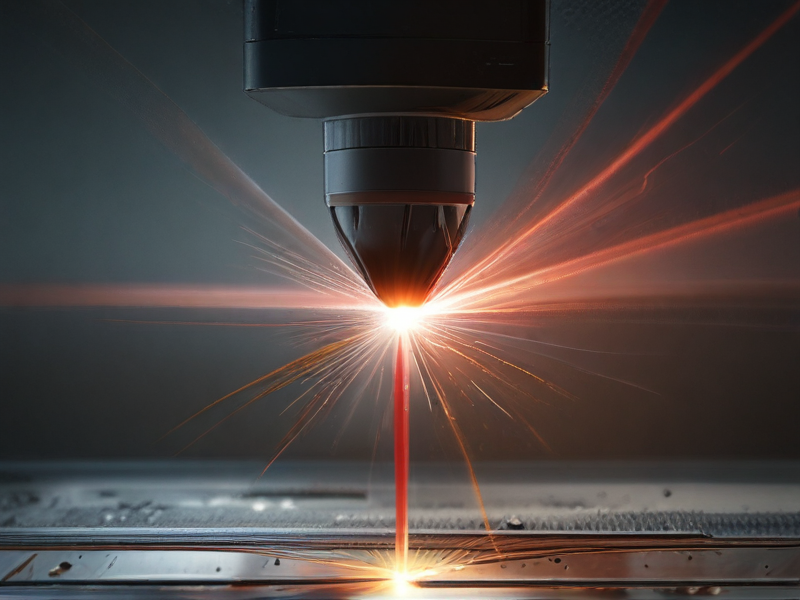

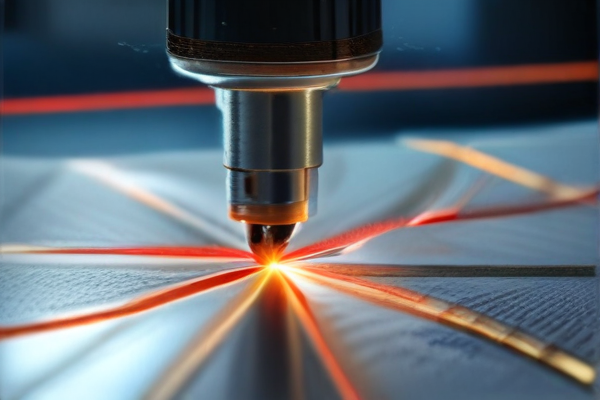

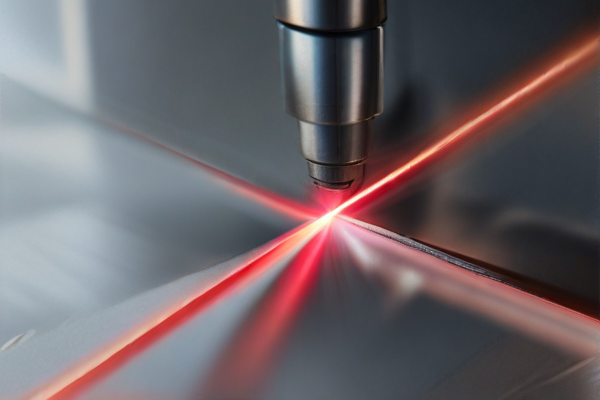

Reliable Metal Cutting with SourcifyChina: Your Trusted Factory for High-Precision Laser Technology

In less than 300 words:

SourcifyChina stands out in the market with its high-precision laser technology for metal cutting. Renowned for its reliability and advanced machinery, SourcifyChina ensures top-notch quality and efficiency in every project. Our factory is equipped with state-of-the-art laser cutting machines designed to handle various types of metals with impeccable precision. Whether you’re looking for custom components or large-scale production, our experienced team is dedicated to meeting your specific requirements seamlessly. Trust SourcifyChina for all your metal cutting needs and experience unmatched service and expertise.

Choosing “SourcifyChina” Factory for purchasing laser machines for metal cutting from China ensures high-quality products at competitive prices. Their advanced technology guarantees precision and efficiency.

Additionally, SourcifyChina provides exceptional customer service and technical support, facilitating smooth transactions and prompt responses to inquiries. They prioritize customer satisfaction.

The factory’s rigorous quality control processes ensure reliability and durability, reducing maintenance costs and downtime. SourcifyChina’s commitment to excellence is evident in every laser machine they produce.

