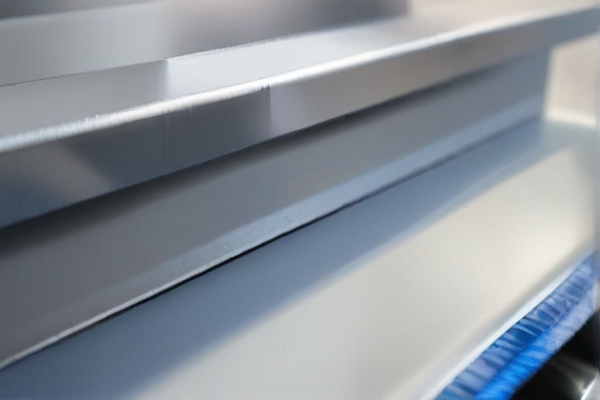

Reliable Source for Metal Fabrication: SourcifyChina Specializes in Precise Bending of Sheet Metal from Trusted Factories

At SourcifyChina, we connect you to dependable factories that excel in the precise bending of sheet metal, ensuring high-quality fabrication and reliable sourcing for your manufacturing needs.

Choosing SourcifyChina Factory for your bending sheet metal needs from China ensures exceptional quality and precision. Their cutting-edge technology and skilled workforce produce top-tier products meticulously tailored to your specifications, enhancing your project’s overall efficiency.

SourcifyChina Factory’s strategic location within China’s industrial heartland provides quick access to raw materials, ensuring seamless supply chains and faster turnaround times. This reduces lead times and helps you meet tight deadlines.

The factory’s rigorous quality control processes guarantee that each sheet metal piece adheres to international standards. Comprehensive inspections and testing protocols minimize defects, delivering reliable, durable, and high-performing components.

Their customer-centric approach offers unparalleled support throughout the purchasing process. Proactive communication and a dedicated team ensure your requirements are understood and met, fostering strong partnerships and satisfaction.

Competitive pricing from SourcifyChina Factory makes them an economical choice without compromising on quality. Their efficient operations and economies of scale translate to cost savings, making high-quality sheet metal products accessible within your budget.

Innovation drives SourcifyChina Factory, with continual investment in advanced machinery and technology. This commitment keeps them at the forefront of industry trends, providing you with cutting-edge solutions and maintaining a competitive edge.

Environmental sustainability is a priority at SourcifyChina Factory. Eco-friendly practices, such as waste reduction and energy-efficient production methods, align with global efforts to minimize ecological impact, appealing to environmentally conscious buyers.

In conclusion, SourcifyChina Factory’s blend of precision, location advantages, strict quality control, exceptional customer service, competitive pricing, innovation, and sustainability makes them the ideal partner for your sheet metal needs. Choosing them ensures you receive top-quality products tailored to your specifications, supported by a reliable and committed team, ultimately driving your success.

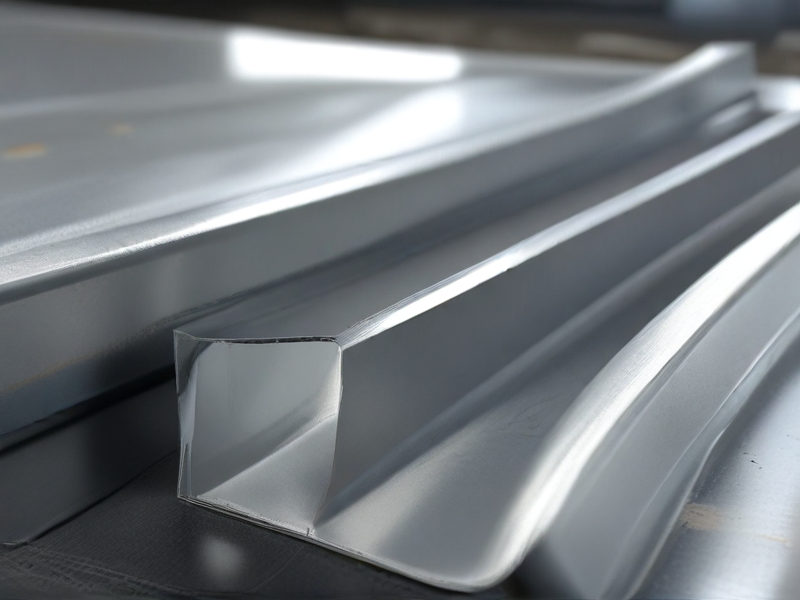

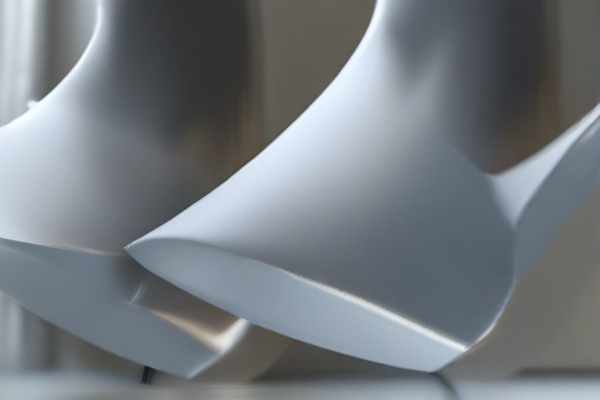

Bending sheet metal is a crucial process in metalworking that involves deforming metal to achieve the desired shape. This is usually done through various techniques depending on the metal’s properties and the required outcome.

