When choosing SourcifyChina Factory for purchasing laser-cut steel from China, you are assured of exceptional quality standards. Their state-of-the-art technology ensures precision and durability in every cut, meeting international quality benchmarks.

SourcifyChina’s competitive pricing offers significant cost savings without compromising on quality. The factory leverages economies of scale and efficient production processes to provide affordable rates, making it a great choice for bulk orders.

Remarkable customer service sets SourcifyChina apart. Their dedicated team offers seamless communication, quick responses, and tailored solutions to meet buyers’ specific requirements, ensuring a smooth and satisfactory experience.

On-time delivery is a hallmark of SourcifyChina. They prioritize stringent timelines and effective logistics management, ensuring that your orders reach you as promised, without delays.

Moreover, SourcifyChina places a high emphasis on sustainability. They follow eco-friendly practices in their manufacturing processes, aligning with global environmental standards, appealing to environmentally-conscious buyers.

In conclusion, choosing SourcifyChina Factory for your laser-cut steel needs ensures high-quality products, competitive pricing, reliable customer service, punctual deliveries, and environmentally-friendly practices. This makes them a trusted and efficient partner for sourcing laser-cut steel from China.

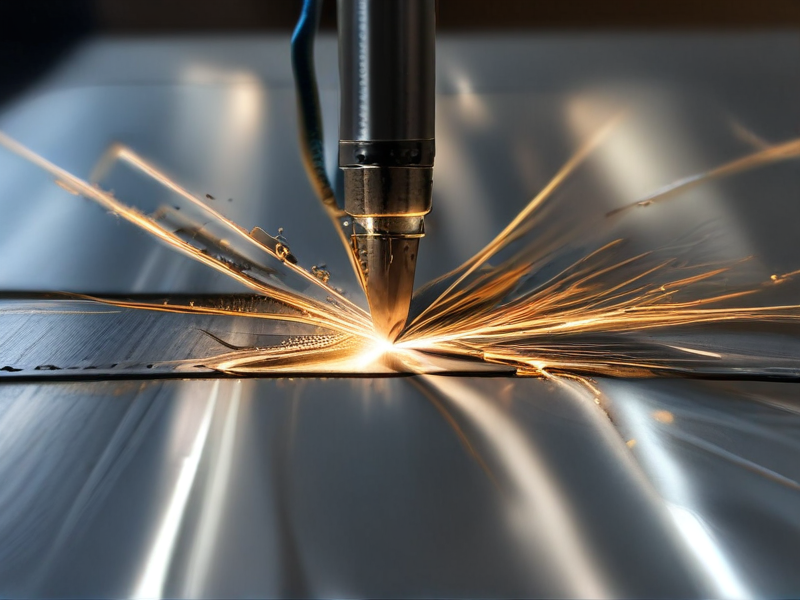

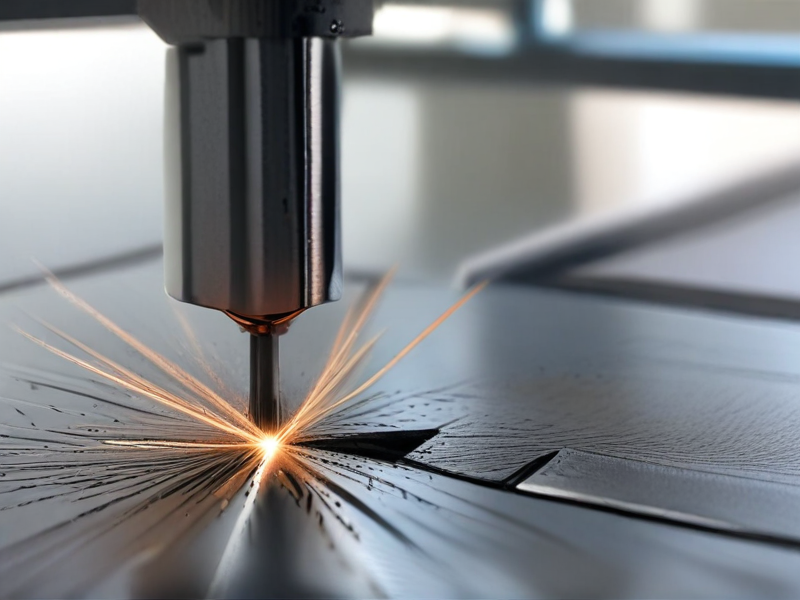

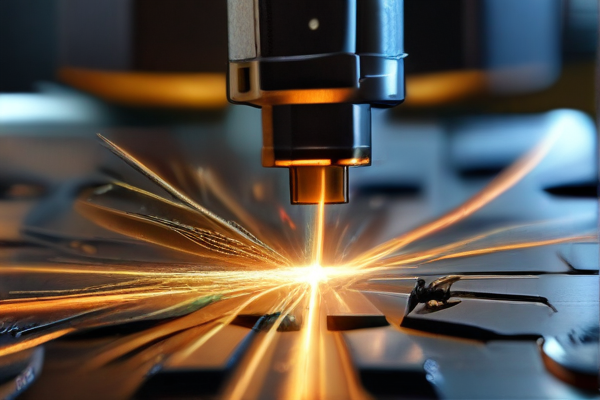

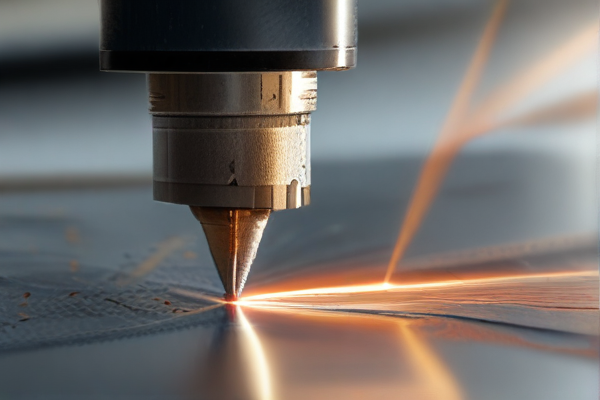

Laser cutting steel involves using a high-powered laser to slice through steel materials with precision. Different types and options cater to various industrial needs and thicknesses.

– CO2 Lasers: Efficient for cutting thicker steel.

– Fiber Lasers: Excellent for cutting thin steel with high speed and precision.

– Nd:YAG Lasers: Ideal for applications requiring high energy in a short burst.

– Laser Cutting Machines: Include CNC-controlled systems for automated precision.