Their extensive industry knowledge and experience mean they can offer tailored solutions to meet specific buyer needs. Partnering with SourcifyChina means gaining access to expertise and innovation.

Multilingual support and a user-friendly ordering process streamline purchasing, making it easy for international buyers. SourcifyChina’s established logistics network ensures timely and safe delivery.

Lastly, purchasing from SourcifyChina means supporting sustainable practices. They implement eco-friendly manufacturing processes and adhere to environmental standards, making them a responsible choice for discerning buyers.

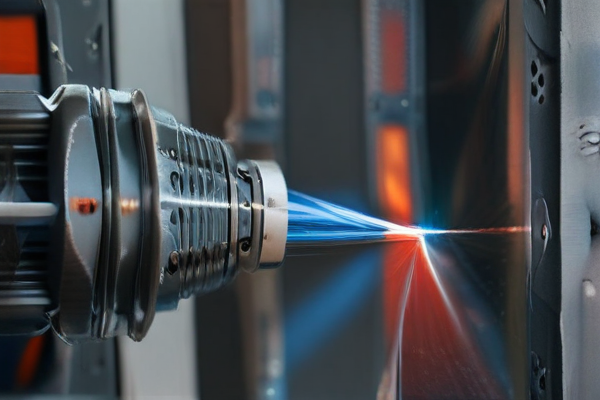

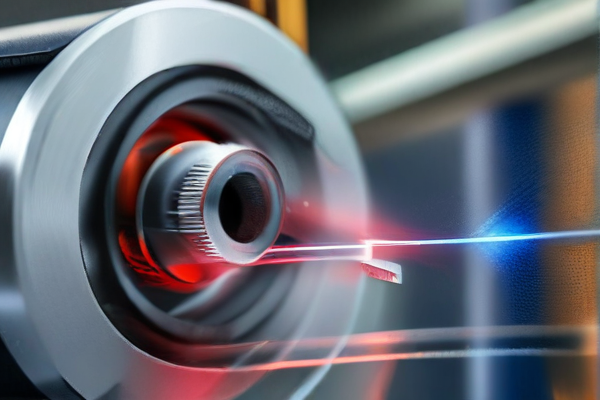

Lasers for cutting metal come in several types, each suited to different applications. The main types include CO2, fiber, and Nd:YAG lasers, each providing unique benefits for various metal-cutting tasks.

– CO2 Lasers: Ideal for cutting and engraving non-metal materials but also effective for cutting stainless steel and aluminum in lower thicknesses.

– Fiber Lasers: Highly efficient for cutting thin metals like steel, brass, and copper with high speed and precision; known for low maintenance and energy consumption.

– Nd:YAG Lasers: Often used for welding and engraving, they can cut metals but are more specialized for thicker materials and slower cuts compared to fiber lasers.

Laser cutting of metal is a precise and efficient technique employed in various industries for shaping, slicing, and fabricating metal components. Its applications span numerous fields because of its accuracy, speed, and versatility.

– Automotive Industry: Used for cutting intricate parts, frames, and bodywork, enhancing the production process.

– Aerospace: Essential for fabricating high-tolerance components, ensuring structural integrity and performance.

– Manufacturing: Streamlines the production of machinery parts, reducing lead times and labor costs.

– Medical Devices: Facilitates the creation of complex surgical instruments and implants with precise dimensions.

– Construction: Aids in cutting metal beams and structural frameworks, contributing to robust and safe infrastructures.

– Jewelry Making: Allows for the intricate design and manufacture of custom metal jewelry pieces.

– Electrical Equipment: Helps in producing precise metal enclosures and components for various electronic devices.

– Art and Sculpture: Empowers artists to create detailed metal artworks and sculptures with ease.

– Signage and Advertising: Used for cutting metal signs, ensuring sharp edges and polished finishes.

– Shipbuilding: Enhances the efficiency of cutting metal sheets and components for ship construction.

– Tool and Die Making: Provides high precision in creating dies and molds used in mass production.

– HVAC Industry: Assists in fabricating ductwork and other essential components with accuracy.

– Agricultural Equipment: Useful in manufacturing parts for tractors and other farming machinery.

– Renewable Energy: Critical for cutting components in wind turbines and solar panel frames.

– Educational and Research Institutions: Employed in experimental setups and creation of prototypes.

