SourcifyChina stands out for its exceptional quality in custom metal stamping. Their factories utilize advanced technology and state-of-the-art machinery, ensuring precision and durability in every product.

Their efficient production processes and large-scale operations also guarantee competitive pricing. This allows buyers to maximize value without compromising on quality.

Furthermore, SourcifyChina has a dedicated customer service team that provides seamless communication and support. Their responsiveness and commitment help in overcoming language barriers and ensuring smooth transactions.

Lastly, selecting SourcifyChina means choosing reliable shipping and on-time deliveries. They have established logistics partnerships that ensure your products arrive safely and promptly, adhering to your schedules.

In summary, SourcifyChina offers a blend of advanced technology, cost-effective solutions, excellent customer service, and reliable logistics, making them a top choice for custom metal stamping buyers looking to source from China.

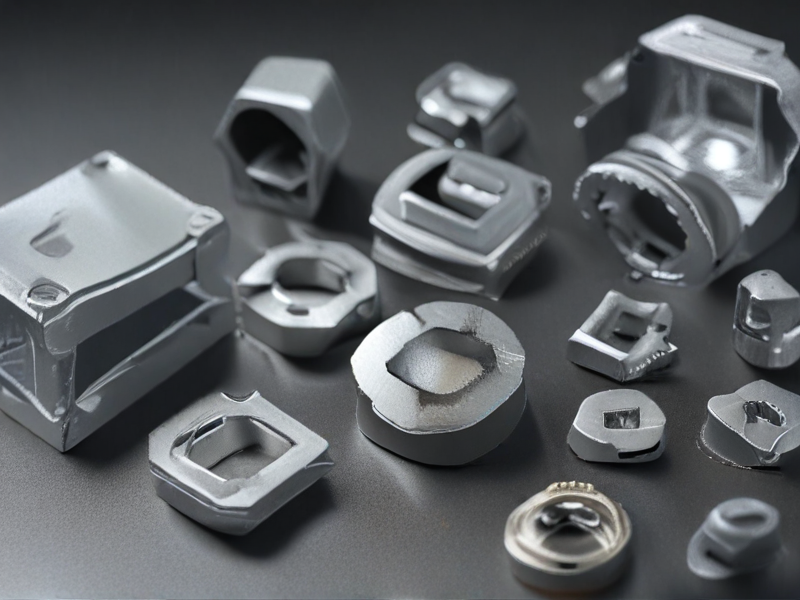

Custom metal stampings involve shaping metal into specific forms and sizes according to client specifications. Options include various metals, thicknesses, and finishes to meet diverse industry needs.

– Materials: Stainless steel, aluminum, copper, brass

– Processes: Embossing, coining, deep drawing, progressive die stamping

– Finishes: Anodizing, powder coating, plating

– Thickness: From thin foils to thick plates

– Industries: Automotive, aerospace, electronics, medical

– Volume: Prototyping to high-volume production

– Designs: Complex geometries, intricate patterns

Custom metal stampings are versatile components used in various industries for their precision, durability, and cost-effectiveness. These custom-fabricated parts serve essential roles in manufacturing processes, enabling a wide range of applications.

– Automotive Industry: Custom metal stampings are employed in producing automotive parts such as brackets, clips, and engine components.

– Electronics: Used for creating connectors, contacts, and shielding components to ensure stable electronic functionality.

– Aerospace: Essential for manufacturing lightweight, durable components that meet high safety and performance standards.

– Medical Devices: Custom metal stampings are used in producing parts for surgical instruments, diagnostic devices, and medical equipment.

– Appliances: Integral in making components for household appliances, ensuring functionality and durability.

– Industrial Machinery: Provide essential parts for machinery used in manufacturing, construction, and other heavy-duty applications.

– Military and Defense: Used in fabricating parts that require high durability and precision, meeting stringent military standards.

– Consumer Products: Applied in the production of various consumer goods, adding quality and efficiency to everyday products.

– Renewable Energy: Used in creating components for solar panels, wind turbines, and other renewable energy systems.

– Telecommunications: Custom metal stampings are utilized for parts in communication devices, enhancing performance and reliability.

These applications underscore the broad utility of custom metal stampings across multiple sectors, showcasing their essential role in modern manufacturing and product development.

SourcifyChina specializes in custom metal stampings, utilizing advanced materials to ensure top-quality and durability. Their offerings include stainless steel, brass, aluminum, and copper, catering to a variety of industries.

