Choosing “SourcifyChina” Factory for purchasing fabricated sheet metal offers unmatched quality and precision in manufacturing. Their state-of-the-art facilities ensure the highest standards, meeting international benchmarks and delivering exceptional products tailored to your specifications.

SourcifyChina’s experienced team provides personalized service, guiding you through every step of the process. Their expertise ensures seamless communication, reducing the risk of errors and ensuring your requirements are fully met.

Competitive pricing is another reason to select SourcifyChina. By leveraging local resources and efficient production techniques, the factory provides cost-effective solutions without compromising on quality, giving you excellent value for money.

Timely delivery is guaranteed with SourcifyChina. Their well-established logistics network and streamlined processes ensure your orders arrive on schedule, minimizing downtime and optimizing your project timelines.

Lastly, SourcifyChina places a strong emphasis on sustainability. Their commitment to eco-friendly practices means you can feel confident that your choices are both high-quality and environmentally responsible, making them an ideal partner for your procurement needs.

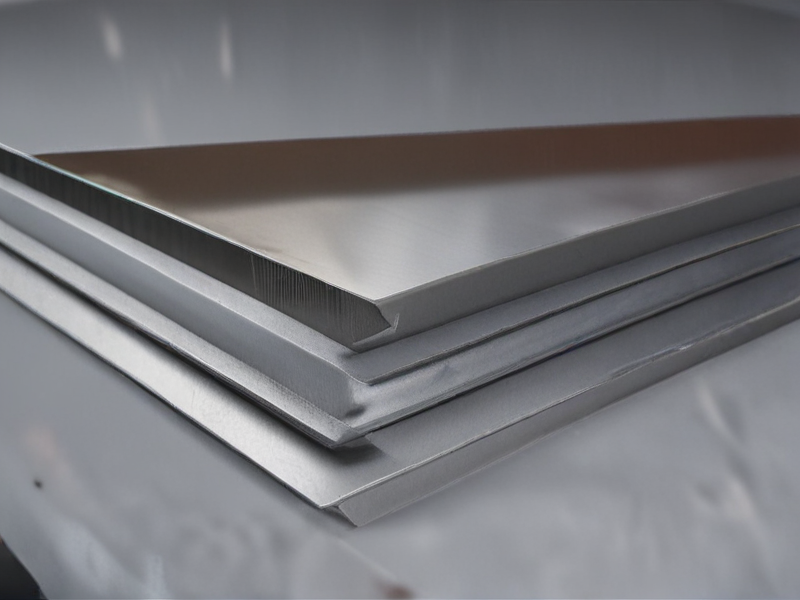

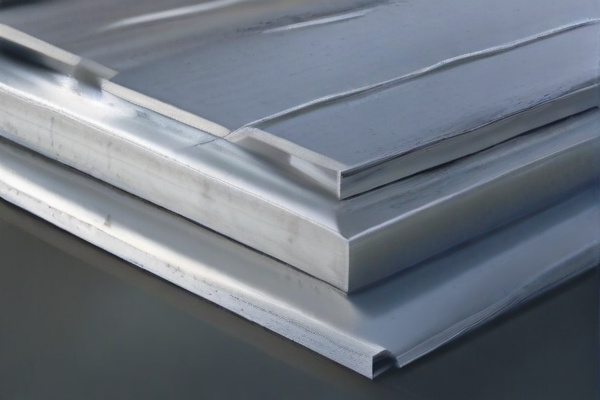

Fabricated sheet metal involves various types and options tailored for different industrial applications. Common materials include aluminum, stainless steel, brass, and copper, each offering unique properties and advantages.

– Aluminum: Lightweight, corrosion-resistant, conductive, and easily formed; ideal for aircraft, automotive, and marine industries.

– Stainless Steel: Strong, corrosion-resistant, and aesthetically appealing; commonly used in medical instruments, kitchen appliances, and construction.

– Brass: Offers good electrical conductivity and corrosion resistance, and is often used in decorative items, plumbing, and musical instruments.

– Copper: Exceptional electrical and thermal conductivity, excellent for electrical components, roofing, and heat exchangers.

Fabrication Processes:

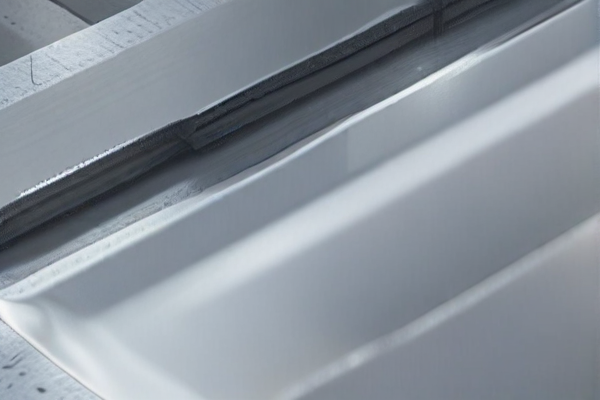

– Cutting: Laser cutting, water jet cutting, plasma cutting, and shearing are used to achieve precise shapes and sizes.

