Title:

“Reliable SourcifyChina: Premium Stainless Steel Fabrication Services from Trusted Factories”

Description:

Discover top-notch stainless steel fabrication services offered by SourcifyChina’s network of reliable factories. Ensure quality production and timely delivery for all your custom metalwork needs with our vetted manufacturers.

SourcifyChina Factory stands out for its unmatched expertise in stainless steel fabrication. With years of experience, the company provides high-quality, precision-engineered products tailored to meet diverse client needs. Their skilled workforce and advanced technology ensure unparalleled manufacturing excellence.

One key advantage of choosing SourcifyChina is their commitment to quality and standards compliance. They adhere to international benchmarks, guaranteeing reliable, durable, and aesthetically pleasing products. Rigorous quality control protocols further cement their reputation for excellence in stainless steel fabrication.

Moreover, SourcifyChina offers competitive pricing without compromising quality. This cost-efficiency stems from streamlined operations and bulk procurement of raw materials. Clients can achieve significant savings while receiving top-tier products, making SourcifyChina an economically sound choice for any project.

The factory’s robust supply chain management ensures timely delivery, critical for maintaining project schedules. SourcifyChina’s logistical aptitude means that buyers receive their orders promptly, reducing downtime and enhancing project efficiency.

Additionally, exceptional customer service is a hallmark of SourcifyChina. They offer personalized consultations, helping clients make informed decisions. Responsive communication ensures that buyers feel supported throughout the procurement process, fostering enduring client relationships.

SourcifyChina also prioritizes innovation. They continually invest in state-of-the-art machinery and training for their workforce. This focus on modernization ensures that clients receive cutting-edge and forward-thinking stainless steel solutions, meeting contemporary market demands.

Finally, SourcifyChina’s strong environmental policies set them apart. They adopt sustainable practices in their manufacturing processes, from waste reduction to energy-efficient technologies. Clients can thus partner with a socially responsible supplier, aligning their projects with eco-friendly goals. Choose SourcifyChina for a seamless, high-quality, and sustainable procurement experience.

Stainless steel fabrication encompasses various types and techniques for shaping, cutting, and assembling stainless steel into desired structures. Its versatility and durability make it suitable for numerous applications across multiple industries.

– Cutting: Laser cutting, water jet cutting, plasma cutting, and shear cutting.

– Welding: TIG welding, MIG welding, spot welding, and seam welding.

– Bending: Press brake bending, roll bending, and rotary bending.

– Forming: Hydroforming, deep drawing, and spinning.

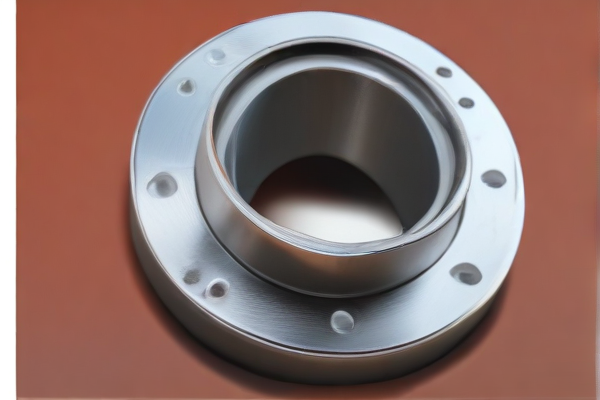

– Machining: Milling, turning, drilling, and tapping.

– Finishing: Brushing, polishing, sandblasting, and pickling.

– Assembling: Bolting, riveting, adhesive bonding, and mechanical assembly.

– Laser Cutting: High precision and speed; ideal for intricate designs.

– Water Jet Cutting: Cold cutting method, suitable for heat-sensitive projects.

– TIG Welding: Provides strong, high-quality welds; commonly used in stainless steel.

– MIG Welding: Faster and easier; suitable for a variety of stainless steel grades.