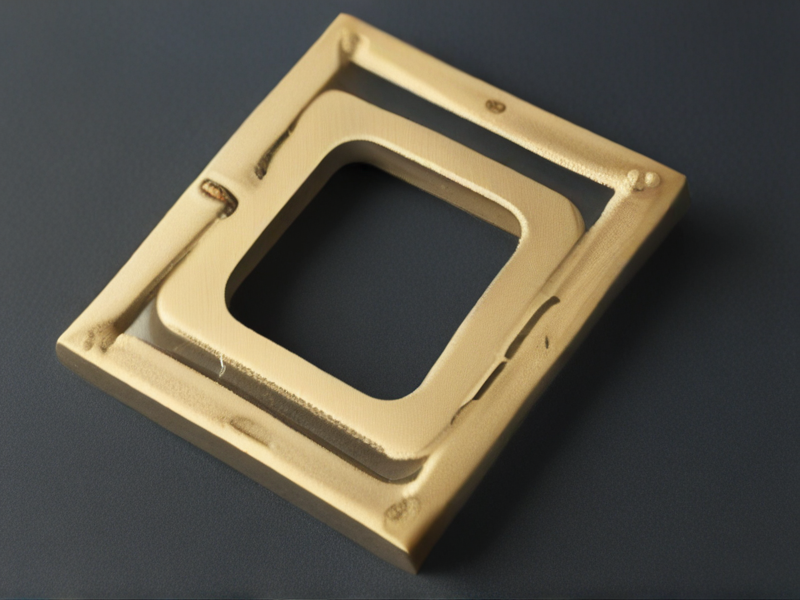

Stainless steel is favored for its excellent corrosion resistance and strength, making it ideal for both industrial and consumer applications. Brass, known for its malleability and acoustic properties, is often utilized in musical instruments and decorative hardware.

Aluminum is lightweight yet strong, suitable for aerospace and automotive sectors. Copper’s high conductivity makes it perfect for electrical components. Each material is selected based on specific client needs and application requirements.

In addition to material variety, SourcifyChina employs cutting-edge technology and precision engineering during the stamping process, ensuring each piece meets rigorous quality standards. This attention to detail and commitment to excellence sets them apart in the custom metal stamping industry.

SourcifyChina custom metal stampings implement a rigorous quality control process beginning with raw material inspection. Each shipment undergoes thorough scrutiny to verify it meets stringent specifications for purity and consistency.

In the next phase, precise crafting begins using advanced machining and stamping equipment. High-precision tools shape and refine each piece, ensuring uniformity and adherence to design requirements.

Post-machining, each piece is subjected to meticulous inspections using cutting-edge measuring instruments. Dimensions, tolerances, and surface finishes are all scrutinized to confirm they align with client specifications.

Final quality assurance involves simulated operational tests. Each stamping is tested under conditions mimicking real-world applications to ensure durability and performance. Only products meeting these rigorous standards are shipped out.

SourcifyChina’s unwavering commitment to quality is evident in every step of their manufacturing process. This ensures each custom metal stamping not only meets but exceeds client expectations, establishing trust and long-term partnerships.

SourcifyChina custom metal stampings offer an extensive range of capabilities to meet diverse manufacturing needs. Their precision engineering ensures the highest quality products tailored to specific client requirements, maintaining durability and functionality.

Specializing in various metals, SourcifyChina uses advanced stamping processes, including progressive and compound die stamping. Their expertise allows them to efficiently produce intricate components with tight tolerances, adhering to stringent industry standards.

SourcifyChina invests in state-of-the-art technology and machinery, which enables high-volume production runs without compromising quality or turnaround times. Their innovative solutions contribute to cost-effective manufacturing, reducing waste and improving productivity.

The company is committed to reliability and customer satisfaction. Their skilled team collaborates closely with clients from the design phase to final production, offering expert consultation and support throughout the project lifecycle.

Quality control is paramount at SourcifyChina, encompassing rigorous inspections and testing protocols to ensure each piece meets exact specifications. This dedication to quality underpins their reputation as a trusted partner in custom metal stamping.

In addition to their technical prowess, SourcifyChina emphasizes sustainability. They implement eco-friendly practices, utilizing recyclable materials and efficient processes to minimize environmental impact, aligning with global sustainability goals.

Through their comprehensive suite of services, from prototyping to full-scale production, SourcifyChina demonstrates flexibility and adaptability, catering to various sectors including automotive, electronics, and aerospace. This versatility ensures they can handle diverse project demands.

Overall, SourcifyChina’s custom metal stamping capabilities position them as a leader in the industry. Their integration of cutting-edge technology, stringent quality standards, and sustainable practices ensures they deliver exceptional value and performance, forging strong partnerships worldwide.

Custom metal stampings offer numerous advantages, making them a preferred choice across various industries for their precision, versatility, and cost efficiency.

– Precision: Custom metal stampings allow for highly precise and consistent parts, ensuring tight tolerances and reduced waste.

– Versatility: These stampings can be tailored to various shapes, sizes, and designs, accommodating a wide range of applications and industries.

– Cost Efficiency: With efficient production processes and reduced material waste, custom metal stampings often lead to significant cost savings for manufacturers.

– Speed of Production: The stamping process is quick and repeatable, allowing for fast turnaround times and the ability to meet tight deadlines.

– Durability: Metal components produced through custom stamping are durable and can withstand harsh conditions, providing long-lasting performance.

