Reliable

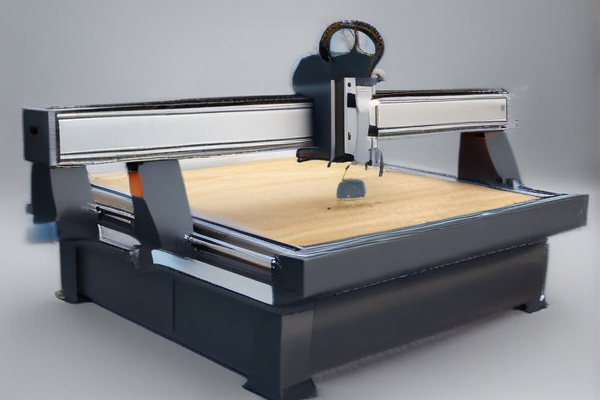

Source: SourcifyChina Factory CNC Router for Wood – High-Quality Precision and Durability

Choosing SourcifyChina Factory for purchasing a CNC router for wood from China ensures high quality and reliable equipment. They maintain strict quality control, ensuring precise and durable CNC routers that meet international standards.

With vast experience in the industry, SourcifyChina Factory offers professional guidance to help you select the most suitable CNC router for your woodwork needs, ensuring optimal performance and efficiency.

Their competitive pricing and excellent after-sales service make SourcifyChina Factory a cost-effective choice for buyers. They provide comprehensive support, ensuring smooth operation and longevity of the CNC routers purchased.

SourcifyChina Factory also offers timely delivery, ensuring that your CNC router for wood reaches you quickly and safely. They have efficient logistics partners committed to prompt and secure shipping.

Additionally, their customer-centric approach guarantees that all your queries and concerns are promptly addressed. SourcifyChina Factory values customer satisfaction and strives to build long-term relationships with their clients through exceptional service.

In conclusion, SourcifyChina Factory stands out for its commitment to quality, affordability, and customer service, making it an ideal choice for buyers seeking CNC routers for wood from China. Their comprehensive support and timely delivery further enhance the purchasing experience.

CNC routers for wood are versatile machines that come in various types and configurations suited for different tasks. Depending on your needs, you can select from desktop models to industrial-scale systems.

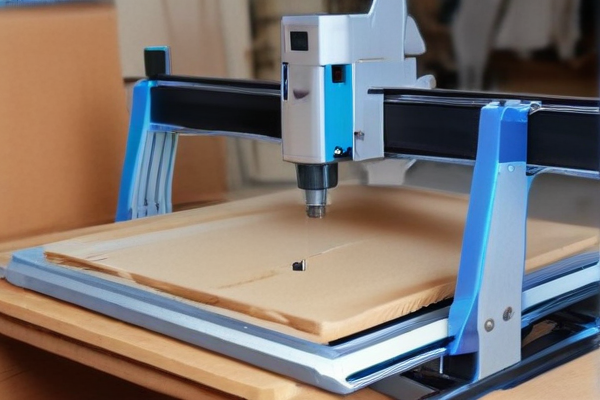

– Desktop CNC Routers: Compact and affordable, ideal for hobbyists and small businesses.

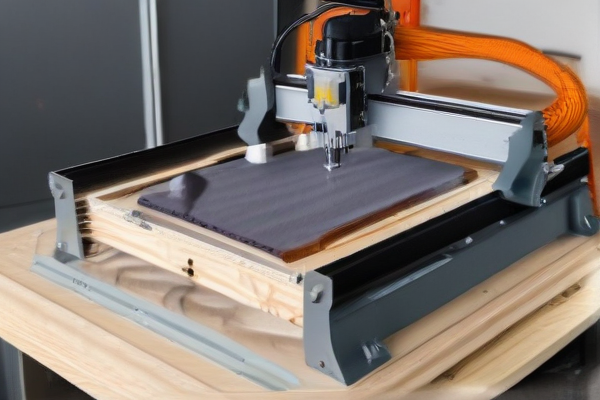

– Benchtop CNC Routers: Slightly larger than desktop models, offers more power and precision.