– Air Bending: Utilizes a punch and die, where the metal doesn’t touch the die completely, allowing for various angles.

– Bottoming: The metal is pressed into the die completely, creating precise bends and angles.

– Coining: Similar to bottoming, but it exerts higher pressure to imprint the die’s shape precisely into the metal.

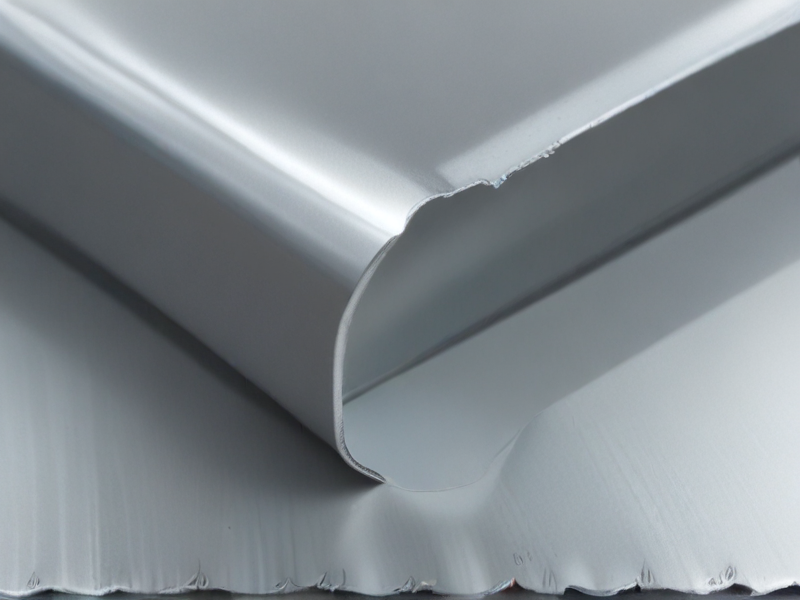

– Roll Bending: The sheet metal is passed through a series of rollers to achieve curved shapes.

– Wipe Bending: The sheet is held by a pressure pad and bent using a wipe die.

– Rotary Bending: Uses a rocker-type tool to create bends without any die marks.

– V-Bending: Employs a V-shaped punch and die to form simple, angular bends.

– Edge Bending: Involves bending the edge of the sheet around a radius using specialized tooling.

– U-Bending: Uses U-shaped tools to achieve a consistent, U-shaped bend.

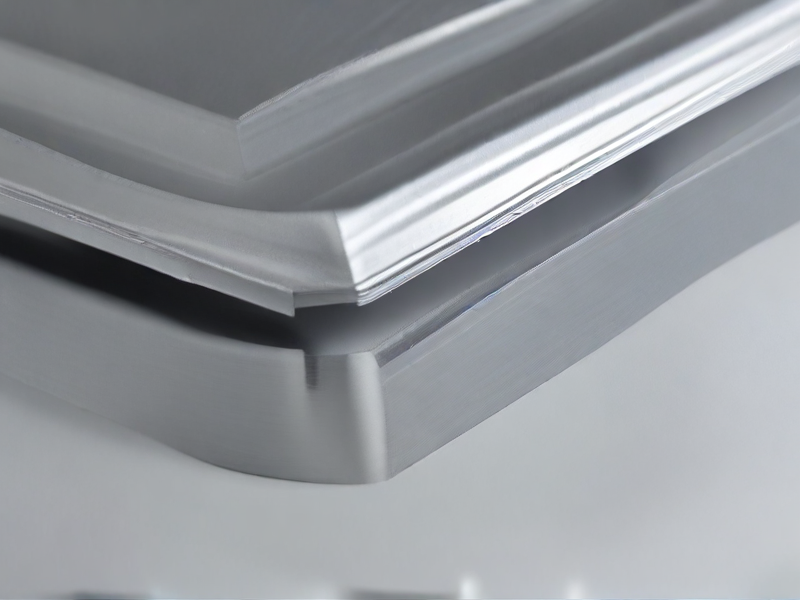

– Hemming: Bends the edge of the sheet back upon itself to strengthen it.