– Military and Defense: Used for producing high-precision parts for weapons and military vehicles.

– Furniture Design: Facilitates the cutting of metal for sturdy and innovative furniture designs.

– Railway Industry: Enhances the manufacture of train components and rail systems with high precision.

SourcifyChina lasers are renowned for their efficiency in metal cutting, utilizing high-powered, fiber laser technology. These lasers offer precision and rapid execution, crucial for industrial applications requiring meticulous detail.

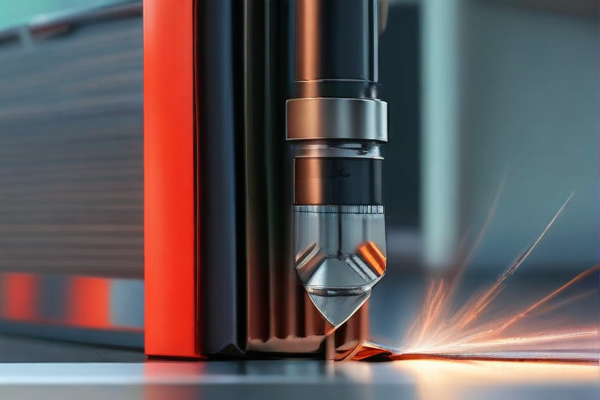

The materials utilized in constructing SourcifyChina lasers include advanced alloys and high-grade stainless steel for the exterior casing. This construction ensures durability and resistance to wear and tear, essential for prolonged usage in demanding environments.

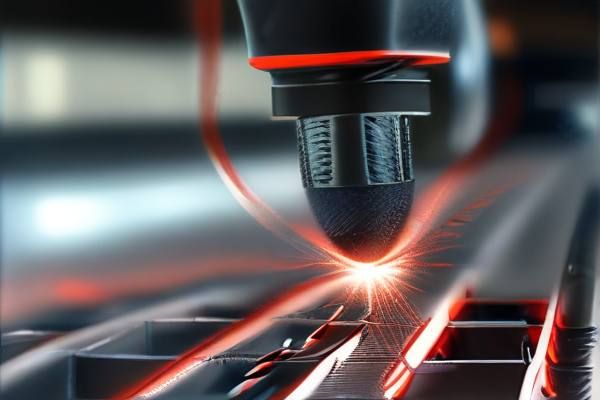

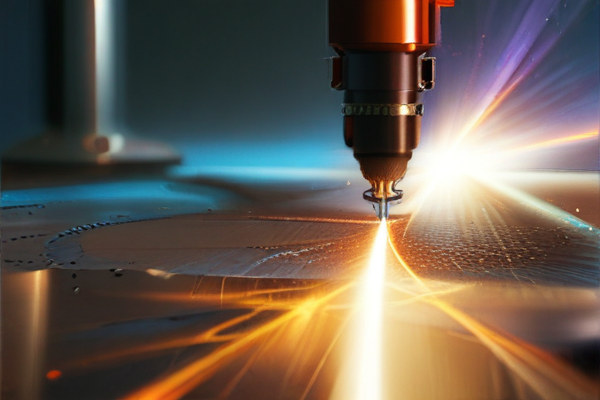

The core components include top-tier optical fibers, which are critical for maintaining consistent laser quality and intensity. These fibers aid in producing a focused and potent laser beam, capable of slicing through various metal types efficiently.

A specialized cooling system, using both air and liquid cooling methods, is integrated to maintain optimal operating temperatures. This ensures the laser remains effective without overheating, extending the machine’s operational life and maintaining performance.

Safety features are also paramount, incorporating robust shielding and emergency shutdown mechanisms. These features protect operators from accidental exposure and ensure compliance with global safety standards, providing peace of mind during operation.

In summary, SourcifyChina lasers are engineered with precision materials, ensuring durable, efficient, and safe metal cutting capabilities. These attributes make them a preferred choice for industrial applications, from automotive to aerospace manufacturing. Their construction and features are designed to meet the rigorous demands of modern industry, making SourcifyChina a trusted name in laser cutting technology.

SourcifyChina ensures stringent quality control during the manufacturing of its metal-cutting lasers, utilizing top-notch raw materials to guarantee durability and precision. Each component undergoes a meticulous inspection process before assembly.

During assembly, highly skilled technicians follow standardized protocols for wiring, positioning, and calibration to ensure optimal performance. Each step is rigorously supervised to eliminate errors and ensure consistency.