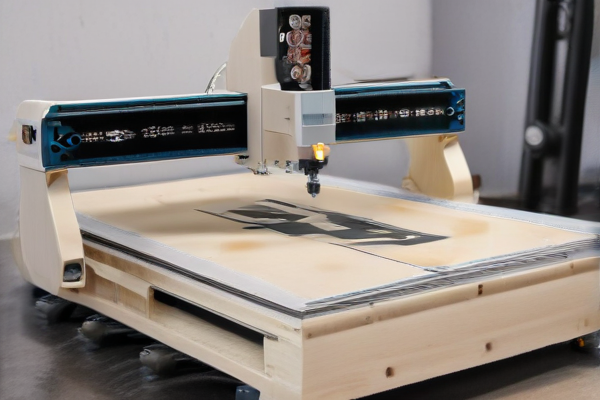

– Industrial CNC Routers: Designed for heavy-duty use, suitable for large-scale production and detailed work.

– 3-Axis Machines: Standard option, can move in X, Y, and Z axes for general woodcutting tasks.

– 4-Axis Machines: Adds rotational movement, allows for more complex designs and sculptures.

– 5-Axis Machines: Offers the highest level of precision and flexibility, capable of intricate cuts and complex geometries.

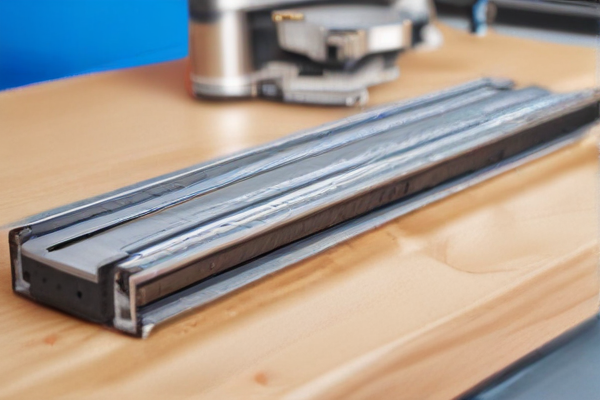

– Vacuum Hold-Down Systems: Ensures the workpiece is securely held in place during operations.

– Tool Changers: Automatic tool changers increase efficiency by swapping tools without manual intervention.

– Dust Collection Systems: Essential for maintaining a clean work environment and prolonging machine life.

– Software Compatibility: Ensure the CNC router is compatible with popular CAD and CAM software for ease of use.

– Spindle Options: Variable speed spindles can handle various materials and thicknesses.

– Budget Considerations: Price ranges from a few hundred dollars for basic models to tens of thousands for industrial machines.

– User Experience Level: Choose a machine that matches your skill set – simpler models for beginners, advanced units for experienced users.

– Customer Support: Reliable customer support and training resources are important for troubleshooting and maximizing productivity.

By carefully selecting the right type and features, you can enhance your woodworking projects, improve efficiency, and achieve high-quality results.

A CNC router for wood is a versatile tool widely used in woodworking shops for its precision and efficiency in cutting, carving, and shaping wood. It automates the woodworking process, enhancing productivity and creativity.

Some applications include:

– Furniture Manufacturing: Creating precise cuts for tables, chairs, and cabinetry.

– Custom Woodworking: Producing intricate designs for custom pieces.

– Sign Making: Crafting detailed and complex signages.

– Artistic Carving: Generating detailed engravings and sculptures.

– Architectural Millwork: Designing decorative moldings, trims, and panels.

– Prototyping: Making accurate models for design validation.

– Musical Instruments: Shaping precise components for guitars, violins, and other instruments.

– Inlay Work: Cutting pieces for detailed inlay projects.

– Panel Processing: Efficiently cutting and engraving wood panels.

– Educational Projects: Assisting in educational and creative endeavors for schools and workshops.

The SourcifyChina CNC router for wood excels for its superior construction materials, ensuring longevity and reliability. Its framework is typically composed of high-grade aluminum, which offers excellent durability while being lightweight. This combination enhances the router’s performance and ease of maneuverability.

The cutting bed is often made from durable, wear-resistant phenolic materials. This offers a stable, flat surface that withstands extensive use, minimizing the risk of warping. Such robustness ensures consistent high-quality cuts over time, which is essential for professional woodworking projects.