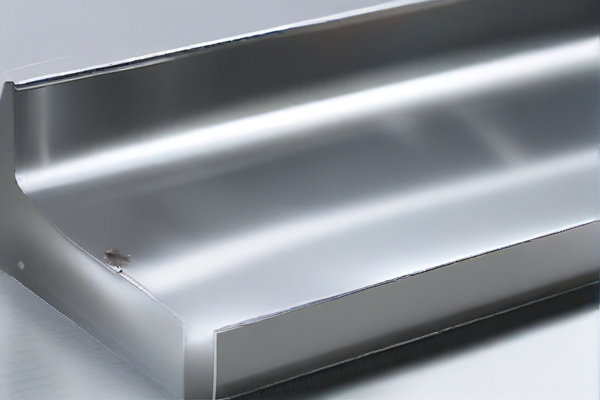

– Bending: Techniques like press braking, tube bending, and roll forming create various angular shapes.

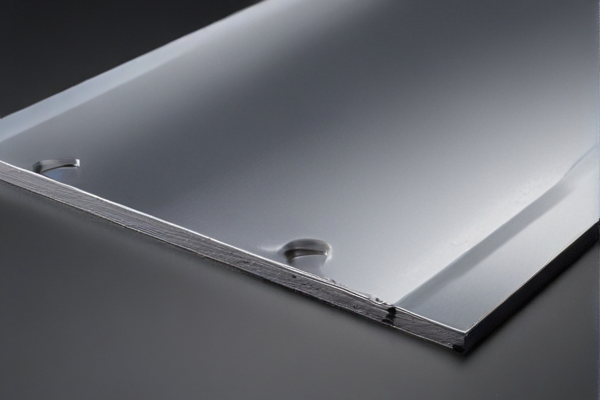

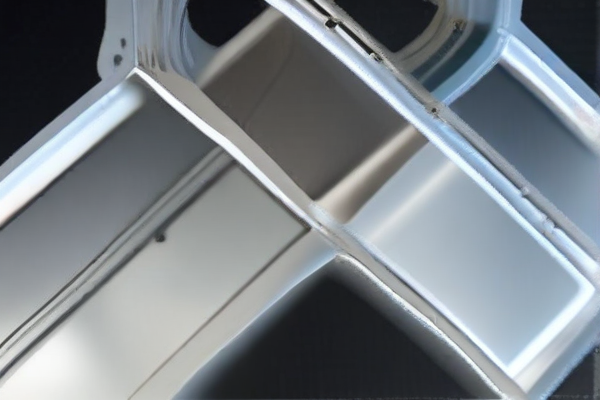

– Joining: Welding (TIG, MIG, spot welding), riveting, and adhesive bonding connect parts securely.

– Forming: Methods such as stamping, deep drawing, and spinning produce complex shapes from flat sheets.

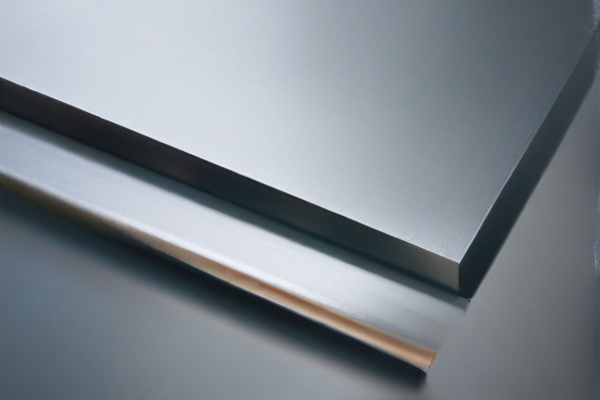

Finishing Techniques:

– Coating: Powder coating, anodizing, and galvanizing protect metal surfaces and enhance aesthetics.

– Polishing: Mechanical and chemical polishing improve surface finish and remove imperfections.

– Deburring: Removes sharp edges and burrs for safety and functionality.

Applications:

– Automotive: Body panels, chassis components.

– Construction: Roofing, structural elements, HVAC systems.

– Electronics: Enclosures, heat sinks.

– Aerospace: Structural frames, fuselage sections.

Fabricated sheet metal offers versatility and customization, catering to diverse industries by adapting to specific needs and conditions.

Fabricated sheet metal is utilized in diverse industries due to its versatility, durability, and ease of customization. From aviation to electronics, its applications are vast and varied, helping create reliable and efficient products.

– Automotive Industry: Used for manufacturing car bodies, chassis, and exhaust systems.

– Aerospace: Essential for aircraft panels, engine components, and structural support.

