approach make them a trusted partner for any manufacturing needs.

SourcifyChina, a prominent player in the precision manufacturing landscape, specializes in CNC wire cut services that cater to a diverse range of industries. Renowned for their high-quality standards and innovative techniques, SourcifyChina leverages advanced CNC wire cutting technology to deliver precise, intricate components with unparalleled accuracy. Their state-of-the-art machinery and skilled workforce ensure that even the most complex designs are executed flawlessly, meeting stringent international standards. The company’s commitment to excellence is evident in their meticulous attention to detail, timely delivery, and competitive pricing, making them a preferred partner for clients worldwide seeking reliable and precise manufacturing solutions. From automotive parts to intricate aerospace components, SourcifyChina’s CNC wire cut services stand as a testament to their dedication to quality, precision, and customer satisfaction.

CNC wire cut machining, also known as Electrical Discharge Machining (EDM), holds a pivotal role in the Aerospace and Defense sectors due to its precision and ability to work with hard metals. This process is essential for manufacturing components such as turbine blades, fuel system parts, and intricate structural elements where tolerances are stringent and material properties critical. In Aerospace, the requirement for high degrees of accuracy and reliability makes CNC wire cut EDM indispensable, as it minimizes human error and produces complex geometries with high precision, ensuring optimal performance and safety. For Defense applications, the ability to manufacture parts from robust and often exotic alloys, which are essential for weapons systems and advanced military hardware, is greatly enhanced by the capabilities of CNC wire cut machining.

In the Marine industry, CNC wire cut EDM is similarly invaluable, especially for crafting components that must withstand harsh oceanic environments, such as propeller shafts, engine parts, and various structural fittings. The method allows for the precise cutting of metals that are resistant to corrosion, such as stainless steel and titanium alloys. The high level of accuracy and excellent surface finish provided by CNC wire cutting means that marine parts can operate more efficiently and with greater longevity. Additionally, the flexibility of CNC wire cut EDM in handling both small and large components alike allows for a broad range of applications, from small precision fittings to large structural components, thus providing substantial benefits in terms of both performance and durability in maritime operations.

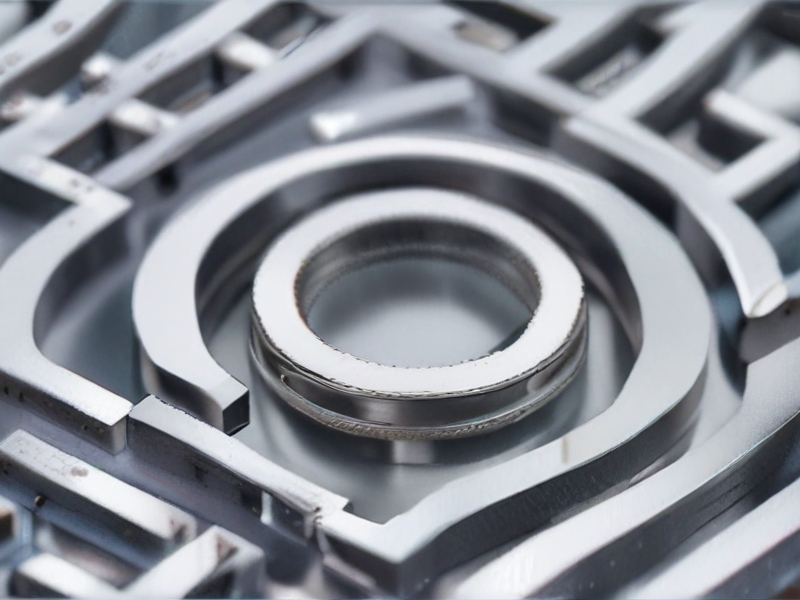

CNC wire cut technology has revolutionized the automotive industry by enabling precise and efficient manufacturing of complex components. This advanced machining process uses a thin, electrically charged wire to cut intricate shapes and patterns in hard materials like steel and titanium. The automotive sector benefits significantly from the accuracy and repeatability of CNC wire cut machines, which are essential for producing engine components, transmission parts, and intricate metal brackets. One notable application is in the production of high-performance gears and fuel injection nozzles, where tolerances need to be within microns. This precision ensures the reliability and efficiency of vehicles, promoting enhanced performance and fuel economy. Additionally, CNC wire cut machines contribute to faster production times and reduced material waste, making them highly cost-effective solutions for mass production.