– Assist Gases: Oxygen, nitrogen, and air are used to improve cutting quality and speed.

– Thickness Capability: Varies by laser type, from thin sheets to thick plates.

– Edge Quality: Can vary, with some lasers providing smoother finishes.

– Cutting Speed: Faster options available with fiber lasers.

– Cooling Systems: Required to handle heat during the cutting process.

– Software Integration: CAD/CAM software for design and accuracy.

– Maintenance Needs: Vary depending on the type of laser and usage.

– Safety Measures: Protective gear and proper ventilation are essential.

– Applications: Covers automotive, construction, aerospace, and art installations.

– Cost: Depending on laser and equipment, can range from affordable to high-end investments.

– Energy Efficiency: Fiber lasers typically offer better energy efficiency.

– Scalability: Suitable for both small-scale projects and large-scale industrial manufacturing.

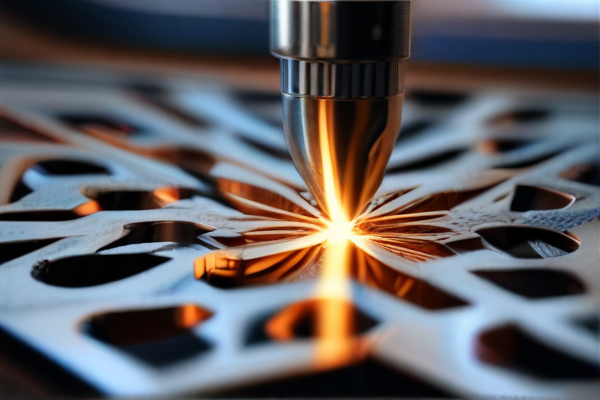

Laser cutting steel offers precision and efficiency, making it ideal for various applications across multiple industries. Its ability to produce clean cuts with intricate designs has revolutionized manufacturing processes.

– Automotive Industry: Produces precise parts for cars and trucks, including body panels, frames, and exhaust systems.

– Construction: Creates structural components, beams, and custom metal art for buildings.

– Aerospace: Manufactures high-precision aircraft parts, ensuring safety and performance standards.

– Medical Devices: Produces surgical instruments, implants, and other medical equipment with high accuracy.

– Manufacturing: Fabricates machine components, gears, and tooling equipment with minimal waste.

– Electronics: Cuts metal parts for electronic devices, ensuring consistency and exact specifications.

– Jewelry Making: Allows for the creation of intricate designs in metal jewelry with precision and speed.

– Signage Industry: Produces signs with detailed typography and logos, enhancing aesthetic appeal.