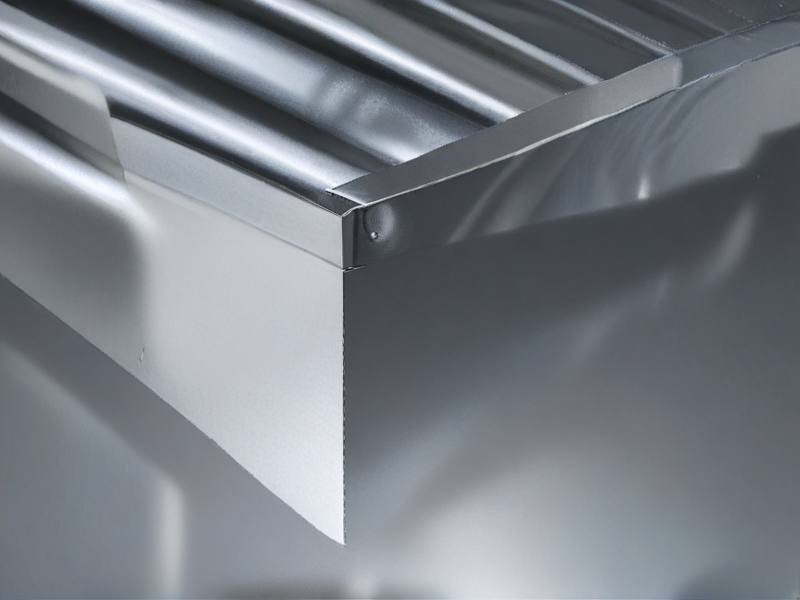

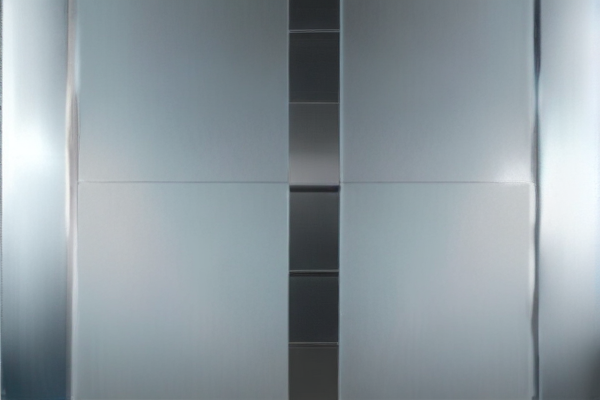

– Construction: Employed in roofing, wall cladding, ductwork, and architectural features.

– Electronics: Used in the creation of enclosures, brackets, and heat sinks for electronic devices.

– Medical Equipment: Fabricated into surgical instruments, hospital beds, and diagnostic machines.

– Agricultural Machinery: Components include machinery parts, storage bins, and silos.

– HVAC Systems: Important for making ducts, vents, and other components in heating and cooling systems.

– Furniture: Utilized in office desks, shelves, and ergonomic chairs.

– Marine Industry: Used in building ship hulls, decks, and other structural components.

– Renewable Energy: Fabricated into frames and supports for solar panels and wind turbines.

– Food Processing: Equipment such as counters, cabinets, and storage units.

– Signage: Custom signs for businesses, traffic, and informational purposes.

– Railway: Utilized in train carriages, track systems, and related infrastructure.

– Defense: Critical for manufacturing armored vehicles, weaponry, and protective structures.

– Consumer Goods: Household appliances such as ovens, refrigerators, and washing machines.

Fabricated sheet metal is indispensable across many sectors, promising innovation, and efficiency in product design and function. Its adaptability ensures it remains a fundamental material in modern manufacturing and construction.

SourcifyChina fabricates high-quality sheet metal using advanced machinery and precise techniques. The company caters to various industries, including automotive, aerospace, and construction, ensuring durability and reliability in the materials produced. Quality control is paramount at SourcifyChina, with each sheet metal undergoing rigorous testing to meet industry standards.

The fabricated sheet metal from SourcifyChina is typically made from materials like steel, aluminum, and stainless steel. These metals are chosen for their superb strength, corrosion resistance, and versatility, making them ideal for a myriad of applications. Each material undergoes a thorough selection process to ensure it meets the exact specifications required by clients.

Customization is a key service offered by SourcifyChina. Clients can specify dimensions, shapes, and additional features according to their project needs. The team at SourcifyChina collaborates closely with clients to deliver products that match their unique requirements while maintaining superior quality and efficiency.

