Connecting with Reliable Sheet Metal Companies in China: SourcifyChina’s Comprehensive Factory Database

Discover a trustworthy network of sheet metal companies in China through SourcifyChina’s extensive factory database. Our platform ensures quality and reliability, helping you streamline your manufacturing process with vetted factory partners. Explore options and connect with top-rated suppliers today.

High-Quality Manufacturing Standards

SourcifyChina Factory adheres to rigorous quality control measures, ensuring top-notch sheet metal products. Their commitment to excellence makes them a reliable choice for international buyers seeking consistency and high standards.

Experienced and Skilled Workforce

The factory employs a highly skilled and experienced workforce. Their technical expertise ensures precision and efficiency in production, catering to the diverse requirements of global clients.

Advanced Technology and Equipment

Equipped with state-of-the-art machinery, SourcifyChina Factory leverages advanced technology to produce high-quality sheet metal components. This investment in technology translates to superior products and satisfied customers.

Competitive Pricing

One of the key advantages of choosing SourcifyChina Factory is their competitive pricing. They offer value for money without compromising on quality, making them a cost-effective solution for sheet metal procurement.

Strong Customer Support

SourcifyChina Factory prides itself on excellent customer support. They maintain open lines of communication and provide timely updates, ensuring a smooth purchasing experience for international buyers.

Commitment to Sustainability

This factory places a strong emphasis on sustainable practices, minimizing environmental impact. Their commitment to eco-friendly manufacturing aligns with the growing global emphasis on sustainability.

Customizable Solutions

SourcifyChina Factory offers customizable solutions to meet specific client needs. Whether it’s a unique design or special material requirement, they have the flexibility to accommodate diverse requests.

On-time Delivery

Reliable and punctual delivery schedules are a hallmark of SourcifyChina Factory. Buyers can trust them for timely shipment, reducing potential delays in their supply chain.

Compliance with International Standards

Adhering to global standards, SourcifyChina Factory ensures their products meet international certifications. This compliance reassures buyers of the factory’s dedication to producing high-quality, reliable sheet metal products.

Positive Client Testimonials

Numerous positive client testimonials affirm SourcifyChina Factory’s reputation. Satisfied customers from various industries highlight their excellence, reliability, and superior customer service, making them a preferred choice for sheet metal procurement.

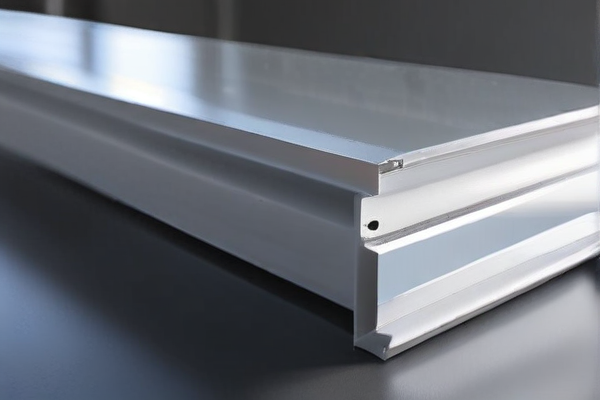

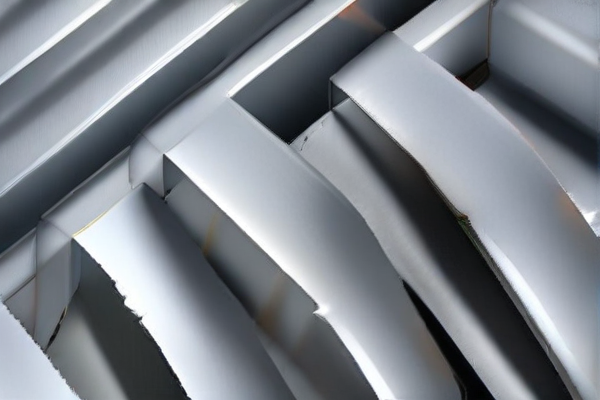

Sheet metal companies specialize in the fabrication and manufacturing of various metal products. They offer services such as cutting, bending, welding, and assembling to meet diverse industrial needs.

– Custom Fabrication: Companies provide tailor-made solutions, ensuring each project meets specific requirements.

