Reliable Metal Sheet Bending Solutions: Partner with SourcifyChina Factory for Precision and Efficiency

Looking for a dependable provider for metal sheet bending? SourcifyChina factory offers precision, efficiency, and reliability in all your manufacturing needs. Partner with us to ensure top-notch quality and timely delivery for your projects.

“SourcifyChina” Factory stands out for its exceptional quality control in metal sheet bending. Each product undergoes rigorous inspection, ensuring top-notch quality that meets international standards.

With years of industry experience, “SourcifyChina” offers unparalleled expertise in metal fabrication, providing precise and reliable metal sheet bending solutions tailored to client specifications.

“SourcifyChina” Factory leverages state-of-the-art technology and advanced machinery. This ensures high precision, efficiency, and consistency in metal sheet bending, minimizing errors and wastage.

Competitive pricing makes “SourcifyChina” an attractive choice for buyers. The factory ensures affordability without compromising on quality, helping clients maintain their budgets and project timelines.

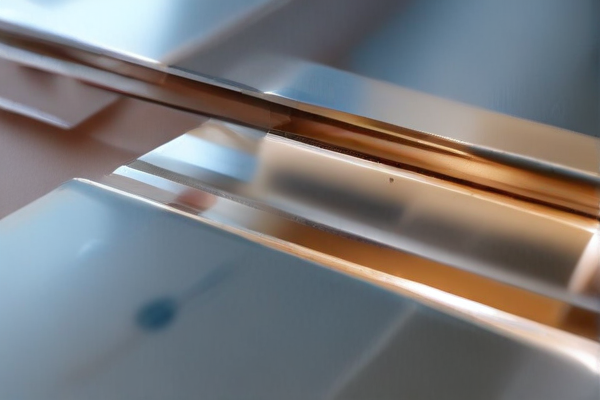

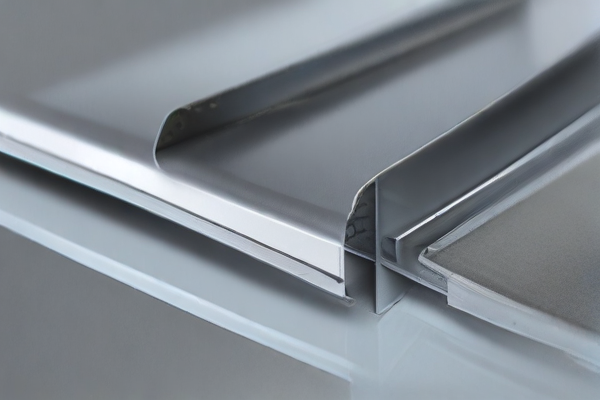

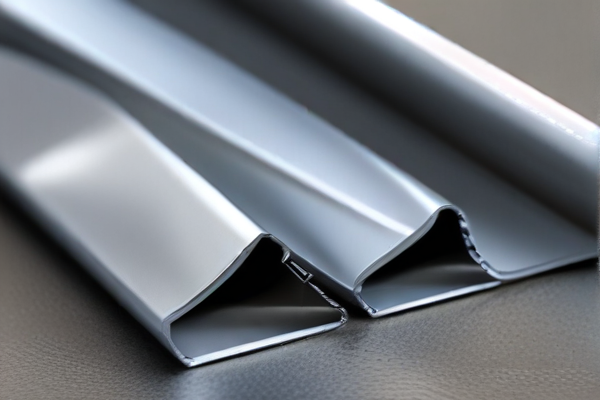

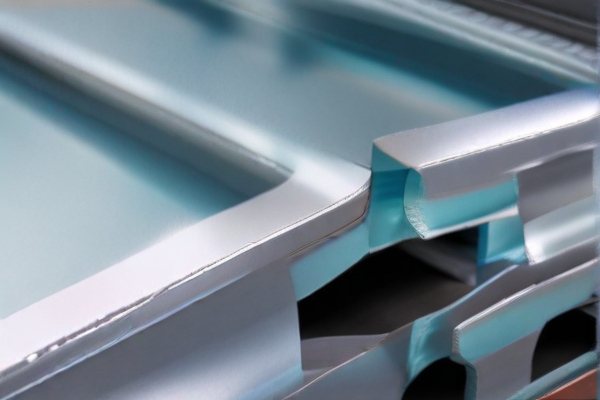

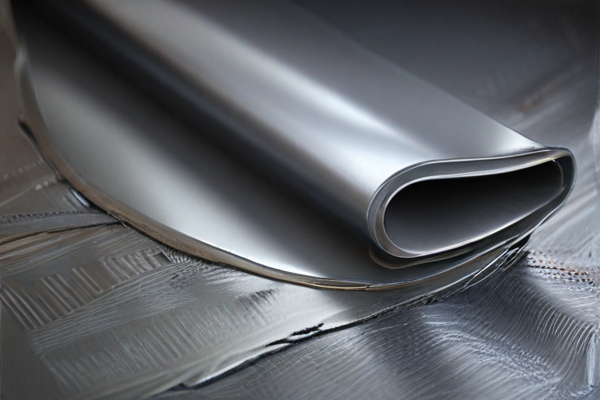

Metal sheet bending is a versatile fabrication process used to form sheets of metal into various shapes. There are several types of metal sheet bending techniques, each suited for different applications and material properties.

– Air Bending: Uses a punch and die but does not press the sheet metal all the way to the bottom of the die, allowing for more flexibility.

– Bottoming: The sheet metal is pressed to the bottom of the die, creating more precise angles and higher strength.

– Coining: Involves a high-pressure application that coins the metal into the shape of the die, ensuring precise angles and a high-quality finish.