– Furniture Design: Crafts metal furniture pieces with complex patterns and forms.

– Prototyping: Enables rapid prototyping of metal parts, expediting the development process.

– Art and Sculpture: Facilitates the creation of metal artwork with fine detail and unique designs.

– Hardware Production: Manufactures components like hinges, brackets, and fasteners reliably and efficiently.

– Oil and Gas: Fabricates parts for pipelines, rigs, and other equipment used in harsh environments.

– Agriculture: Produces machinery parts, tools, and equipment used in farming and food production.

– Marine Industry: Makes parts for ships and boats, including hull components and fittings.

– Defense: Manufactures precision components for military applications, such as armor plating and weaponry.

– Renewable Energy: Constructs parts for wind turbines, solar panels, and other green energy systems.

– Railway Industry: Produces components for trains and rail infrastructure with high durability.

– Consumer Goods: Creates metal parts for household items and kitchen appliances.

– Tool and Die Making: Crafts molds and dies used in manufacturing processes with high precision.

These diverse applications highlight the versatility and indispensability of laser cutting in modern industry.

SourcifyChina utilizes high-quality steel for its laser cutting services, reflecting a commitment to durability and precision. The materials are rigorously selected to ensure optimal performance in various applications, ranging from industrial components to intricate decorative items.

The steel used in SourcifyChina’s laser cutting process is characterized by its excellent machinability and strength. This allows for precise and clean cuts, accommodating intricate designs without compromising structural integrity. Various grades of steel can be chosen based on the specific requirements of each project, enhancing versatility.

Additionally, the laser cutting process employed by SourcifyChina results in minimal distortion and high accuracy. This precision is vital for applications that demand stringent tolerances and impeccable edge quality. The end products exhibit smooth finishes and reduced need for secondary processing, saving time and costs.

SourcifyChina’s laser cutting services are environmentally friendly due to reduced waste and energy efficiency. The advanced technology minimizes material usage while providing superior results. Their professional team ensures compliance with international standards, reflecting their dedication to quality and customer satisfaction.

In summary, SourcifyChina’s expertise in laser cutting is complemented by their use of top-tier steel, leading to high-precision and durable results. Their environmentally-conscious approach and commitment to quality make them a reliable partner for diverse laser cutting needs.

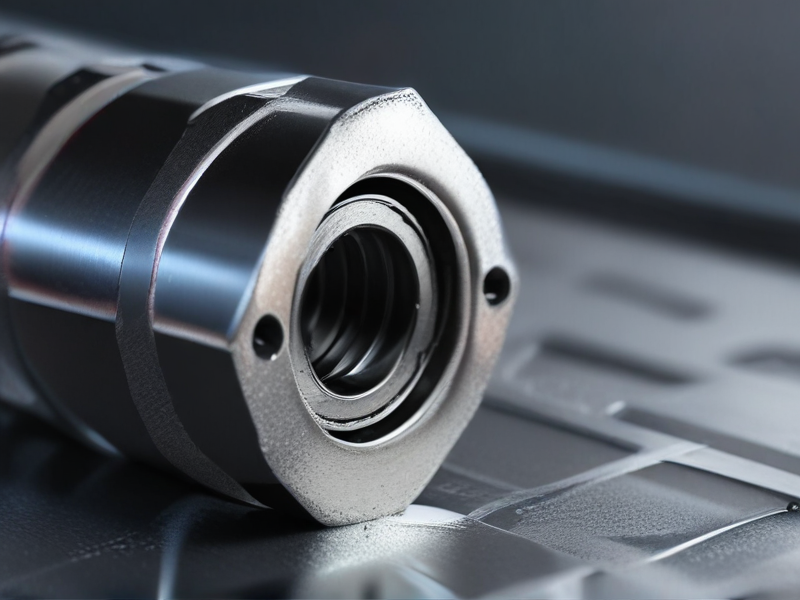

SourcifyChina is renowned for its meticulous quality control processes in laser cutting steel. They employ advanced technology to ensure precision in every cut, starting with rigorous material inspection. This step guarantees that only the highest quality steel is used, minimizing defects in the final product.

The company leverages state-of-the-art laser cutting machines, ensuring accuracy and consistency across large batches. These machines are regularly calibrated and maintained to uphold strict quality standards. The use of automation minimizes human error and enhances operational efficiency, allowing for complex designs to be executed flawlessly.

Once the cutting process is complete, each piece undergoes thorough inspection. Quality control experts check for dimensional accuracy, surface finish, and any potential defects. Any non-conforming pieces are promptly identified and rectified, ensuring that only the best products are delivered to customers.