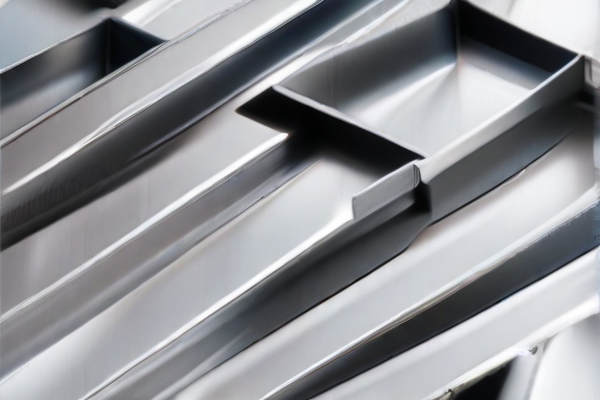

– Cutting Services: Advanced techniques like laser cutting, waterjet, and plasma cutting.

– Sheet Metal Bending: Precision bending with tools such as press brakes and folding machines.

– Welding and Assembly: Professional welding, including TIG, MIG, and spot welding, for durable assemblies.

– CNC Machining: Computer-controlled precision for complex parts and designs.

– Prototyping: Rapid prototyping services to validate designs before full-scale production.

– Finishing Services: Options like powder coating, painting, and galvanizing for aesthetic and protective finishes.

– Stamping: Mass production of parts using high-speed stamping presses.

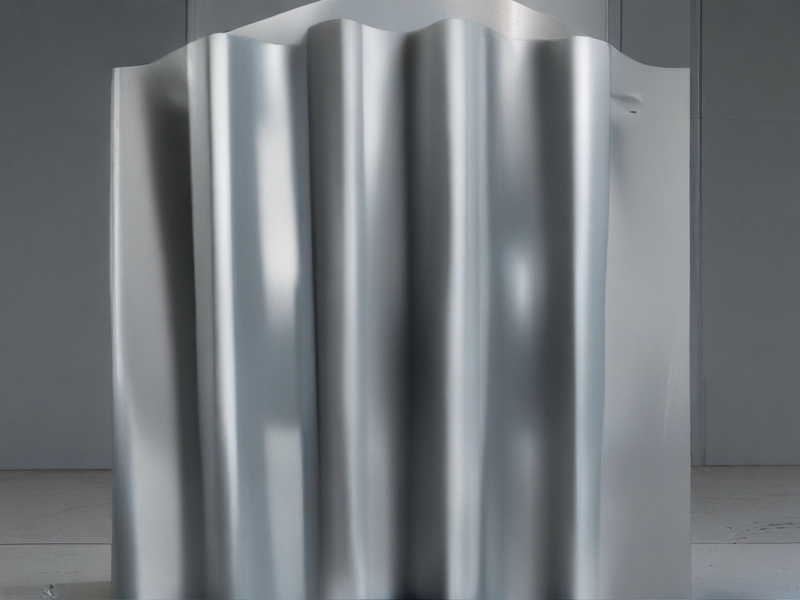

– Forming and Rolling: Creating curves and rolls in metal sheets through specialized forming techniques.

– Shearing: Cutting large sheets into smaller, precise sections.

– Punching and Blanking: Creating holes and shapes in metal sheets using punching machines.

– Die Casting: Producing complex shapes with molten metal and reusable molds.

– Fabrication of Components: Creation of parts for various industries, including automotive, aerospace, and construction.

– Material Sourcing: Sourcing various metals like steel, aluminum, copper, and more to match project needs.

– Engineering Support: Providing design assistance and engineering expertise for optimal production.

– Quality Control: Rigorous testing and inspection to ensure high standards and compliance.

Sheet metal companies cater to different sectors, offering versatility and precision to meet varied manufacturing requirements. Their expertise and advanced technologies ensure high-quality, durable products customized to client specifications.

Sheet metal companies play a crucial role in various industries, offering fabrication, customization, and repair services essential for numerous applications. Their expertise ensures high-quality, durable products.

– Automotive Industry: Custom parts, body panels, exhaust systems.

– Construction: Roofing, HVAC components, structural elements.

– Aerospace: Aircraft components, structural supports.

– Electronics: Enclosures for devices, heat sinks.

– Medical Devices: Equipment casings, structural parts.

– Agriculture: Equipment parts, storage solutions.

– Furniture: Metal frames, custom fixtures.

– Renewable Energy: Solar panels, wind turbine components.

– Marine Industry: Boat parts, custom fittings.

– Manufacturing: Tooling, machinery parts.

– Defense: Vehicle armor, equipment housings.

– Signage: Custom metal signs, display fixtures.

