SourcifyChina stands out for its stellar reputation in the sheet metal fabrication industry. Known for quality and precision, the factory ensures each product meets strict international standards, guaranteeing customer satisfaction.

Expert engineers at SourcifyChina employ cutting-edge technology to deliver superior sheet metal products. They consistently innovate, ensuring timely and cost-effective production without compromising on quality or efficiency.

Choosing SourcifyChina means gaining access to comprehensive quality control processes. From raw material sourcing to final inspection, every step is meticulously monitored to ensure the highest standards are maintained, providing peace of mind for buyers.

Agility and flexibility are core strengths of SourcifyChina. The factory is equipped to handle both large-scale and custom orders, tailored to meet specific client requirements. This versatility makes them a preferred choice for diverse industries.

Exceptional customer service underscores SourcifyChina’s commitment to client satisfaction. Dedicated account managers streamline communication and facilitate smooth transactions, making it easier for buyers to navigate the complexities of international procurement.

Competitive pricing is another significant advantage of partnering with SourcifyChina. By leveraging economies of scale and efficient production techniques, the factory offers high-quality sheet metal products at cost-effective rates, maximizing value for buyers.

In summary, SourcifyChina Factory is an outstanding choice for sheet metal fabrication needs. Their dedication to quality, innovation, and customer satisfaction coupled with competitive pricing and flexible production capabilities makes them a top contender in the global market. Choosing SourcifyChina ensures reliable, high-quality products tailored to meet your unique requirements, all while maintaining cost-effectiveness.

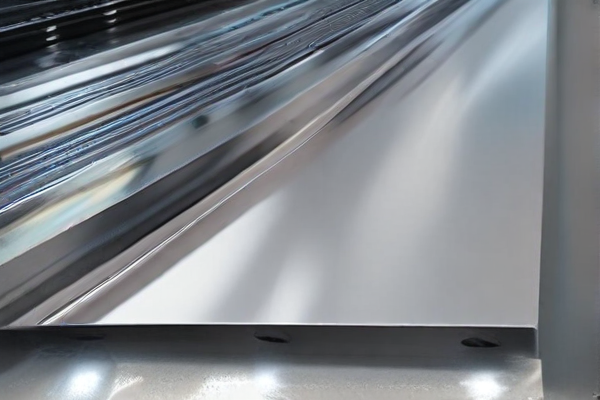

Fabrication of sheet metal involves cutting, bending, and assembling processes to create structures and components. Various methods and advanced technologies are used to achieve precise and durable results in different applications.

– Cutting:

– Laser Cutting: High precision, suitable for intricate designs.

– Plasma Cutting: Quick, effective for thicker metals.

– Water Jet Cutting: Uses high-pressure water, minimal thermal distortion.

– Shearing: Straight-line cuts, cost-effective for high volumes.

– Bending:

– Press Brake: Most common, precise angles.

– Roll Bending: Curved shapes, cylindrical parts.

– Rotary Bending: Continuous bends, often for more complex designs.

– Assembling:

– Welding: Strong, permanent joints; various types like MIG, TIG, and spot welding.

– Riveting: Mechanical fasteners, used in aerospace and automotive industries.

– Adhesive Bonding: Uses glues, suitable for dissimilar materials.

– Punching: Creating holes and indentations.

– Stamping: Complex shapes from metal sheets using dies.

– Deep Drawing: Forming deep, cup-shaped parts.

– Spinning: Rotating sheet metal against a forming tool to create symmetrical shapes.

Each method has its own application-specific benefits, choice based on material type, desired precision, production volume, and cost considerations.

Fabrication of sheet metal involves manipulating metal sheets to create specific shapes and structures, serving diverse industries including automotive, aerospace, and construction. This process includes cutting, bending, and assembling to produce intricate designs and components.

– Automotive: Manufacturing car bodies, panels, and various automotive parts.

– Aerospace: Crafting airplane fuselages, wing components, and interior structures.

– Construction: Producing roofing elements, structural frameworks, and interior fittings.

– Electronics: Creating enclosures, chassis, and brackets for electronic devices.

– Healthcare: Making surgical instruments, medical device housings, and hospital equipment.