In the realm of electronics, CNC wire cut technology is indispensable for manufacturing intricate components required in circuit boards, semiconductors, and connectors. The micro-level precision offered by CNC wire cut machines allows for the creation of finely detailed parts needed in sophisticated electronic devices, such as smartphones, tablets, and computer hardware. This process ensures that each component fits perfectly within the densely packed circuitry, maintaining the reliability and performance of electronic products. For instance, CNC wire cutting is critical in producing lead frames, which form the metal backbone for semiconductor devices. These machines can handle extremely thin and delicate materials without causing deformation, ensuring that the final products meet stringent quality standards. As electronic devices continue to shrink in size while increasing in capability, the role of CNC wire cut technology becomes ever more vital in pushing the boundaries of innovation and precision manufacturing.

CNC wire cut technology, or wire electrical discharge machining (wire EDM), is a significant asset in the construction industry. Its ability to produce highly accurate and complex geometries makes it ideal for creating intricate components essential for modern architectural designs. For example, custom brackets, joinery elements, and other engineered metal parts that demand high precision can be efficiently manufactured using this technology. Additionally, CNC wire cut machines allow for minimal material wastage and lower production costs, making them an environmentally friendly option. By ensuring precise and customizable cuts, this technology supports the enhancement of structural integrity and aesthetic versatility in construction projects.

In the energy sector, CNC wire cut technology plays a critical role, particularly in the manufacturing and maintenance of components for power generation and energy storage systems. Turbine blades, for instance, require high precision to function efficiently, and wire EDM is capable of meeting these stringent specifications. The technology is also employed in creating components for batteries and renewable energy systems, where meticulous engineering is crucial for performance optimization. Moreover, as the energy sector moves towards greater efficiency and sustainability, the precision and reliability offered by CNC wire cut technology become increasingly valuable. By enabling the production of intricate components with exacting tolerances, this technology supports advancements in both traditional and renewable energy systems, contributing to a more sustainable and efficient energy future.

The CNC wire cut technology, widely utilized in the industrial equipment sector, revolutionizes the precision machining of complex and intricate parts. This method employs a thin, electrically charged wire to erode material from a workpiece with unparalleled accuracy, making it ideal for manufacturing components that require intricate shapes and tight tolerances. Industrial sectors such as aerospace, automotive, and medical devices benefit significantly from CNC wire cut machines. These machines enable the production of components with complex geometries, such as turbine blades, engine parts, and medical implants, ensuring consistency, repeatability, and high precision. Their ability to cut hard materials like titanium, hardened steel, and carbide further enhances their applicability in producing durable and high-performance industrial equipment.

In addition to high precision and versatility, CNC wire cut machines improve operational efficiency and cost-effectiveness in the industrial equipment manufacturing process. Automated CNC programming reduces the need for manual intervention, minimizing human error, and significantly speeding up production. This automation facilitates mass production of high-quality parts and reduces overall manufacturing costs. CNC wire cut technology also fosters innovation by allowing designers to experiment with complex geometries that were previously challenging to achieve. Features such as intricate internal cavities and fine details become feasible, opening new possibilities in product design and functionality. As such, the adoption of CNC wire cut technology in the industrial equipment industry delivers substantial benefits in terms of quality, efficiency, and innovation, solidifying its role as a critical player in advanced manufacturing processes.

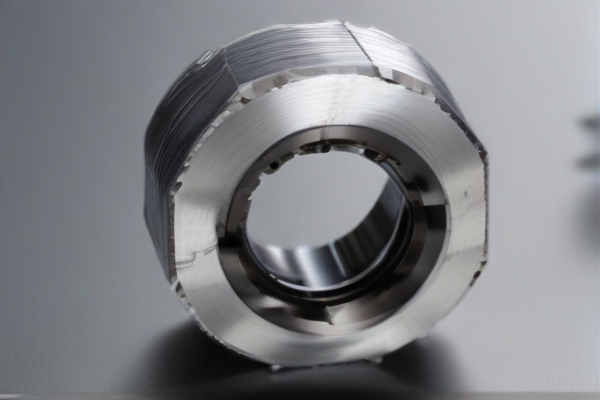

CNC wire cut technology, also known as Wire Electrical Discharge Machining (Wire EDM), has found significant applications in the medical devices industry due to its precision and ability to work with hard materials. Medical devices often require intricate components with high accuracy, which CNC wire cut machines can deliver. Materials commonly used in medical devices, such as titanium, stainless steel, and certain polymers, are difficult to machine with traditional methods. However, Wire EDM can easily handle these materials, producing high-quality finishes with tolerances in the micrometer range. This capability is particularly advantageous for manufacturing components like surgical instruments, orthopedic implants, and cardiovascular devices where precision and reliability are paramount.