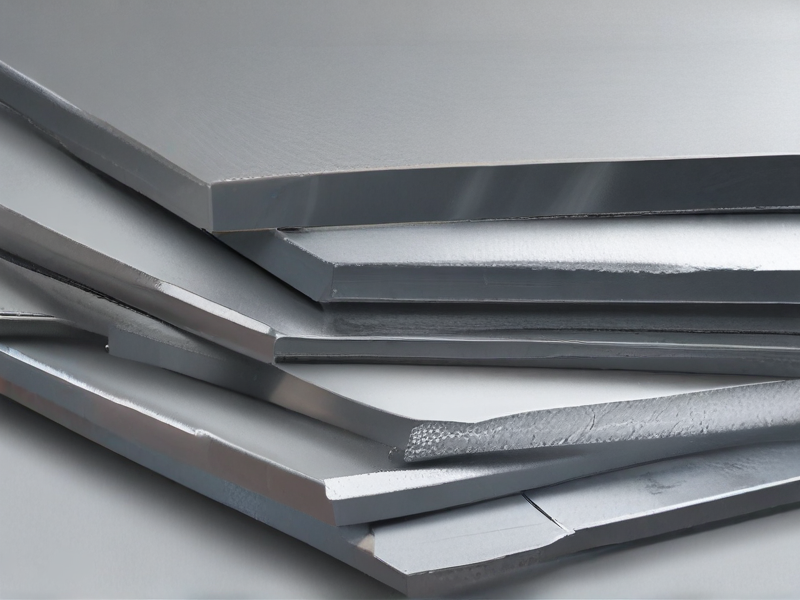

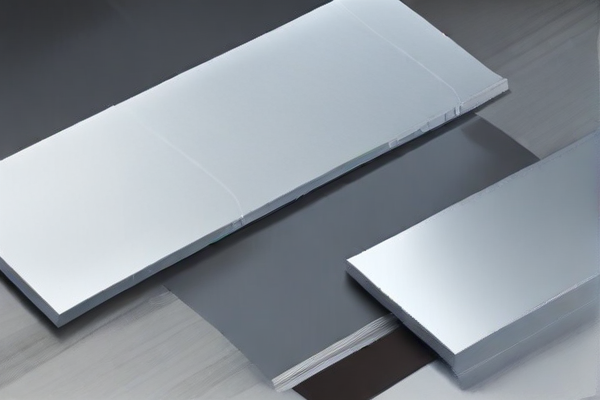

SourcifyChina sheet metal companies specialize in high-quality metal fabrication services. They offer materials such as stainless steel, aluminum, and galvanized steel, which are commonly used for various industries. These companies utilize advanced machinery and techniques to ensure precision and durability.

Their stainless steel is known for its corrosion resistance and strength, making it ideal for harsh environments. Aluminum is lightweight yet strong, perfect for applications where weight is a concern. Galvanized steel, coated in zinc, provides long-lasting protection against rust and corrosion, suitable for outdoor use.

SourcifyChina sheet metal companies prioritize quality control. They adhere to strict standards and use state-of-the-art equipment for cutting, bending, and welding. This ensures that each product meets customer specifications and industry regulations. Their team of skilled technicians and engineers work diligently to deliver consistent results.

Customization is a key service offered by SourcifyChina. They provide tailored solutions to meet unique project requirements. Whether it’s custom enclosures, chassis, or brackets, these companies possess the expertise to fabricate complex shapes and structures accurately.

In addition to high-quality materials and precision fabrication, SourcifyChina sheet metal suppliers focus on sustainable practices. They implement efficient processes to minimize waste and promote recycling. This commitment to environmental responsibility aligns with global efforts to reduce carbon footprints and support sustainable manufacturing.

Overall, SourcifyChina sheet metal companies offer a comprehensive range of materials and services. Their dedication to quality, customization, and sustainability sets them apart in the industry. Clients can expect superior products and reliable partnerships, ensuring successful project outcomes. With a strong emphasis on innovation and customer satisfaction, these companies continue to advance in the field of sheet metal fabrication.

SourcifyChina sheet metal companies prioritize stringent quality control measures throughout their manufacturing processes. Each stage, from material selection to final inspection, is scrutinized to ensure adherence to international standards.

The initial stage involves meticulous material examination, ensuring that only top-grade metals are used. Rigorous testing for strength, durability, and compatibility is performed to prevent any future discrepancies.

Throughout fabrication, precision is maintained using advanced machinery and skilled technicians. Continuous monitoring and real-time adjustments help uphold high precision, reducing the chance of defects.