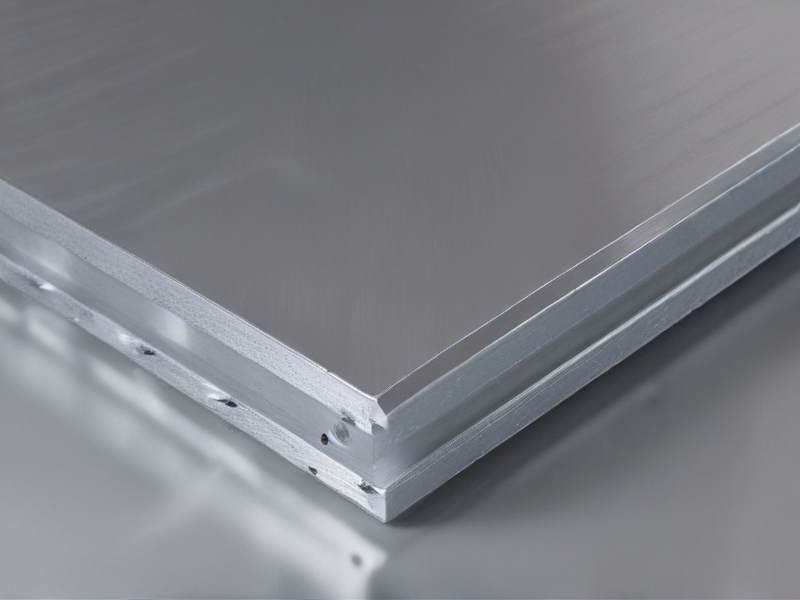

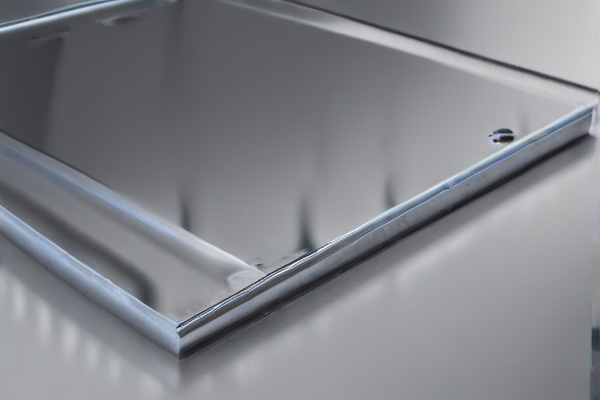

Investments in state-of-the-art equipment and robust manufacturing processes enable SourcifyChina to maintain high production rates without compromising on quality. Technologies such as laser cutting, CNC machining, and precision welding are employed to achieve the desired outcomes, ensuring each piece of sheet metal is fabricated to perfection.

By focusing on stringent quality checks and advanced manufacturing technologies, SourcifyChina consistently delivers sheet metal products that are durable, reliable, and tailored to client needs. The company’s commitment to excellence makes it a trusted partner for high-quality fabricated sheet metal solutions worldwide.

SourcifyChina places a high emphasis on quality control in sheet metal fabrication. The process starts with raw material verification, ensuring each metal sheet meets stringent quality standards before production.

Next, computer-aided design (CAD) software is employed to create precise blueprints. These detailed plans guide the cutting, bending, and assembling phases, minimizing errors and maximizing accuracy in each component.

Throughout the fabrication process, multiple inspection checkpoints are established. Trained inspectors utilize advanced measurement tools to verify dimensions, ensuring each piece adheres to design specifications without compromising structural integrity.

After assembly, products undergo rigorous functional testing. This phase includes stress tests, load-bearing evaluations, and environmental simulations to confirm durability and performance under real-world conditions.

Finally, a thorough visual inspection is conducted to ensure aesthetic quality. Once all quality checks are completed, the products are carefully packaged to prevent damage during transit, guaranteeing they reach customers in pristine condition. This comprehensive quality control process underscores SourcifyChina’s commitment to delivering high-quality fabricated sheet metal products.

SourcifyChina excels in precision sheet metal fabrication, providing tailored, high-quality solutions to meet diverse industrial requirements. Their advanced machinery ensures perfect cuts, bends, and finishes.

The company boasts state-of-the-art CNC machinery, allowing for intricate designs and swift production. This technological edge ensures high standards of accuracy and efficiency in every project.

SourcifyChina specializes in various fabrication techniques, including laser cutting, punching, welding, and forming. These diverse capabilities enable them to handle complex and custom specifications with ease.

The team consists of skilled engineers and technicians dedicated to delivering superior craftsmanship. Their expertise allows SourcifyChina to tackle projects of any scale, ensuring client satisfaction.

Quality control is stringent at SourcifyChina, with thorough inspections at every production stage. Such meticulous attention guarantees high-quality and reliable sheet metal products.

SourcifyChina offers a versatile range of materials, such as stainless steel, aluminum, and copper. This material diversity ensures they can cater to all specific client needs and applications.

Their services extend to finishing processes like powder coating and galvanizing, providing durable and aesthetic final products. These finishing touches enhance both form and function.

SourcifyChina’s commitment to sustainability is evident. They utilize eco-friendly practices and materials, minimizing environmental impact while delivering top-notch products.

Customer service at SourcifyChina is exceptional. Their team maintains open communication channels, ensuring clients are continuously updated and satisfied with the project progress.

SourcifyChina also provides cost-effective solutions without compromising quality. Their efficient processes and resource management allow competitive pricing, benefiting clients economically.

With a focus on innovation and continual improvement, SourcifyChina stays ahead in the industry. They invest in research and development to incorporate the latest trends and technologies.

In summary, SourcifyChina’s expertise in sheet metal fabrication, bolstered by advanced technology, skilled professionals, strict quality control, and excellent customer service, makes them a reliable partner in delivering high-quality, customized metal products efficiently and sustainably.