– HVAC: Fabricating ducts, vents, and air conditioning components.

– Marine: Building ship hulls, decks, and superstructures.

– Agricultural Equipment: Forming parts for tractors, harvesters, and other farming machinery.

– Energy: Constructing parts for wind turbines, solar panel mounts, and oil rigs.

– Furniture: Designing metal frames, shelves, and fittings for modern furniture.

– Custom Prototyping: Developing bespoke metal components for specific projects.

– Signage: Creating metal signs, display boards, and decorative panels.

– Jewelry: Crafting detailed and precise metal pieces for adornments.

– Appliances: Manufacturing outer casings and internal parts of household appliances.

– Safety Equipment: Producing barriers, cages, and protective covers.

– Transportation: Building components for railways, buses, and trucks.

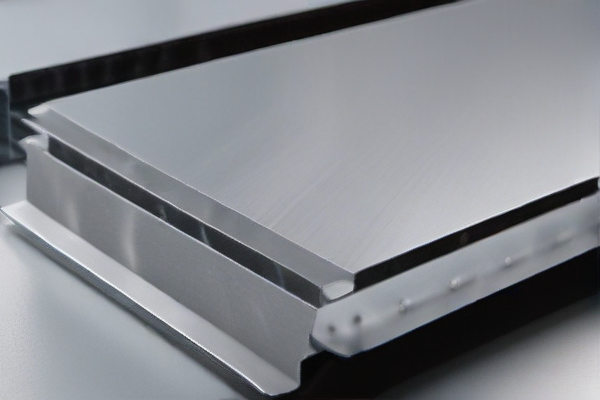

SourcifyChina is a premier company specializing in the fabrication of sheet metal. Using state-of-the-art technology, they offer custom solutions tailored to meet diverse industrial needs, ensuring durability and precision.

Their materials range includes high-grade steel, aluminum, and copper, meticulously selected to ensure longevity and optimal performance. These materials are sourced responsibly, reinforcing their commitment to quality and sustainability.

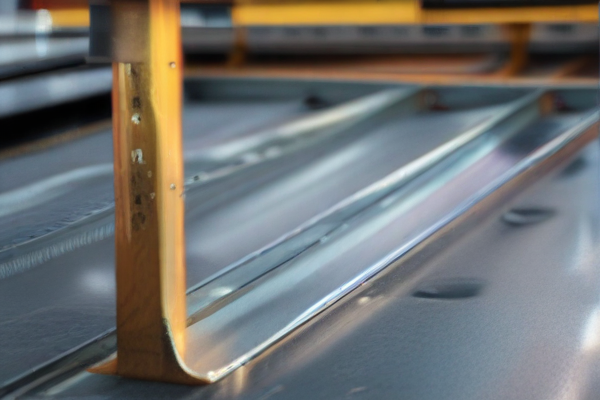

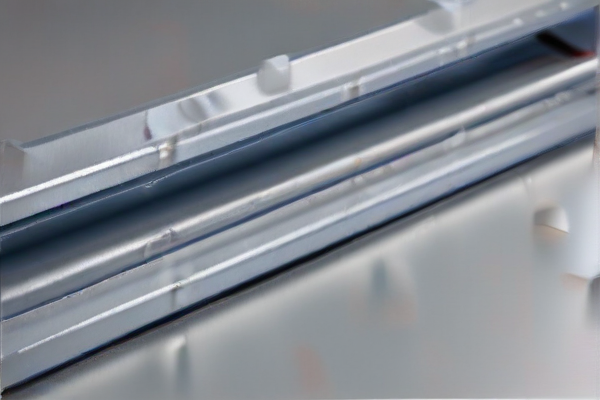

One of the distinguishing features of SourcifyChina is their cutting-edge machinery, which allows for precise cutting, bending, and welding. Advanced laser cutting and CNC machining ensure that every piece meets exact specifications.

They pride themselves on stringent quality control measures. Every stage of the manufacturing process is monitored rigorously to adhere to international standards. This dedication to quality ensures reliable and high-performance sheet metal products.