Final quality checks involve thorough inspections, where each piece undergoes detailed measurement validation and surface finishing analysis. This ensures that products meet specified dimensions and aesthetic requirements.

Customer satisfaction is a pivotal goal, achieved by maintaining transparency and consistent quality. Continuous feedback mechanisms are in place to make necessary improvements, ensuring that each batch surpasses the previous in quality.

In conclusion, SourcifyChina’s comprehensive quality control process, from material procurement to final inspection, ensures that each sheet metal product meets the highest standards of durability, precision, and customer satisfaction. This unwavering commitment to quality makes them a trusted name in the industry.

SourcifyChina sheet metal companies excel in precision fabrication, specializing in the production of a wide range of metal components. Their expertise spans from cutting, bending, and welding to final assembly.

Advanced technologies are at the core of SourcifyChina’s capabilities. They utilize state-of-the-art CNC machinery, laser cutting, and robotic welding to ensure tight tolerances and high-quality outputs for every project.

Customization is another strength. SourcifyChina offers tailored solutions for clients’ specific needs, whether it involves intricate designs or unique material requirements. Their skilled engineers work closely with clients to bring their visions to life.

Additionally, SourcifyChina maintains rigorous quality control processes. Each product undergoes meticulous inspection, adhering to international standards to guarantee consistency and reliability. This focus on quality makes them a trusted partner in various industries.

Timely delivery and efficient logistics are also key elements of SourcifyChina’s service. They ensure that projects are delivered on schedule, which is crucial for clients working within strict timelines and tight budgets.

Lastly, SourcifyChina places a strong emphasis on sustainability. Their operations adhere to environmentally-friendly practices, aiming to minimize waste and reduce their carbon footprint. This commitment to eco-friendly processes aligns with global trends towards sustainable manufacturing. Overall, SourcifyChina sheet metal companies offer a comprehensive range of services, combining advanced technology, customized solutions, stringent quality control, timely delivery, and sustainability.

Sheet metal companies offer numerous advantages, ranging from cost efficiency to high precision. Their expertise is paramount in various industries, including automotive and construction.

– Cost Efficiency: Sheet metal fabrication is typically less expensive than other methods, making it a cost-effective solution for large-scale projects.

– Durability: Sheet metal is highly durable and resistant to various environmental factors, increasing the lifespan of the final product.

– Customization: Companies can tailor sheet metal products to meet specific client needs, thereby offering high levels of customization.

– Versatility: Sheet metal can be used in a wide array of industries, such as automotive, construction, aerospace, and electronics.

– Precision: Advanced technologies, such as CNC machines, enable high precision in the cutting, bending, and forming of sheet metal, ensuring consistent quality.

– Reduced Waste: Modern fabrication processes are designed to maximize material usage, leading to less waste and lower overall material costs.

– Fast Turnaround: The efficiency of sheet metal fabrication means projects can be completed quickly, which is beneficial in time-sensitive industries.

– Scalability: Whether you’re working on a small prototype or a large production run, sheet metal companies can scale their operations to meet your needs.

– Innovation: The industry constantly evolves with new technologies and methods, ensuring that companies remain at the forefront of innovation.

Choosing a reputable sheet metal company ensures high-quality, cost-effective, and customized solutions tailored to your specific industry requirements.

Sheet metal companies offer a wide array of features that make them essential in various industries. These businesses provide precision, customization, and high-quality products tailored to customer specifications.

– Advanced Machinery: Utilizing CNC machines, laser cutters, and other state-of-the-art equipment for precise fabrication.

– Customization: Ability to create highly tailored products to meet specific client requirements.

– Material Variety: Expertise in working with different metals such as aluminum, steel, copper, and more.

– Prototyping Services: Offering design and prototype services to ensure accuracy before full production.

– Mass Production Capabilities: Efficiently handling large-scale production runs.

– Quality Control: Rigorous quality assurance processes to meet industry standards and customer expectations.

– Engineering Support: Providing technical assistance and consultation for complex projects.

– Cost-Effective Solutions: Optimizing production processes to deliver economical solutions without compromising quality.

– Fast Turnaround Times: Efficient workflow management to meet tight deadlines.

– Environmental Considerations: Implementing eco-friendly practices and sustainable materials.

– Welding and Assembly: Offering additional services such as welding, assembly, and finishing.

– Versatility: Serving multiple industries including automotive, aerospace, construction, and healthcare.