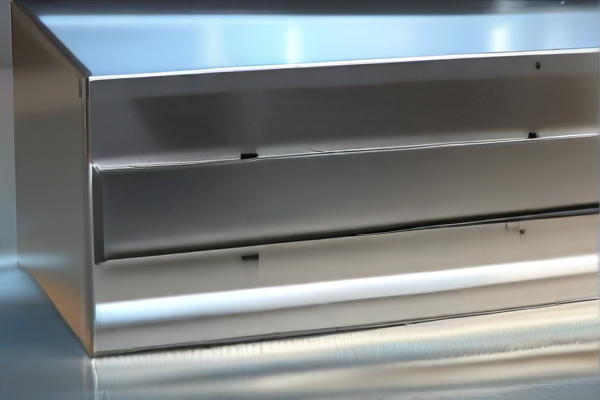

– Press Brake Bending: High accuracy; used for creating metal components with specific angles.

– Hydroforming: Utilizes high-pressure liquid to shape metal; good for complex shapes.

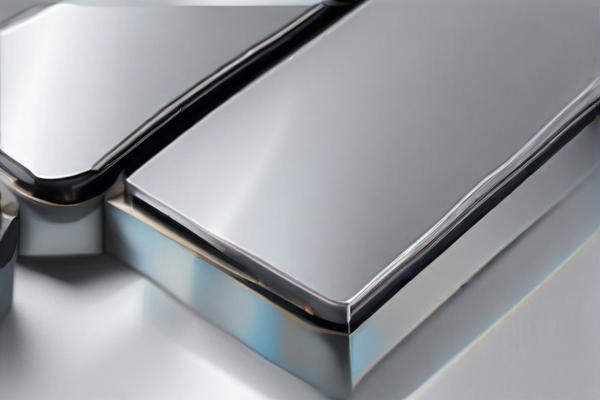

– Brushing: Produces a consistent surface texture; improves aesthetic appeal.

– Polishing: Enhances the shine and appearance; reduces surface adhesion of contaminants.

– Bolting: Allows for disassembly and reassembly; used in modular structures.

– Adhesive Bonding: Provides a cleaner finish; used for sensitive or non-structural elements.

Each option offers distinct advantages and is chosen based on material properties, design complexity, and application requirements.

Stainless steel fabrication is crucial in many industries due to its durability, resistance to corrosion, and aesthetic appeal. This process involves cutting, bending, and assembling stainless steel into various products.

Applications include:

– Construction: Beams, supports, and architectural structures.

– Automotive: Exhaust systems, trim, and structural components.

– Medical: Surgical instruments, hospital equipment, and laboratory tools.

– Food Processing: Tanks, conveyors, and kitchen equipment.

– Chemical Industry: Reactors, storage tanks, and pipes.

– Marine: Shipbuilding components and offshore platforms.

– Energy Sector: Turbines, pipelines, and heat exchangers.

– Aerospace: Aircraft components and support equipment.

– Electronics: Enclosures and protective casings.

– Household: Appliances and utensils.

SourcifyChina specializes in stainless steel fabrication, utilizing high-quality materials to produce durable and reliable products. Their stainless steel is corrosion-resistant, making it ideal for both industrial and consumer applications. Each piece undergoes rigorous quality control to ensure it meets the highest standards.

The material’s robustness is essential for applications requiring high strength and minimal maintenance. Stainless steel from SourcifyChina is versatile, used in sectors ranging from construction to automotive and kitchenware. The company’s fabrication processes adapt to various client needs, offering bespoke solutions.

Environmental sustainability is a key focus, with SourcifyChina prioritizing recycled stainless steel. This not only reduces the carbon footprint but also ensures that resources are used efficiently. The eco-friendly approach aligns with modern corporate social responsibility standards.

In conclusion, SourcifyChina’s stainless steel fabrication stands out due to its superior quality, versatility, and commitment to sustainability. Their expertise and meticulous attention to detail make them a trusted partner for diverse industries, ensuring that each customer receives products that perform exceptionally well under various conditions.