Fabricated sheet metal offers significant advantages across various industries, ensuring reliability, durability, and efficiency in numerous applications.

– Cost-Effective: The manufacturing process of sheet metal is highly efficient, reducing production costs and conserving resources.

– High Precision: Modern fabrication techniques allow for high precision and accuracy, ensuring components fit perfectly in their intended applications.

– Durability: Sheet metal is highly durable, offering resistance to wear, corrosion, and extreme temperatures, extending the longevity of products.

– Versatility: It can be molded into various shapes and sizes, making it suitable for diverse applications across different sectors, from automotive to aerospace.

– Lightweight: Despite its strength, sheet metal is relatively lightweight, improving energy efficiency in transportation applications.

– Sustainability: Sheet metal is recyclable, promoting environmental sustainability and reducing waste in manufacturing processes.

– Quick Production: Fabrication methods such as stamping and cutting provide rapid production rates, meeting quick turnaround times for projects.

– Customization: It allows for easy customization to meet specific requirements, ensuring that unique project specifications are met without compromising on quality.

– Strength-to-Weight Ratio: The excellent strength-to-weight ratio of sheet metal makes it ideal for structural applications where reducing weight without losing strength is crucial.

– Aesthetics: Sheet metal can be finished in various ways like painting, plating, or anodizing, enhancing the visual appeal of the final product.

In conclusion, fabricated sheet metal’s efficiency, durability, and versatility make it an invaluable resource across many industries, catering to complex, high-demand applications while promoting sustainability and cost-effectiveness.

Fabricated sheet metal has diverse features that make it crucial in various industries, ranging from automotive to aerospace and construction. Below are some key features:

– Versatility: Fabricated sheet metal can be used to create a wide range of products.

– Durability: Offers high strength and resilience to wear and tear.

– Complex Shapes: Can be easily bent, cut, and shaped into intricate designs.

– Lightweight: Maintains structural integrity while being relatively light.

– Corrosion Resistance: Certain metals like stainless steel or aluminum resist rust.

– Cost-Efficiency: Mass production reduces material and labor costs.

– Conductivity: Good electrical and thermal conductivity for electronic applications.

– Precision: High accuracy in creating parts to specific dimensions.

– Recyclability: Can be recycled, making it an eco-friendly option.

– Surface Finish: Compatible with various finishing processes for enhanced aesthetics.

– Weldability: Easily weldable for complex assemblies.

– Customization: Tailored to meet specific customer requirements.

– Efficiency: Quick fabrication reduces production time.

– Integration: Compatible with other materials and components.

SourcifyChina specializes in custom-fabricated sheet metal products tailored to meet unique client requirements. Known for precision and reliability, their services encompass a wide range of industries, including automotive, aerospace, and electronics.

Utilizing advanced technology and expert craftsmanship, SourcifyChina ensures that each piece meets exact specifications. From prototyping to mass production, their processes are efficient and cost-effective, minimizing lead times and maximizing quality.

Clients benefit from comprehensive project management including design, fabrication, and finishing. SourcifyChina’s team of skilled engineers works closely with customers to bring their visions to life, offering valuable insights and solutions throughout the project lifecycle.

The company’s commitment to quality is evident in its rigorous quality control measures. Each product undergoes stringent testing to ensure it meets industry standards and client expectations.

In addition to standard sheet metal services, SourcifyChina offers customization options like laser cutting, welding, and powder coating. Their versatile capabilities enable them to handle complex projects of all sizes and scopes.

Customer satisfaction is a priority, and SourcifyChina prides itself on delivering exceptional service. By maintaining transparent communication and providing timely updates, they build long-term relationships with clients.

Moreover, SourcifyChina is dedicated to sustainability. Implementing eco-friendly practices, they minimize waste and strive for energy efficiency in all operations.

Overall, SourcifyChina stands out as a premier choice for custom-fabricated sheet metal products. Their blend of cutting-edge technology, skilled workforce, and customer-centric approach ensures they deliver unparalleled solutions that meet diverse industry needs.

SourcifyChina is a premier company specializing in the manufacturing and provision of high-quality fabricated sheet metal products. Renowned for its precision engineering and cutting-edge technology, SourcifyChina caters to a diverse range of industries including automotive, aerospace, construction, and electronics. Utilizing advanced CNC machinery and laser cutting techniques, the company ensures exacting standards of durability and excellence. Their commitment to customer satisfaction is reflected in personalized service, timely delivery, and competitive pricing. Adhering to strict international quality standards, SourcifyChina not only emphasizes innovation and efficiency but also places a strong focus on sustainable practices and eco-friendly manufacturing processes. This dedication to excellence and sustainability has cemented SourcifyChina’s reputation as a trusted partner for businesses globally, seeking reliable and high-performance sheet metal solutions.