– Folding: Utilizes a folding machine that clamps the metal and lifts it to create a precise bend.

– Mandrel Bending: Inserts a mandrel inside the tube for preventing collapse during bending.

– Elastomer Bending: Utilizes a rubber pad to distribute the bending force evenly.

Options for equipment include manual, hydraulic, and CNC-controlled machines, varying in precision and automation. Advanced software aids in simulation and design, ensuring accurate results with minimal errors.

Bending sheet metal is essential in manufacturing sectors, enabling the creation of complex shapes and structures. It finds significant applications across various industries due to its versatility and strength.

– Automotive Industry: Used in the production of car bodies, panels, and structural components.

– Aerospace: Vital for creating aircraft fuselages, wings, and other critical parts.

– Construction: Utilized in building frameworks, roofing panels, and architectural features.

– Electronics: Integral for making enclosures, chassis, and heat sinks.

– Household Appliances: Shapes casings and internal components of washers, dryers, and refrigerators.

– Furniture Manufacturing: Forms metal frameworks for desks, chairs, and beds.

– HVAC Systems: Constructs ductwork, vents, and connection pieces.

– Marine Industry: Crafts hulls, decks, and structural elements of ships and submarines.

– Medical Devices: Essential for creating durable and sterile casings for medical equipment.

– Signage and Displays: Shapes metal for durable and visually appealing signs and displays.

– Agricultural Equipment: Forms parts for tractors, plows, and harvesters.

– Military and Defense: Develops robust structures for vehicles and weaponry.

– Tool and Die Making: Produces precise and durable parts for tooling and dies.

– Transportation Industry: Shapes parts for trains, buses, and other public transit vehicles.

– Energy Sector: Constructs components of wind turbines, solar panels, and electrical enclosures.

– Food Processing Equipment: Helps manufacture hygienic and sturdy machinery for food production.

– Oil and Gas Industry: Used in making offshore rigs and pipeline components.

– Recreational Equipment: Essential for producing bikes, playgrounds, and sporting goods.

– Art and Sculptures: Allows artists to create intricate and sturdy metal sculptures.

– Packaging: Shapes metal containers for storing and transporting goods securely.

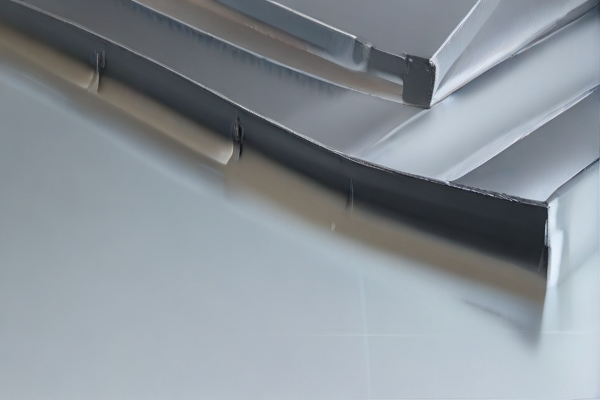

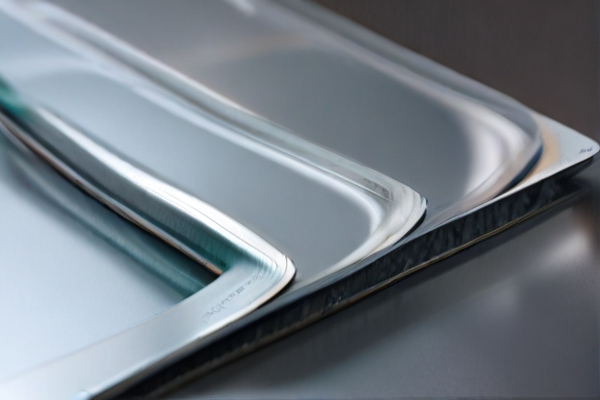

SourcifyChina specializes in bending various types of sheet metal, employing materials like stainless steel, aluminum, and galvanized steel. These metals offer excellent durability and resistance to corrosion, making them ideal for various industrial applications.

Stainless steel provides a high level of strength and longevity, perfect for use in harsh environments. Its resistance to rust and corrosion ensures a longer lifecycle for parts and components, which is crucial for long-term projects.

Aluminum is favored for its lightweight nature and high strength-to-weight ratio. This material is widely used in the aerospace and automotive industries due to its excellent conductivity and malleability.

Galvanized steel, with its protective zinc coating, offers enhanced resistance to rust and corrosion. This makes it suitable for outdoor applications, including construction and electrical installations, where durability is essential.

By utilizing these versatile materials, SourcifyChina ensures that their bending sheet metal services meet the diverse needs of their customers. Their expertise in handling these metals allows them to produce high-quality, custom-fabricated parts that are both durable and reliable.