– Roll Bending: Uses rollers to form cylindrical shapes from sheet metal; ideal for large pieces.

– Wipe Bending: Employs a wiping die to bend the metal around an edge for simple, straightforward bends.

– Rotary Bending: Utilizes a rotating die to form bends, suitable for creating complex shapes without marring the material.

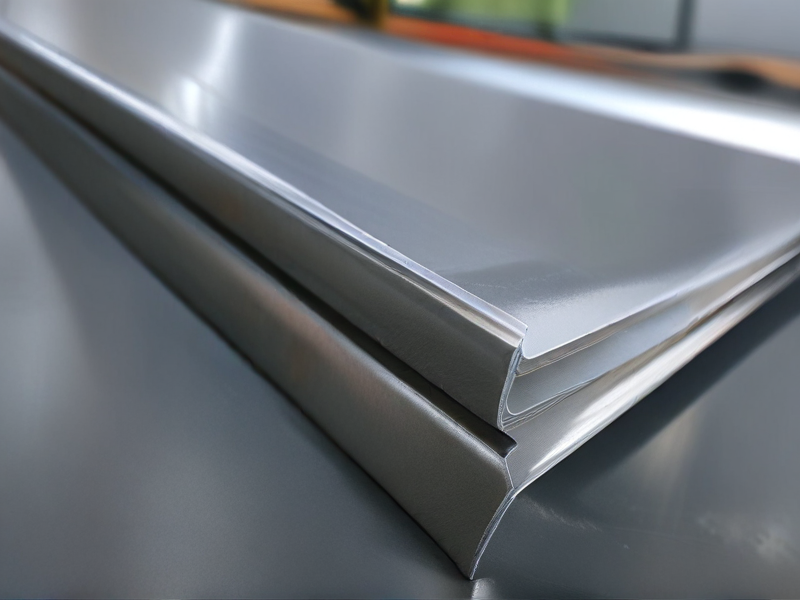

– Folding: Involves a clamping beam that holds the sheet while a folding beam lifts to bend the sheet around an edge.

– V-Bending: A simplified form of air bending with a V-shaped die; commonly used for creating V-shaped bends in sheet metal.

– Edge Bending: Uses a punch along the edge to form detailed bends; ideal for small, intricate parts.

– Mandrel Tube Bending: Includes a mandrel inserted into the tube to prevent collapsing during bending, used for tubes and pipes.

Each of these methods offers distinct advantages depending on the specific requirements of the project, such as the complexity of the shape, the precision needed, and the material’s properties.

Metal sheet bending is a versatile fabrication process applicable in various industries to create functional and aesthetic components from flat sheets of metal.

– Automotive: Manufacturing car body panels and structural components.

– Aerospace: Fabricating aircraft skins and support structures.

– Construction: Producing roofing, claddings, and framework elements.

– Electronics: Crafting enclosures and brackets for devices.

– Furniture: Creating frames and decorative finishes for metal furniture.

– HVAC: Forming ductwork and ventilation systems.

– Marine: Shaping ship hulls and other marine components.

– Medical: Developing equipment casings and structural parts.

– Appliances: Building outer casings and internal structural supports.

– Agriculture: Producing equipment such as plows and harvesters.

Beyond these industry-specific uses, metal sheet bending is crucial in custom manufacturing, repair works, and any application requiring durable, precisely-shaped metal components.

