Choosing “SourcifyChina” Factory for procuring metal processing services provides an unparalleled advantage in quality. Their rigorous standards ensure each product meets international specifications, guaranteeing client satisfaction.

Moreover, SourcifyChina offers a competitive pricing structure, making cost-effective sourcing without compromising quality a reality. Buyers gain significant savings and outstanding product performance.

Timeliness is another hallmark of SourcifyChina. Their efficient workflows and dedicated team ensure on-time delivery, essential for maintaining your project’s timelines and credibility.

Lastly, SourcifyChina’s robust customer support system addresses any concerns promptly, offering peace of mind. Their expert team is always ready to assist, ensuring smooth transactions and beneficial partnerships.

In summary, choosing SourcifyChina Factory means gaining high-quality products, competitive pricing, timely delivery, and exceptional customer support. These elements together create a seamless, efficient, and rewarding purchasing experience for buyers seeking metal processing services in China.

Metal processing companies specialize in various techniques and services to shape, cut, and finish metals to meet industry requirements. They cater to diverse sectors such as automotive, aerospace, construction, and electronics.

– Cutting:

– Laser cutting

– Plasma cutting

– Waterjet cutting

– Saw cutting

– Forming:

– Rolling

– Stamping

– Forging

– Spinning

– Machining:

– CNC machining

– Milling

– Turning

– Drilling

– Welding:

– MIG welding

– TIG welding

– Spot welding

– Arc welding

– Finishing:

– Polishing

– Plating

– Anodizing

– Powder coating

– Casting:

– Sand casting

– Die casting

– Investment casting

– Permanent mold casting

– Heat Treatment:

– Annealing

– Quenching

– Tempering

– Case hardening

– Joining:

– Brazing

– Soldering

– Adhesive bonding

– Riveting

– Specialized Services:

– Prototype development

– Metal recycling

– Surface treatment

– Custom fabrication

– Materials Handled:

– Steel

– Aluminum

– Copper

– Titanium

– Brass

These companies offer customized options to enhance the strength, durability, and functionality of metal parts, ensuring they meet stringent quality and safety standards. Advanced technology and skilled labor are crucial for delivering precise and efficient metal processing solutions.

Metal processing companies have diverse applications across various industries, providing essential services such as cutting, shaping, and finishing metals to create precise and durable components.

– Aerospace Industry: Manufacturing high-strength parts for aircraft, including engine components, structural elements, and landing gear.

– Automotive Sector: Producing parts like engines, transmissions, body panels, and exhaust systems, ensuring vehicles’ performance and safety.

– Construction: Fabricating beams, columns, and other structural components for buildings and infrastructure.

– Consumer Goods: Creating durable home appliances, kitchenware, and electronic devices.

– Medical Devices: Producing surgical instruments, implants, and specialized equipment that meet stringent health standards.

– Oil and Gas Industry: Fabricating pipelines, drill bits, and other tools critical for extraction and transportation.

– Renewable Energy: Manufacturing parts for wind turbines, solar panels, and other clean energy technologies.

– Defense Sector: Creating military-grade equipment and vehicles, including armor, weapons, and communication systems.

– Mining: Producing equipment for extraction, transportation, and processing of minerals.

– Marine Industry: Constructing ship parts, offshore drilling equipment, and submarines.

– Electronics: Manufacturing components like heat sinks, frames, and connectors for electronic devices.

– Heavy Equipment: Producing parts for industrial machinery, including excavation and agricultural equipment.

– Tool and Die Making: Creating precision tools, molds, and dies essential for manufacturing processes.

– Art and Sculpture: Providing materials and services for artists and sculptors working with metal.

These applications highlight the critical role metal processing companies play in advancing technology and supporting various sectors.

“SourcifyChina” collaborates with a variety of metal processing companies in China, which specialize in different methods such as casting, forging, and machining. They utilize advanced technology and skilled labor to produce high-quality metal components tailored to client specifications.

These companies frequently work with a range of metals, including steel, aluminum, and copper. The availability of diverse materials makes it possible to cater to various industries such as automotive, aerospace, and consumer electronics, ensuring durability and precision.

Environmentally friendly practices are often incorporated into the metal processing workflow. This can include recycling scrap metals and implementing energy-efficient technologies to reduce the ecological footprint.

SourcifyChina ensures that all partnered companies adhere to international standards and certifications such as ISO9001. This guarantees that the metal components produced not only meet high-quality requirements but also maintain consistency in production.