SourcifyChina also offers comprehensive post-fabrication services, such as powder coating and galvanizing, to enhance product durability. Their commitment to client satisfaction is evident through their thorough follow-up and support.

Ultimately, SourcifyChina’s expertise in sheet metal fabrication makes them a reliable partner for industries ranging from automotive to aerospace. Their superior material selection, advanced technology, and steadfast quality control underscore their reputation for excellence.

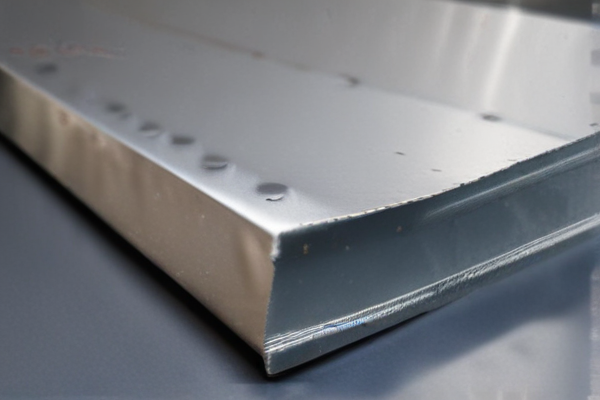

SourcifyChina’s fabrication of sheet metal emphasizes stringent quality control throughout the manufacturing process. This begins with the meticulous selection of raw materials, ensuring they meet precise standards for durability and consistency. Advanced technology is employed for cutting, bending, and shaping the metal, guaranteeing accurate dimensions and impeccable finishes.

Regular inspections are conducted at various stages of production to identify and rectify any defects. Skilled engineers use industry-leading measurement tools to maintain tight tolerances. Each component is rigorously tested for strength and reliability under simulated operational conditions.

Post-production, a final quality audit evaluates the entire batch of sheet metal fabrications. This comprehensive assessment includes visual inspections, as well as functional and performance tests. Detailed reports are generated to document compliance with all specifications.

SourcifyChina also incorporates continuous improvement practices by gathering feedback from clients and internal audits. Any identified issues lead to immediate corrective actions, ensuring future batches meet even higher standards. This closed-loop system helps in maintaining high quality consistently.

The focus on quality control not only minimizes defects and rework but also enhances customer satisfaction and trust in SourcifyChina’s products. Robust training programs ensure that all employees are skilled in the latest quality management techniques. This commitment to excellence is what sets SourcifyChina apart in the competitive field of sheet metal fabrication.

SourcifyChina specializes in the fabrication of sheet metal, leveraging advanced technology and precision engineering. They offer customized solutions tailored to clients’ specific requirements, ensuring high-quality outcomes.

Their capabilities include laser cutting, which provides precise and efficient handling of various metals. This enables intricate designs and reduces material wastage, thus optimizing production costs.

SourcifyChina also excels in CNC punching, which offers versatility in creating complex shapes and patterns. This method ensures higher repeatability and accuracy for mass production, enhancing overall manufacturing efficiency.

Bending and forming services at SourcifyChina ensure that each metal piece meets stringent dimensional requirements. They employ advanced machinery to achieve complex bends and detailed formations with minimal distortion.

Welding is another forte of SourcifyChina, providing both MIG and TIG welding techniques. These ensure robust and clean joints, meeting industry standards for durability and strength.

In addition to these services, they offer surface treatments like powder coating and anodizing. These finishes not only enhance the visual appeal but also provide protection against corrosion and wear.

SourcifyChina’s commitment to quality is evident in their thorough inspection processes. Each product undergoes rigorous quality checks to meet client specifications and industry standards.

Their team of skilled engineers and technicians work closely with clients to offer design assistance and improve manufacturability. This collaborative approach ensures optimal outcomes and customer satisfaction.

With a focus on innovation and continuous improvement, SourcifyChina stays ahead of industry trends. They invest in state-of-the-art equipment and employ the latest techniques to maintain their competitive edge.

In summary, SourcifyChina’s comprehensive sheet metal fabrication capabilities, from cutting and punching to bending, welding, and surface treatments, ensure high-quality, customized solutions. Their commitment to quality, combined with advanced technology and expert personnel, make them a reliable partner for all metal fabrication needs.