– Client Communication: Maintaining clear and consistent communication to ensure project alignment.

– Certifications: Holding industry-recognized certifications to guarantee compliance and quality.

– Research and Development: Continuously innovating and improving products and processes.

These features collectively make sheet metal companies indispensable partners in manufacturing and construction, ensuring both quality and efficiency.

SourcifyChina specializes in connecting businesses with top-notch sheet metal companies in China. Their extensive network of reliable suppliers ensures precise and high-quality custom products tailored to meet various project specifications.

From intricate prototypes to large-scale production runs, SourcifyChina handles projects of all sizes. Their suppliers employ advanced fabrication techniques, including CNC machining, laser cutting, and stamping. This guarantees accuracy and durability in every delivery.

Focus on efficiency and cost-effectiveness sets SourcifyChina apart. Clients save on manufacturing costs without compromising on quality, thanks to the competitive pricing offered by Chinese suppliers.

The company places great emphasis on communication and transparency throughout the production process. Regular updates and thorough quality checks ensure that the final products meet stringent international standards.

SourcifyChina offers a seamless experience from initial consultation to final delivery. Their dedicated team assists with everything from design optimization to logistics, ensuring timely and satisfactory completion of every project.

Whether it’s automotive, aerospace, consumer electronics, or any other industry, SourcifyChina’s commitment to excellence makes them a trusted partner for custom sheet metal projects. Their focus on client satisfaction, combined with unparalleled expertise, guarantees successful and innovative outcomes every time.

SourcifyChina is a prominent facilitator in the realm of sheet metal fabrication, acting as a vital bridge between international clients and reputable Chinese sheet metal companies. With an extensive network of vetted manufacturers, SourcifyChina ensures quality and precision in every product, catering to a diverse array of industries including automotive, aerospace, and construction. The company’s robust quality assurance processes, coupled with its adept project management team, guarantee that all projects align with the highest industry standards. SourcifyChina’s commitment to transparency and cost-effective solutions has garnered a strong reputation in the global market, while its localized expertise provides clients with a seamless supply chain experience, minimizing risks and maximizing efficiency. Through a blend of innovation, reliability, and customer-centric service, SourcifyChina has solidified itself as a cornerstone in the sheet metal manufacturing sector.

Sheet metal companies play a pivotal role in the aerospace, defense, and marine industries by providing customized metallic components essential for the structural integrity and functionality of various vehicles and equipment. In aerospace, precision-engineered sheet metal parts are critical for aircraft manufacturing, from the fuselage and wings to internal components and brackets. These companies leverage advanced technologies such as Computer Numerical Control (CNC) machining and laser cutting to produce parts that meet stringent industry standards for durability, weight efficiency, and aerodynamic performance. The accuracy and reliability of sheet metal components ensure the safe operation of aircraft under demanding conditions, contributing to the overall efficiency of the aviation sector.

In the defense and marine sectors, sheet metal companies are instrumental in the fabrication of robust and resilient structures required for military vehicles, naval ships, and submarines. Defense applications often demand materials that offer high tensile strength, corrosion resistance, and protection against ballistic impacts. Sheet metal fabricators use state-of-the-art techniques to create armored plating, structural frames, and various other critical components that meet rigorous defense specifications. For marine applications, the emphasis is on corrosion resistance and durability to withstand harsh oceanic environments. The use of advanced alloys and precise fabrication methods ensures that these components perform reliably over extended periods, thereby ensuring the safety and operational readiness of naval fleets. Through the expertise of sheet metal companies, the aerospace, defense, and marine industries achieve superior performance, safety, and longevity in their operational assets.

Sheet metal companies play a crucial role in the automotive industry by providing essential components that form the backbone of vehicle structures. These companies specialize in fabricating parts such as body panels, chassis, and intricate under-hood components. The versatility of sheet metal allows automotive manufacturers to achieve precise specifications and high-strength performance required for modern vehicles. Advanced techniques like stamping, bending, and laser cutting enable the production of lightweight yet durable parts, contributing to overall vehicle efficiency and safety. Additionally, sheet metal companies often employ innovative processes like hydroforming and computer-aided design (CAD) to enhance the structural integrity and aesthetics of automotive components, ensuring they meet stringent industry standards and consumer expectations.