Furthermore, the CNC wire cut process leaves minimal residual stress on the machined parts, which is a critical factor for the performance and longevity of medical devices. The technology allows for the production of complex geometries that would be challenging or impossible to achieve with conventional machining methods. For instance, certain minimally invasive surgical tools have complex shapes and internal features that can only be accurately fabricated using wire EDM. Additionally, the automation and programmability of CNC wire cut machines enhance production efficiency and quality control, ensuring consistent results in large-scale manufacturing. This technological advantage translates into improved patient outcomes and the advancement of medical interventions.

CNC wire cut, also known as wire EDM (Electrical Discharge Machining), is a pivotal technology in the machining and manufacturing industry. This process involves using a thin, electrically conductive wire to cut through metal with high precision. The wire is typically made of brass or molybdenum and is continually fed through the workpiece, which is submerged in a dielectric fluid. The electrical discharges between the wire and the workpiece generate intense heat, melting away the material in a controlled manner. This method is particularly advantageous for producing intricate and complex shapes that would be challenging to achieve with traditional machining methods. The high level of accuracy, usually within microns, makes CNC wire cut ideal for precision components in industries such as aerospace, automotive, and medical devices.

The advantages of CNC wire cut extend beyond mere accuracy. One of the significant benefits is its ability to machine hard and exotic materials without causing thermal distortion or mechanical stress, which often occurs with conventional cutting methods. The technology supports the manufacturing of components with extremely tight tolerances and fine surface finishes, reducing the need for secondary operations like polishing or grinding. Additionally, the CNC aspect enables automation and repeatability, crucial for mass production scenarios. The ability to operate continuously and produce consistent results enhances productivity and efficiency, thereby lowering overall manufacturing costs. Thus, CNC wire cut plays a critical role in modern manufacturing, driving advancements in complex product design and material utilization.

FAQ for CNC Wire Cut Quality Work from SourcifyChina Factory

1. What is CNC Wire Cutting?

CNC wire cutting, also known as wire EDM (Electrical Discharge Machining), is a manufacturing process where a thin wire is used to cut intricate shapes and details in various materials, often metals. The CNC system ensures precision and repeatability.

2. Why should I choose SourcifyChina for CNC wire cut services?

SourcifyChina is known for its high-precision machineries and skilled technicians. Our factory guarantees top-quality wire cut work with strict adherence to international standards. We offer competitive pricing and quick turnaround times.

3. What materials can SourcifyChina’s CNC wire cutting handle?

Our CNC wire cutting services can handle a variety of materials including but not limited to steel, aluminum, brass, copper, and titanium. If you have specific material requirements, please contact us for verification.

4. What is the maximum thickness and size of material that can be cut?

We can cut materials up to a thickness of 300mm and a maximum workpiece size of 1000mm x 800mm. Please reach out to discuss any special requirements.

5. What industries does SourcifyChina serve?

We serve a range of industries including automotive, aerospace, medical devices, electronics, mold making, and general manufacturing. Our precision cutting meets the stringent requirements of these sectors.

6. What information do you need to provide a quote?

To provide an accurate quote, we need details such as material type, thickness, dimensions, and the complexity of the design. CAD drawings or specification sheets can help expedite the quoting process.

7. How long does it take to complete an order?

Lead times vary based on order complexity and volume. Typically, orders are completed within 1-2 weeks. For urgent requirements, please contact us to discuss expedited options.

8. How does SourcifyChina ensure quality?

Quality is ensured through rigorous inspection protocols and state-of-the-art equipment. Our quality control team inspects each part at various stages of production to ensure it meets or exceeds customer specifications.

9. Can you handle custom or specialized requests?

Yes, SourcifyChina specializes in custom and specialized wire cut projects. We work closely with our clients to ensure their unique requirements are met with the highest precision.

10. How do I get in touch with SourcifyChina?

When considering CNC wire cut manufacturing from SourcifyChina Factory, keep these tips in mind to ensure optimal results:

1. Understand the Process: CNC wire cut involves using a thin wire to erode material through electrical discharges. It’s excellent for precision parts with intricate designs and tight tolerances.

2. Material Selection: Verify the compatibility of your chosen materials. Common materials include conductive metals like steel, aluminum, and brass. SourcifyChina should offer a range of compatible materials for your needs.

3. Design for Manufacturability: Ensure your designs are optimized for CNC wire cut. Complex geometries are possible, but maintaining reasonable tolerances will reduce costs and lead times.