With a solid understanding of both local and global markets, SourcifyChina continually strives to improve supply chain efficiency. By connecting businesses with the right metal processing companies, they streamline procurement processes and provide cost-effective solutions.

In summary, SourcifyChina’s collaboration with proficient metal processing companies in China plays a critical role in offering high-quality and environmentally conscious metal components. By adhering to rigorous standards and continually optimizing supply chains, they provide a reliable and comprehensive service to their global clientele.

SourcifyChina collaborates with metal processing companies to ensure stringent quality control throughout the manufacturing process. Adhering to international standards, they employ state-of-the-art technologies to monitor every production stage meticulously. From raw material inspection to final product testing, each element is scrutinized for excellence.

Advanced machinery like CNC machines and laser cutters are utilized to maximize precision and minimize human error. Real-time data analytics help identify potential issues, enabling immediate corrective actions. Consistent training programs ensure that their workforce remains adept with the latest industry practices and regulatory requirements.

Quality assurance teams conduct rigorous inspections, using specialized equipment to measure tolerances and specifications accurately. Random sampling and batch testing further ensure that only defect-free products reach customers’ hands. Constant feedback loops with clients guarantee continuous improvement in processes and products.

SourcifyChina also emphasizes sustainable and ethical manufacturing practices. They adhere to environmental guidelines and promote resource-efficient methods, reducing wastage. By maintaining transparent and open communication channels, they foster trust and long-term relationships with clients.

Through a comprehensive quality control system, SourcifyChina metal processing companies consistently meet and exceed client expectations. Their unwavering commitment to quality, innovation, and sustainability solidifies their reputation as leaders in the metal processing industry. Continuous improvement initiatives and robust quality assurance protocols ensure that they deliver superior, reliable products every time.

SourcifyChina metal processing companies specialize in a wide range of services including precision machining, stamping, and casting. They strive for impeccable quality and adhere to stringent international standards.

These companies utilize state-of-the-art equipment such as CNC machines and robotic arms to ensure precision and efficiency. This technological advancement allows them to handle complex projects seamlessly.

Skilled technicians and engineers form the backbone of these enterprises. Their expertise ensures that every project meets client specifications and industry standards without compromising on quality or timelines.

Clients benefit from comprehensive services that include design consultation, rapid prototyping, and mass production. This end-to-end approach simplifies the supply chain and reduces costs.

One of the key advantages is their ability to handle large volumes without sacrificing quality. This scalability makes them an ideal partner for businesses needing consistent and reliable production.

Perhaps most importantly, SourcifyChina companies are committed to continuous improvement. They invest in research and development to stay ahead of industry trends, enhancing their capabilities and offering innovative solutions.

In summary, SourcifyChina metal processing companies provide a comprehensive suite of services backed by advanced technology and skilled personnel. Their commitment to quality and scalability make them invaluable partners in the metal processing industry.

Metal processing companies play a crucial role in numerous industries by transforming raw metal materials into finished goods, ensuring precision and quality. These companies provide many benefits that enhance both industrial and consumer products.

– Enhanced Product Quality: Metal processing companies employ advanced technologies and methods to ensure products meet high-quality standards.

– Customization: They offer tailored solutions to meet specific client requirements, enabling unique product designs and specifications.

– Cost Efficiency: Bulk processing of metals reduces overall production costs, offering economical solutions for businesses.

– Durability and Strength: Processed metals often have improved durability and strength, making them ideal for structural and mechanical applications.

– Innovation: These companies drive technological advancements, continually improving processes and materials for better performance.

– Economic Growth: They contribute significantly to economic growth by providing jobs and supporting related industries like construction, automotive, and aerospace.

– Environmental Responsibility: Many metal processing companies adopt eco-friendly practices, such as recycling and waste reduction, to minimize environmental impact.

– Versatility: They work with various metals, including steel, aluminum, and copper, to create a wide range of products, from household items to industrial machinery.

– Increase in Productivity: Efficient metal processing enhances overall productivity in manufacturing processes.

By leveraging the capabilities of metal processing companies, industries can achieve greater efficiency, quality, and innovation in their products.

Metal processing companies offer a wide range of services to transform raw metal into finished products used across various industries. These features include precision, versatility, and advanced technology.