After assembly, the lasers undergo comprehensive testing procedures, including operational and stress tests, to verify their reliability and efficiency. These tests simulate real-world conditions to ensure the product meets the highest standards.

Final quality checks involve detailed inspections and functionality tests, including laser output verification and safety assessments. This step confirms that the product meets all prescribed specifications and regulatory requirements, ensuring customer satisfaction and safety.

Customer feedback and field performance data are continuously monitored and analyzed. This approach enables SourcifyChina to refine and enhance its manufacturing processes, further assuring the quality and reliability of their metal-cutting lasers.

In conclusion, SourcifyChina’s rigorous quality control manufacturing process, spanning from material selection to final performance testing, ensures that every laser for cutting metal meets superior standards. This meticulous approach guarantees top-grade products that consistently deliver precision and reliability in metal-cutting applications.

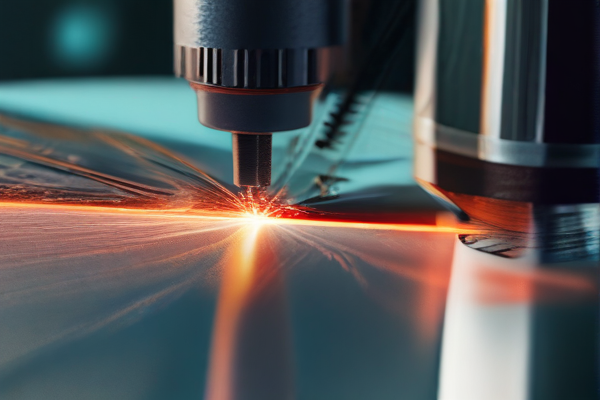

SourcifyChina’s laser cutting machines are renowned for their precision and efficiency in metal cutting operations. Capable of handling various metal types, including steel, aluminum, and copper, the machines employ high-powered laser beams to achieve accurate and clean cuts. This precision ensures minimal waste, resulting in cost savings and optimized material usage.

The versatility of SourcifyChina lasers is evident in their adaptability for both intricate designs and bulk production. The software integrated with the machines allows for easy customization, catering to diverse industrial needs. From automotive components to delicate jewelry, these lasers deliver exceptional quality consistently.

Furthermore, SourcifyChina laser cutters boast impressive speed without compromising quality. This high-speed capability significantly reduces production times, boosting overall productivity. The advanced cooling mechanisms mitigate heat distortion, ensuring the integrity of the metal is maintained throughout the cutting process.

In terms of maintenance, SourcifyChina provides robust support and user-friendly interfaces. This ease of maintenance prolongs the lifespan of the machines, making them a cost-effective investment. Additionally, the company’s extensive network of service centers ensures swift technical support, minimizing downtime.

Overall, the capabilities of SourcifyChina lasers for cutting metal make them an indispensable tool for modern manufacturing. Combining precision, versatility, speed, and easy maintenance, these machines empower industries to achieve high-quality outcomes efficiently.

Laser cutting is a highly efficient method for metal fabrication, offering several advantages over traditional techniques. Here are the key benefits:

– Precision: Laser cutting provides unparalleled precision, allowing for intricate designs and tight tolerances.

– Speed: The process is much faster than conventional cutting methods, increasing productivity.

– Versatility: Capable of cutting various types of metals, including steel, aluminum, and titanium, without compromising quality.

– Reduced Waste: Minimal material wastage due to precision and efficient material usage.

– Minimal Distortion: The high focus of the laser beam reduces heat-affected zones, minimizing metal distortion.

– Reduced Tool Wear: No physical contact means tools don’t wear out, reducing maintenance costs.

– Automation: Easily integrated with CNC systems for automated production, enhancing consistency and efficiency.

– Cleaner Cuts: Produces smooth edges that often require little to no further finishing.

These benefits make laser cutting an essential technology in modern metalworking industries.

Laser cutting technology offers impressive precision and efficiency for metal fabrication. Leveraging a concentrated beam of light, it enables clean, accurate cuts on a variety of metal types.

Features:

– Precision: Provides extremely accurate cuts, often within micrometers.

– Speed: Capable of rapid cutting, increasing production efficiency.

– Versatility: Suitable for metals like steel, aluminum, brass, and more.

– Minimal Distortion: Reduces thermal distortion due to concentrated heat.