SourcifyChina’s bending sheet metal quality control process begins with the raw materials inspection. Only high-grade metals are selected, ensuring that the final product meets stringent durability and performance criteria.

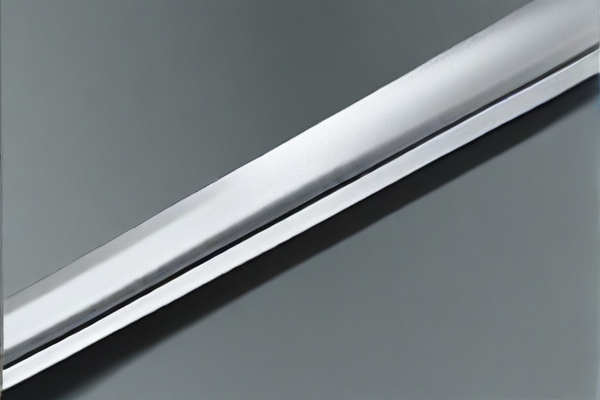

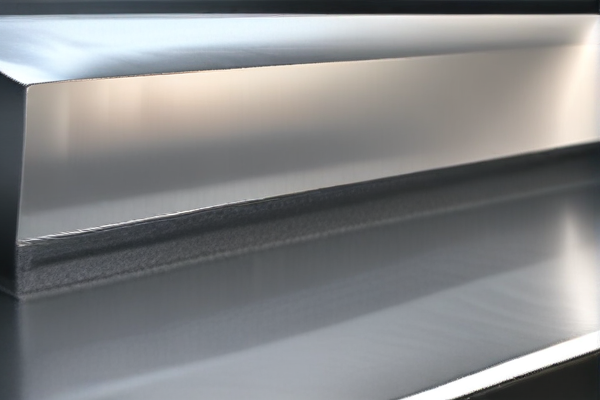

Next, precision machinery is utilized for bending operations. The state-of-the-art equipment is regularly calibrated and maintained, reducing variations and ensuring consistent dimensions and angles across all pieces.

Skilled technicians continually monitor the bending process. They verify measurements and angles at multiple stages, making real-time adjustments to address any discrepancies immediately, thereby preventing defects.

Each bent sheet metal piece undergoes a thorough inspection for surface quality. This includes checking for scratches, dents, and blemishes, ensuring that only flawless pieces proceed to the next stage.

Non-destructive testing methods, such as ultrasonic and X-ray inspections, are employed to detect internal flaws. This ensures that even hidden defects are identified and rectified before the product reaches the customer.

Furthermore, dimensional accuracy is verified using advanced metrology tools. These tools measure the components against design specifications to ensure exact fit and functionality in their intended application.

In the final stage, all parts are assembled and tested under simulated working conditions. This helps confirm that the sheet metal components perform as expected within their designated applications.

The comprehensive quality control process at SourcifyChina not only adheres to international standards but also integrates continuous improvement practices. Feedback loops allow for constant refinement of processes based on past performance data, ensuring consistently high-quality output.

By implementing a multi-faceted quality control approach, SourcifyChina ensures that every bent sheet metal piece meets the highest standards of excellence. This thoroughness enhances customer satisfaction and maintains the company’s reputation for delivering superior products.

SourcifyChina excels in bending sheet metal, employing state-of-the-art technologies to ensure precision and quality. Their advanced machinery can handle various metals, including steel, aluminum, and copper. This versatility allows them to cater to diverse industries.

Their skilled workforce is a crucial asset, meticulously programming and configuring bending machines to achieve accurate results every time. This expertise ensures consistent, high-quality products, meeting stringent client specifications. SourcifyChina’s commitment to training its personnel further enhances their capabilities.

SourcifyChina prioritizes efficiency in their operations. By integrating automation with traditional craftsmanship, they optimize production timelines without sacrificing quality. This approach makes them a reliable partner for time-sensitive projects, adding value through swift delivery.

Furthermore, quality control is a cornerstone of SourcifyChina’s bending sheet metal capabilities. They employ rigorous inspection protocols at every production stage to ensure each piece meets required standards. This commitment to quality is evident in the durability and precision of their finished products.

Lastly, SourcifyChina offers flexible, customized solutions, adapting their bending processes to meet specific client needs. Their engineering team collaborates closely with customers, providing tailored solutions that ensure both functionality and aesthetic appeal. By focusing on client satisfaction and product excellence, SourcifyChina continues to set industry standards in sheet metal bending.

Bending sheet metal offers numerous advantages in manufacturing and construction, enhancing both the functionality and aesthetic appeal of metal components.

– Versatility: Bending allows the creation of complex shapes and designs, accommodating various industrial needs.

– Cost-Effective: Reduces the need for additional components and assembly, saving on material and labor costs.