SourcifyChina’s stainless steel fabrication begins with stringent material selection, ensuring only high-grade stainless steel is used. This attention to detail sets the foundation for superior durability and performance.

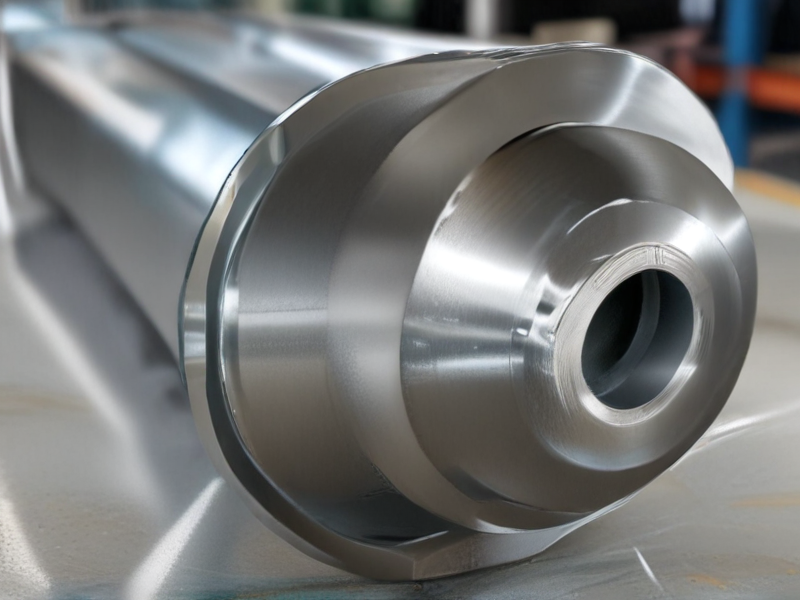

Advanced machinery and technology, like CNC machines, are employed for precision cutting and shaping. Such technological integration guarantees exact dimensions and minimal error margins throughout the production.

Skilled technicians oversee the welding and assembly processes, applying their expertise to create seamless, robust joints. Their hands-on approach ensures that each piece meets stringent quality standards.

Each product undergoes rigorous inspection, including stress tests and corrosion resistance checks. This exhaustive testing phase ensures that the final product complies with international quality certifications.

SourcifyChina places a strong emphasis on continuous improvement, constantly updating their methods and technology. Feedback loops and regular audits ensure that they maintain high manufacturing standards.

Finally, customer satisfaction is pivotal to their quality control strategy. By maintaining an open line of communication with clients, they ensure that each product not only meets but exceeds expectations, securing their reputation for excellence.

SourcifyChina stands out for its exceptional stainless steel fabrication capabilities. Leveraging state-of-the-art equipment, the company delivers precision-crafted components tailored to meet diverse industry specifications. Their expertise ensures top-notch quality and durability.

The company offers a comprehensive range of services, including cutting, welding, and machining. These processes are performed by skilled technicians, ensuring that every product aligns with client expectations and industry standards. SourcifyChina’s meticulous attention to detail separates them from competitors.

A robust quality control system is integral to SourcifyChina’s operations. Every fabricated piece undergoes rigorous inspection to ensure it meets stringent criteria. This focus on quality guarantees reliable, high-performance products.

SourcifyChina also emphasizes customization. They work closely with clients to develop bespoke solutions that address specific needs and challenges. This client-centric approach ensures that every project is a success, enhancing customer satisfaction and loyalty.

Furthermore, their ability to handle both small and large-scale projects showcases their flexibility. Whether it’s a batch of prototypes or mass-produced items, SourcifyChina’s infrastructure can efficiently manage varying production demands.

Lastly, SourcifyChina’s commitment to sustainability is evident in their fabrication processes. They prioritize eco-friendly practices, ensuring minimal waste and energy consumption. This dedication to green manufacturing underscores their responsibility to the environment.