– Automation: Easily integrated into automated systems for mass production.

– Complex Designs: Can produce intricate patterns and shapes with ease.

– Smooth Edges: Results in clean and smooth cut edges, reducing the need for post-processing.

– Energy Efficiency: Modern lasers offer energy-efficient solutions, reducing overall operational costs.

– Safety: Equipped with safety features to protect operators from laser exposure.

– Maintenance: Requires minimal maintenance compared to mechanical cutting systems.

These features underscore the laser’s role as a powerful tool in modern metal fabrication, balancing precision, speed, and cost-efficiency.

SourcifyChina specializes in providing advanced laser cutting solutions for metal, allowing precise cuts for various custom products. Our state-of-the-art machinery ensures minimal waste and superior accuracy, perfect for intricate designs.

Serving a diverse range of industries, from automotive to aerospace, our laser cutting technology guarantees high-quality results for every project. Whether it’s sheet metal, stainless steel, or aluminum, we cater to your specific needs meticulously.

Our expert team collaborates closely with clients to transform their visions into reality. We handle projects of all sizes efficiently, balancing speed and precision to meet tight deadlines without compromising quality.

Innovation drives us. Constantly upgrading our technology, we strive to offer the best cutting-edge solutions. Customized laser cutting, tailored specifically to your requirements, continually pushes the boundaries of what’s possible, making your products stand out.

Customer satisfaction is our top priority. From initial consultation to final output, we offer comprehensive support and transparent communication. Trust SourcifyChina for reliability and excellence in custom metal cutting projects. Experience the fusion of technology and craftsmanship.

SourcifyChina Laser is a pioneering company specializing in high-precision laser cutting technology for metal applications, standing at the forefront of industrial advancement in China. With a robust portfolio that caters to various sectors, including automotive, aerospace, and construction, the company has garnered a reputation for delivering cutting-edge solutions that combine efficiency, accuracy, and reliability. Leveraging state-of-the-art fiber laser systems, SourcifyChina Laser ensures optimal performance and minimal maintenance, meeting the demanding standards of modern manufacturing processes. Their unwavering commitment to innovation is reflected in continuous investment in research and development, enabling them to stay ahead in a competitive market. The company’s customer-centric approach is evident in their personalized service offerings, providing tailored solutions that address the unique needs of each client. SourcifyChina Laser not only enhances operational productivity but also drives significant cost savings, making them a vital partner for businesses aiming for excellence in metal cutting operations.

Laser cutting technology has revolutionized the aerospace industry, where precision and efficiency are paramount. In aircraft manufacturing, lasers are used for cutting intricate shapes and complex components from high-strength materials, such as titanium and aluminum alloys. Their unmatched accuracy ensures that each part meets exact specifications, enhancing the structural integrity and aerodynamic performance of aircraft. Additionally, laser cutting minimizes material waste and reduces processing time compared to traditional methods. This not only lowers production costs but also contributes to the rapid prototyping and production cycles necessary to keep up with the dynamic demands of the aerospace sector.

In the defense and marine industries, the application of laser cutting technology is equally transformative. For defense purposes, lasers are employed to produce high-precision parts for vehicles, weaponry, and electronic systems, ensuring reliability and durability under extreme conditions. The ability to cut through thick armor plating and composite materials with ease is particularly valuable for military applications. Meanwhile, in the marine industry, laser cutting is used to fabricate ship components and structures, ranging from hull sections to intricate machinery parts. The precision and efficiency of laser cutting not only enhance the performance and longevity of maritime vessels but also streamline the construction process, allowing shipbuilders to meet stringent deadlines and quality standards. These advancements collectively enhance the capabilities and competitiveness of the defense and marine sectors.

Lasers have revolutionized the automotive industry by providing high precision and efficiency in metal cutting applications. In the production of cars, laser cutting is employed to shape components with intricate designs and tight tolerances, resulting in high-quality parts with minimal waste. This technology is particularly valuable for cutting complex patterns in body panels, exhaust systems, and structural components, where traditional methods might fall short in terms of accuracy and speed. Additionally, laser cutting allows for rapid prototyping and customization, a growing demand in the automotive sector for bespoke models and parts. The non-contact nature of lasers also ensures minimal mechanical deformation of the components, which is crucial to maintaining the integrity and performance of automotive parts.