Additionally, SourcifyChina implements statistical process control (SPC) to monitor and control the manufacturing process. This method helps in early detection of potential issues, maintaining a consistently high-quality output. Continuous training for employees ensures that everyone is up-to-date with best practices and quality control measures.

Finally, feedback from customers is actively sought and analyzed to make continuous improvements. This feedback loop ensures that SourcifyChina stays ahead of industry standards, providing unparalleled quality in laser-cut steel products. Through these comprehensive quality control measures, SourcifyChina guarantees reliable and precise steel components for various applications, earning the trust and satisfaction of its global clientele.

SourcifyChina specializes in precision laser cutting for various types of steel, offering cutting-edge technology that ensures exactitude and quality. Their advanced laser systems can handle complex designs with minimal material wastage.

The company provides services for a range of steel thicknesses and types, accommodating diverse industrial needs. Whether it’s stainless steel, carbon steel, or specialized alloys, their equipment is calibrated for optimal performance.

SourcifyChina’s laser cutting services are ideal for automotive, aerospace, and manufacturing sectors, where precision is critical. They offer rapid turnaround times, ensuring that project deadlines are consistently met.

By using state-of-the-art machinery and skilled technicians, SourcifyChina guarantees dimensional accuracy and a high-quality finish. Their commitment to excellence makes them a trusted partner in the steel industry.

With a focus on innovation, SourcifyChina continuously upgrades its technology to remain at the forefront of laser cutting capabilities. This ensures they can handle both traditional and cutting-edge applications effectively.

In conclusion, SourcifyChina’s laser cutting services provide unparalleled precision, versatility, and efficiency. They cater to various industries, offering tailored solutions that meet specific requirements, making them a leading choice for steel laser cutting.

Laser cutting steel offers precision, efficiency, and versatility, making it an ideal choice for various industrial applications. Here are some key benefits:

– Precision: Laser cutting offers extremely tight tolerances and detailed cuts, ensuring high accuracy.

– Efficiency: Faster cutting speeds reduce production time, increasing throughput.

– Quality: Smooth, clean edges eliminate or reduce the need for additional finishing processes.

– Flexibility: Capable of cutting complex shapes and intricate designs, accommodating custom and specialized requirements.

– Material Utilization: Minimizes waste due to its high accuracy and precision, leading to cost savings.

– Automation: Easily integrated with computer-aided design (CAD) software for automated, repeatable cuts.

– Versatility: Suitable for cutting a wide range of steel types and thicknesses.

By leveraging these benefits, industries can achieve higher productivity, lower costs, and superior product quality.

Laser cutting steel is a highly efficient and precise method utilized in modern manufacturing industries. It offers numerous advantages over traditional cutting methods.

– Precision: Laser cutting provides exceptional accuracy, producing clean and precise cuts with minimal material waste.

– Speed: The process is much faster compared to mechanical cutting methods, improving production rates.

– Versatility: It can handle various steel grades and thicknesses, making it suitable for diverse applications.

– Quality: The edges produced are often burr-free, reducing the need for secondary finishing processes.

– Complexity: Capable of cutting intricate shapes and patterns that are difficult to achieve with other methods.

– Automation: Easily integrated with CNC systems for automated and repeatable operations.

– Reduced Heat-Affected Zone (HAZ): Minimized thermal distortion and structural changes to the material due to the focused heat source.

– Material Utilization: Enhanced nesting capabilities optimize material usage, reducing scrap rates.

– Non-contact Process: Eliminates wear and tear on cutting tools, extending the lifespan of the equipment.

– Safety: Offers a safer working environment as it reduces the need for manual handling and mechanical cutting tools.

In summary, laser cutting steel brings precision, speed, versatility, and reduced material waste to manufacturing processes. Its capabilities enable high-quality production and complex designs, ensuring efficiency and safety in operations.

By choosing laser cutting, manufacturers gain a competitive advantage through improved product quality, reduced operational costs, and enhanced production capabilities.

SourcifyChina’s laser-cutting steel solutions are redefining standards in custom product creation. Utilizing advanced laser technology, precision, and durability are guaranteed, ensuring every project surpasses client expectations.

From intricate patterns to heavy-duty components, SourcifyChina excels in delivering versatile laser cutting services. Their expert team can handle a wide range of steel types and thicknesses, catering to diverse industry needs.

Innovation is at the heart of SourcifyChina’s approach. They strive to incorporate the latest advancements in laser cutting to enhance productivity and efficiency, providing clients with cutting-edge solutions for their custom projects.