Fabricated sheet metal plays a crucial role in aerospace, defense, and marine applications due to its versatility, strength, and lightweight properties. In the aerospace industry, it is extensively used in the construction of aircraft components such as fuselage panels, wing structures, and engine parts. The ability to fabricate sheet metal into complex, precise shapes allows for the creation of aerodynamic and robust structures essential for flight. Advanced materials like aluminum and titanium alloys are often selected to meet the stringent weight and strength requirements. This ensures not only optimal performance but also fuel efficiency and safety in both commercial and military aviation.

In the defense and marine sectors, fabricated sheet metal is integral in the construction of armored vehicles, naval vessels, and submarines. For defense, it offers the necessary durability and protection in combat situations, forming parts of tanks, troop carriers, and missile housings. In marine applications, it’s used for hulls, decks, and bulkheads, where corrosion resistance and structural integrity are paramount. Stainless steel and specialized coatings are employed to withstand harsh marine environments. Additionally, the precision fabrication capabilities enable integrating intricate components, such as navigation and communication systems, ensuring these vessels meet rigorous operational demands. The use of fabricated sheet metal thus provides a reliable, efficient, and adaptable solution across these high-stakes industries.

Fabricated sheet metal plays a pivotal role in the automotive industry, serving as a fundamental material in vehicle construction and design. Its versatility and reliability allow it to be utilized in a multitude of applications ranging from structural components to aesthetic finishes. Car bodies, chassis, and enclosures for engines are predominantly fashioned from sheet metal due to its strength and malleability. The ability to mold sheet metal into complex shapes permits manufacturers to create aerodynamic and efficient designs while maintaining structural integrity. Additionally, the use of variegated metals like steel, aluminum, and titanium based on specific requirements further underscores the material’s adaptability. With advancements in fabrication technologies such as laser cutting, CNC machining, and robotic welding, automotive manufacturers can achieve higher precision and faster production rates, enhancing both the safety and aesthetics of vehicles.

In the electronics sector, fabricated sheet metal is integral to the creation of enclosures and components that are both protective and functional. Electronics enclosures, such as those used in computers, telecommunications equipment, and industrial machinery, often rely on sheet metal to provide robust yet lightweight housing that shields sensitive components from electromagnetic interference (EMI) and environmental hazards. The thermal conductivity of metals like aluminum and copper also aids in heat dissipation, preventing overheating of critical electronic parts. Custom fabrication techniques allow for the creation of intricate cutouts, bends, and assemblies necessary to accommodate various electronic layouts and connector interfaces. The precision and scalability of sheet metal fabrication ensure that manufacturers can consistently meet the tight tolerances and high production volumes demanded by the rapidly evolving electronics industry. Overall, the employment of sheet metal in both automotive and electronics applications exemplifies its essential role in modern engineering and manufacturing.

Fabricated sheet metal is a cornerstone in the construction industry due to its versatility, durability, and adaptability to various design specifications. In the realm of architectural development, sheet metal is often used to craft roofing, wall claddings, and structural components, offering both aesthetic appeal and robust protection against environmental elements. Materials like aluminum, steel, and copper are commonly chosen for their resistance to corrosion and weathering, ensuring long-term sustainability. Additionally, modern fabrication techniques, such as laser cutting and CNC machining, enable precise customization, allowing sheet metal to meet the diverse needs of complex architectural projects. This adaptability not only accelerates construction timelines but also supports innovative designs that push the boundaries of contemporary architecture.

In the energy sector, fabricated sheet metal plays a critical role in enhancing efficiency and supporting sustainable practices. For instance, in renewable energy installations such as solar panels and wind turbines, sheet metal components are essential for the structures that house and support the machinery. These metals are chosen for their strength and lightweight properties, which are crucial for the stability and portability of energy solutions. Moreover, the fabrication of heat exchangers, ductwork, and enclosures used in various power generation systems benefits from the precision and durability of sheet metal. Advanced applications even extend to battery enclosures and protective casings for sensitive equipment in energy storage and distribution networks. By delivering reliable performance and ease of installation, fabricated sheet metal contributes significantly to the efficient production and management of energy resources.

Fabricated sheet metal plays a pivotal role in the industrial equipment industry, serving as a fundamental material in the manufacturing of various machinery and components. The process of fabricating sheet metal involves cutting, bending, and assembling flat sheets of metal into bespoke shapes and forms to meet specific requirements. This versatility makes it indispensable in creating parts for heavy machinery, conveyor systems, and enclosure panels. The durability and strength of sheet metal ensure that the resultant components can withstand the rigors of industrial operations, including exposure to harsh environments and constant wear and tear. By leveraging advanced techniques such as laser cutting, CNC machining, and robotic welding, manufacturers can achieve high precision and consistency, which is critical for maintaining the performance and reliability of industrial equipment.