Sheet metal fabrication offers numerous advantages, including durability, versatility, and cost-efficiency. It’s widely used in various industries for creating prototypes and finished products.

– Strength and Durability: Sheet metal parts provide high strength and longevity, making them ideal for robust applications.

– Versatility: Capable of being shaped into numerous forms and sizes, sheet metal can be customized for a wide range of uses.

– Cost-Effective: The fabrication process is relatively inexpensive, especially for large-scale production, providing economic benefits.

– Recyclability: Sheet metal is easily recyclable, contributing to environmental sustainability.

– Precision: Advanced fabrication techniques allow for high accuracy and tight tolerances, ensuring consistent quality.

– Speed: Modern machinery enables rapid production, reducing lead times significantly.

– Finish Options: Various finishing techniques such as painting, powder coating, and plating can be applied for aesthetic and protective purposes.

– Weight Efficiency: Despite its strength, sheet metal can be lightweight, important for applications in transportation and aerospace.

Sheet metal fabrication’s blend of efficiency, precision, and adaptability makes it an invaluable process across industries like automotive, aerospace, construction, and electronics. Its long-lasting properties ensure products that stand the test of time, while its cost-effectiveness and speed in manufacturing provide notable competitive advantages.

Sheet metal fabrication involves turning flat sheets of metal into structures and products through various processes. It’s fundamental in industries like automotive, aerospace, and construction.

– Cutting: Techniques like laser cutting, plasma cutting, and waterjet cutting provide precision and efficiency in shaping metal sheets.

– Bending: Methods such as brake bending or roll forming shape the metal into desired angles and curves.

– Welding: Essential for joining metal parts, with various types such as MIG, TIG, and spot welding used depending on the application.

– Stamping: Involves pressing the metal into the desired shape using a mold or die, commonly used for mass production.

– Punching: Creating holes or shapes in metal sheets using a punch and a die set.

– Forming: Processes like rolling, spinning, and stretching transform the metal without removing material.

– Shearing: Cutting large sheets into smaller pieces using a shear machine.

– Finishing: Includes processes like grinding, polishing, and coating to enhance the metal’s appearance and resistance to corrosion.

– Assembly: Combining multiple fabricated parts through riveting, welding, or using fasteners to create the final product.

– CAD/CAM Integration: Utilizing computer-aided design (CAD) and computer-aided manufacturing (CAM) software for precision and efficiency.

– Quality Control: Rigorous testing and inspection to ensure the metal parts meet specified standards.

By employing these techniques, sheet metal fabrication allows for the creation of durable, precise, and intricate metal components.

SourcifyChina specializes in the fabrication of custom sheet metal products and projects. Utilizing advanced technology and skilled craftsmanship, they deliver high-quality and precision-engineered items tailored to specific client needs.

This company offers a broad range of services, including laser cutting, bending, welding, and finishing. Their state-of-the-art machinery ensures consistent accuracy and durability in every piece produced.

SourcifyChina caters to diverse industries, such as automotive, aerospace, and electronics, providing solutions that meet stringent safety and performance standards. Their expertise allows them to handle both small-scale and large-scale productions efficiently.

Commitment to customer satisfaction drives their operations. They collaborate closely with clients from the design phase to final production, ensuring all requirements are met. Prompt delivery schedules and competitive pricing further enhance their reputation.

With a focus on sustainability, SourcifyChina adopts eco-friendly practices throughout its manufacturing processes. This dedication not only supports environmental conservation but also aligns with global green initiatives.

Clients benefit from the company’s comprehensive quality assurance protocols. Every product undergoes rigorous testing to ensure it meets specified criteria and performs reliably under various conditions.

In summary, SourcifyChina exemplifies excellence in sheet metal fabrication, offering customized solutions, superior craftsmanship, and outstanding customer service. Their innovative approach and dedication to quality make them a preferred partner for custom sheet metal projects worldwide.