The spindle motor is an essential component crafted from high-strength steel, known for its ability to handle rigorous tasks without degradation. This material choice contributes to the motor’s longevity and consistent performance, even under continuous usage. High-precision ball screws and linear guides are also likely manufactured from hardened steel, ensuring the accuracy and smooth operation of the CNC router.

In summary, the SourcifyChina CNC router features a blend of high-quality aluminum, durable phenolic materials, and tough steel components. These materials collectively provide a stable, precise, and enduring tool for both hobbyists and professionals in woodworking. This meticulous material selection results in a CNC router that is highly reliable and optimized for superior performance in a variety of woodworking tasks.

The quality control manufacturing process at SourcifyChina for CNC routers for wood begins with the selection of premium raw materials, ensuring durability and precision in each machine. Rigorous supplier audits guarantee that only the best components are used.

The engineering team at SourcifyChina meticulously designs each CNC router, implementing advanced software to verify structural integrity and functionality. Each prototype undergoes comprehensive testing to identify and rectify any potential issues before mass production.

During assembly, each unit is carefully constructed by skilled technicians who follow strict procedural guidelines. These professionals conduct inline inspections to ensure that each part meets the required specifications and tolerances.

Finished CNC routers undergo an extensive series of quality control tests, including precision checks, operational tests, and endurance trials. This multiphase testing ensures that each machine performs optimally under real-world conditions.

Finally, a detailed quality assurance report is generated for each CNC router, documenting all inspections, tests, and verifications. This report serves as a comprehensive record that guarantees the machine’s reliability and performance, providing customers with a high-quality product they can trust.

SourcifyChina CNC router for wood is renowned for its precision and versatility. It caters to a wide range of woodworking demands, offering intricate detailing and smooth finishes.

Boasting high-speed spindles, SourcifyChina CNC routers can cut through various types of wood effortlessly. This ensures efficient production without sacrificing quality or detail.

Equipped with advanced software, these routers allow seamless design integration. Users can easily convert design files into precise wood carvings, enhancing both creativity and productivity.

With robust build quality and consistent performance, SourcifyChina CNC routers stand out for their durability. They are designed to withstand the rigors of constant use in industrial settings.

Safety features are a key aspect. Automatic shutoff mechanisms and user-friendly interfaces ensure that operators work in a secure environment, minimizing the risk of accidents.

Customer support from SourcifyChina is exemplary. They offer comprehensive training and troubleshooting assistance, ensuring that users can maximize the potential of their CNC routers.

In conclusion, the SourcifyChina CNC router for wood is a powerful and reliable tool. Its precision, speed, and user-friendly design make it an excellent choice for both hobbyists and professionals in woodworking.

A CNC router for wood offers unparalleled precision and efficiency in woodworking projects, making it an invaluable asset for both professionals and hobbyists.

– Precision: Achieves consistent, high-quality cuts with intricate detail.

– Efficiency: Speeds up production, reducing manpower and time.

– Versatility: Capable of handling complex designs and a variety of wood types.

– Repeatability: Ensures uniformity across multiple pieces, ideal for mass production.

– Automation: Minimizes human error, offering reliable and consistent results.

– Customization: Easily adapts to custom projects with detailed programming.

– Cost-Effectiveness: Reduces waste through precise material usage.

– Safety: Lowers the risk of accidents by automating cutting processes.

– Skill Accessibility: Allows users with varying skill levels to produce professional-quality work.

– Speed: Completes tasks faster than manual methods, enhancing productivity.

– Integration: Compatible with various software for design and automation, streamlining workflow.

– Reduced Waste: Optimizes material use, making projects more sustainable and cost-efficient.

In combining these benefits, a CNC router transforms traditional woodworking into a more streamlined, precise, and scalable craft.

A CNC router for wood is a highly versatile machine designed to cut, carve, and shape wood with computer-controlled precision. Here are some key features:

– Precision and Accuracy: Provides exact cuts, intricate designs, and replicates patterns consistently.

– Automation: Allows for unattended operation and increases productivity by reducing manual labor.

– Versatility: Capable of handling various materials like hardwood, softwood, plywood, and MDF.

– Ease of Use: Often includes user-friendly interfaces and software for design and execution.

– High Speed: Operates at higher speeds than manual tools, expediting project completion.

– Durability: Built with high-quality components to withstand continuous operation.

– Dust Collection: Integrated systems to manage wood dust and debris, maintaining a clean work environment.