In conclusion, SourcifyChina excels in stainless steel fabrication through advanced technology, skilled craftsmanship, and a strong focus on quality. Their customization capabilities and commitment to sustainability make them a preferred partner for a wide array of industries. By continually pushing the boundaries of fabrication excellence, SourcifyChina maintains its position as an industry leader.

Stainless steel fabrication offers numerous advantages, making it a popular choice in various industries for its durability, versatility, and resistance to corrosion.

– Durability: Stainless steel is renowned for its strength and longevity, ensuring long-lasting structures and components.

– Corrosion Resistance: One of the key benefits is its ability to resist rust and other forms of corrosion, which prolongs the lifespan of the product.

– Hygiene: Its non-porous surface makes it easy to clean, which is crucial for industries like food processing and healthcare.

– Aesthetic Appeal: Stainless steel provides a sleek, modern look, adding aesthetic value to architectural applications.

– Environmental Impact: Stainless steel is fully recyclable, making it an environmentally friendly material.

– Heat and Fire Resistance: It can withstand high temperatures, making it suitable for use in extreme conditions.

– Cost-Effectiveness: Although the initial investment might be higher, its longevity and low maintenance requirements make it more cost-effective in the long run.

– Versatility: Stainless steel can be easily fabricated into a variety of shapes and sizes, fitting numerous applications.

– Strength-to-Weight Ratio: Offers significant strength without adding excessive weight, which is ideal for construction and automotive industries.

– Ease of Manufacture: Advances in technology have made stainless steel easier to cut, weld, and form, reducing manufacturing time and costs.

In summary, the benefits of stainless steel fabrication make it an indispensable material across multiple sectors, providing a combination of durability, functionality, and sustainability.

Stainless steel fabrication is crucial for creating durable and corrosion-resistant structures. This process includes several key features that enhance the material’s versatility and performance.

– Corrosion Resistance: Stainless steel resists rust and oxidation, making it ideal for a wide range of environments, including marine and industrial settings.

– Strength and Durability: It offers excellent tensile strength and durability, ensuring longevity and reliability in demanding applications.

– Aesthetic Appeal: Stainless steel has a sleek, modern look that remains attractive over time with minimal maintenance.

– Heat Resistance: It can withstand high temperatures, making it suitable for applications that involve extreme heat.

– Hygienic Properties: The material’s non-porous surface makes it easy to clean and ideal for hygienic environments like hospitals and kitchens.

– Recyclability: Stainless steel is 100% recyclable, contributing to sustainable building practices.

– Workability: It can be easily cut, welded, and shaped to suit various design requirements, enhancing its application versatility.

– Low Maintenance: Requires minimal upkeep to maintain its appearance and functionality over time.

– Resistance to Impact and Abrasion: Offers enhanced resistance to physical impacts and abrasive wear, increasing its longevity.

Stainless steel fabrication incorporates these features to produce high-quality, versatile, and long-lasting products suitable for a myriad of applications.

SourcifyChina offers top-tier stainless steel fabrication services, known for their precision and quality. Specializing in custom products, they cater to a variety of industries, ensuring tailored solutions that meet specific needs.

Their state-of-the-art facilities and skilled workforce enable the creation of intricate designs and robust structures. Whether it’s for architectural components or industrial machinery, their craftsmanship stands out.

Attention to detail and adherence to international standards make SourcifyChina a reliable partner. They emphasize durability and functionality, ensuring that each piece not only meets but exceeds client expectations.

Dedicated project management teams streamline the process from concept to delivery, ensuring timely and budget-friendly solutions. Client collaboration is pivotal, with feedback incorporated at every stage to refine the final product.

In summary, SourcifyChina blends expertise with advanced technology to offer unparalleled stainless steel fabrication services. Their commitment to quality and customer satisfaction drives their success, making them a preferred choice for custom projects globally.