– Strength: Enhances structural integrity, making components more robust and durable.

– Accuracy: Advanced machinery ensures precise bends, leading to high-quality, consistent results.

– Efficiency: Faster production times due to streamlined processes, improving overall productivity.

– Customization: Easily adaptable to different specifications, allowing for tailored solutions.

– Material Optimization: Minimizes waste, promoting more sustainable manufacturing practices.

– Improved Aesthetics: Provides smooth, clean lines for better visual appeal.

– Reduced Welding: Less need for welding joints, lowering the risk of weak spots.

– Maintenance: Simplifies assembly and disassembly, facilitating easier maintenance and repairs.

By incorporating sheet metal bending, industries can achieve enhanced efficiency, cost savings, and improved product performance.

Sheet metal bending involves manipulating sheet metal into various shapes, typically using tools like press brakes or rollers. This process has several critical features:

– Versatility: Sheet metal bending can create diverse shapes, from simple bends to complex forms.

– Precision: Advanced machines allow for highly accurate bends, essential for high-tolerance applications.

– Material Efficiency: Minimizes material waste compared to cutting or welding.

– Cost-Effective: Largely automated processes reduce labor costs.

– Strength Retention: Maintains the strength and integrity of the metal.

– Customization: Capable of handling small to large production runs with adjustments for specific requirements.

– Speed: Automated equipment ensures quick turnaround times.

– Surface Quality: Ensures smooth finishes without compromising the material.

Understanding these features is essential for industries like automotive, aerospace, and construction where precision and efficiency are paramount.

SourcifyChina specializes in providing custom sheet metal bending solutions tailored to various industrial needs. With state-of-the-art machinery, they ensure precision and quality in every project, meeting specific client requirements.

Clients from sectors like automotive, aerospace, and construction turn to SourcifyChina for their metal bending needs. Their ability to work with various metals, including aluminum and stainless steel, provides flexibility for diverse applications.

In addition to standard bend angles, SourcifyChina excels in complex geometries, enabling unique project designs. Their expert team collaborates closely with clients, offering advice and adjustments to achieve optimal results.

Quality assurance is a top priority for SourcifyChina. Every finished product undergoes rigorous inspections to ensure it meets industry standards and customer expectations. This commitment to excellence has earned them a solid reputation in the market.

Customer satisfaction is at the heart of SourcifyChina’s operations. From initial consultation to final delivery, they maintain open communication, ensuring each project is completed on time and within budget. This dedication to service makes them a trusted partner in metal bending solutions.

SourcifyChina is a leading company specializing in the bending and fabrication of sheet metal, leveraging advanced technologies and a wealth of expertise to deliver high-quality solutions tailored to diverse customer needs. Located in the industrial heartland of China, the company prides itself on its precision engineering and commitment to excellence. Their services encompass a wide array of metalworking processes including CNC precision bending, laser cutting, and welding, making them a one-stop-shop for businesses seeking reliable and customizable metal fabrication services. SourcifyChina serves a global clientele across various industries such as automotive, electronics, construction, and aerospace, ensuring that each project meets stringent international standards. With a team of experienced engineers and state-of-the-art machinery, the company is capable of transforming complex designs into meticulously crafted products, ensuring durability and precision with every piece. Sustainability and innovation are central to SourcifyChina’s business philosophy, driving them to adopt environmentally friendly practices while continuously enhancing their technical capabilities. This commitment to quality and customer satisfaction has solidified their reputation as a trusted partner in the sheet metal fabrication industry.

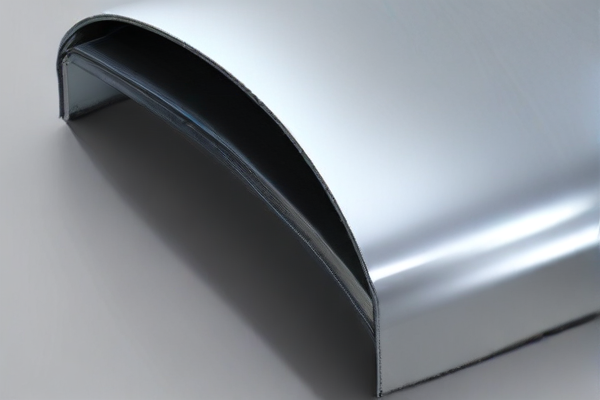

Bending sheet metal is a crucial process in the aerospace industry, as it allows for the creation of complex, yet lightweight, structural components essential for aircraft and spacecraft. Techniques like brake forming, roll bending, and hydroforming are commonly employed to shape sheet metal into fuselage panels, wing ribs, and other aerodynamic surfaces, ensuring they meet the industry’s stringent strength-to-weight requirements. The precision and consistency achieved in bending are critical to maintaining the structural integrity and performance of aerospace components, which must withstand extreme temperatures, pressures, and mechanical stresses during flight operations.