– Customizability: Offers the ability to customize settings according to specific project requirements.

– Multi-axis Capability: Some models feature 4 or 5-axis movements for more intricate and complex designs.

– Safety Features: Includes emergency stop buttons and protective guards to ensure operator safety.

– Software Integration: Compatible with various CAD/CAM software to streamline the design-to-production process.

These features make CNC routers an invaluable tool in modern woodworking, enhancing both the quality and efficiency of production.

SourcifyChina offers a diverse range of CNC routers for woodwork, catering to custom products and projects with precision and reliability. These machines are designed to handle intricate patterns, ensuring high-quality finishes.

Their advanced CNC routers are equipped with the latest technology, providing accurate cuts and consistent results. This makes it easier for businesses and hobbyists to create detailed wood products efficiently and effectively.

Custom projects are a breeze with SourcifyChina’s CNC routers, which support various wood types and project scales. From furniture to decorative items, these routers allow for extraordinary customization and creativity.

With a focus on customer satisfaction, SourcifyChina ensures that each CNC router meets rigorous standards. This commitment to quality means that users can rely on their machines for long-term use without compromising performance.

In addition, SourcifyChina provides excellent customer support and after-sales service, ensuring that clients have all the assistance they need for optimal CNC router operation. This dedication to service further cements their reputation as a leader in the woodwork industry.

Whether you are a large-scale manufacturer or a small business, SourcifyChina’s CNC routers offer the versatility and dependability required for diverse woodworking projects. Their products enable the production of unique, high-quality wood items with ease.

Overall, SourcifyChina’s CNC routers for wood stand out for their precision, reliability, and support, making them an ideal choice for anyone looking to undertake custom woodworking projects. From the initial design to the final product, these machines deliver exceptional results every time.

SourcifyChina is a leading name in the CNC router market, specializing in high-precision machinery specifically tailored for wood applications. Renowned for integrating cutting-edge technology with robust construction, the company’s CNC routers stand out for their efficiency, reliability, and superior performance. Catering to both small workshops and large-scale production facilities, SourcifyChina offers a wide range of models that meet diverse industry needs, from intricate carvings and detailed engravings to large-format cutting and shaping. The company places a strong emphasis on customer service, offering comprehensive technical support and training to ensure users can maximize the capabilities of their machinery. With a commitment to innovation and quality, SourcifyChina has established itself as a trusted partner in the woodworking industry, continually pushing the boundaries of what’s possible with CNC technology.

CNC routers, traditionally known for their use in woodworking, have found versatile applications in fields as demanding as Aerospace, Defense, and Marine. In aerospace, the precision and flexibility of CNC routers allow for the crafting of complex, lightweight structures essential for aircraft interiors and non-critical components. With the ability to utilize a variety of materials such as composites and advanced polymers, CNC routers contribute significantly to reducing the weight and improving the performance of aerospace parts. Furthermore, the meticulous detailing offered by CNC routing ensures that parts meet the stringent safety and performance standards critical to the aerospace industry.

In the realms of Defense and Marine applications, CNC routers for wood are instrumental in producing durable and precise components. For defense, these routers can manufacture sophisticated wooden molds for composite materials used in armor and vehicles, ensuring resilience and integrity under harsh conditions. Meanwhile, in the marine industry, CNC routers facilitate the creation of detailed molds for boat hulls and precise wooden patterns for various fittings. These routers also enable the efficient production of ergonomic and customized wooden fixtures and interiors that enhance both the functionality and aesthetics of marine vessels. The accuracy and repeatability of CNC routing technology ensure that all components align perfectly, significantly enhancing the overall performance and reliability of defense and marine applications.

A CNC router for wood, traditionally associated with carpentry and furniture-making, has found remarkable applications in the automotive industry. Automotive interiors, for instance, extensively utilize wooden components for a touch of elegance and sophistication. CNC routers for wood enable precise and intricate carvings on dashboards, door trims, and center consoles, thereby enhancing the aesthetic appeal of automobiles. The accuracy and repeatability of CNC routers facilitate the production of complex designs that would be challenging to achieve with manual tools. Furthermore, the technology accelerates the prototyping process, allowing automakers to swiftly iterate and refine components during the design phase. This efficiency not only reduces production time but also ensures high-quality finishes essential for luxury automotive markets.