In addition to its functional benefits, fabricated sheet metal offers significant cost advantages. The material is relatively inexpensive and its fabrication process can be highly efficient, resulting in reduced production costs. This makes it an attractive option for the industrial equipment industry, where there is continual pressure to optimize costs while ensuring quality and durability. Furthermore, sheet metal’s recyclability aligns with the industry’s increasing focus on sustainable practices. By using recycled materials and minimizing waste during the fabrication process, manufacturers can contribute to environmental conservation efforts while maintaining high standards of production. Overall, the application of fabricated sheet metal in the industrial equipment sector is a testament to its versatility, durability, and cost-effectiveness, making it a cornerstone material for modern industrial manufacturing.

Fabricated sheet metal is instrumental in the medical devices industry due to its versatility, durability, and precision. Medical devices require materials that can withstand stringent sterilization processes and provide reliable performance over time. Sheet metal meets these criteria as it can be easily sterilized, has a long lifespan, and offers excellent mechanical properties. Among its varied applications, sheet metal is commonly used in the construction of surgical instruments, hospital beds, and diagnostic equipment. For instance, surgical instruments such as scalpels and forceps often have components fabricated from stainless steel sheets, known for their corrosion resistance and ability to maintain sharpness. Similarly, durable and adjustable hospital beds are constructed using robust frame structures fabricated from sheet metal, ensuring patient safety and comfort.

Additionally, sheet metal fabrication allows for high precision, crucial for the development of intricate medical devices and components. Techniques such as laser cutting, punching, and CNC (computer numerical control) machining are employed to achieve the exact dimensions and tolerances required. This precision is particularly vital in the manufacture of components like implantable devices, prosthetics, and specialized enclosures for electronic medical instruments. The adaptability of sheet metal means it can be engineered into complex shapes and sizes, meeting the unique requirements of various medical applications. Furthermore, the use of biocompatible metals like titanium in sheet form enhances its application for implants and prosthetics, ensuring that they are compatible with human tissue and can function effectively within the body. Consequently, the integration of fabricated sheet metal into medical devices plays a critical role in advancing healthcare technology and improving patient outcomes.

Fabricated sheet metal plays an essential role in various machining and manufacturing applications due to its versatility, strength, and ease of customization. In the context of machining, sheet metal can be cut, bent, and formed using processes such as laser cutting, stamping, and CNC machining to create precise components and assemblies that cater to specific design requirements. Techniques like punching and embossing allow for intricate features and patterns, which can significantly enhance the functionality and aesthetic appeal of the final product. Additionally, the material’s lightweight yet durable nature makes it suitable for producing parts across various industries, including automotive, aerospace, electronics, and construction. This adaptability ensures that fabricated sheet metal remains a cornerstone of modern manufacturing.

Manufacturing applications heavily utilize fabricated sheet metal, particularly in the production of enclosures, brackets, chassis, and structural elements. Industries such as consumer electronics rely on sheet metal for casing and housing components, ensuring both protection and heat dissipation for sensitive internal parts. In the construction sector, sheet metal is commonly used for roofing, gutters, and facades, demonstrating its resilience to environmental factors and its ability to undergo various finishes like galvanizing and powder coating for added durability. Furthermore, the capability of sheet metal to be mass-produced rapidly with consistent quality makes it an indispensable resource for high-volume production runs. As manufacturing technologies continue to evolve, the demand for fabricated sheet metal is expected to grow, driven by its adaptability, cost-effectiveness, and reliable performance in diverse applications.

Sure, here is a list of frequently asked questions (FAQ) with answers related to manufacturing “fabricated sheet metal quality work” from SourcifyChina Factory, keeping each answer concise and within the word limit:

Q: What materials does SourcifyChina use for sheet metal fabrication?

A: SourcifyChina uses a variety of materials including stainless steel, aluminum, galvanized steel, and carbon steel to meet different project requirements.

Q: How does SourcifyChina ensure the quality of fabrications?

A: We implement stringent quality control measures, including material certification, dimensional inspection, surface finish checks, and ISO 9001 compliance to ensure top-notch quality.

Q: Can SourcifyChina handle custom sheet metal designs?

A: Yes, SourcifyChina specializes in custom fabrication and can work with your designs, specifications, and drawings to create tailored solutions.

Q: What are the typical lead times for manufacturing projects?

A: Lead times vary depending on the complexity and volume of the project but generally range from 2 to 6 weeks from order confirmation to delivery.

Q: Does SourcifyChina provide prototyping services?

A: Yes, we offer prototyping services to help clients visualize and refine their designs before moving to full-scale production.

Q: What finishing options are available?

A: We provide various finishing options including powder coating, anodizing, electroplating, and painting to meet specific aesthetic and protective requirements.

Q: Can SourcifyChina handle large-volume production?

A: Absolutely, our factory is equipped to manage both small and large-scale production runs efficiently.

Q: What industries does SourcifyChina serve?

A: We serve diverse industries such as automotive, aerospace, electronics, construction, and medical equipment, among others.

Q: How does SourcifyChina handle shipping and delivery?

A: We coordinate closely with leading logistics providers to ensure timely and safe delivery of products to your specified location, globally.

Q: How can I get a quote for my project?

A: You can submit your project details and design files through our website or contact our sales team directly. We typically respond with a detailed quote within 1-3 business days.