SourcifyChina is a premier fabrication company specializing in sheet metal manufacturing with a commitment to excellence and innovation. Located in one of the world’s manufacturing hubs, China, the company leverages advanced technology and skilled craftsmanship to deliver high-quality metal products that meet diverse industrial needs. Whether you’re looking for custom metal parts for automotive, aerospace, electronics, or construction, SourcifyChina has the expertise to bring your designs to life with precision and efficiency. Their state-of-the-art facilities are equipped with cutting-edge machinery, including CNC punching, laser cutting, and automated bending, ensuring that every piece meets stringent quality standards. With a focus on client satisfaction, SourcifyChina offers comprehensive services from initial design consultation to final production, ensuring your project is completed on time and within budget. By maintaining rigorous quality control and fostering continuous improvement, SourcifyChina has established itself as a trusted partner in the global manufacturing landscape, dedicated to delivering exceptional value and unmatched service.

The fabrication of sheet metal is a critical process in the aerospace, defense, and marine industries, characterized by its versatility, precision, and strength. In aerospace, sheet metal fabrication is used to construct everything from the fuselage of aircraft to intricate components such as wing spars and ribs. The high strength-to-weight ratio of materials like aluminum and titanium is particularly advantageous, ensuring that aircraft can achieve the necessary structural integrity while maintaining fuel efficiency. Techniques such as laser cutting, bending, and stamping are employed to meet the stringent tolerances and specifications required in aerospace applications, ensuring that each component contributes to the overall safety and performance of the aircraft.

In the defense sector, sheet metal fabrication is pivotal in creating armor, vehicle bodies, and various structural elements required for military equipment. The ability to manipulate high-strength metals through processes such as welding, machining, and forming ensures the production of robust and resilient components capable of withstanding harsh environments and combat conditions. Marine applications also benefit significantly from sheet metal fabrication, especially in the construction of ship hulls, bulkheads, and superstructures. Corrosion-resistant metals like stainless steel and special marine-grade alloys are often used to elongate the lifespan of marine vessels. Precision in fabrication processes ensures the structural soundness and sea-worthiness of ships, contributing to their durability and efficiency in both commercial and defense maritime operations. Overall, the flexible and adaptive nature of sheet metal fabrication makes it indispensable across these high-stakes industries.

Sheet metal fabrication plays a pivotal role in the automotive industry due to its versatility and cost-effectiveness. The process involves cutting, bending, and assembling flat sheets of metal into complex shapes and structures essential for vehicle manufacturing. Automakers rely heavily on sheet metal to create car bodies, chassis, fuel tanks, and various structural components, ensuring both strength and malleability. Techniques such as stamping, laser cutting, and CNC folding allow for precise and efficient production of parts that meet rigorous safety and performance standards. The ability to mass-produce these components consistently helps manufacturers streamline their production lines while maintaining high quality and reducing costs. Additionally, advancements in materials, such as high-strength steels and aluminum alloys, further enhance vehicle performance, fuel efficiency, and crashworthiness.

In the electronics sector, sheet metal fabrication is equally crucial, offering a robust solution for housing and protecting delicate components. The fabrication process is used to create enclosures, brackets, and chassis for various electronic devices, including computers, servers, and telecommunications equipment. Precision is paramount, as these metal housings must meet exacting specifications to ensure proper fit and function while providing effective shielding against electromagnetic interference (EMI). Furthermore, the development of customized sheet metal parts allows electronics manufacturers to innovate and adapt to rapidly changing technological demands. By employing advanced techniques such as laser cutting and automated bending, manufacturers can achieve high levels of accuracy and repeatability, which are critical for maintaining the reliability and performance of electronic products. Thus, sheet metal fabrication continues to be an indispensable element in the production of automotive and electronic applications, driving advancement and efficiency across both industries.

The fabrication of sheet metal stands as a cornerstone in the construction industry, offering unparalleled versatility and durability for a multitude of applications. From structural components like beams, columns, and supports to aesthetic elements such as facades, roofing, and cladding, sheet metal’s adaptability ensures it meets varied construction needs. The precision and efficiency in fabrication processes allow for the production of custom pieces that fit exact specifications, reducing waste and improving installation times. Additionally, sheet metal’s robustness and corrosion resistance make it ideal for constructing lasting infrastructures capable of withstanding environmental stressors. Coupled with advances in computer-aided design (CAD) and automation, the fabrication of sheet metal significantly enhances the quality, safety, and sustainability of construction projects.