In the realm of electronics, CNC routers for wood play a pivotal role in crafting custom enclosures and casings. With the burgeoning trend of bespoke and DIY electronics, enthusiasts and small businesses alike leverage CNC routers to produce tailor-made wooden cases for devices such as speakers, amplifiers, and computer peripherals. The capability to cut precise apertures and engrave detailed patterns opens up new avenues for product personalization and branding. Additionally, the thermal insulating properties of wood make it an attractive material for certain electronic applications, ensuring both aesthetic appeal and functional performance. As electronics continuously evolve towards more compact and visually appealing designs, the utility of CNC routers for wood is poised to grow, melding craftsmanship with cutting-edge technology in unique and innovative ways.

CNC routers for wood have significantly transformed the construction industry, offering precision and efficiency that manual tools simply cannot match. In construction, particularly in the creation of intricate wood components such as staircases, cabinetry, and decorative elements, CNC routers prove indispensable. These machines enable architects and builders to convert digital designs into physical realities with pinpoint accuracy, ensuring each cut and contour meets exact specifications. This not only reduces material waste but also speeds up the production process, allowing for quicker project turnaround times. Moreover, the repetitive precision of CNC routers minimizes human error, ensuring consistency across multiple components, which is vital for large-scale construction projects.

In the realm of energy applications, CNC routers for wood are equally transformative, especially in the production of wooden components for renewable energy infrastructures. For instance, wooden blades for small wind turbines and frames for solar panel arrays can be meticulously crafted using CNC technology, which ensures both durability and optimal performance. The precision of CNC routers allows for the creation of complex geometries and fine-tuned designs that maximize the efficiency of energy capture and conversion systems. Additionally, using wood as a primary material is a sustainable option, aligning with the ethos of renewable energy. CNC routers thus not only advance the capabilities of energy technology but also promote environmentally responsible manufacturing processes.

The industrial equipment industry has seen significant advancements with the integration of CNC routers for woodworking applications. These computer-controlled machines are designed to automate the cutting, shaping, and carving processes typically associated with wood manufacturing, bringing unprecedented precision and efficiency to the craft. With CNC routers, companies can produce intricate designs, detailed carvings, and complex joinery with minimal human intervention. This not only reduces the margin for error but also slashes production time, enabling businesses to meet high demand without compromising on quality. Additionally, CNC routers are particularly beneficial for large-scale production environments, where consistency and repeatability are critical. They allow manufacturers to replicate exact designs across multiple pieces effortlessly, thereby ensuring uniformity and professional finish in every unit produced.

Moreover, the versatility of CNC routers extends beyond mere cutting to a wide array of woodworking applications, such as engraving, milling, and even 3D modeling. This multifunctionality has paved the way for innovation in custom furniture design, cabinetry, and architectural elements, among other products. Small businesses and artisanal woodworkers are also reaping the benefits of CNC routers by enhancing their ability to offer customized, intricate designs that were once considered too time-consuming or complex. Furthermore, the digitization of woodworking through CNC technologies has contributed to significant material savings and reduced waste, as the precision cuts minimize the scrap wood generated. This, in turn, translates into cost savings and more sustainable manufacturing practices, aligning with growing environmental stewardship in industrial operations. In essence, CNC routers have revolutionized the woodworking sector within the industrial equipment industry, combining advanced technology with traditional craftsmanship to drive innovation and efficiency.

While CNC routers are traditionally associated with woodworking, they have found significant applications in the medical device industry, particularly in the creation of custom parts and prototypes. One primary use is in the fabrication of ergonomic and precisely-fitted orthotic and prosthetic devices. Using advanced computer-aided design (CAD) software, medical professionals can create detailed 3D models of an individual’s specific limb or body part. These models are then used to cut and shape materials like medical-grade plastics and lightweight metals with extreme precision, thanks to the CNC router’s capabilities. This method ensures a perfect fit, leading to improved patient comfort and efficacy of the device. Additionally, the customization process is swift, ensuring that patients receive their tailored medical devices more quickly compared to traditional fabrication methods.