– Precision Cutting & Shaping: Advanced machinery enables accurate cutting, shaping, and forming of metals to specified dimensions.

– Welding & Fabrication: High-quality welding techniques ensure strong and durable metal structures.

– Surface Treatment: Processes like electroplating, painting, and powder coating enhance durability and appearance.

– Custom Design Capabilities: Tailor-made solutions to meet specific customer requirements.

– Quality Control Systems: Rigorous inspections and testing to ensure product quality and consistency.

– CNC Machining: Computer numerical control (CNC) technology allows for intricate and precise machining operations.

– Material Handling & Storage: Efficient logistics and storage solutions to manage raw materials and finished goods.

– Prototype Development: Capability to create prototypes for testing and validation before full-scale production.

– Sustainability Practices: Implementation of eco-friendly processes and waste management to minimize environmental impact.

– Technical Expertise & Support: Experienced professionals provide engineering support and technical advice.

– Scalability: Ability to handle both small-scale custom jobs and large-scale production runs.

– Innovative Techniques: Use of cutting-edge technology such as laser cutting, robotic welding, and 3D printing to stay competitive.

– Compliance with Standards: Adhering to industry standards and regulations to ensure safety and reliability.

These features highlight the significant role metal processing companies play in manufacturing and industrial sectors, contributing to the creation of high-quality, durable products across a broad spectrum of applications.

SourcifyChina specializes in connecting businesses with top-notch metal processing companies in China. These companies are known for their precision and high-quality outputs, ensuring that each project meets the industry standards and specific client requirements.

Custom metal products are one of SourcifyChina’s fortes. They offer a wide range of services, including cutting, welding, bending, and assembling various metal components to meet bespoke specifications. This allows businesses to obtain unique solutions tailored exactly to their needs.

The companies partnered with SourcifyChina maintain consistent quality through rigorous testing and quality control processes. They utilize advanced machinery and skilled labor to produce components that adhere to stringent tolerances, making sure every piece is up to mark.

Cost-effectiveness is another key advantage of using SourcifyChina’s network. Chinese metal processing firms offer competitive prices without compromising quality, allowing businesses to maximize their budget. This economic efficiency is a crucial aspect for companies trying to balance quality and cost.

SourcifyChina also prides itself on timely delivery and excellent customer service. They understand the importance of meeting deadlines and keeping communication channels open, ensuring projects are completed smoothly and on schedule. This commitment to customer satisfaction makes them a reliable partner.

In conclusion, SourcifyChina offers unparalleled access to China’s finest metal processing companies, excelling in custom products and projects. Their comprehensive services, competitive pricing, and dedication to quality and timeliness make them an ideal partner for businesses looking to innovate and excel.

SourcifyChina Metal Processing Companies is a distinguished entity in the realm of metal manufacturing and engineering solutions, headquartered in China. Renowned for its precision and high-quality output, the company specializes in a wide array of metal processing services, including CNC machining, sheet metal fabrication, casting, and forging. They leverage state-of-the-art technology and innovative production techniques to cater to diverse industrial sectors ranging from automotive and aerospace to electronics and heavy machinery. With a keen focus on customer satisfaction, SourcifyChina adheres to stringent quality control protocols, ensuring that each product meets international standards. Their adept team of engineers and technicians brings extensive expertise and a commitment to excellence, driving continual improvements and fostering just-in-time delivery systems. Furthermore, SourcifyChina’s competitive pricing and flexible manufacturing capabilities make it a preferred partner for businesses looking to optimize costs without compromising on quality. By upholding principles of sustainability and efficiency, SourcifyChina Metal Processing Companies continues to forge a robust presence in the global marketplace, contributing significantly to the advancement of modern manufacturing.

Metal processing companies play a crucial role in the aerospace, defense, and marine sectors by providing high-quality, precision-engineered components essential for the rigorous demands of these industries. In the aerospace sector, the need for lightweight but strong materials is paramount, given the stringent performance and safety standards. Metal processing firms employ advanced techniques such as additive manufacturing, CNC machining, and heat treatment to produce parts ranging from turbine blades to fuselage components. These companies ensure that metals like titanium, aluminum alloys, and high-strength steel meet exacting specifications, ensuring optimum performance, reduced weight, and enhanced durability for aircraft.