Customer satisfaction is paramount. SourcifyChina prioritizes clear communication and timely delivery, building lasting relationships through reliable and quality service, ensuring each client’s vision becomes a reality.

Ideal for both small-scale and large-scale projects, SourcifyChina’s laser cutting services are integral to industries like automotive, construction, and manufacturing. Their commitment to perfection drives excellence in every detail.

SourcifyChina offers competitive pricing without compromising on quality. By maintaining stringent quality control processes, they ensure that each product meets the highest standards of precision and craftsmanship.

In conclusion, SourcifyChina’s laser cutting steel solutions provide unmatched precision, versatility, and reliability. They offer a comprehensive service that caters to various industries, ensuring each custom product and project is crafted to perfection. With their advanced technology and dedicated team, SourcifyChina continues to set the benchmark for excellence in laser cutting services.

SourcifyChina Laser Cutting Steel is a distinguished company renowned for its precision in metal fabrication services. Specializing in laser cutting technology, it offers unparalleled accuracy and efficiency in cutting through various types of steel materials. Based in China, the company caters to a global clientele, providing high-quality, customized solutions for industries ranging from automotive to aerospace. SourcifyChina prides itself on using state-of-the-art laser cutting equipment, which ensures minimal material wastage and superior finish. Their expertise is not confined to just cutting; they also offer extensive ancillary services, including welding, bending, and assembly. This makes them a one-stop-shop for comprehensive metal fabrication needs. The company boasts a team of skilled engineers and technicians who work collaboratively to bring intricate design visions to life. Adhering to stringent quality control standards, SourcifyChina ensures that each project meets international specifications, reinforcing their commitment to excellence and customer satisfaction.

Laser cutting steel is a pivotal technology in the Aerospace, Defense, and Marine sectors, offering precision and efficiency that are critical to these demanding industries. In aerospace, laser cutting is utilized for manufacturing highly intricate components such as turbine blades, aircraft frames, and intricate body panels. The precision of laser cutting ensures minimal material wastage and results in components with superior dimensional accuracy, which is crucial for achieving the exacting standards required in aircraft manufacturing. This not only enhances the overall performance and safety of the aircraft but also significantly reduces production times and costs.

In the Defense and Marine sectors, the application of laser cutting steel is equally transformative. For defense, it enables the production of complex geometries needed for armored vehicles, weapons systems, and support infrastructure. The precision and reliability of laser cutting are essential for producing components that must withstand extreme conditions and perform flawlessly in critical situations. In the Marine industry, laser cutting is vital for fabricating large steel sections for shipbuilding, including hulls, decks, and internal structures. The ability to cut steel with high precision and consistency speeds up construction timelines and enhances the structural integrity and robustness of marine vessels, contributing to improved safety and operational efficiency.

Laser cutting technology has significantly transformed the automotive industry by enabling unparalleled precision and speed in the manufacturing process. In automotive manufacturing, laser cutting steel is used to produce intricate components such as body panels, intricate frameworks, and critical engine parts. This technology allows for complex geometries that are difficult or impossible to achieve with traditional machining methods. The high precision of laser cutting minimizes material wastage, reduces the margin for error, and ensures parts fit together seamlessly, improving the overall structural integrity and performance of vehicles. Furthermore, the non-contact nature of laser cutting means there is minimal mechanical stress on the materials being cut, which is crucial for maintaining the strength and durability of the automotive components.

In the realm of electronics, laser cutting steel serves a pivotal role in the precise fabrication of components for devices such as smartphones, laptops, and other high-tech gadgets. The method is particularly valued for its ability to cut extremely thin and detailed sections of steel, which are necessary for creating the intricate circuits and protective casings found in modern electronic devices. Laser cutting ensures consistency and repeatability, vital for mass production of electronic components where even minor deviations can lead to significant product failures. Additionally, the process is highly adaptable and can be easily programmed to accommodate rapid changes in design, which is particularly advantageous in the fast-paced electronics industry where innovation and customization are key drivers. The precision and efficiency of laser cutting steel thereby significantly contribute to the reliability and advancement of electronic devices.