Moreover, CNC routers are vital in producing specialized surgical instruments and components of diagnostic equipment. As medical technology advances, the demand for tools and devices with intricate designs and exceptional accuracy has grown. CNC routers are adept at creating small, complex parts that meet stringent medical standards. They are used to construct components for devices such as endoscopic tools, implantable devices, and precision diagnostic instruments. The precise manufacturing process ensures that even the smallest parts are free of defects, which is crucial in a field where even minor inaccuracies can have serious consequences. By utilizing CNC router technology, the medical device industry can produce highly complex and reliable tools that contribute to better patient outcomes and more effective healthcare solutions.

CNC routers are quintessential in the realm of woodworking, providing unparalleled precision, efficiency, and versatility. These computer-controlled machines can execute complex cuts, engravings, and carvings that would be labor-intensive or even impossible to achieve manually. In manufacturing applications, CNC routers for wood streamline production processes by automating repetitive tasks such as cutting intricate patterns and shapes, enhancing both the speed and consistency of outputs. The machine’s ability to handle a variety of wood types—from soft woods like pine to hard woods like oak—allows manufacturers to produce diverse products ranging from custom furniture to cabinetry and decorative items. A key advantage is the reduction in material waste due to the accuracy of cuts, which ultimately translates to cost savings.

In the context of machining, CNC routers for wood bridge the gap between design and finished product. By using CAD (Computer-Aided Design) software, machinists can design intricate parts and then seamlessly transfer these designs to the router, which precisely executes the cuts. This level of integration simplifies the production process, reducing the need for multiple intermediate steps and minimizing human error. Additionally, the adaptability of CNC routers allows for rapid prototyping, enabling quicker turnaround times for product development and testing. Beyond the woodworking industry, these routers are also employed in education for training purposes and in small businesses where bespoke woodworking projects are crafted, showcasing their broad applicability and transformative potential in both mass production and artisanal craftsmanship.

What materials can the CNC router from SourcifyChina factory handle?

The CNC routers from SourcifyChina factory are specifically designed for wood but are also capable of handling other materials such as MDF, acrylic, and some soft metals. However, optimal performance is achieved with wood.

What is the maximum processing size of the CNC router?

The maximum processing size varies by model, but common ranges include 1300mm x 2500mm or larger. For specific dimensions, please consult the product specifications.

How precise is the CNC router for detailed woodworking projects?

Our CNC routers feature high precision and accuracy, typically within a tolerance of ±0.05mm. This ensures detailed and meticulous work, suitable for intricate woodworking projects.

What software is compatible with the CNC router from SourcifyChina?

The CNC routers are compatible with popular CAD/CAM software such as Vectric Aspire, AutoCAD, and ArtCAM. The machines come with basic software pre-installed for immediate use.

Is technical support available after purchasing a CNC router from SourcifyChina?

Yes, SourcifyChina offers comprehensive technical support including installation assistance, troubleshooting, and maintenance guidelines. Our support team is available via email and phone.

How energy-efficient are the CNC routers?

Our CNC routers are designed to be energy-efficient, typically consuming between 3 to 7 kilowatts per hour depending on the model and usage. This ensures minimal energy waste and cost savings over time.

What safety measures are included with the CNC router?

Safety is a priority; our CNC routers include emergency stop buttons, protective covers, and safety sensors to prevent accidents and ensure a safe working environment.

Can the CNC router be customized according to specific needs?

Yes, SourcifyChina offers customization options to meet specific requirements, including size modifications, additional features, and special software configurations. Contact us to discuss your customization needs.

When considering a CNC router for wood manufacturing from SourcifyChina factory, here are some crucial tips to ensure you get the best machine for your needs:

1. Specifications: Ensure the CNC router has the right specifications for your projects. Key parameters include spindle power, table size, and machine precision. Higher spindle power and larger table sizes are beneficial for more extensive and intricate woodworking tasks.

2. Material Compatibility: Verify the router’s compatibility with different types of wood. It should efficiently handle hardwoods, softwoods, and composite materials.

3. Software Compatibility: CNC routers rely on software for design and operation. Ensure the machine is compatible with standard CAD/CAM software and supports file formats like DXF, STL, or G-code.

4. Machine Durability: Look for a robust build quality with durable materials, as this affects the longevity and performance of the router. Quality brands often use high-grade aluminum or steel for the machine frames.