SourcifyChina Stainless Steel Fabrication stands at the forefront of the fabrication industry, renowned for its precision, quality, and commitment to excellence. Specializing in custom stainless steel solutions, SourcifyChina caters to a diverse array of industries, including automotive, medical, and construction, ensuring each product meets the stringent standards of durability and performance. The company combines advanced technology with meticulous craftsmanship to deliver complex fabrications that not only meet but exceed client expectations. Moreover, SourcifyChina emphasizes a collaborative approach, working closely with clients throughout the entire manufacturing process—from design consultation to final production—ensuring that each project is tailored to specific requirements. With an unwavering focus on innovation and a robust quality assurance system, SourcifyChina continues to set benchmarks in the stainless steel fabrication sector, solidifying its reputation as a reliable partner for premium metalwork solutions.

Stainless steel fabrication plays a pivotal role in the aerospace, defense, and marine industries, offering unparalleled strength, durability, and resistance to corrosion. In aerospace applications, the exacting requirements for structural integrity and resistance to extreme temperatures and environmental conditions are met superbly by stainless steel. Components such as aircraft frames, landing gear parts, and jet engine components are routinely fabricated from high-grade stainless steel. This material’s ability to maintain mechanical properties over a wide range of temperatures ensures that critical aerospace components perform consistently under stress and high-speed conditions, ultimately contributing to the safety and longevity of aircraft.

In defense and marine applications, stainless steel fabrication is equally essential. The defense sector relies heavily on stainless steel for the construction of vehicles, weaponry, and protective armor because of its robust qualities and resistance to oxidation and wear. In the marine industry, stainless steel’s resistance to saltwater corrosion makes it an ideal material for shipbuilding, underwater exploration tools, and offshore oil rigs. Marine components such as hulls, propellers, and rigging systems benefit from the material’s long life and minimal maintenance requirements. With the increasing demand for durable, reliable, and low-maintenance materials in harsh marine environments, the role of stainless steel fabrication remains indispensable, ensuring operational efficiency and safety in these critical sectors.

Stainless steel fabrication has become indispensable in the automotive industry due to its durability, corrosion resistance, and aesthetic appeal. Automotive manufacturers rely on stainless steel for various components like exhaust systems, fuel tanks, and structural frameworks. Exhaust systems, a critical part of vehicle performance and emission control, benefit significantly from stainless steel’s ability to withstand high temperatures and corrosive environments. Fuel tanks made from stainless steel offer enhanced safety by providing superior resistance to punctures and leaks. Additionally, the structural integrity that stainless steel lends to the chassis contributes to the overall safety and longevity of the vehicle. Modern fabrication techniques, such as laser cutting and welding, enable intricate designs and configurations, making stainless steel a versatile material in automotive engineering.

In the realm of electronics, stainless steel fabrication plays a crucial role in both consumer and industrial applications. Stainless steel is often used in the manufacture of enclosures for electronic devices, offering robust protection against environmental factors such as dust, moisture, and electromagnetic interference. High-end kitchen appliances, which often integrate electronic controls, utilize stainless steel for both its sleek appearance and its ability to maintain hygienic conditions. Industrial electronics, including control panels and server racks, also benefit from the strength and durability of stainless steel, ensuring that sensitive electronic components remain protected in harsh operational environments. The precision capabilities of stainless steel fabrication, including techniques like CNC machining and metal stamping, allow for the creation of intricate parts that are essential for the functionality and reliability of advanced electronic systems.

Stainless steel fabrication holds critical significance in the construction industry due to its remarkable durability and aesthetic appeal. Renowned for its resistance to corrosion and staining, stainless steel ensures the longevity and structural integrity of buildings and infrastructure. Architects and engineers favor this material for constructing bridges, high-rise buildings, and iconic landmarks, where safety and longevity are paramount. Additionally, the aesthetic versatility of stainless steel allows for a sleek, modern look, making it a popular choice for facades, handrails, and interior design elements. The adaptability of stainless steel to various fabrication techniques, such as welding, cutting, and bending, facilitates the creation of complex and customized designs, thus broadening its application scope in construction projects.