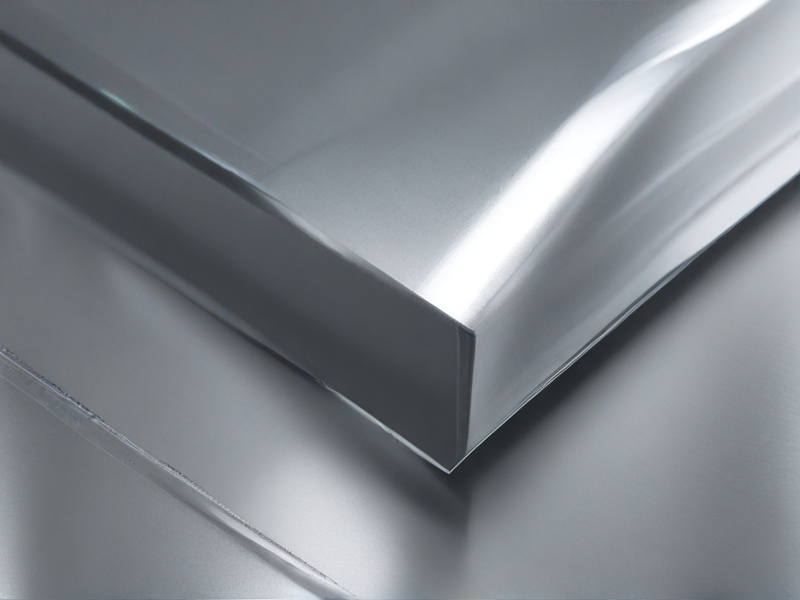

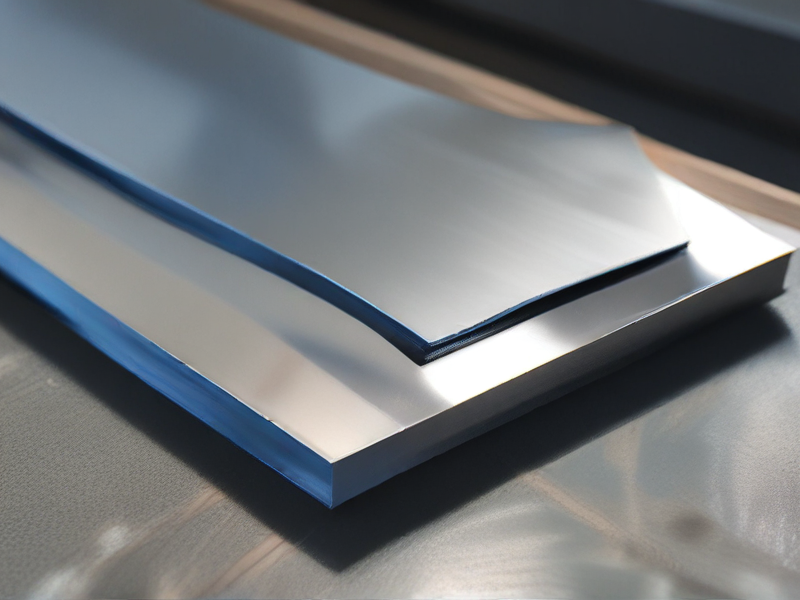

SourcifyChina offers premium metal sheet bending services, utilizing high-quality materials that are durable and versatile. Their expertise encompasses a range of metals, including stainless steel, aluminum, and carbon steel. Each type of metal is selected based on the requirements of durability, weight, and resistance to corrosion.

Stainless steel is a popular choice for its excellent corrosion resistance and strength, making it ideal for applications in harsh environments. Aluminum, known for its light weight and malleability, is perfect for projects that require easy maneuvering and superior electrical conductivity.

Carbon steel is another material commonly used for its versatility and affordability. It offers good hardness and can be readily bent to create various shapes and structures. SourcifyChina ensures all materials used meet industry standards and undergo rigorous quality checks.

By leveraging modern technology and skilled technicians, SourcifyChina guarantees precision and efficiency in their metal sheet bending processes. Their commitment to quality ensures that each project is completed to exact specifications, delivering products that meet or exceed client expectations.

SourcifyChina ensures top-notch quality control in metal sheet bending through a meticulous and structured manufacturing process. They begin with selecting premium raw materials and employing advanced machinery to guarantee precise bending angles.

The company utilizes state-of-the-art CNC machines that offer a high degree of accuracy and repeatability. This technology minimizes human error and ensures consistent quality across mass production. Skilled technicians oversee these machines, routinely calibrating and maintaining them for optimal performance.