In the energy sector, the fabrication of sheet metal is equally critical, serving as a fundamental element for various energy generation and distribution systems. For instance, in the renewable energy realm, sheet metal is used extensively in the manufacturing of solar panels, wind turbine components, and bioenergy plants due to its lightweight, strength, and thermal conductivity properties. In traditional power plants, sheet metal fabrication is indispensable for building boilers, turbines, and ductwork. Furthermore, it plays a pivotal role in the oil and gas industry for creating pipelines, storage tanks, and offshore platforms that must endure extreme conditions. The precision and customizability afforded by modern sheet metal fabrication techniques also facilitate the development of more efficient and advanced energy systems, aiding in the economic and sustainable distribution of energy resources.

The industrial equipment industry heavily relies on the fabrication of sheet metal to create robust and functional components that meet various operational needs. Fabrication of sheet metal involves processes such as cutting, bending, and assembling to manufacture frames, enclosures, brackets, and panels integral to machines and equipment used in sectors ranging from automotive to aerospace. The customizability and durability of sheet metal make it an ideal material for producing precise and tailored parts that can withstand high stress and adverse conditions. Advanced techniques such as laser cutting and CNC (Computer Numerical Control) machining contribute to the high precision and efficiency required for large-scale industrial applications, promoting innovation and improving product longevity.

Additionally, the versatility of sheet metal fabrication in the industrial equipment industry allows for the rapid prototyping and development of new machinery, facilitating a quicker transition from concept to production. The ability to fabricate intricate designs and integrate various functionalities into a cohesive unit helps manufacturers maintain a competitive edge in a fast-paced market. Moreover, sheet metal’s recyclability and cost-effectiveness align with the increasing emphasis on sustainable manufacturing practices. As industries continue to adopt automation and smart manufacturing technologies, the demand for expertly fabricated sheet metal components is likely to grow, further underscoring its essential role in producing advanced, reliable, and high-performance industrial equipment.

The fabrication of sheet metal plays a crucial role in the manufacturing of various medical devices, offering both precision and durability essential for the medical field. One of its primary applications is in the production of hospital equipment such as beds, stretchers, and surgical tables. These items require robust, corrosion-resistant structures that can be easily sanitized, qualities that sheet metal, particularly stainless steel, provides. Advanced fabrication techniques such as laser cutting, bending, and welding ensure high precision and uniformity, critical in maintaining the stringent safety standards of medical environments. The adaptability of sheet metal allows for customized designs tailored to specific medical requirements, supporting the evolving needs of healthcare facilities.

Moreover, sheet metal fabrication is integral to the creation of diagnostic and therapeutic devices, including imaging machines like MRI and CT scanners, as well as dialysis machines and ventilators. These devices often involve complex enclosures and housings that must safeguard sensitive electronics while allowing for ease of access and maintenance. The versatility of sheet metal fabrication methods enables the production of complex geometries and tight tolerances necessary for these intricate applications. Additionally, sheet metal’s excellent strength-to-weight ratio is invaluable, assisting in the portability and user-friendliness of medical apparatuses. The use of advanced computer-aided design (CAD) and precision manufacturing technologies ensures that these devices meet the high standards of accuracy and reliability required to deliver effective patient care.

Machining and manufacturing in the realm of sheet metal fabrication are critical processes employed across various industries such as automotive, aerospace, construction, and consumer electronics. In these applications, the precision and efficiency of machining methods like laser cutting, CNC punching, and press braking play a pivotal role in transforming flat sheet metals into complex, high-performance parts. Laser cutting, for instance, ensures high accuracy and minimal waste by utilizing focused light beams to melt and vaporize metal along precise paths. CNC punching, on the other hand, leverages computer-controlled systems to punch holes and create shapes with consistent accuracy and speed, while press braking molds sheet metal into specific angles and bends through a series of mechanical presses. These machining techniques enable manufacturers to meet stringent tolerances and intricate design specifications, culminating in products that uphold high quality and durability standards.