In the realm of electronics, sheet metal companies provide indispensable solutions for the protection and functionality of various devices. They manufacture enclosures, brackets, and chassis that house delicate electronic components, safeguarding them from environmental factors and physical damage. The precision offered by sheet metal fabrication ensures that these components are not only robust but also maintain the necessary tolerances for optimal performance. Techniques like CNC punching and folding are employed to produce complex geometries required in devices such as computers, medical equipment, and telecommunications hardware. Furthermore, the adaptability of sheet metal allows for the integration of cooling solutions, grounding tabs, and electromagnetic interference (EMI) shielding, enhancing the reliability and lifespan of electronic products. The collaboration between sheet metal companies and the electronics industry underscores the importance of meticulous design and manufacturing practices in delivering high-quality, durable electronic devices.

Sheet metal companies play a crucial role in the construction industry by providing essential materials and components used in various building projects. These firms fabricate, cut, and assemble metal sheets into versatile building elements such as roofing panels, wall cladding, ventilation ducts, and structural supports. The customization capabilities of sheet metal make it an invaluable resource for constructing both residential and commercial edifices. High durability, resistance to environmental factors, and the ability to handle heavy loads are inherent properties of sheet metal, which make it ideal for construction applications. Moreover, these companies are increasingly incorporating advanced technologies like computer-aided design (CAD) systems and automated manufacturing processes to ensure precision and efficiency, thereby enhancing the overall quality and safety of building projects.

In the realm of energy applications, sheet metal companies contribute significantly by supplying the components needed for various types of energy systems. These include parts for renewable energy installations such as solar panels and wind turbines, as well as traditional energy generation equipment like boilers and heat exchangers. The versatility of sheet metal allows for the fabrication of customized and energy-efficient components designed to optimize performance and sustainability. For instance, in solar energy applications, sheet metal is used to create highly reflective and durable mounting systems that ensure optimal orientation and stability of solar panels. Similarly, in the case of wind turbines, sheet metal is utilized to construct aerodynamic housings and support structures. By leveraging their expertise in materials and fabrication techniques, sheet metal companies are indispensable in advancing modern energy solutions and contributing to a more sustainable future.

These two paragraphs provide a succinct overview of how sheet metal companies are indispensable in both construction and energy sectors, highlighting their versatility and critical role in advancing modern infrastructure and sustainable energy solutions.

Sheet metal companies play a pivotal role in the industrial equipment sector by providing precision-engineered components essential for the manufacturing and functioning of various machinery. These companies specialize in fabricating metal sheets into intricate shapes and designs, catering to the specific needs of industrial equipment such as HVAC systems, conveyor belts, and heavy machinery enclosures. The versatility of sheet metal allows for the creation of durable and robust parts that withstand the rigorous demands of industrial environments. Advanced techniques like laser cutting, bending, and stamping are employed to ensure precise dimensions and high-quality finishes, allowing for enhanced efficiency and longevity of the equipment.

Moreover, the integration of computerized design and automated manufacturing processes in sheet metal companies has streamlined production, leading to cost-effective and timely delivery of components. This technological advancement supports the customization of parts to meet unique industrial requirements without compromising on performance or safety standards. By partnering with sheet metal companies, manufacturers in the industrial equipment industry can achieve improved product innovation, quicker turnaround times, and reduced material waste. Consequently, this collaboration not only boosts productivity but also fosters sustainable practices, making the industrial equipment sector more responsive to the evolving demands of modern manufacturing.

Sheet metal companies play a pivotal role in the medical device industry, contributing to the production of a wide array of essential medical equipment. From surgical instruments to hospital beds and diagnostic machines, sheet metal is a versatile material that offers durability, corrosion resistance, and precision—all crucial traits for medical applications. Companies specialize in processes such as cutting, bending, and welding sheet metal to create custom components tailored to the stringent requirements of medical devices. For instance, MRI and CT scan machine housings, surgical lights, and sterilization containers all benefit from the robustness and adaptability of sheet metal. The ability to engineer complex geometries and lightweight structures also makes sheet metal an ideal choice for the ergonomic and functional design of medical devices.

In addition to manufacturing, sheet metal companies are increasingly integrating advanced technologies like CNC machining, laser cutting, and robotic welding to meet the high standards of precision and cleanliness required in the medical field. These companies often operate in controlled environments to ensure that the components are free from contaminants and defects. Furthermore, regulatory compliance with standards such as ISO 13485 for medical devices is a priority, assuring quality and safety in the final products. By leveraging their expertise in sheet metal fabrication, these companies not only enhance the performance and safety of medical devices but also contribute to innovations that improve patient care and treatment outcomes.