Each metal sheet undergoes rigorous inspection at various stages of the bending process. Advanced measurement tools, such as laser scanners and micrometers, validate the dimensions and angles of the bent sheets, ensuring adherence to exact specifications.

To maintain high standards, SourcifyChina implements a stringent quality assurance protocol. Random samples from each batch undergo stress tests to check their durability and structural integrity. These measures ensure that the final products can withstand rigorous use and meet client expectations.

Customer satisfaction is paramount at SourcifyChina, who integrates continuous feedback loops into their process. This allows for real-time adjustments and enhancements, ensuring that customer requirements are met consistently. The team’s dedication to excellence lands them a competitive edge in the metalworking industry.

In summary, SourcifyChina’s comprehensive quality control in the metal sheet bending process combines advanced technology, skilled craftsmanship, and stringent inspection protocols. This approach ensures that every product not only meets but exceeds quality standards, reaffirming their commitment to excellence and customer satisfaction.

SourcifyChina excels in metal sheet bending, offering precision and efficiency. Their advanced machinery ensures accurate bends for various applications, reducing waste and maximizing productivity.

They specialize in custom bending services, tailoring each project to meet specific customer needs. The skilled team handles complex designs with seamless execution, delivering high-quality results consistently.

Quality control is stringent at SourcifyChina. Each piece undergoes thorough inspection to meet rigorous standards. This dedication to excellence ensures reliable performance in all metal bending projects.

In addition to standard bends, SourcifyChina offers intricate shapes and angles. Their innovative techniques accommodate unique requirements, offering versatile solutions for diverse industries.

Client satisfaction is paramount at SourcifyChina. They provide exceptional customer service, promptly addressing inquiries and offering expert guidance. This client-centered approach fosters long-term partnerships and repeat business.

Overall, SourcifyChina’s metal sheet bending capabilities make them a leader in the industry. Their combination of advanced technology, skilled personnel, and customer-focused service ensures optimal results for every project, earning them a reputation for reliability and excellence.

Metal sheet bending is a crucial manufacturing process with numerous benefits, enhancing both functionality and aesthetics in various industries.

– Versatility: Metal sheet bending allows for creating complex shapes, making it suitable for various applications, from automotive parts to architectural elements.

– Strength: Bending enhances the structural integrity of metals, providing increased strength and durability compared to flat sheets.

– Cost-Effective: It reduces the need for additional fixtures and joints, leading to lower production costs and faster turnaround times.

– Customization: This process allows for tailored solutions, meeting specific requirements and design needs.

– Material Efficiency: By minimizing waste, metal bending is an environmentally friendly option that optimizes material use.

– Improved Appearance: It provides smooth, clean edges and uniform surfaces, contributing to a professional and attractive look.

– Durability: Metal parts created through bending are generally more resistant to wear and tear, extending their lifespan.

– Automation-Friendly: Bending processes can be easily automated, improving precision and consistency while reducing labor costs.

Metal sheet bending is a critical process in manufacturing, shaping flat metal sheets into desired angles and forms through various methods.

Key features of metal sheet bending include:

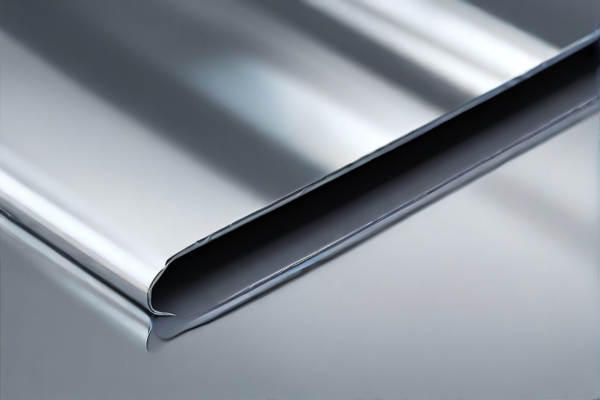

– Precision and Accuracy: Advanced machinery like CNC (Computer Numerical Control) ensures precise bends, meeting exact specifications.

– Versatility: Can handle different metals like steel, aluminum, and copper, varying in thickness.

– Strength and Durability: Maintains the integrity of metal without compromising its strength.

– Cost-Effective: Automated processes reduce labor costs and material wastage.

– Complex Geometries: Capable of producing intricate shapes and designs.

– Consistency: Repeated, uniform bends across production batches.