In the defense and marine industries, metal processing companies are integral in producing components that must endure harsh environments and extreme conditions. For defense applications, this includes the manufacturing of armored vehicles, missile casings, and various weapon systems where precision, strength, and reliability are non-negotiable. Similarly, in the marine sector, these companies contribute to the construction of ships and submarines, providing corrosion-resistant materials to withstand prolonged exposure to saltwater and varying pressure levels. Advanced metal processing techniques such as welding, forging, and surface treatment are employed to enhance the overall resilience and longevity of these vessels, ensuring they can operate safely and effectively in demanding environments.

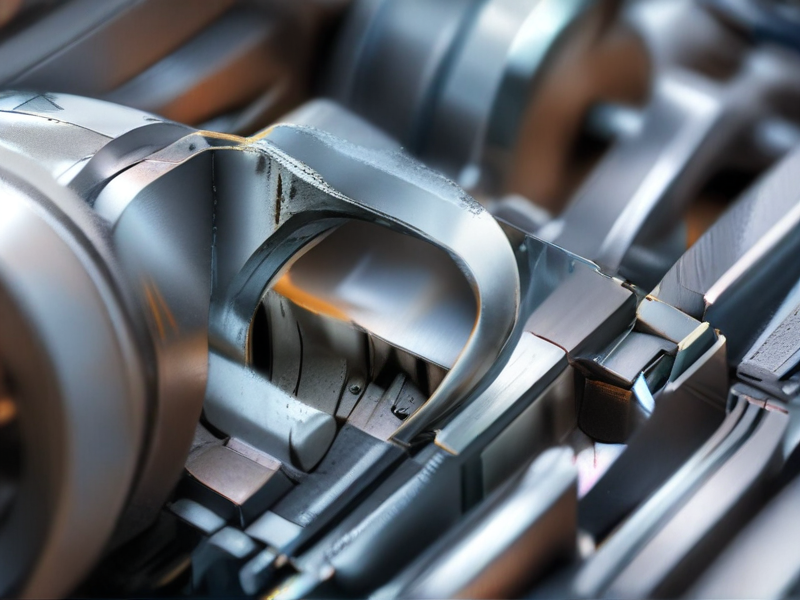

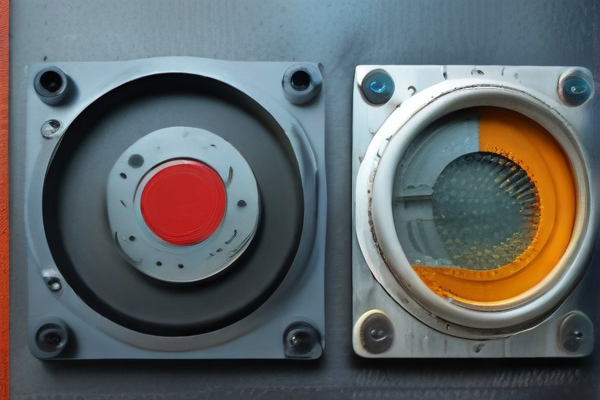

Metal processing companies play a critical role in the automotive industry by providing meticulously crafted components that meet high-performance and durability standards. These companies are involved in various stages of automobile manufacturing, including the forging, stamping, and machining of parts such as engine components, transmission systems, and structural elements. Advanced techniques such as CNC machining and die casting ensure precision and efficiency, enabling the production of lightweight yet robust materials crucial for modern fuel-efficient and electric vehicles. Furthermore, the adoption of technologies like additive manufacturing (3D printing) allows for rapid prototyping and the creation of complex geometries that were previously impossible or cost-prohibitive, thereby driving innovation and reducing time to market.

In the realm of electronics, metal processing companies contribute significantly to the fabrication of components essential for the functionality and miniaturization of electronic devices. High-purity metals and alloys, such as copper, aluminum, and gold, are processed into intricate parts used in printed circuit boards (PCBs), connectors, and semiconductor devices. Precision metal stamping and photochemical etching enable the production of minute components with exact specifications required for high-speed data transfer and reliable performance. Additionally, the use of advanced surface treatments and coatings enhances electrical conductivity and protects against corrosion, which is vital for the longevity and reliability of electronic gadgets. As consumer electronics continue to evolve with trends like IoT and wearable technology, metal processing companies remain at the forefront, supplying sophisticated materials that empower next-generation devices.