In the defense and marine sectors, bending sheet metal is equally vital for fabricating durable and resilient structures. In defense, it is used to manufacture armored vehicle parts, missile components, and various other military hardware that require superior strength and resistance to harsh environments. The ability to bend high-strength metals accurately ensures that these components can endure the rigors of combat and extreme operational conditions. In the marine industry, bending sheet metal enables the production of hull sections, bulkheads, and other ship components that need to endure corrosive sea environments and dynamic loads. Advanced bending processes help achieve watertight and aerodynamically efficient designs, ensuring the safety, longevity, and performance of naval and commercial marine vessels.

Bending sheet metal plays a crucial role in the automotive industry, where precision and durability are paramount. This process allows for the creation of complex, lightweight, and sturdy components that form the structural backbone of modern vehicles. The sheet metal is manipulated through various techniques such as V-bending, U-bending, and edge bending to produce parts like brackets, chassis, and body panels. The precision in bending ensures that these components fit seamlessly into the vehicle, contributing to the overall aerodynamics and safety standards. Furthermore, advancements in computerized numerical control (CNC) machines enable highly accurate and consistent bends, reducing production time and costs while maintaining high-quality standards. This precision in manufacturing is essential in the automotive sector, where even slight deviations can affect vehicle performance and safety.

In the electronics industry, bending sheet metal is equally significant, particularly in the manufacturing of enclosures, chassis, and mounting brackets for various devices. This process helps in constructing protective casings that house delicate electronic components, shielding them from external impacts and interference. Given the miniaturization trend in electronics, the ability to bend sheet metal with high precision delivers compact, reliable, and aesthetically pleasing designs. Moreover, materials like aluminum and stainless steel are often used for their excellent balance between strength and weight. These metals, when bent accurately, ensure proper heat dissipation and structural integrity, essential for the longevity and functionality of electronic devices. The development of automated bending machines allows manufacturers to scale production efficiently, catering to the high demand for consumer electronics while maintaining stringent quality controls.

Bending sheet metal is a fundamental technique in the construction industry, offering both functional and aesthetic benefits. It enables the fabrication of complex architectural elements such as custom roofs, façades, and structural supports. For instance, bent metal sheets are frequently used to form cladding panels that not only provide a contemporary and sleek appearance but also enhance the building’s weather resistance and insulation properties. Furthermore, bending sheet metal allows for the creation of intricate shapes and angles necessary for advanced designs, making it possible to achieve unique, modernistic structures that would be difficult or impossible with other materials. In addition, this technique can contribute to sustainability in construction by allowing precise, seamless joints which minimize waste and reduce the need for additional materials like sealants and fasteners.

In the energy sector, the application of bending sheet metal is critical for the production of various components essential for efficient energy systems. One major area of use is in the creation of enclosures and housings for solar panels and wind turbines, where precision and durability are paramount. Bent sheet metal shapes structural frames that can withstand harsh environmental factors, extending the lifespan and reliability of renewable energy apparatus. Additionally, bent metal sheets are integral to the manufacture of heat exchangers and coil systems used in thermal energy storage and distribution. Their ability to be molded into compact, efficient forms maximizes the surface area for thermal transfer while minimizing space requirements. This optimization is particularly advantageous for facilities like power plants and HVAC systems, which demand high performance and efficiency in often constrained environments. By allowing the construction of efficient, reliable, and innovative energy solutions, bending sheet metal plays a pivotal role in advancing technology for sustainable energy production and distribution.

The industrial equipment industry relies heavily on the process of bending sheet metal to create various components and structural elements used in manufacturing machinery and infrastructure. Bending sheet metal involves deforming metal sheets into desired angles and shapes through the application of force, typically using press brakes, folding machines, or similar equipment. This process is essential for fabricating parts with precision and consistency, which are crucial in the production of items such as enclosures, brackets, chassis, and supports. The ability to bend sheet metal efficiently allows manufacturers to produce robust and durable components that meet exact specifications, ensuring that machinery operates reliably and safely in diverse applications ranging from automotive manufacturing to aerospace engineering.

In addition to enhancing the structural integrity and functionality of industrial equipment, bending sheet metal also contributes to cost-efficiency and material optimization. By precisely bending metal sheets, manufacturers can minimize material wastage and reduce the need for additional welding or joining processes, which can be time-consuming and costly. This leads to more streamlined production workflows and lower overall costs. Furthermore, advancements in computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies have enabled more complex and intricate bending operations, expanding the design possibilities for engineers and designers. As a result, the industrial equipment industry can innovate with materials and shapes, improving performance and leading to the development of more advanced machinery and products that meet the evolving demands of modern industries.