– Speed: Efficient process, capable of high-volume production runs.

– Manual and Hydraulic Bending: Options for manual presses for simpler jobs, and hydraulic presses for more complex tasks.

– Tooling Variety: Wide range of tools and dies available for different bend profiles.

– Surface Finish: Maintains smooth and clean surface without cracks or imperfections.

– Thickness and Grade Adaptability: Suitable for various thicknesses and grades of metal sheets.

– Customization: Tailoring the bending process to specific project requirements.

– Safety: Modern equipment often includes safety features to protect operators.

– Reduced Lead Time: Streamlined processes reduce overall lead time for projects.

– Material Efficiency: Optimal use of material, minimizing scrap.

Metal sheet bending is integral in numerous industries, from automotive to aerospace, contributing significantly to the production of durable and complex metal components.

SourcifyChina specializes in creating custom metal sheet bending products to meet unique project requirements. Leveraging advanced technology, our team ensures each product is accurately crafted to client specifications, maintaining exceptional quality.

Our custom metal sheet bending solutions are ideal for a diverse range of industries, including automotive, construction, and electronics. We utilize state-of-the-art machinery to offer precise bends and consistent results, adhering to stringent industry standards.

At SourcifyChina, our design and engineering teams work closely with clients from concept to completion. This collaborative approach ensures products are both functional and aligned with clients’ visions, resulting in tailor-made solutions.

We pride ourselves on delivering high-quality bent metal products efficiently, meeting tight deadlines without compromising on quality. Our robust supply chain and experienced staff enable us to provide reliable services at competitive prices.

Whether you need small batch production or large volume orders, SourcifyChina is equipped to handle projects of all sizes. Our commitment to excellence, innovation, and customer satisfaction sets us apart in the metal fabrication industry.

SourcifyChina Metal Sheet Bending is a distinguished leader in precision metal fabrication services, offering unparalleled expertise in the bending and shaping of metal sheets for various industrial applications. Established in the heart of China’s manufacturing hub, SourcifyChina leverages cutting-edge technology and state-of-the-art machinery to deliver high-quality, customized metal components that meet stringent international standards. The company prides itself on its commitment to excellence, continuous improvement, and customer satisfaction, ensuring meticulous attention to detail in every project. Their comprehensive suite of services caters to diverse industries, including automotive, aerospace, construction, and electronics, providing them with robust and precise metal solutions. With a team of highly skilled engineers and technicians, SourcifyChina combines innovative techniques with traditional craftsmanship, offering flexible, cost-effective, and timely solutions tailored to each client’s specific needs. Their dedication to sustainable practices and optimal resource utilization further underscores their position as a responsible and forward-thinking player in the metal fabrication sector.

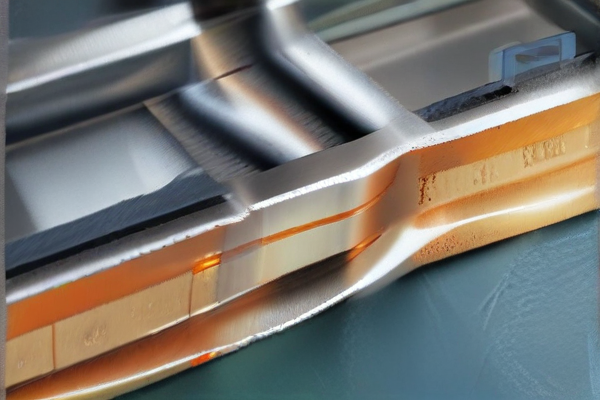

Metal sheet bending is a critical process in the aerospace, defense, and marine industries due to its ability to produce complex, precise, and durable components. In aerospace applications, sheet metal bending is essential for fabricating parts such as aircraft skins, wing components, and fuselage sections. These parts must withstand high stress and extreme environmental conditions, making precision and material choice vital. Titanium, aluminum, and high-strength steel are commonly used in aerospace bending processes due to their strength-to-weight ratio and corrosion resistance. Precision bending techniques, such as CNC (Computer Numerical Control) bending, are employed to ensure tight tolerances and repeatability, critical to the safety and efficiency of aerospace structures.

In the defense sector, metal sheet bending is used for manufacturing armored vehicle panels, missile casings, and structural components of military aircraft and naval vessels. The need for robust and resilient defense equipment necessitates the use of advanced bending techniques to produce parts that can endure harsh operational environments and hostile conditions. High-strength materials such as ballistic steel and composite laminates are often employed in these applications. Similarly, the marine industry relies on sheet metal bending to create hulls, bulkheads, and other structural parts of ships and submarines. Corrosion resistance and long-term durability in saltwater environments are crucial, necessitating the use of materials like stainless steel and marine-grade aluminum. Accurate bending ensures that these components fit seamlessly, contributing to the overall integrity and performance of marine vessels.