Machining and manufacturing in sheet metal companies are integral to producing a wide array of components utilized across various industries such as automotive, aerospace, construction, and consumer electronics. The process begins with sheet metal fabrication, involving cutting, bending, and assembling flat metal sheets into desired shapes and structures. Advanced technologies such as CNC (Computer Numerical Control) machining, laser cutting, and water jet cutting are employed for high precision and efficiency. CNC machining automates the control of machining tools via computers executing pre-programmed sequences, ensuring consistent and intricate designs with high accuracy. Laser cutting uses high-powered lasers to achieve fine cuts with minimal material wastage, while water jet cutting leverages high-pressure water streams mixed with abrasives to slice through metals without generating heat, thus preserving the structural integrity of the material.

Additionally, sheet metal companies focus on adopting lean manufacturing principles to optimize production processes, reduce waste, and enhance overall efficiency. This includes implementing just-in-time manufacturing strategies, which minimize inventory costs by synchronizing production schedules with demand. These companies also maintain a strong emphasis on quality control, employing techniques such as Six Sigma and ISO standards to ensure that products meet stringent quality specifications. Modern sheet metal companies often employ CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software for designing and planning the fabrication process, which reduces human errors and improves the workflow. These technological advancements enable sheet metal companies to deliver high-quality, customized solutions tailored to the specific needs of their clients, driving innovation and competitiveness in today’s fast-paced manufacturing landscape.

Sure, here are some frequently asked questions (FAQ) for sheet metal companies looking for quality work from SourcifyChina factory:

1. What is SourcifyChina’s expertise in sheet metal manufacturing?

SourcifyChina specializes in precision sheet metal fabrication, including laser cutting, bending, stamping, and welding. Our experienced team ensures high-quality output tailored to your specifications.

2. What materials does SourcifyChina work with for sheet metal fabrication?

We work with a variety of materials, including stainless steel, aluminum, carbon steel, and other alloys. We choose materials based on your project requirements and performance needs.

3. How does SourcifyChina ensure the quality of its sheet metal work?

We adhere to stringent quality control processes, including thorough inspections at each production stage. Our certifications, such as ISO 9001, ensure compliance with international standards.

4. Can SourcifyChina handle custom sheet metal designs?

Yes, we collaborate closely with clients to understand their specific needs. Our advanced machinery and skilled personnel can accommodate custom designs and complex geometries.

5. What is the lead time for sheet metal projects at SourcifyChina?

Lead times vary based on project complexity and volume. Typically, prototypes are completed within 2-3 weeks, while larger production runs might take 4-6 weeks. We prioritize timely delivery without compromising quality.

6. Does SourcifyChina offer prototype and mass production services?

Yes, we provide both prototype and mass production services. Whether you need a single unit for testing or thousands for full-scale production, we have the capabilities to meet your needs.

7. How can I get a quote for my sheet metal project?

You can request a quote by contacting us through our website or via email. Please provide detailed specifications, including material, dimensions, and quantity, to help us give you an accurate estimate.

8. What are the shipping options for international clients?

We offer various shipping options including air freight, sea freight, and express courier services. We work with trusted logistics partners to ensure safe and timely delivery worldwide.

9. Are there any minimum order requirements?

We accommodate both small and large orders. Our flexible manufacturing processes allow us to handle low-volume prototypes as well as high-volume production runs.

10. How does SourcifyChina handle post-production support?

When dealing with sheet metal manufacturing companies from SourcifyChina, it’s crucial to be well-prepared and informed to ensure a seamless experience. Here are some key tips:

1. Research and Vetting: Start by thoroughly researching potential companies. Look for reviews, case studies, and testimonials. SourcifyChina likely offers vetted suppliers, but it’s important to do your due diligence.

2. Clear Communication: Ensure you have clear and consistent communication. Language barriers can be an issue, so make sure you’re comfortable with the communication style and they understand your requirements.

3. Detailed Specifications: Provide precise and detailed specifications for your sheet metal needs. This includes materials, dimensions, tolerances, finishes, and any other special requirements.

4. Sampling: Request samples before full-scale production. This helps verify the quality and ensures that the product meets your expectations.

5. Quality Control: Implement a robust quality control process. Consider third-party inspections to ensure the quality and adherence to specifications.

6. Lead Times: Be clear about lead times and ensure they align with your project timelines. Understand that shipping from China may add extra time to the overall delivery schedule.

7. Cost Transparency: Ensure transparency in pricing. Clarify if the quote includes all costs such as tooling, production, shipping, and any possible tariffs.