In the electronics industry, precision is paramount, and lasers for cutting metal play a critical role in the manufacturing of intricate electronic components. With the ability to make narrow cuts and fine details, lasers are ideal for creating metal parts used in electronic devices such as smartphones, computers, and circuit boards. This technology enables the production of heat sinks, shielding cans, and microelectronic connectors with exceptional precision, essential for the optimal performance of miniaturized devices. Furthermore, the automation capabilities of laser cutting systems enhance production efficiency, making it possible to meet the high demands of the fast-paced electronics market. The consistent quality and repeatability of laser-cut components ensure reliability and longevity in electronic products, solidifying the laser’s role as an indispensable tool in the industry.

Laser cutting technology has revolutionized the construction industry by introducing unprecedented precision and efficiency in metal fabrication. Traditional methods like mechanical sawing or plasma cutting often result in rough edges and require extensive follow-up work to smooth and finish. In contrast, laser cutting employs concentrated beams of light, allowing for highly accurate cuts with smooth edges, significantly reducing the need for secondary processing. This precision is especially valuable for creating intricate architectural designs and customized components that fit together seamlessly, enhancing both the structural integrity and aesthetic appeal of buildings. Moreover, laser cutters can be operated through computerized systems, enabling builders to execute complex designs directly from CAD (Computer-Aided Design) files, thereby accelerating project timelines and reducing labor costs.

In the energy sector, the use of laser cutting for metal is equally transformative. Renewable energy installations, such as wind turbines and solar panels, often require specialized metal components that are both durable and lightweight. Laser cutting technology is pivotal in manufacturing these parts with high precision, ensuring they meet rigorous engineering standards. For instance, the structural frames and support structures for solar panels can be precisely fabricated to optimize their strength-to-weight ratio, enhancing their effectiveness and lifespan. Additionally, in the maintenance and development of oil and gas infrastructure, laser cutting allows for the exact customization and swift production of intricate pipelines and assembly parts, which improves the safety and efficiency of energy extraction and transportation processes. Overall, the application of laser cutting in the energy sector not only expedites production but also enhances the performance and reliability of critical infrastructure.

In the industrial equipment industry, the application of lasers for cutting metal represents a transformative technological advancement that enhances efficiency, precision, and versatility in manufacturing processes. Laser cutting employs high-powered, focused beams of light to melt, burn, or vaporize material, which allows for intricate and complex designs that traditional mechanical cutting methods struggle to achieve. The precision of laser cutting minimizes material waste, thereby reducing costs and enhancing sustainability. Furthermore, the contactless nature of laser cutting reduces mechanical wear-and-tear, leading to lower maintenance requirements and longer equipment life spans. Industries such as automotive, aerospace, and electronics benefit significantly from these advantages, enabling them to produce high-quality components with tight tolerances and intricate details.

In addition to its precision, laser cutting technology excels in its versatility and adaptability within the industrial equipment sector. Various types of metals, including steel, aluminum, brass, and titanium, can be efficiently cut using different laser types such as CO2, fiber, and YAG lasers. This adaptability means that manufacturers can switch between different materials and thicknesses with relative ease, increasing the flexibility of production lines. Advanced laser cutting systems are also integrated with computer numerical control (CNC) technology, allowing for automated and highly repeatable processes. This integration enables manufacturers to produce large volumes of parts with consistent quality, catering to both mass production and custom orders. As industries continue to push for higher efficiency and greater innovation, the role of laser cutting in metal fabrication is poised to expand, driving forward the capabilities and competitiveness of the industrial equipment sector.

The application of laser technology for cutting metal in the medical device industry has revolutionized the manufacturing process, yielding unmatched precision and consistency. Laser cutting uses concentrated beams of light, typically from a fiber or CO2 laser, to cut through various metals like stainless steel, titanium, and aluminum with micrometer precision. This technology enables the production of intricate components essential for medical devices, such as surgical instruments, implants, and stents. The ability to produce consistent and highly accurate cuts ensures that the medical devices meet stringent quality and safety standards, which is critical for patient outcomes.

Beyond precision, laser cutting offers significant advantages in terms of efficiency and versatility. The non-contact nature of laser cutting means there is minimal thermal distortion or mechanical stress on the metal, preserving the material’s inherent properties. This is particularly advantageous when working with delicate or complex geometries required in advanced medical devices. Additionally, laser systems can be automated and programmed for rapid production, reducing lead times and operational costs. The sterile cutting environment of laser technology also minimizes the risk of contamination, which is crucial for devices used in surgical and therapeutic settings. Thus, the integration of laser cutting in the medical device manufacturing process not only enhances product quality but also aligns with the industry’s rigorous regulatory requirements.