Automotive Applications:

Metal sheet bending is a pivotal process in the automotive industry, providing the precision and strength necessary for manufacturing various components. It plays a crucial role in forming body panels, chassis, and structural frames, ensuring they meet the high standards for safety, durability, and aesthetic appeal. Through intricate bending techniques, manufacturers can create complex shapes and contours that are integral to vehicle aerodynamics and crashworthiness. Automated bending machines allow for high repeatability and accuracy, crucial for mass production. This process also facilitates the integration of lightweight materials like aluminum and advanced high-strength steels, which enhance vehicle performance and fuel efficiency by reducing overall weight without compromising structural integrity.

Electronics Applications:

In the electronics industry, metal sheet bending is essential for creating precise and compact enclosures, brackets, and frames for various devices. This technique ensures that metal casings fit perfectly, providing optimal protection and heat dissipation for sensitive electronic components. Custom metal bending allows for the design of intricate internal structures that can house wiring and electronic boards securely, maintaining the integrity and function of the devices. Additionally, the miniaturization trend in electronics has increased the demand for high-precision bending processes that can produce extremely small and complex parts. Technologies such as computer numerical control (CNC) bending machines are employed to attain the required precision and consistency, enabling the production of sleek, robust, and functional designs critical for consumer electronics, telecommunications, and computing equipment.

Metal sheet bending is a cornerstone technique in the construction industry, essential for creating various structural components and enhancing architectural aesthetics. By manipulating metal sheets into specific angles and shapes, architects and engineers can design and construct complex structures such as support beams, brackets, and custom façades. This versatility in shaping metal allows for innovative building designs that are both functional and visually appealing. For instance, curved metal panels are often used to create sleek, modern exteriors for commercial buildings. Additionally, metal sheet bending facilitates the production of durable roofing materials, gutters, and pipe systems, providing both protection and longevity to structures. The ability to precisely bend metal sheets also ensures that components fit perfectly, reducing the need for further adjustments on-site and streamlining the construction process.

In the energy sector, metal sheet bending plays a critical role in the development and maintenance of various energy systems, from renewable energy solutions to traditional power generation infrastructure. One significant application is in the fabrication of wind turbine components, where the aerodynamic blades are shaped through precise bending to optimize wind capture and efficiency. Similarly, in solar power installations, metal sheets are bent to create frames and mounting systems that securely hold photovoltaic panels in place, ensuring optimal orientation towards the sun. In the realm of fossil fuel energy, bent metal sheets are crucial for constructing pipelines, storage tanks, and structural supports that withstand high pressure and harsh environmental conditions. Overall, the ability to bend metal sheets into required forms not only enhances the performance and reliability of energy systems but also contributes to advancements in energy efficiency and sustainability.

The industrial equipment industry extensively utilizes sheet metal bending due to its ability to produce precise and durable components for a myriad of applications. Sheet metal bending involves deforming metal plates to specified angles and configurations, utilizing machines such as press brakes, hydraulic presses, and CNC bending machines. This process is indispensable in manufacturing components for machinery, automotive parts, construction equipment, and aerospace structures. By bending metal sheets, manufacturers can create structural frames, brackets, enclosures, and a variety of custom shapes that meet rigorous industry standards. The precision and repeatability of modern sheet metal bending technology ensure consistent quality, contributing to the overall reliability and performance of industrial equipment.

In addition, advancements in automation and robotics have revolutionized sheet metal bending processes, leading to increased production efficiency and reduced labor costs. Automated bending systems can handle complex bending sequences with minimal human intervention, significantly improving throughput and decreasing production times. Integration with computer-aided design (CAD) and computer-aided manufacturing (CAM) systems enables the fabrication of intricate and bespoke designs with high accuracy, allowing for greater design flexibility and innovation. Moreover, the adoption of high-strength materials and sophisticated bending techniques has amplified the structural capabilities of bent sheet metal components, supporting the development of more robust and lighter industrial machinery. Consequently, sheet metal bending stands as a critical technique in the industrial equipment sector, driving advancements in manufacturing processes and product performance.