8. Legal and Compliance: Understand the legal and compliance aspects of importing from China. This includes customs duties and ensuring that the products meet your country’s regulatory standards.

9. Payment Terms: Discuss and agree on payment terms early in the process. It’s common to pay a deposit upfront and the remainder upon completion or delivery.

10. After-Sales Support: Ensure the company offers reliable after-sales support and that they handle any potential issues effectively.

By following these tips, you can foster a productive and reliable partnership with sheet metal manufacturing companies through SourcifyChina.

Frequently Asked Questions (FAQ) About Sourcing Sheet Metal Companies from SourcifyChina Factory

Q1: What services does SourcifyChina offer for sourcing sheet metal companies?

A1: SourcifyChina provides end-to-end sourcing services, including identifying credible manufacturers, evaluating their capabilities, facilitating communication, and managing quality control to ensure you receive reliable and high-quality sheet metal components.

Q2: How can I verify the quality of sheet metal products from SourcifyChina’s factories?

A2: SourcifyChina conducts thorough factory audits and quality inspections. They provide detailed reports, samples, and certifications to ensure the products meet your specifications and industry standards.

Q3: What are the lead times for sourcing sheet metal components from SourcifyChina?

A3: Lead times vary depending on the complexity and volume of your order. Typically, it ranges from 4 to 8 weeks, including production and shipping. It’s advisable to discuss timelines during the initial consultation.

Q4: Are there any minimum order quantities (MOQ) to consider?

A4: Yes, MOQs may vary depending on the factory and specific product requirements. SourcifyChina will help you find manufacturers that match your desired order size to maximize cost-efficiency.

Q5: How does SourcifyChina ensure competitive pricing for sheet metal sourcing?

A5: SourcifyChina leverages its extensive network and market knowledge to negotiate favorable terms. They compare quotations from multiple suppliers to provide you with the best possible pricing without compromising quality.

Q6: Can SourcifyChina assist with design and customization of sheet metal parts?

A6: Absolutely! SourcifyChina collaborates with experienced engineers and designers who can assist with product design, prototyping, and customization to meet your specific requirements.

Q7: How do I initiate a sourcing project with SourcifyChina?

A7: Start by contacting SourcifyChina via their website or email with your project details. They’ll set up an initial consultation to understand your needs and develop a tailored sourcing strategy.

Q8: What payment terms are available when sourcing through SourcifyChina?

A8: Payment terms can vary, but common options include a percentage deposit upfront with the balance payable upon product completion or shipment. Specific terms will be outlined in your agreement.

Q9: Are shipping and logistics services included in SourcifyChina’s sourcing process?

Sourcing sheet metal companies via SourcifyChina can streamline your search, ensuring you find reliable suppliers. Here are some tips to get started:

1. Define Your Requirements:

– Clearly specify your product requirements, including material type, dimensions, quantities, and any special treatments or finishes.

2. Use Detailed Keywords:

– When searching on SourcifyChina, use specific keywords such as “sheet metal fabrication,” “stainless steel sheet metal,” “aluminum sheet metal services,” etc.

3. Filter and Sort Results:

– Utilize filters for location, certification, and years of experience to narrow down results to the most relevant suppliers.

4. Verify Capabilities:

– Look for companies that highlight their capabilities in handling various metals and advanced fabrication processes like laser cutting, bending, and welding.

5. Review Certifications:

– Ensure suppliers have necessary certifications (e.g., ISO 9001) to ensure quality management standards are met.

6. Check Supplier Profiles:

– Read detailed profiles and reviews from past clients to gauge reliability and quality. Focus on companies with strong reputations and positive feedback.

7. Request Quotes:

– Contact multiple suppliers to request quotes. Provide detailed specifications to get accurate pricing. Comparing quotes can help you get the best deal.

8. Assess Communication:

– Evaluate the responsiveness and professionalism of the suppliers. Good communication is crucial for successful collaboration and problem resolution.

9. Request Samples:

– Before committing to large orders, ask for samples to verify the quality of workmanship and materials.

10. Negotiate Terms:

– Discuss payment terms, lead times, and delivery logistics thoroughly. Clear agreements help prevent future disputes.

11. Utilize SourcifyChina Support:

– Leverage any support services offered by SourcifyChina to assist with vetting suppliers and handling transactions.

By following these steps, you can find reliable sheet metal companies on SourcifyChina, ensuring high-quality production for your needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.