Beyond individual components, sheet metal fabrication is instrumental in the production of assembled structures and enclosures that require rigorous conformity to design and functionality requirements. Techniques such as welding, riveting, and fastening are commonly used to join multiple sheet metal parts, ensuring structural integrity and longevity of the final product. This is particularly relevant in the creation of metal housings for electronic devices, where precise fabrication prevents component misalignment and contributes to overall device reliability. Additionally, advancements in automation and robotics have further optimized these processes, reducing production times and associated costs while enhancing safety and repeatability. Consequently, the integration of sophisticated machining and manufacturing approaches within sheet metal fabrication continues to drive innovation and efficiency across diverse industrial applications, underscoring its significance in modern manufacturing landscapes.

Sure, here are some frequently asked questions (FAQ) and their answers, related to the manufacturing and fabrication of sheet metal quality work from SourcifyChina factory:

Q1: What materials can SourcifyChina work with for sheet metal fabrication?

A1: SourcifyChina can work with a variety of materials including stainless steel, aluminum, copper, brass, and various grades of steel to meet the specific requirements of your project.

Q2: What are the typical turnaround times for sheet metal fabrication orders?

A2: Turnaround times can vary depending on the complexity and size of the order. Generally, standard projects can take between 2-6 weeks. Custom, intricate jobs may require additional time.

Q3: Can SourcifyChina handle custom design and prototype projects?

A3: Yes, SourcifyChina specializes in custom design work and prototyping. Our skilled engineers can assist with design modifications and improvements to ensure your product meets the highest quality standards.

Q4: What quality control measures are in place at SourcifyChina?

A4: SourcifyChina utilizes rigorous quality control processes including material verification, dimensional inspections, welding inspections, and surface finish checks to ensure all products meet client specifications and industry standards.

Q5: Do you offer finishing services for sheet metal products?

A5: Yes, we provide a range of finishing services such as powder coating, anodizing, electroplating, and painting to enhance the appearance and durability of the products.

Q6: What are the payment terms for orders placed with SourcifyChina?

A6: Our standard payment terms typically require a 30% deposit upon order placement and the remaining balance upon completion prior to shipment. Custom terms can be discussed for large or recurring orders.

Q7: How can I request a quote for my sheet metal fabrication project?

A7: To request a quote, you can visit our website and fill out the quote request form with your project details, or contact our sales team directly via email or phone.

Q8: What industries does SourcifyChina serve?

A8: SourcifyChina serves a wide range of industries including automotive, aerospace, electronics, construction, and medical sectors, providing tailor-made solutions to meet diverse industrial needs.

Q9: Do you provide international shipping for manufactured products?

A9: Yes, SourcifyChina offers international shipping services. We work with reliable logistics partners to ensure timely and safe delivery of products worldwide.

When considering the fabrication of sheet metal manufacturing from SourcifyChina factory, several tips can help ensure a successful partnership and high-quality outcomes.

1. Understand Specifications: Clearly define and communicate your technical requirements, including dimensions, materials, tolerances, and finishes. Providing detailed CAD drawings can minimize misunderstandings.

2. Material Selection: Consult with SourcifyChina about the most suitable materials for your project, considering factors such as durability, cost, and ease of fabrication.

3. Prototyping: Start with a small-scale prototype to test the design and materials. This can help identify potential issues early in the process and reduce costly mistakes in large-scale production.

4. Quality Control: Ensure SourcifyChina has robust quality control measures in place. Regular inspections and adherence to ISO standards can significantly impact the final product’s quality.

5. Lead Time and Flexibility: Discuss realistic lead times and be prepared for slight variances. Flexibility in your production schedule can accommodate unforeseen delays and ensure timely delivery.

6. Cost Transparency: Request a detailed breakdown of costs, including material, labor, processing, and shipping. Transparency helps prevent unexpected expenses and facilitates budget management.

7. Communication: Maintain clear and consistent communication with the manufacturing team at SourcifyChina. Regular updates and direct contact can solve issues quickly and ensure alignment with your project goals.