Metal sheet bending plays a crucial role in the manufacturing of medical devices, where precision and reliability are paramount. Techniques such as press braking, roll bending, and air bending are frequently used to shape metal sheets into components that meet exacting specifications. These formed metal parts are integral to devices like surgical instruments, diagnostic equipment, and implantable devices. For example, surgical trays and casings for electronic medical equipment often require precisely bent metal sheets to ensure both durability and a proper fit. Given the stringent regulations governing the medical device industry, the bending processes must achieve high precision to ensure that the final products are both safe and effective.

Moreover, the application of metal sheet bending in medical devices extends to the customization of patient-specific solutions. Devices such as orthopedic implants, prosthetics, and dental appliances can be tailored to unique anatomical requirements through advanced bending techniques. The ability to bend metal sheets accurately allows for the production of highly customizable components that can conform to patient-specific dimensions. Additionally, materials used in these devices often include biocompatible metals like stainless steel and titanium, which not only necessitate precise bending but also the ability to maintain their structural integrity after shaping. This makes metal sheet bending an indispensable process in the realm of modern medical device manufacturing, enabling the creation of innovative and highly effective medical solutions.

Metal sheet bending is a critical machining process used extensively in the manufacturing sector to form metal sheets into various shapes and angles. This process involves applying a force to a metal sheet to alter its geometry, typically using specialized equipment like press brakes, roll benders, or folding machines. The precision and accuracy achieved through metal sheet bending are vital for creating components with exact specifications, which is essential for industries such as automotive, aerospace, and construction. The ability to produce complex bends and geometries enables manufacturers to fabricate parts that meet stringent design criteria, contributing to the overall reliability and functionality of the final product.

In the context of industrial applications, metal sheet bending plays a pivotal role in producing a wide range of products, from simple brackets and enclosures to intricate chassis and structural frames. Advanced techniques such as CNC (Computer Numerical Control) bending have further revolutionized the field by allowing for high-precision and repeatability, reducing material waste and production time. This level of automation and control is particularly beneficial for high-volume production runs and complex design patterns. By integrating metal sheet bending operations into their production lines, manufacturers can enhance operational efficiency, reduce costs, and ensure consistent product quality, thereby meeting the ever-evolving demands of modern engineering and consumer markets.

1. What materials does SourcifyChina factory work with for metal sheet bending?

SourcifyChina factory primarily works with a variety of metals including steel, aluminum, stainless steel, and copper, ensuring high quality and precision in bending operations.

2. What is the maximum thickness of metal sheets you can bend?

We can bend metal sheets up to 20mm thick, depending on the type of metal and the complexity of the bend required.

3. What are your tolerances for metal sheet bending?

Our standard bending tolerance is ±0.5mm. However, tighter tolerances can be achieved based on specific project requirements.

4. Do you offer custom bending services?

Yes, SourcifyChina factory provides custom metal sheet bending services tailored to meet your specific needs and designs.

5. Can you handle both small and large volume orders?

Absolutely. We have the capacity to manage both small and large volume orders efficiently, providing timely and cost-effective solutions.

6. What bending technologies do you use?

We utilize advanced CNC press brakes and other state-of-the-art machinery to ensure precision and consistency in metal bending processes.

7. How do you ensure the quality of your metal sheet bending work?

Our quality assurance process includes rigorous inspections and testing at various stages of production to ensure all bent metal sheets meet the highest standards.

8. What is your turnaround time for metal bending projects?

Turnaround time varies based on the complexity and volume of the order. Typically, it ranges from 1 to 3 weeks.

9. Do you provide design assistance for metal sheet bending projects?

Yes, our skilled engineers can provide design assistance to optimize your metal bending projects for both performance and cost-efficiency.

10. How can I get a quote for my metal sheet bending project?

You can contact us via our website or email with your project specifications and requirements. Our team will evaluate and provide a detailed quote promptly.

Metal sheet bending is a critical process in manufacturing, and SourcifyChina factory is well-regarded for its precision and efficiency in this domain. Here are some essential tips to optimize your metal sheet bending manufacturing with them:

1. Material Selection: Choose the appropriate metal type and thickness suitable for your product’s needs. SourcifyChina can work with various metals, ensuring your material’s properties align with its intended use.

2. Advanced Machinery: SourcifyChina uses state-of-the-art CNC bending machines, guaranteeing precise and consistent bends. Leverage this technology to achieve complex bends and reduce material waste.

3. Design Considerations:

– Bend Radius: Keep the bend radius consistent with the material thickness to prevent cracking or warping.

– K-Factor: Factor this in your designs to account for material stretch and ensure accurate measurements.