This FAQ should provide a clear and concise overview of SourcifyChina’s capabilities and processes for fabricated sheet metal quality work.

Fabricated sheet metal manufacturing is a critical process in various industries ranging from automotive to electronics. Choosing a reliable partner like SourcifyChina can significantly streamline your production. Here are some essential tips:

1. Material Selection: Ensure the factory understands and utilizes the appropriate metal types, such as steel, aluminum, or copper, tailored to your product’s requirements.

2. Precision and Technology: Verify that SourcifyChina employs advanced machinery such as CNC punching, laser cutting, and bending machines to maintain high precision and quality.

3. Experience and Expertise: Partner with a factory that has extensive experience and a skilled workforce in sheet metal fabrication. SourcifyChina’s years of expertise can be a significant advantage.

4. Prototyping Capabilities: Confirm that the factory can create prototypes. Prototyping ensures that any design issues are addressed before mass production.

5. Quality Control: Ensure rigorous quality control processes are in place. You should inquire about their inspection protocols, including ISO certifications or other relevant standards.

6. Customization Options: Check if the factory provides custom fabrication services. This can range from bespoke designs to specific tolerances or finishes needed for your product.

7. Cost Efficiency: SourcifyChina is known for competitive pricing. Evaluate their cost structures and ensure there are no hidden fees that could impact your budget.

8. Lead Time: Understand their production lead times and capacity to meet your deadlines without compromising on quality.

9. Communication: Efficient communication is pivotal. Work with a factory that offers clear and prompt communication channels to avoid misunderstandings.

10. Sustainability Practices: With the growing emphasis on sustainability, inquire about the factory’s eco-friendly practices and waste management systems.

Selecting SourcifyChina for your fabricated sheet metal needs can prove beneficial if these factors align with your project requirements.

Q: What types of fabricated sheet metal can SourcifyChina provide?

A: SourcifyChina offers a variety of fabricated sheet metal options, including but not limited to aluminum, stainless steel, cold-rolled steel, and galvanized steel. They cater to custom specifications and various finishes to meet specific project requirements.

Q: How can I request a quote from SourcifyChina for fabricated sheet metal?

A: To request a quote, you can visit their website and fill out the online inquiry form, providing detailed information about your project specifications, quantities, and desired materials. You can also contact their sales team directly via email or phone.

Q: What is the typical lead time for orders from SourcifyChina?

A: The lead time for fabricated sheet metal orders varies depending on the complexity and size of the order. Generally, production lead times range from 2 to 6 weeks. It is advisable to confirm specific timelines with the sales team during the quotation process.

Q: Does SourcifyChina offer prototyping services?

A: Yes, SourcifyChina offers prototyping services to help you evaluate the design and functionality of your fabricated sheet metal product before committing to mass production. This ensures the final product meets your quality and design standards.

Q: What quality control measures are in place at SourcifyChina?

A: SourcifyChina has stringent quality control processes, including material inspections, in-process quality checks, and final product inspections. They adhere to international quality standards and provide certifications upon request.

Q: Can SourcifyChina handle large volume orders?

A: Yes, SourcifyChina is equipped to handle both small and large volume orders. Their advanced manufacturing facilities and skilled workforce enable them to scale production according to customer needs.

Q: What payment terms does SourcifyChina offer?

A: Payment terms vary based on the order size and customer relationship. Commonly accepted terms include T/T (telegraphic transfer), L/C (letter of credit), and sometimes other agreed-upon terms. It’s best to discuss payment terms directly with the sales team during the ordering process.

Sourcing fabricated sheet metal from SourcifyChina factory can be a streamlined process if you follow these tips:

1. Clear Specifications:

– Provide detailed blueprints or CAD drawings.

– Specify material type, thickness, and finish requirements.

2. Communication:

– Use clear, concise, and professional language.

– Be mindful of time zone differences for efficient communication.

3. Supplier Verification:

– Request samples to assess quality.

– Check reviews or ask for references from previous clients.

4. MOQ (Minimum Order Quantity):

– Understand and negotiate the MOQ to align with your production needs.

5. Quality Control:

– Implement a quality control plan.

– Consider third-party inspections or audits.

6. Lead Times:

– Clarify production and shipping lead times in advance.

– Factor in potential delays and buffer accordingly.

7. Payment Terms:

– Discuss payment methods, terms, and conditions upfront.

– Be cautious of paying large sums upfront; a phased payment plan could be safer.

8. Logistics:

– Decide whether you prefer FOB (Free on Board) or CIF (Cost, Insurance, and Freight) shipping terms.

– Work with a reliable freight forwarder for smooth customs clearance.

9. Contracts:

– Draft clear contracts detailing the scope of work, deliverables, timelines, and penalties for non-compliance.

10. After-Sales Support:

– Clarify warranty terms and support policies.

– Ensure they have mechanisms for addressing any post-delivery issues.

By adhering to these practices, you can minimize risks and ensure a reliable supply of high-quality fabricated sheet metal from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.