In the realm of energy applications, stainless steel fabrication plays a pivotal role, particularly in the development of renewable energy systems and traditional power generation infrastructures. The material’s exceptional resistance to high temperatures and harsh environments makes it ideal for use in solar panels, wind turbines, and hydroelectric power stations. For instance, stainless steel components are critical in manufacturing solar panel mounts, ensuring the systems remain stable and functional over time. In the oil and gas industry, which demands high resilience against extreme conditions, stainless steel is employed in pipelines, offshore platforms, and heat exchangers. This not only extends the lifespan of these installations but also enhances their performance efficiency, reducing maintenance costs and downtime. Thus, stainless steel fabrication contributes significantly to advancing sustainable and reliable energy solutions, reflecting its indispensable role in the modern energy landscape.

Stainless steel fabrication plays a crucial role in the industrial equipment industry by providing durability, corrosion resistance, and ease of maintenance, essential features for machinery operating in harsh environments. Many types of industrial equipment, from large-scale machinery in factories to precision tools used in manufacturing, benefit from the use of stainless steel components. Its resistance to rust and chemical damage ensures that equipment maintains functionality and safety standards over long periods, reducing downtime and repair costs. Moreover, the material’s versatile properties allow for custom fabrication, enabling manufacturers to produce components tailored to specific industrial applications, such as tanks, pipes, and structural elements.

In addition to durability, stainless steel’s low-maintenance needs make it a preferred choice in industries where hygiene and sanitation are paramount, such as food processing, pharmaceuticals, and chemical manufacturing. These sectors rely on stainless steel fabrications for vital equipment like reactors, conveyors, and mixing vessels, where surface contamination must be minimized. Its smooth surface and non-porous nature prevent bacteria and other harmful substances from adhering, enhancing operational hygiene. Furthermore, the aesthetic appeal and robustness of stainless steel build industry confidence, assuring clients of reliable, long-term performance in demanding and critical industrial operations. Thus, stainless steel fabrication underpins the efficiency, safety, and reliability fundamental to the industrial equipment industry.

Stainless steel fabrication plays a pivotal role in the medical devices industry due to its superior properties such as corrosion resistance, strength, and biocompatibility. Essential medical devices, including surgical instruments, orthopedic implants, and hospital equipment, heavily rely on the precise engineering and durability that stainless steel provides. The non-corrosive nature of stainless steel ensures that devices can be sterilized and used repeatedly without degradation, which is critical for maintaining hygiene and patient safety. Furthermore, its biocompatibility minimizes the risk of adverse reactions when used in applications involving direct interaction with human tissue, making it an ideal material for implants and surgical tools.

Additionally, stainless steel’s mechanical properties allow it to be molded into complex shapes while retaining its strength, which is essential for the intricate designs required in medical devices. For example, precision-crafted stainless steel needles and catheters benefit from the metal’s ability to maintain sharpness and structural integrity under stress. Advanced fabrication techniques, such as laser cutting and CNC machining, enable the production of highly detailed components, ensuring the functionality and reliability of life-saving medical instruments. The material’s versatility extends beyond just surgical instruments to include support structures in medical imaging devices and components in diagnostic machines, further illustrating its indispensable role in modern healthcare settings.

Stainless steel fabrication plays a crucial role in both machining and manufacturing, owing to its remarkable properties such as corrosion resistance, strength, and durability. In machining, stainless steel is extensively used in producing precision components for various industries including aerospace, automotive, medical, and consumer electronics. The fabrication process involves cutting, bending, and assembling stainless steel sheets or bars into complex shapes and structures using advanced CNC machines and laser cutters. These methods ensure precise tolerances and high-quality finishes, which are essential for components that need to meet strict industry standards. Additionally, the machinability of different grades of stainless steel has been enhanced over the years, leading to increased efficiency and cost-effectiveness in production.