– Relief Cuts: Incorporate relief cuts in corners and complex bends to avoid material deformation and ensure clean bends.

4. Prototyping: Start with a prototype to validate the design before moving into mass production. SourcifyChina provides rapid prototyping to iron out any potential issues early.

5. Tooling: Utilize appropriate tooling to match the job requirements. SourcifyChina offers a range of tools to handle different bending needs, ensuring precision in every bend.

6. Quality Control: Ensure stringent quality control processes. SourcifyChina employs thorough inspection methods at each stage of production to maintain high standards.

7. Consultation: Work closely with SourcifyChina’s engineering team. Their expertise can provide valuable insights into optimizing your designs for manufacturability and cost-efficiency.

By following these tips and leveraging SourcifyChina’s advanced capabilities, you can achieve high-quality metal sheet bending results, enhancing your product’s performance and reliability.

Sure, here is a concise FAQ for sourcing metal sheet bending services from the SourcifyChina factory:

Q1: What types of metal sheets can SourcifyChina bend?

A1: SourcifyChina can bend various metal sheets including aluminum, steel, stainless steel, copper, and more.

Q2: What is the maximum thickness SourcifyChina can handle for sheet bending?

A2: The factory can bend metal sheets up to 10mm in thickness, depending on the material type and specific requirements.

Q3: What bending techniques does SourcifyChina use?

A3: SourcifyChina utilizes a range of bending techniques including press braking, roll bending, and V-bending to achieve the desired result.

Q4: Can SourcifyChina handle custom bending specifications?

A4: Yes, SourcifyChina welcomes custom bending orders and can work with your detailed specifications to meet your project needs.

Q5: How does SourcifyChina ensure the quality of bent metal sheets?

A5: SourcifyChina adheres to strict quality control measures, including material inspection, precise bending tolerances, and final product inspections.

Q6: What is the lead time for metal sheet bending orders?

A6: Standard lead times range from 2 to 4 weeks, depending on the order size and complexity. Expedited services may be available upon request.

Q7: Does SourcifyChina offer prototyping services?

A7: Yes, SourcifyChina provides prototyping services to help you verify designs and make necessary adjustments before mass production.

Q8: What are the payment terms for sourcing from SourcifyChina?

A8: Payment terms typically include a 50% deposit upfront and the remaining balance upon completion of the order. Special arrangements can be discussed for large projects.

Q9: How can I get a quote for metal sheet bending from SourcifyChina?

A9: You can request a quote by providing detailed drawings and specifications via email or through their website contact form.

Q10: Can SourcifyChina assist with shipping and logistics?

A10: Yes, SourcifyChina offers comprehensive shipping and logistics support to ensure your order is delivered safely and on time.

This FAQ should cover the most essential inquiries and provide a clear overview of SourcifyChina’s metal sheet bending services within a concise format.

Sourcing metal sheet bending services from a factory like SourcifyChina can be a streamlined and efficient process if approached correctly. Here are some concise tips to help:

1. Specify Requirements:

– Clearly outline your project specifications, including material type, dimensions, bending angles, tolerances, and finishes. This ensures you receive accurate quotes and quality products.

2. Research the Factory:

– Investigate SourcifyChina’s reputation through reviews, certifications, and past client testimonials. Ensure they have experience in metal sheet bending and quality assurance processes.

3. Request Samples:

– Ask for samples of previous work or a prototype of your design. This can help verify the factory’s capability to meet your standards before committing to a larger order.

4. Quality Control:

– Inquire about the factory’s quality control measures. Ensure they conduct inspections at various production stages and provide detailed reports.

5. Cost Estimation:

– Compare quotes from SourcifyChina with other suppliers. Consider factors such as material costs, labor, shipping, and any potential hidden fees.

6. Communication:

– Maintain clear and frequent communication. This helps to address issues promptly and ensures that your project stays on track.

7. Lead Times:

– Understand the factory’s lead times and factor in additional time for shipping and potential delays. Confirm their capacity to meet your deadlines.

8. Contractual Agreements:

– Draft a contract that covers all aspects of the project, including payment terms, delivery schedules, and penalties for non-compliance.

9. Intellectual Property Protection:

– Ensure that intellectual property rights are protected in your agreement, particularly if proprietary designs are involved.

10. Logistics:

– Plan your logistics carefully. Consider the most efficient shipping methods and customs regulations to avoid delays and additional costs.

By following these tips, you can effectively source metal sheet bending services from SourcifyChina, ensuring quality, cost-efficiency, and timely delivery.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.