Metal processing companies play a pivotal role in the construction industry, providing essential materials that form the backbone of modern infrastructure. These companies process raw metal into beams, sheets, rods, and various other shapes that are foundational in building structures like skyscrapers, bridges, and residential housing. Their precision engineering and ability to produce high-strength materials ensure that the buildings can withstand diverse environmental stresses such as wind, seismic activity, and heavy loads. Advanced metal processing techniques like laser cutting, welding, and forging allow for the creation of custom designs and components tailored to specific architectural requirements. Additionally, innovations in metal processing contribute to the construction of more sustainable buildings by enabling the use of recycled metal, which reduces waste and lowers the carbon footprint associated with new construction projects.

In the energy sector, metal processing companies are indispensable for their role in manufacturing components used in power generation, transmission, and storage. Critical infrastructure such as wind turbines, solar panels, and nuclear reactors require high-quality metal parts with precise tolerances to ensure efficiency and reliability. For instance, turbine blades must be made from metals that can endure extreme mechanical stress and temperature variations, and this is made possible through advanced metallurgy and fabrication processes. Moreover, metal processing companies produce the intricate parts necessary for electric grid systems, including generators, transformers, and transmission lines. By employing cutting-edge techniques like additive manufacturing and surface treatment, these companies enhance the performance and lifespan of energy systems, thereby optimizing the production and distribution of energy. This synergy between metal processing and energy applications not only boosts operational efficiency but also supports the transition to more sustainable and renewable energy sources.

The industrial equipment sector heavily relies on metal processing companies for manufacturing, maintaining, and enhancing machinery used across various industries. These companies specialize in transforming raw metal materials into precision-engineered components essential for constructing robust and efficient industrial equipment. Processes such as cutting, welding, casting, and machining are employed to meet the stringent specifications demanded by industries like automotive, aerospace, construction, and manufacturing. For instance, metal processing companies supply custom-made parts for heavy-duty machines, conveyor systems, and structural elements that are integral to the industrial operation. This ensures the production of high-quality, durable equipment capable of withstanding rigorous conditions and extended usage, thereby optimizing operational efficiency and safety.

Moreover, metal processing companies contribute significantly to the innovation within the industrial equipment sector by incorporating advanced technologies such as CNC machining, laser cutting, and additive manufacturing. These innovations allow for greater precision, reduced material waste, and faster production times, which are critical for staying competitive in today’s market. By leveraging these cutting-edge techniques, metal processing companies enable equipment manufacturers to produce more complex and high-performance machinery. This collaboration not only drives technological advancements but also facilitates the adoption of sustainable practices, such as the development of lightweight yet sturdy components that enhance energy efficiency. In essence, metal processing companies are pivotal in driving both the evolution and sustainability of the industrial equipment sector.

Metal processing companies play a crucial role in the medical device industry, providing essential components that meet the stringent standards for safety, precision, and reliability. These companies are adept at manipulating various metals such as titanium, stainless steel, and cobalt-chrome alloys to produce components like surgical tools, implants, and diagnostic equipment. The high degree of precision required in the medical field means that metal processing firms must employ advanced techniques like CNC machining, laser cutting, and additive manufacturing. These methods ensure that the final products meet or exceed the rigorous specifications set by regulatory bodies like the FDA. Moreover, specialized surface treatments and coatings are often applied to enhance biocompatibility and durability, ensuring these devices function flawlessly within the human body.

In addition to manufacturing, metal processing companies are extensively involved in the research and development of new materials and devices. Collaborating closely with medical researchers and device manufacturers, they help to innovate next-generation solutions that can offer better clinical outcomes. For instance, their expertise in metallurgy has led to the development of biodegradable metal implants that gradually dissolve in the body, eliminating the need for secondary surgeries. Furthermore, advancements in nanotechnology and precision engineering have enabled the creation of micro-scale devices for minimally invasive surgeries, providing patients with faster recovery times and fewer complications. By continually pushing the boundaries of what is possible with metal processing, these companies are integral to the advancement of medical technology and patient care.