5. Precision and Tolerances: Pay attention to the precision levels and tolerances the machine can achieve, critical for detailed and high-quality woodworking.

6. Customer Support: SourcifyChina’s after-sales support is crucial. They should provide adequate setup, troubleshooting, and maintenance services. Positive reviews and testimonials about their support are a good indicator.

7. Cost vs. Value: Compare the cost with the value the machine offers. Sometimes, a higher initial investment in a quality machine saves more in the long run due to better performance and fewer repairs.

8. Training and Safety: Consider what training materials or sessions SourcifyChina provides. Proper training enhances safety and efficiency.

9. Lead Time and Shipping: Be clear on the delivery lead time and shipping logistics. Understanding these factors helps you plan better and avoid unnecessary delays in your production schedule.

By focusing on these aspects, you can make an informed decision and maximize the benefits of your CNC router investment from SourcifyChina.

Sure! Here are some frequently asked questions (FAQ) for sourcing a CNC router for wood from SourcifyChina factory:

Q: What types of CNC routers for wood does SourcifyChina offer?

A: SourcifyChina provides a range of CNC routers for woodworking, including 3-axis, 4-axis, and 5-axis routers. They offer various models catering to different levels of production requirements, from small-scale hobbyists to large-scale industrial applications.

Q: How can I place an order for a CNC router at SourcifyChina?

A: You can place an order by contacting their sales team through their official website, email, or phone. They will guide you through the selection process, provide quotations, and finalize the purchase.

Q: What is the lead time for delivery?

A: The lead time varies depending on the model and specifications of the CNC router. Typically, it ranges from 20 to 45 days after the order is confirmed. It’s best to confirm specific lead times with their sales representatives.

Q: What payment methods are accepted?

A: SourcifyChina accepts various payment methods, including T/T (telegraphic transfer), L/C (letter of credit), and PayPal. Detailed payment terms can be discussed with their sales team.

Q: Is there a warranty for the CNC routers?

A: Yes, SourcifyChina offers a warranty period for their CNC routers, which usually ranges from 1 to 2 years. The warranty covers manufacturing defects and component failures under normal operating conditions.

Q: Do they provide after-sales support?

A: SourcifyChina offers comprehensive after-sales support, including technical assistance, troubleshooting, and spare parts supply. They also provide remote assistance and on-site training if needed.

Q: Can CNC routers be customized according to specific requirements?

A: Yes, SourcifyChina can customize CNC routers to meet specific customer requirements, including size, power, and additional features. Customization requests can be discussed during the inquiry phase.

Q: How is the quality of CNC routers ensured?

A: SourcifyChina adheres to strict quality control measures throughout the manufacturing process. They use high-quality materials and components and conduct multiple testing phases to ensure product reliability and performance.

Q: Are there any certifications for the CNC routers?

Sourcing a CNC router for wood from a factory like SourcifyChina can be a straightforward process if you follow these tips:

1. Research and Identify Needs: Determine the specific requirements for your CNC router, such as size, power, and features. This helps in communicating your needs clearly.

2. Verify the Supplier: Check SourcifyChina’s credentials, including business licenses and certifications. Look for reviews or references from previous customers.

3. Request Detailed Quotes: Contact SourcifyChina for detailed quotes, including product specifications, pricing, lead times, and minimum order quantities.

4. Evaluate Quality: Request product samples if possible. Ask about the materials used and the quality control processes in place.

5. Communicate Clearly: Keep your communication clear and concise. Ask specific questions and ensure that both parties understand the requirements and terms.

6. Negotiate Smartly: Don’t just focus on price; consider terms of warranty, service, and after-sales support. Discuss shipping options and costs.

7. Check Compliance: Ensure the products meet relevant safety and compliance standards for your country.

8. Payment Terms: Discuss and agree on favorable payment terms. Consider using secure payment methods like letters of credit or escrow to protect your investment.

9. Logistics and Shipping: Clarify the logistics details. Determine whether SourcifyChina handles shipping or if you need to arrange this.

10. Start Small: If possible, start with a smaller order to verify the product quality and reliability before scaling up.

11. Build Relationships: Cultivate a good relationship with the supplier for better service and potential discounts in the future.

Following these tips will help ensure a smooth sourcing process and a better chance of obtaining a high-quality CNC router for your woodworking needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.