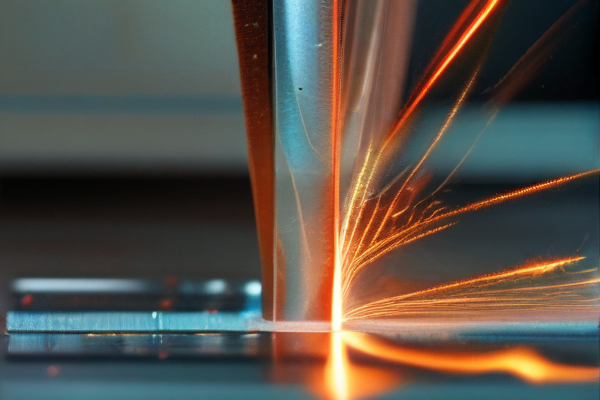

Laser cutting steel has revolutionized the construction industry by providing unparalleled precision, speed, and flexibility in fabricating structural components. Unlike traditional cutting methods, laser cutting utilizes a focused beam of light to melt, burn, or vaporize the material, resulting in highly accurate cuts with minimal heat-affected zones. This level of precision significantly reduces waste and allows for complex shapes and intricate designs that would otherwise be difficult or impossible to achieve with conventional tools. Moreover, the automation potential that laser cutting offers can streamline production processes, reducing labor costs and lead times. From cutting structural beams and columns to intricate architectural elements, laser cutting is becoming a cornerstone technology in modern construction, enabling the realization of more ambitious and innovative project designs.

In the energy sector, laser cutting steel holds significant promise for improving the production and maintenance of renewable energy systems. For instance, precision-cut steel components are essential in the fabrication of solar panel mounts, wind turbine parts, and supports for hydroelectric systems. The high efficiency and accuracy of laser cutting ensure that each component fits perfectly, enhancing the overall performance and longevity of the energy systems. Additionally, the rapid prototyping capabilities afforded by laser cutting allow for quicker iterations in the design and testing of new energy technologies, thereby accelerating innovation in the field. Beyond renewables, laser cutting steel is also pivotal in the oil and gas industry, where it is used to manufacture pipe systems, structural assemblies, and other critical infrastructure with enhanced safety and efficiency. The versatility and exactness of laser cutting thus play a crucial role in advancing energy solutions that are both sustainable and reliable.

Laser cutting steel has revolutionized the industrial equipment industry by providing unparalleled precision and efficiency in manufacturing processes. Utilizing high-powered lasers with computer-controlled automation, laser cutting can produce intricate and complex shapes with a high degree of accuracy. This technology is invaluable for industries that demand precise metal fabrications, ranging from automotive to aerospace and heavy machinery. The ability to cut through varying thicknesses of steel quickly and with minimal material wastage translates to significant cost savings and enhanced production speeds. Moreover, the consistency of laser cuts ensures that parts and components meet exact specifications, thereby reducing the need for post-processing and manual adjustments.

The advantages of laser cutting steel extend beyond mere accuracy and efficiency. This clean cutting method also minimizes thermal distortion, which is a common issue with traditional cutting processes such as plasma or oxy-fuel cutting. As a result, the structural integrity of the steel remains unaltered, preserving its mechanical properties. Additionally, the integration of advanced software systems enables the automation of the entire cutting process, leading to reduced labor costs and increased workplace safety. With these benefits, industries can meet high production demands while maintaining stringent quality standards. As laser technology continues to evolve, its application in the industrial equipment sector is poised to expand, offering even more sophisticated capabilities and further driving innovation and productivity.

Laser cutting steel is an essential technique in the development and manufacturing of medical devices, owing to its unparalleled precision and efficiency. Utilizing high-powered lasers, the method allows for the intricate cutting and shaping of various steel components which are crucial for medical instruments, implants, and intricate devices like surgical instruments. The precision of laser cutting ensures minimal thermal distortion and burr formation, resulting in smoother edges and higher quality products that meet the stringent hygienic and safety standards required in the medical field. This level of precision is particularly vital for producing complex geometries and micro-scale components that are often required in advanced medical technologies.

Additionally, laser cutting is highly adaptable to both prototyping and mass production, allowing for rapid design iterations and scalability. This flexibility is invaluable in the medical device industry, where innovation and time-to-market are critical. Laser cutting technology also supports material versatility, capable of handling a variety of steels including stainless steel and specialized medical-grade alloys, which possess the corrosion resistance and biocompatibility required for medical applications. The automation potential of laser cutting further enhances its appeal, reducing labor costs and human error while improving throughput and consistency. Thus, the deployment of laser cutting in the manufacturing of medical devices not only accelerates innovation but also ensures the production of safer, more reliable medical tools and implants.