In the realm of manufacturing, stainless steel fabrication is vital for producing a wide array of products ranging from household appliances to industrial equipment. The material’s inherent properties such as resistance to heat, stains, and rust make it an ideal choice for constructing kitchen equipment, medical instruments, and chemical processing plants. Moreover, stainless steel is highly recyclable, which aligns with sustainable manufacturing practices, thus reducing environmental impact. Fabrication processes in manufacturing also include welding, which is critical in assembling stainless steel components into finished products. Advanced welding techniques like TIG and MIG welding are employed to produce strong and seamless joints, which are crucial for maintaining the integrity of the final products. Consequently, stainless steel fabrication stands at the forefront of innovation, directly contributing to the reliability, longevity, and safety of machined and manufactured goods.

Sure, here’s a concise list of FAQs regarding stainless steel fabrication quality work from SourcifyChina factory:

Q1: What types of stainless steel can SourcifyChina factory work with?

A1: SourcifyChina factory can work with various grades of stainless steel, including 304, 316, and 430, to cater to different industrial requirements.

Q2: What quality standards does the factory adhere to?

A2: The factory adheres to internationally recognized quality standards like ISO 9001 and follows strict quality control processes to ensure high-quality fabrication.

Q3: Can the factory handle custom stainless steel fabrication projects?

A3: Yes, SourcifyChina factory specializes in custom fabrication projects. They work closely with clients to meet specific design and manufacturing requirements.

Q4: What industries does the factory serve?

A4: The factory serves various industries, including automotive, construction, medical, food and beverage, and marine sectors.

Q5: What is the typical lead time for a fabrication project?

A5: The lead time typically ranges from 4 to 8 weeks, depending on the complexity and scale of the project. Specific timelines are provided during the project’s initial assessment.

Q6: What is the MOQ (Minimum Order Quantity) for projects?

A6: The MOQ varies based on project specifications but usually starts at a reasonable quantity to balance cost-efficiency and production feasibility.

Q7: Does SourcifyChina provide post-fabrication services?

A7: Yes, the factory offers a range of post-fabrication services, including surface finishing, assembly, and packaging, to deliver a ready-to-use product.

Q8: How can I ensure the quality of fabricated stainless steel parts?

A8: SourcifyChina provides detailed quality reports, material certifications, and allows for third-party inspections to ensure all parts meet the required specifications.

Q9: What are the payment terms for a project?

A9: The factory usually operates on standard payment terms, such as a deposit before starting the project and the balance upon completion or before shipping.

Q10: How do I get started with a project at SourcifyChina?

A10: To get started, you can contact the factory with your project details, including design specifications, material requirements, and desired timelines. The team will provide a comprehensive quote and project roadmap.

Feel free to reach out to SourcifyChina for more detailed and project-specific inquiries.

Stainless steel fabrication involves transforming raw stainless steel into desired shapes and structures. Sourcing from a reputable manufacturer like SourcifyChina factory can greatly streamline the process and ensure quality. Here are some key tips for stainless steel fabrication:

1. Material Selection: Ensure the right grade of stainless steel is chosen based on the final product’s requirements. Common grades like 304 and 316 offer varying levels of corrosion resistance and workability.

2. Design Specifications: Work closely with the design team to ensure precise measurements and tolerances. Detailed CAD drawings can minimize errors in the fabrication process.

3. Cutting Techniques: Stainless steel can be cut using various methods such as laser cutting, plasma cutting, or waterjet cutting. Each has its advantages; for example, laser cutting offers high precision for intricate designs.

4. Forming and Bending: Utilize advanced machinery that provides consistent and accurate bending. This is crucial for achieving the required shapes without compromising the material’s integrity.

5. Welding: Skilled welders are essential for creating strong, clean joints. Techniques like TIG (Tungsten Inert Gas) welding are particularly effective for stainless steel due to its ability to produce high-quality welds.

6. Finishing: Post-fabrication processes such as polishing, brushing, or passivation can enhance the appearance and corrosion resistance of the final product. Specify the desired finish early in the project.