4. Tolerance and Precision Requirements: Clearly specify your tolerance levels. CNC wire cutting can achieve high precision, but tighter tolerances may increase cost and production time.

5. Surface Finish: Discuss your surface finish requirements with SourcifyChina. The wire cut process typically produces a smooth finish, but secondary processes may be needed for improved surface quality.

6. Batch Size: Determine your production volume. SourcifyChina should cater to both prototype and large-scale production runs, but costs can vary significantly based on quantity.

7. Turnaround Time: Inquire about lead times. Ensure SourcifyChina’s delivery schedule aligns with your project timeline to avoid delays.

8. Quality Assurance: Confirm that SourcifyChina has robust quality control measures. This includes inspection protocols and certifications like ISO to ensure consistent quality.

9. Communication: Maintain clear and consistent communication. Language barriers and time zone differences can be managed with regular updates and clarifications.

10. Cost Considerations: Request detailed quotes and understand the cost breakdown. Factor in material costs, machining time, and any additional services like post-processing or shipping.

Choosing SourcifyChina Factory for your CNC wire cut manufacturing needs can provide high-quality, cost-effective solutions if these considerations are taken into account.

Sure, here are some frequently asked questions (FAQ) about sourcing CNC wire cut services from SourcifyChina factory:

Q1: What is CNC wire cut machining?

A1: CNC wire cut machining, also known as wire EDM (Electro-Discharge Machining), uses a thin, electrically charged wire to cut intricate and precise shapes from metal materials. It is primarily used for creating complex parts with tight tolerances and fine details.

Q2: What materials can be cut using CNC wire cut services at SourcifyChina?

A2: SourcifyChina factory can handle a wide range of materials, including but not limited to, steel, aluminum, stainless steel, brass, titanium, and various alloys.

Q3: What information do I need to provide for a quote?

A3: To get an accurate quote, you will need to provide detailed CAD drawings or similar technical specifications, the material type, tolerances required, quantities, and any special processing or finishing requirements.

Q4: How accurate are the CNC wire cut services provided by SourcifyChina?

A4: The CNC wire cut services offered by SourcifyChina are known for high precision and accuracy, often achieving tolerances as tight as ±0.0001 inches (±0.0025 mm).

Q5: What is the typical lead time for CNC wire cut orders?

A5: Lead times can vary depending on the complexity of the project, material availability, and order volume. Typically, you can expect a lead time ranging from a few days to a few weeks.

Q6: Can SourcifyChina handle bulk orders for CNC wire cut parts?

A6: Yes, SourcifyChina factory is well-equipped to manage both small batch productions as well as large volume orders efficiently.

Q7: What quality control measures are in place at SourcifyChina?

A7: SourcifyChina adheres to strict quality control protocols, including thorough inspections, testing, and compliance with international standards to ensure the highest quality of parts produced.

Q8: How do I place an order with SourcifyChina?

A8: You can place an order by contacting SourcifyChina’s sales team through their website or email. Provide your project specifications, and their team will guide you through the process.

Q9: What payment methods are accepted?

Sourcing CNC wire cut services from SourcifyChina can be streamlined with these tips:

1. Research and Verify Credentials:

– Check SourcifyChina’s credentials, including ISO certifications and quality standards.

– Review customer testimonials and ratings to ensure reliability.

2. Clear Specifications:

– Provide detailed CAD drawings and technical specifications.

– Outline material types, tolerances, and surface finish requirements.

3. Request Samples:

– Ask for sample cuts to assess precision and quality before large-scale production.

4. Cost Transparency:

– Clarify all costs involved, including tooling, production, shipping, and potential customs fees.

5. Communication:

– Maintain clear and regular communication via email or video calls.

– Use translation tools if language is a barrier.

6. Lead Times and Flexibility:

– Confirm lead times and the factory’s ability to meet deadlines.

– Discuss flexibility in case of urgent changes or additional orders.

7. Quality Control:

– Establish a quality control plan and inspection criteria.

– Specify if third-party inspections are needed.

8. Payment Terms:

– Negotiate favorable payment terms, ideally with staged payments tied to production milestones.

9. Logistics Support:

– Ensure SourcifyChina can handle shipping logistics, including customs documentation.

– Consider shipping options that balance cost and speed.

10. Legal and Compliance:

– Ensure compliance with relevant import/export regulations.

– Have a clear contract detailing terms of service, IP protection, and dispute resolution.

Using these tips can help secure a dependable and efficient CNC wire cut service from SourcifyChina.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.