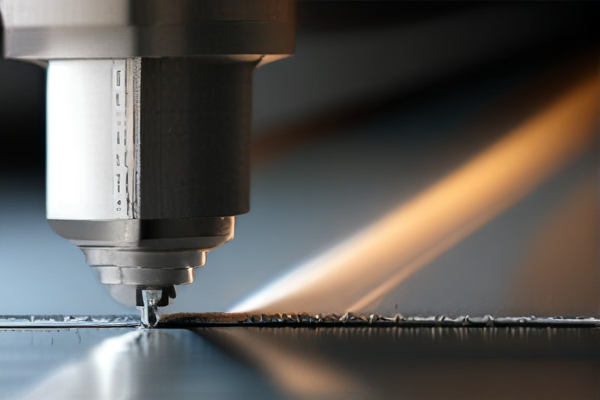

Laser cutting steel has revolutionized the machining and manufacturing sectors by providing a highly precise and efficient method for material removal. This technology utilizes a focused laser beam to melt, burn, or vaporize material, enabling intricate shapes and designs to be created with exceptional accuracy. The process is controlled by CNC (computer numerical control) systems, which translate digital designs into physical components. This ensures repeatability and precision, allowing manufacturers to produce large volumes of parts without compromising on quality. As a result, laser cutting is extensively used in industries such as automotive, aerospace, and sheet metal fabrication, where precision and efficiency are paramount.

Additionally, the manufacturing application of laser cutting steel significantly reduces material waste and processing time. Traditional methods such as mechanical cutting or stamping often result in significant material wastage and require multiple processing steps. Laser cutting, on the other hand, offers superior edge quality and can perform complex cuts in a single pass. Its ability to handle a variety of thicknesses and types of steel further adds to its versatility. Beyond cutting, laser systems can also engrave and etch, adding functionality like part identifications or decorative elements. The adoption of laser cutting technology helps manufacturers achieve lower production costs, shorter lead times, and enhanced product innovation, contributing to their overall competitive advantage in the market.

Sure! Below are some frequently asked questions (FAQs) and their answers related to manufacturing laser cutting steel quality work from the SourcifyChina factory.

1. What types of steel can be laser cut by SourcifyChina?

SourcifyChina can laser cut a wide range of steel types including mild steel, stainless steel, and carbon steel. Each type of steel requires specific settings to ensure precise and clean cuts.

2. What is the maximum thickness of steel that can be laser cut?

The factory can handle laser cutting of steel up to 25mm thickness for mild steel and up to 20mm for stainless steel, depending on the specific type and grade of steel.

3. What are the tolerances for laser cutting steel at SourcifyChina?

SourcifyChina ensures high precision with tolerances typically within ±0.1mm. For specific tolerance requirements, it’s best to consult directly with the factory.

4. What kind of finishes can be expected from the laser cutting process?

The laser cutting process at SourcifyChina produces clean, burr-free edges. Depending on the material and thickness, some finishing touches like deburring might be needed for optimal results.

5. Can SourcifyChina handle custom laser cutting designs?

Yes, SourcifyChina excels in custom projects. You can provide your CAD files, and the factory will ensure your designs are accurately translated into high-quality steel components.

6. How does SourcifyChina ensure quality and precision in laser cutting?

The factory utilizes advanced laser cutting machinery and software, coupled with stringent quality control processes to ensure high precision and consistency in every cut.

7. What is the typical lead time for laser cutting projects?

Lead times vary depending on the project’s complexity and volume. Generally, small to medium-sized projects can expect a lead time of 1-2 weeks.

8. Is there a minimum order quantity (MOQ) for laser cutting services?

SourcifyChina typically requires an MOQ, which can vary depending on the specific project requirements. It’s recommended to consult with the factory for precise information regarding MOQ.

9. What information is needed to get a quote for laser cutting services?

To get a quote, provide detailed specifications including material type and thickness, design files (preferably in CAD format), quantity, and any special requirements.

When considering laser cutting steel manufacturing from SourcifyChina factory, efficient production and quality output are paramount. Here are some key tips:

1. Understand Material Specifications: Ensure you have detailed information on the types and thicknesses of steel you plan to cut. SourcifyChina offers a variety of steel grades; choose the one that suits your product requirements for strength and durability.

2. Precision and Tolerances: Specify your precision needs. High-quality laser cutting can achieve tight tolerances, ideal for intricate designs. Insisting on precision ensures consistency and reduces post-processing work.

3. Technology and Equipment: Inquire about the types of laser cutting machines used. SourcifyChina’s factory may use CO2 or fiber lasers. Fiber lasers are particularly effective for cutting steel, offering faster speeds and higher energy efficiency.

4. Sample Testing: Request samples before full-scale production. This helps assess cutting accuracy, quality of edges, and potential material waste, ensuring the end product meets your standards.