Bending sheet metal is a critical process in the manufacturing of medical devices, leveraging its precision and versatility to create components that meet stringent healthcare standards. High-quality medical devices often require intricate, durable, and biocompatible components, which can be efficiently produced through sheet metal bending techniques. For instance, surgical instruments such as forceps, scalpels, and retractors often feature complex shapes that need to fit ergonomically in a surgeon’s hand while maintaining structural integrity under stress. Bending sheet metal allows manufacturers to produce these delicate contours and angles with high accuracy, ensuring that the devices perform reliably during medical procedures.

Beyond surgical instruments, bending sheet metal is also essential in the production of durable medical equipment casings and housings for diagnostic machines like MRI scanners and X-ray units. These devices require robust enclosures that protect sensitive internal components while being easy to clean and maintain. Sheet metal bending ensures that these enclosures can be produced efficiently, offering both the strength and the customizability needed for different applications. Additionally, the process allows for the integration of features such as ventilation panels, brackets, and mounting points, which are crucial for the functional assembly of these complex machines. With advancements in bending technology, including CNC bending and automated systems, the production of medical devices using bent sheet metal can meet the exacting demands of the healthcare industry in terms of precision, reliability, and hygiene.

Bending sheet metal is a fundamental machining and manufacturing process extensively utilized within industries ranging from automotive to aerospace. The procedure involves applying force to a flat sheet of metal to induce plastic deformation, effectively changing its shape without compromising its integrity. This method allows for the creation of complex geometries and is pivotal in forming components like brackets, enclosures, and chassis. The precision and accuracy afforded by modern bending technologies, such as CNC press brakes, ensure that parts meet stringent specifications. Tooling, including dies and punches, plays a crucial role in defining the shape, angle, and radius of the bends. Advanced techniques like air bending and bottoming are employed to achieve the desired bend configurations, optimizing material strength and resilience.

In manufacturing, bending sheet metal significantly contributes to rapid prototyping and mass production due to its versatility and cost-effectiveness. Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems streamline the design-to-production process, allowing engineers to simulate and program bends with high precision, reducing lead times and material waste. Additionally, the customization capabilities of bending operations cater to specific industry requirements, making it ideal for bespoke projects and modular assemblies. Quality control measures, such as bend testing and 3D inspection, ensure the structural integrity and dimensional accuracy of the finished parts. Consequently, bending sheet metal stands as a cornerstone technique in manufacturing, blending innovation with practicality to drive advancements in product development and industrial applications.

## FAQ for Bending Sheet Metal Quality Work from SourcifyChina Factory

1. What materials can be used for bending at SourcifyChina Factory?

We specialize in bending various types of metal sheets, including but not limited to steel, aluminum, stainless steel, and copper. Our advanced machinery can handle different material thicknesses while maintaining high precision and quality.

2. How accurate is the bending process at SourcifyChina Factory?

We utilize state-of-the-art CNC bending machines equipped with advanced controls to ensure high precision and repeatability. Tolerances can be maintained as tight as ±0.1mm, depending on the material and part complexity.

3. Do you offer custom bending solutions?

Yes, we provide customized bending solutions tailored to meet your specific requirements. Our experienced engineering team can assist you in designing and prototyping to ensure your project is executed perfectly.

4. What is the lead time for orders?

Lead times depend on the project complexity and order volume. Generally, our lead times range from 2 to 4 weeks for standard orders. However, we strive to accommodate urgent requests and can expedite processes when necessary.

5. How do you ensure quality control?

Quality control is a crucial aspect of our manufacturing process. We follow rigorous inspection protocols, including first-article inspection, in-process inspections, and final quality checks. We are also ISO 9001 certified, ensuring our processes meet international quality standards.

6. Can you produce large volume orders?

Yes, SourcifyChina Factory is well-equipped to handle both small and large volume orders. Our scalable production capabilities and efficient workflow allow us to meet high-volume demands without compromising quality.

7. What information do I need to provide for a bending sheet metal quote?

To provide an accurate quote, we need detailed information about your project, including material type, thickness, dimensions, tolerance requirements, and any specific finishing or additional processing needs.

8. Do you offer additional finishing services?

Yes, we offer a range of finishing services including powder coating, anodizing, plating, and polishing to meet your specific needs and ensure the highest quality appearance and durability of your sheet metal parts.

9. Where is SourcifyChina Factory located?

Bending sheet metal is a critical process in manufacturing that requires precision and expertise. SourcifyChina factory is renowned for its quality in this domain. Here are some tips to ensure successful bending of sheet metal with their services:

1. Material Selection: Choose the right material based on the product’s application. SourcifyChina can help guide choices between aluminum, steel, and other metals, optimizing for strength and malleability.

2. Design Considerations: Incorporate bend allowances and radii in your designs. This minimizes errors and material stress, ensuring parts meet specifications without cracking or warping.