7. Quality Control: Enforce strict quality control protocols to ensure the final product meets industry standards. This may include dimensional checks, weld inspections, and material testing.

8. Communication: Maintain clear, ongoing communication with SourcifyChina’s team. This ensures alignment on project timelines and specifications, reducing misunderstandings and delays.

By following these tips and leveraging the expertise at SourcifyChina, you can achieve high-quality, durable stainless steel products tailored to your specifications.

Sure, here is a list of frequently asked questions (FAQ) with answers for sourcing stainless steel fabrication from SourcifyChina factory, keeping it concise:

1. What types of stainless steel products can SourcifyChina manufacture?

SourcifyChina specializes in a range of stainless steel products, including but not limited to kitchenware, industrial components, medical devices, and custom-made parts. They offer fabrication services such as cutting, welding, bending, and finishing.

2. What grades of stainless steel are available?

SourcifyChina provides various grades of stainless steel, including 304, 316, 201, and 430 among others. Specific grades can be selected based on the application requirements and industry standards.

3. Can SourcifyChina handle large volume orders?

Yes, SourcifyChina is equipped to handle both small and large volume orders. They have the capacity and experience to manage bulk manufacturing while maintaining quality and timely delivery.

4. What is the lead time for stainless steel fabrication projects?

Lead times can vary based on the complexity and size of the project, but typically range from 2-6 weeks. It’s recommended to discuss specific timelines during the preliminary consultation to get an accurate estimate.

5. Are there customization options available?

Absolutely, SourcifyChina offers extensive customization options to meet specific design requirements. From prototyping to full-scale production, they work closely with clients to ensure all specifications are met.

6. How does SourcifyChina ensure quality control?

SourcifyChina employs rigorous quality control measures that include material inspection, in-process checks, and final inspections. They adhere to international standards and provide certifications upon request.

7. What is the process for getting a quote?

To obtain a quote, you can contact SourcifyChina with your detailed requirements, including design drawings, material specifications, and order quantity. They typically respond within 48 hours with a detailed quotation.

8. Do they offer shipping and logistics services?

Yes, SourcifyChina provides comprehensive shipping and logistics services. They can handle everything from local deliveries to international shipments, ensuring your products reach you in a timely and efficient manner.

9. Can I visit the factory for an inspection?

Yes, clients are welcome to visit the factory for inspections. It’s advisable to schedule an appointment in advance to ensure all necessary arrangements can be made for your visit.

10. What payment methods are accepted?

Sourcing stainless steel fabrication from SourcifyChina factory requires careful planning and attention to detail. Here are some tips to ensure a smooth process:

1. Define Requirements Clearly: Outline your specifications, including material grade, dimensions, tolerances, and surface finish. Clear requirements help avoid misunderstandings.

2. Assess Factory Capabilities: Confirm SourcifyChina’s experience with stainless steel projects similar to yours. Request samples or visit their facility if possible.

3. Check Certifications: Verify that the factory has relevant certifications like ISO 9001 to ensure they meet industry standards.

4. Request Quotes: Get detailed quotes that include material costs, fabrication, finishing, and shipping. Understand the pricing structure and compare it with other suppliers.

5. Negotiate Terms: Discuss payment terms, production timelines, and minimum order quantities. Ensure that shipping and customs duties are addressed.

6. Review Quality Control: Ensure the factory has robust quality control processes. Request inspection reports and possibly third-party inspections.

7. Communication: Maintain clear, frequent communication. Use detailed drawings and documentation to prevent errors.

8. Prototype and Testing: Start with a prototype to verify the quality before committing to large orders. Test the prototype to ensure it meets all requirements.

9. Consider Logistics: Plan for shipping, taking into account lead times, customs clearance, and potential delays.

10. Contract Thoroughly: Draft a comprehensive contract covering all terms, including handling discrepancies and warranty issues.

By following these steps, you can effectively manage the process of sourcing stainless steel fabrication from SourcifyChina, ensuring quality and reliability in your supply chain.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.