The application of lasers for cutting metal has revolutionized the machining and manufacturing industry, offering a level of precision and efficiency that traditional methods could not achieve. Laser cutting utilizes a high-powered laser beam to melt, burn, or vaporize material, allowing for extremely accurate and clean cuts. This technique is highly advantageous in manufacturing processes where intricate designs or complex geometries are required, as the laser can be controlled very precisely to follow highly detailed patterns. Additionally, laser cutting is a contactless process, significantly reducing the wear and tear on tools and machines, which in turn lowers maintenance costs and extends the lifespan of equipment.

In terms of efficiency, laser cutting stands out due to its rapid processing speed and minimal material waste. This efficiency translates to quicker turnaround times for production, which is crucial in both large-scale manufacturing and custom or small-batch production scenarios. The versatility of laser cutting also means it is compatible with a wide range of metals, from steel and aluminum to more delicate materials like titanium and copper alloys, making it a multifaceted tool in modern manufacturing. Moreover, advances in laser technology have led to innovations such as fiber lasers and CO2 lasers, each offering unique advantages in terms of power consumption, cutting speed, and precision. In essence, the integration of laser cutting into machining and manufacturing processes not only enhances productivity but also opens up new possibilities for innovation and complexity in metalwork.

Sure! Here’s a list of Frequently Asked Questions (FAQ) related to manufacturing laser machines for cutting metal from SourcifyChina factory.

—

Q: What types of metal can the laser cutting machine from SourcifyChina cut?

A: Our laser cutting machines can efficiently cut a variety of metals including stainless steel, carbon steel, aluminum, copper, brass, and titanium.

Q: What is the maximum thickness the laser can cut?

A: Depending on the model, our lasers can cut through metals up to 25mm thick for mild steel and 20mm for stainless steel.

Q: What power output do your laser cutting machines provide?

A: We offer laser cutting machines with power outputs ranging from 500W to 12,000W to suit different cutting needs and thicknesses.

Q: Are your lasers compatible with CNC systems?

A: Yes, our laser cutting machines are fully compatible with CNC systems for precise and automated metal cutting operations.

Q: What is the accuracy and repeatability of the laser cutting machines?

A: Our machines offer high precision with an accuracy of ±0.03mm and repeatability of ±0.02mm, ensuring consistent quality cuts.

Q: Do you provide training and technical support?

A: Yes, we provide comprehensive training programs and 24/7 technical support to ensure smooth operation and maintenance of the machines.

Q: What kind of maintenance is required for your laser cutting machines?

A: Regular maintenance includes cleaning the lenses and mirrors, checking alignments, and ensuring proper cooling to keep the machines in optimal working condition.

Q: How long is the warranty for your laser cutting machines?

A: We offer a standard one-year warranty on our laser cutting machines, covering parts and labor, with options to extend the warranty period.

Q: Can I get a customized laser cutting solution?

A: Absolutely! We can customize our laser cutting machines to fit specific needs including size, power, and additional features.

Q: How quickly can you deliver a laser cutting machine?

A: Delivery times vary depending on the customization and order size, but typically, it takes 2-4 weeks for standard machines.

—

This concise FAQ should help customers understand the manufacturing capabilities and services provided by SourcifyChina for their laser cutting machines.

When considering the use of a laser for cutting metal from SourcifyChina factory, there are several key tips to ensure optimal performance and efficiency:

1. Understand the Requirements: Clarify your specific needs, including the type of metals, thickness, and production volume. Different metals like steel, aluminum, and copper require specific laser settings for optimal cutting.

2. Choose the Right Laser Type: CO2 lasers are excellent for cutting, boring, and engraving. Fiber lasers are more energy-efficient and better for cutting reflective metals like aluminum and copper.

3. Power and Speed Settings: Higher power settings ensure faster cutting speeds and the ability to cut thicker materials. However, excessive power can cause burns or rough edges. Adjust speed settings to maintain a balance between cut quality and productivity.

4. Maintenance and Repairs: Regular maintenance can prevent downtime and extend the lifespan of the laser. This includes checking mirrors, lenses, and alignment regularly. SourcifyChina can assist with specific maintenance protocols for their machines.