3. Tooling Precision: Utilize SourcifyChina’s advanced tooling capabilities to ensure precise bends. Their range of press brakes and CNC machines provide high accuracy for complex bends and tight tolerances.

4. Communication: Maintain clear and detailed communication regarding design requirements and specifications. Sharing CAD files and detailed drawings helps in aligning expectations and achieving desired outcomes.

5. Prototype Testing: Request prototypes before full-scale production. This allows for testing and verification, ensuring the final product meets all functional and quality requirements.

6. Surface Finish: Consider post-bending treatments like deburring, polishing, or coating. SourcifyChina offers comprehensive finishing services to improve aesthetics and durability.

7. Consistency Checks: Incorporate regular quality inspections. SourcifyChina adheres to stringent QC protocols, ensuring consistency and high standards across all batches.

8. Cost Efficiency: Leverage SourcifyChina’s ability to source high-quality materials at competitive prices, and their efficient production processes to keep costs down without sacrificing quality.

9. Lead Time Management: Discuss and plan for lead times, especially for large or complex orders, to ensure timely delivery.

By following these tips, you can maximize the efficiency and quality of your sheet metal bending projects with SourcifyChina factory.

FAQs for Sourcing Bending Sheet Metal from SourcifyChina Factory

1. What is the typical lead time for bending sheet metal orders?

The typical lead time for bending sheet metal orders from SourcifyChina Factory ranges from 2 to 4 weeks, depending on the complexity and volume of the order. Custom designs may require additional time for prototyping and approval.

2. Are there minimum order quantities (MOQ) for sheet metal bending services?

Yes, the minimum order quantity (MOQ) for sheet metal bending services is typically 50 pieces. However, this can vary based on the specific requirements of your project. It’s best to discuss your needs with a SourcifyChina representative.

3. What materials can SourcifyChina Factory work with for bending sheet metal?

SourcifyChina Factory can handle a variety of materials, including aluminum, stainless steel, carbon steel, and copper. If you have specific material requirements, please consult with the factory to ensure they can accommodate your needs.

4. What tolerances can SourcifyChina Factory achieve in sheet metal bending?

SourcifyChina Factory can typically achieve bending tolerances of ±0.1 mm, depending on the material and thickness. For more precise tolerances, additional considerations and processes may be required.

5. Can SourcifyChina Factory provide custom finishes for bent sheet metal parts?

Yes, custom finishes such as powder coating, anodizing, painting, and plating are available upon request. Be sure to specify your desired finish when submitting your order to ensure accuracy and quality.

6. How do I submit a design for a bending sheet metal project?

You can submit your design via email or through the SourcifyChina Factory’s online portal. Preferred formats include DXF, DWG, and PDF. Make sure your design includes all necessary dimensions, material specifications, and tolerances.

7. What quality control measures are in place at SourcifyChina Factory?

SourcifyChina Factory employs a rigorous quality control process that includes first article inspection (FAI), in-process checks, and final inspections to ensure all products meet customer specifications and standards.

8. Can SourcifyChina Factory handle large-scale production runs?

Sourcing bending sheet metal from SourcifyChina factory can be an efficient process if approached methodically. Here are some key tips to ensure success:

1. Define Your Specifications: Clearly outline the metal type, thickness, bending radius, dimensions, and any other specific requirements. Detailed drawings and CAD files can help convey these specifications accurately.

2. Initial Research: Understand the factory’s capabilities by reviewing their website, portfolios, and customer reviews. Ensure they have experience with projects similar to yours.

3. Request Samples: Ask for samples of their previous work to evaluate the quality. This step helps verify their capabilities and craftsmanship.

4. Clear Communication: Maintain clear and consistent communication. Use visual aids like drawings and photos to avoid misunderstandings, and consider setting up video calls to discuss details.

5. Get Multiple Quotes: Obtain quotes from multiple suppliers, including SourcifyChina, to compare costs, lead times, and services. This will help ensure competitive pricing and terms.

6. Quality Control: Establish quality control processes. Request detailed information on their QC measures and consider hiring a third-party inspection service.

7. Negotiate Terms: Discuss payment terms, delivery schedules, and minimum order quantities. Clear terms help avoid future disputes and ensure a smooth transaction.

8. Understanding Logistics: Plan for shipping and customs clearance. Ensure the supplier is capable of handling export processes and can provide guidance on logistics.

9. Trial Order: Start with a small trial order to test the supplier’s reliability and the quality of their work before committing to a larger volume.

10. Legal Aspects: Have contracts in place that outline all terms, conditions, and responsibilities clearly to protect your interests.

By following these tips, you can effectively source high-quality bending sheet metal from SourcifyChina factory, ensuring your needs are met efficiently and economically.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.