5. Communication and Support: Maintain clear communication with the SourcifyChina team. Understand their process, lead times, and quality control measures. A dedicated support team can help promptly address any issues.

6. Customized Solutions: If your project has unique needs, discuss customization options. SourcifyChina can tailor operations such as cutting patterns, sizes, and batch volumes to meet specific project demands.

7. Cost Management: Laser cutting can be cost-effective for both short and long runs. Discuss the pricing structure, including setup fees and per-unit costs, to ensure it aligns with your budget.

8. Sustainability: Inquire about waste management and recycling practices. Efficient material use and proper disposal contribute to sustainable manufacturing processes.

Leveraging these tips ensures a smooth, productive partnership with SourcifyChina for your laser cutting steel needs, helping achieve optimal manufacturing outcomes.

Sure, here is a concise list of Frequently Asked Questions (FAQ) regarding sourcing laser-cut steel from SourcifyChina factory:

Q: What types of steel can SourcifyChina cut with laser technology?

A: SourcifyChina offers laser cutting services for a wide range of steel types including carbon steel, stainless steel, and alloy steel. Please contact us for specifics on the grades and thicknesses available.

Q: What is the maximum thickness of steel that can be laser cut?

A: SourcifyChina can laser cut steel up to a maximum thickness of 25mm for carbon steel and 20mm for stainless steel.

Q: What is the lead time for laser-cut steel orders?

A: Lead times can vary depending on order volume and complexity. Typically, most orders are completed within 7-14 days. For more precise timelines, please consult our sales team.

Q: Can SourcifyChina handle custom designs for laser cutting?

A: Yes, we can accommodate custom designs. Please provide us with the detailed drawings or digital files in formats like DXF, DWG, or AI to ensure accuracy.

Q: What are the quality control measures in place?

A: SourcifyChina employs rigorous quality control measures including inspection of raw materials, precision calibration of laser cutting machines, and post-processing inspections to ensure the highest quality of finished products.

Q: What are the payment terms offered?

A: We offer flexible payment terms including T/T (Telegraphic Transfer), LC (Letter of Credit), and PayPal. For detailed payment arrangements, please contact our finance department.

Q: How is the packaging and shipping handled?

A: We use secure, industry-standard packaging materials to protect your products during transit. We offer multiple shipping options including sea freight, air freight, and express courier services.

Q: Is there a minimum order quantity (MOQ)?

A: Yes, the MOQ varies depending on the specific project requirements. It is generally more cost-effective to place larger orders. Please discuss your project with our sales team for exact MOQ details.

Q: How can I get a quote for my laser cutting project?

A: To receive a quote, please send us your detailed project requirements, including material type, thickness, design drawings, and quantity. Our sales team will respond promptly with a detailed quotation.

Sourcing laser-cutting steel from a reliable factory like SourcifyChina requires a strategic approach. Here are some effective tips:

1. Research Thoroughly: Start by scrutinizing SourcifyChina’s official website and reputable reviews. Look for client testimonials and case studies to gauge their credibility and expertise in laser-cutting steel.

2. Clarify Requirements: Clearly define your specifications, including material grade, thickness, dimensions, and any specific geometric tolerances. This ensures the factory understands your needs precisely.

3. Evaluate Capabilities: Confirm that SourcifyChina has the necessary advanced laser-cutting technology. Check if they offer secondary operations like bending, welding, or finishing if required.

4. Request Samples: Ask for sample products to assess the quality of their laser-cutting services. Examine the precision, edge quality, and overall finish of the samples.

5. Check Certifications: Validate that the factory complies with international quality standards (e.g., ISO 9001) and has relevant certifications in laser cutting and steel processing.

6. Negotiate Terms: Discuss pricing, lead times, minimum order quantities, and payment terms. Ensure these align with your budget and project timeline.

7. Inspect Facility: If possible, visit the factory to inspect their equipment, facilities, and processes. This firsthand view can provide assurance of their operational competence.

8. Assess Communication: Ensure there’s clear, responsive communication with SourcifyChina’s representatives. Effective communication is crucial for smooth project execution.

9. Consider Logistics: Work out shipping and logistics details. Understanding delivery times, shipping costs, and customs clearance processes is essential to avoid unexpected delays.

10. Secure a Contract: Draft a detailed contract outlining your agreement, including quality standards, delivery schedules, and penalties for non-compliance. This protects your interests legally.

By following these steps, you can effectively source high-quality laser-cutting steel from SourcifyChina, ensuring your project’s success while minimizing risks.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.