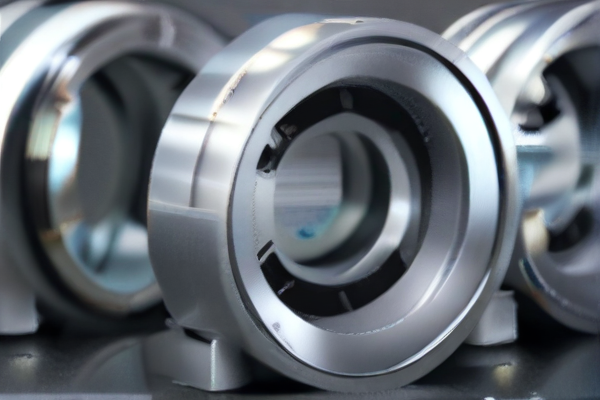

Metal processing companies play a pivotal role in the realm of manufacturing and machining by transforming raw metal materials into intricate and high-precision components essential for a myriad of industries. Utilizing advanced machining techniques such as CNC (Computer Numerical Control) machining, these companies can accurately shape metal pieces to exact specifications, ensuring uniformity and quality in production. CNC machines, for instance, enable the creation of complex parts through automated controls and precise movements, drastically reducing human error and enhancing efficiency. Metal processing companies also leverage various other methods like milling, turning, and drilling to meet diverse industrial needs, from aerospace to automotive, medical devices, and consumer electronics.

Furthermore, the application of metal processing in manufacturing extends to surface treatments and finishing processes that enhance the durability and performance of metal components. Techniques such as heat treatment, anodizing, and electroplating are employed to improve the hardness, corrosion resistance, and aesthetic appeal of metal parts. This comprehensive approach not only ensures that metal components meet stringent industry standards but also extends their lifecycle, offering better value and reliability. By integrating state-of-the-art technologies and skilled labor, metal processing companies are instrumental in driving innovation and ensuring the seamless production of high-quality metal products that are foundational to modern infrastructure and technological advancements.

What types of metal processing services does SourcifyChina factory offer?

SourcifyChina factory specializes in a wide range of metal processing services including cutting, welding, bending, stamping, machining, and surface treatment like painting and plating.

What materials can SourcifyChina factory handle?

Our factory can process various materials such as steel, aluminum, copper, brass, and other metal alloys suitable for diverse industrial applications.

How does SourcifyChina ensure the quality of its metal processing work?

We adhere to strict quality control measures including regular inspections, precision testing with advanced equipment, and compliance with international industrial standards to ensure high-quality output.

Can SourcifyChina provide custom metal processing solutions?

Yes, we offer customized metal processing services tailored to meet specific needs. Clients can supply their own designs or collaborate with our team to develop custom solutions.

What is the typical lead time for metal processing orders?

Lead time varies depending on the complexity and volume of the order. Generally, it ranges from 2 to 6 weeks. Expedited services are available upon request.

Does SourcifyChina factory offer prototyping services?

Yes, we provide prototyping services to help clients refine their product designs before moving into full-scale production.

What certifications does the factory hold?

SourcifyChina factory is ISO 9001 certified, ensuring that our quality management systems meet international standards. We also hold other industry-specific certifications as required.

Can SourcifyChina handle large-scale production runs?

Absolutely. Our factory is equipped with advanced machinery and a skilled workforce capable of handling both small and large-scale production runs efficiently.

How can I get a quote for my project?

You can request a quote by contacting us through our website, providing details about your project including design specifications, material requirements, and quantity needed. We aim to respond within 24-48 hours.

What are the payment terms?

We offer flexible payment terms which can be discussed during the contract negotiation phase. Common payment methods include wire transfer, letter of credit, and other secure payment options.

For more detailed information or specific inquiries, please contact our customer service team.

Partnering with metal processing companies manufacturing through SourcifyChina factory can be a strategic move for any business looking to enhance its production capabilities. Here are some key tips to maximize the benefits and ensure smooth operations:

1. Identify Your Needs:

– Clearly outline your product specifications, materials, and processing techniques required. This will help in selecting the right manufacturer who meets your exact needs.

2. Thorough Research:

– Utilize Sourcify’s resources to vet potential manufacturers. Check for ISO certifications, quality control measures, and assess their past projects and client reviews.

3. Samples and Prototyping:

– Request prototypes before making full-scale production commitments. This confirms the quality and precision of the manufacturer’s capabilities.

4. Supply Chain Integration:

– Ensure seamless integration of the manufacturer’s supply chain with your operations. Assess lead times, logistics, and the manufacturer’s ability to scale production.

5. Communication:

– Establish clear communication channels. Language barriers and time zone differences can be challenging; using Sourcify’s platform can streamline this.

6. Cost Analysis:

– Compare quotes and consider not only the price but also the overall value including quality, reliability, and long-term partnership potential.