8. Shipping and Compliance: Discuss shipping options and ensure compliance with international trade regulations and standards. Properly labeled and documented shipments avoid delays at customs.

9. Cultural Awareness: Understanding and respecting cultural differences can foster a better working relationship and smoother negotiations.

By following these tips, you can optimize the fabrication process of sheet metal manufacturing with SourcifyChina, ensuring high-quality products and a successful collaboration.

Q1: What types of sheet metal fabrication services does SourcifyChina factory offer?

A1: SourcifyChina factory provides a wide range of sheet metal fabrication services including cutting, bending, welding, punching, laser cutting, stamping, and assembly. We handle various metals such as steel, aluminum, and stainless steel to suit different project requirements.

Q2: Can I get custom sheet metal fabrication from SourcifyChina factory?

A2: Yes, SourcifyChina factory specializes in custom sheet metal fabrication. You can provide your specifications, drawings, or prototypes, and we will create custom parts tailored to your needs.

Q3: What is the minimum order quantity (MOQ) for sheet metal fabrication at SourcifyChina?

A3: The MOQ for sheet metal fabrication varies depending on the complexity and requirements of the project. Please contact us with your project details for a specific MOQ.

Q4: What lead times can I expect for my sheet metal fabrication order?

A4: Lead times vary based on the project’s specifications and volume. Generally, it ranges from 2 to 6 weeks. For exact lead times, please discuss your project with our team.

Q5: Does SourcifyChina offer prototyping services for sheet metal parts?

A5: Yes, we offer prototyping services to help you test and refine your designs before full-scale production. This ensures the final product meets your expectations.

Q6: What quality control measures are in place at SourcifyChina factory?

A6: SourcifyChina factory adheres to stringent quality control processes including inspections at every stage of production, material verification, and final product testing to ensure high-quality output.

Q7: How can I get a quote for my sheet metal fabrication project from SourcifyChina?

A7: To request a quote, simply send us your detailed project specifications including drawings, material requirements, and quantity. Our team will review and provide you with a competitive quote promptly.

Q8: What materials can SourcifyChina work with for sheet metal fabrication?

A8: SourcifyChina works with a variety of materials including mild steel, stainless steel, aluminum, galvanized steel, and more, to meet diverse project requirements.

Q9: Can SourcifyChina handle large-scale production runs?

A9: Yes, SourcifyChina is equipped to manage both small and large-scale production runs efficiently, ensuring consistent quality and timely delivery.

Sure, sourcing sheet metal fabrication from SourcifyChina factory can be efficient and cost-effective if approached correctly. Here are some tips:

1. Research and Vetting:

Conduct thorough research on SourcifyChina’s credibility. Check reviews, ask for references, and verify certifications like ISO 9001.

2. Detailed Specifications:

Provide precise specifications for your sheet metal requirements—material type, thickness, dimensions, and tolerances. Clear details reduce errors and ensure accurate quotes.

3. Sample Request:

Request samples to assess the quality of fabrication and adherence to your specifications. This step helps in judging production capabilities and quality control.

4. Communication:

Maintain clear and consistent communication. Utilize video calls, emails, and messaging platforms to ensure your requirements are well understood.

5. Pricing and Quotes:

Obtain detailed quotations that break down costs—including materials, labor, shipping, and any additional charges. This transparency helps in budget management and comparison with other suppliers.

6. Production Timeline:

Discuss and agree on realistic production timelines. Ensure the factory can meet your deadlines to avoid disruptions in your supply chain.

7. Quality Assurance:

Confirm the factory’s quality control processes. Request regular quality checks and reports during the production phase.

8. Contracts and Agreements:

Draft clear contracts outlining terms of service, payment schedules, delivery timelines, and quality standards. Legal safeguards help in resolving disputes amicably.

9. Shipping Logistics:

Plan the logistics of shipping. Weigh the options between air and sea and consider customs regulations and duties to prevent delays and added costs.

10. Building Relationships:

Establish a strong working relationship with the factory. Good rapport and trust can lead to better service, preferred terms, and smoother transactions in future orders.

By following these steps, you can ensure a successful partnership with SourcifyChina for your sheet metal fabrication needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.