5. Software Compatibility: Ensure the laser machine is compatible with your design software. Many modern systems support a variety of file formats, which is essential for seamless design and execution.

6. Training and Support: Take advantage of any training and support offered by SourcifyChina. Proper operation and troubleshooting knowledge can significantly enhance the efficiency and lifespan of the equipment.

7. Safety First: Implement appropriate safety measures, including protective eyewear for operators, proper ventilation to avoid inhaling fumes, and strict adherence to operational guidelines.

8. Evaluate Cost Efficiency: Consider the total cost of ownership, including the initial purchase, maintenance, and operating costs. Fiber lasers, for instance, might have a higher upfront cost but lower operating expenses over time.

9. Quality Assurance: Verify the quality and precision of cuts through sample testing. This ensures the laser machine meets your quality standards before full-scale production.

By adhering to these tips, you can maximize the benefits of using a laser for cutting metal in your manufacturing processes, leading to increased productivity and superior quality outcomes.

Certainly! Below is a list of frequently asked questions and answers regarding sourcing metal-cutting lasers from the SourcifyChina factory.

1. What types of metal-cutting lasers do you offer?

– SourcifyChina offers a wide range of metal-cutting lasers, including fiber lasers, CO2 lasers, and diode lasers. Each type is tailored for different metal types and cutting thicknesses.

2. What is the minimum order quantity (MOQ)?

– The MOQ for metal-cutting lasers from SourcifyChina varies depending on the model and specifications. However, they typically start at one unit.

3. Can I request a sample unit for testing purposes?

– Yes, SourcifyChina can provide a sample unit for testing. Please note that sample units are subject to availability and may incur additional costs.

4. What are the shipping options available?

– SourcifyChina offers multiple shipping options including air freight, sea freight, and express couriers like DHL, FedEx, or UPS. Delivery time varies based on the shipping method chosen.

5. Are the lasers customizable?

– Yes, SourcifyChina offers customization options to meet specific requirements such as power level, cutting speed, and additional features.

6. Do you offer any warranties or return policies?

– SourcifyChina provides a standard one-year warranty on all metal-cutting lasers. They also offer a return policy for defective products, subject to terms and conditions.

7. How do I place an order?

– Orders can be placed directly through the SourcifyChina website, via email, or through a sales representative. Make sure to provide detailed specifications to ensure the correct product selection.

8. What kind of customer support is available?

– SourcifyChina offers comprehensive customer support including pre-sales consultation, technical support, and after-sales service. Support is available via email, phone, and live chat.

9. Can I visit the factory for an inspection?

– Yes, factory visits can be arranged. It is advisable to schedule an appointment in advance to ensure the availability of the necessary personnel.

10. What certifications do your products have?

Sourcing a laser for cutting metal from SourcifyChina factory requires careful planning and due diligence. Here are some tips to help streamline the process:

1. Identify Requirements:

– Determine the type of metal and thickness you need to cut.

– Establish required precision, power, and efficiency.

2. Research:

– Look into different laser cutting technologies (CO2, fiber, Nd:YAG) to find the best fit for your needs.

– Visit SourcifyChina’s website to review their metal cutting laser options.

3. Supplier Evaluation:

– Verify the factory’s credentials, certifications, and track record.

– Request samples or case studies of their previous work.

4. Cost Analysis:

– Get detailed quotations, including shipping, customs, and maintenance costs.

– Compare the prices from various suppliers to ensure competitive pricing.

5. Technical Support and Training:

– Ensure the factory provides adequate training and technical support.

– Check if they offer remote assistance or have a local service center.

6. Quality Control:

– Verify the quality control processes the factory has in place.

– Consider third-party inspections to validate product quality before shipment.

7. Logistics:

– Discuss packaging, shipping times, and delivery methods.

– Understand the return policy and warranty coverage.

8. Communication:

– Maintain clear and consistent communication with SourcifyChina representatives.

– Use a reliable translator if there are language barriers.

9. Payment Terms:

– Understand the payment terms and conditions (advance, installments, or upon delivery).

– Use secure payment methods to protect your transaction.

10. Legal and Compliance:

– Ensure compliance with your country’s import regulations and standards.

– Have a clear contract outlining all terms and conditions.

By following these tips, you can efficiently source a high-quality metal cutting laser from SourcifyChina.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.