7. Quality Assurance:

– Implement strict quality control processes. Regularly inspect production runs and consider third-party audits to maintain high standards.

8. Contracts and Compliance:

– Draft detailed contracts outlining all terms, conditions, and compliance with international manufacturing standards to protect your business interests.

9. Cultural Sensitivity:

– Understanding Chinese business culture and practices can improve negotiations and foster stronger relationships.

10. Sustainability:

– Consider manufacturers that adopt sustainable practices. This aligns with global trends and can enhance your brand’s image.

Following these tips can lead to a successful partnership with SourcifyChina factory metal processing companies, enhancing product quality, cost efficiency, and market responsiveness.

Sure! Here are a few frequently asked questions (FAQs) with answers for sourcing metal processing companies from SourcifyChina Factory:

Q: What types of metal processing services do SourcifyChina Factory offer?

A: SourcifyChina Factory offers a wide range of metal processing services, including but not limited to CNC machining, metal stamping, casting, forging, laser cutting, and metal fabrication. They cater to a variety of industries such as automotive, aerospace, electronics, and construction.

Q: How can I ensure the quality of metal products sourced from SourcifyChina Factory?

A: SourcifyChina Factory implements strict quality control measures, including ISO certification, routine inspections, and adherence to international standards. Additionally, you can request third-party inspections or factory audits to further ascertain quality.

Q: What is the typical lead time for metal processing orders?

A: Lead times can vary depending on the complexity and quantity of your order. Generally, prototyping takes around 1-3 weeks, while bulk production can take 4-8 weeks. It’s best to communicate your specific needs directly with SourcifyChina Factory for an accurate estimate.

Q: Are there minimum order quantities (MOQs) for metal processing services?

A: SourcifyChina Factory does have MOQs, which can vary depending on the type of service and metal being used. It’s advisable to discuss your project details directly with the factory to understand any specific MOQ requirements.

Q: How do I get a quote for my metal processing project?

A: To get a quote, you will need to provide SourcifyChina Factory with detailed specifications, including drawings or CAD files, materials, quantities, and any special requirements. The factory typically responds with a quotation within a few business days.

Q: What payment terms does SourcifyChina Factory accept?

A: Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes PayPal or credit card for smaller orders. Usually, a deposit is required upfront with the balance paid before shipment.

Q: How do I handle shipping and logistics for orders from SourcifyChina Factory?

A: SourcifyChina Factory can manage shipping and logistics on your behalf, or you can use your own freight forwarder. They offer multiple shipping options, including air freight, sea freight, and courier services, depending on your urgency and budget.

Certainly! Sourcing metal processing companies from SourcifyChina factory can streamline your supply chain and ensure high-quality production. Here are some concise tips to help you get started:

1. Define Your Requirements: Clearly outline the specifications for your metal products. This includes material type, dimensions, tolerances, quantity, and any finishing processes required.

2. Utilize SourcifyChina’s Platform: Leverage SourcifyChina’s database to find reliable suppliers. The platform categorizes companies by industry, making it easier to identify specialized metal processing firms.

3. Check Company Profiles: Review the company profiles on SourcifyChina. Pay attention to their service offerings, experience, certifications, and customer reviews. Look for companies with a strong history in metal processing.

4. Evaluate Capabilities: Ensure the company can handle your specific processing needs—such as CNC machining, stamping, welding, or casting. Verify that they have the necessary technology and machinery.

5. Request Samples: Before making any commitments, ask for sample products to assess their quality and adherence to specifications.

6. Assess Communication: Effective communication is crucial. Evaluate how promptly and clearly the suppliers respond to your inquiries. Clear communication helps prevent misunderstandings and ensures smoother collaboration.

7. Visit Factories: If possible, arrange visits to shortlisted factories. This allows you to inspect production facilities, and quality control measures, and establish personal connections with the management team.

8. Negotiate Terms: Once you’ve selected a potential supplier, negotiate the terms of the contract covering pricing, minimum order quantities, lead times, payment terms, and warranty provisions.

9. Audit and Compliance: Ensure the supplier adheres to international quality standards and has the necessary certifications. Regular audits can help maintain consistent quality.

10. Build a Relationship: Establish a strong relationship with your supplier. Open and ongoing communication can lead to better service and potential cost reductions over time.

By following these steps, you can effectively source reputable metal processing companies through SourcifyChina and foster successful, long-term partnerships.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.