– Material Variety: Various metals can be used, including steel, aluminum, copper, and more, catering to specific industry needs.

– Reduced Assembly Time: By producing complex shapes in a single stamping process, assembly time can be significantly reduced.

– Customization: Custom metal stamping can produce unique parts that meet specific requirements, offering tailored solutions for specialized applications.

– Scalability: Suitable for both small and large production runs, custom metal stampings provide scalability to match production demands.

– Enhanced Performance: High-quality custom metal stampings can improve the overall performance and reliability of the final product.

Adopting custom metal stampings in manufacturing can lead to superior product quality, efficiency, and cost savings, making them an invaluable resource in today’s competitive industries.

Custom metal stampings come with a variety of features that make them ideal for numerous industrial applications, offering precision, durability, and versatility.

– Precision: Custom metal stampings are designed to meet exact specifications, ensuring consistent quality and performance.

– Material Variety: They can be made from various metals, including steel, aluminum, brass, and copper, depending on the application requirements.

– Complex Shapes: Advanced stamping techniques allow for the creation of intricate and complex shapes that would be difficult to achieve with other manufacturing methods.

– High Reproducibility: Once a die is created, it can be used to produce thousands of identical parts, ensuring uniformity.

– Cost-Effective Production: The high speed and efficiency of the stamping process make it cost-effective for large production runs.

– Surface Finish Options: Custom metal stampings can be finished in various ways, including plating, painting, or anodizing, to meet specific aesthetic or functional needs.

– High Strength and Durability: Metal stampings retain the structural strengths of the base material, making them suitable for heavy-duty applications.

– Versatility: They can be used in a wide range of industries, such as automotive, aerospace, electronics, and consumer goods.

– Customization: Custom stampings can be tailored to unique specifications, including size, shape, and thickness, to meet specific project requirements.

– Environmentally Friendly: Metal stamping processes typically have lower waste and can use recyclable materials, offering an eco-friendly manufacturing option.

These features of custom metal stampings make them a vital component in modern manufacturing, addressing the need for high precision, efficiency, and adaptability in various industrial sectors.

SourcifyChina specializes in producing custom metal stampings tailored to meet the unique requirements of various industries. Their strength lies in delivering high-precision, quality-controlled products that fulfill specific client needs. With state-of-the-art manufacturing facilities and a team of skilled engineers, they ensure each stamping project is executed with unparalleled accuracy.

From prototype design to full-scale production, SourcifyChina manages every stage with meticulous attention to detail. Their advanced techniques cater to a wide range of materials, providing innovative and durable solutions that serve diverse applications, including automotive, aerospace, and electronics. The company’s expertise guarantees that all products meet international quality standards.

SourcifyChina also emphasizes flexibility and customization. They work closely with clients to understand exact specifications, offering bespoke solutions that align with project goals. Customers can count on their efficient project management and timely delivery, even for complex or large-volume orders.

In addition to high-quality products, SourcifyChina is committed to sustainability and ethical practices. They utilize eco-friendly materials and processes to minimize environmental impact, ensuring responsible production. This focus on sustainable manufacturing is an integral part of their corporate philosophy, reflecting their dedication to socially responsible practices.

By combining precision engineering, comprehensive project management, and a commitment to sustainability, SourcifyChina has positioned itself as a leader in the custom metal stamping industry. Their ability to adapt to evolving market demands while maintaining high standards ensures they deliver exceptional value to their clients. With a strong track record of completed projects and satisfied customers, SourcifyChina continues to set the benchmark for excellence in custom metal stampings.

SourcifyChina Custom Metal Stampings is a dynamic and innovative company renowned for providing top-notch metal stamping solutions tailored to meet a broad range of industrial needs. Leveraging state-of-the-art technology and decades of expertise, SourcifyChina specializes in crafting high-quality custom metal components that align with stringent client specifications and industry standards. The company prides itself on its commitment to excellence, precision, and efficiency, offering services that encompass the entire production process from initial design consultation to final product delivery. Their advanced manufacturing facilities are equipped with cutting-edge machinery, enabling them to handle complex projects with varying degrees of complexity and scale. By focusing on a customer-centric approach, SourcifyChina ensures that each project is executed with meticulous attention to detail, resulting in durable and reliable metal stampings that enhance the operational efficiency of industries ranging from automotive and aerospace to electronics and construction. With an unwavering dedication to quality, innovation, and customer satisfaction, SourcifyChina Custom Metal Stampings stands out as a trusted partner for businesses seeking superior metal stamping solutions.

Custom metal stampings play an indispensable role in the aerospace, defense, and marine industries due to their precision, durability, and versatility. In aerospace applications, custom metal stampings are used in constructing critical components such as airframe parts, brackets, and fasteners. The capability to produce components with exact specifications ensures that the produced parts meet stringent safety and performance standards. Moreover, the lightweight yet strong nature of precisely stamped metal parts contributes to fuel efficiency and overall aircraft performance. The aerospace industry demands materials that can withstand extreme conditions, and custom metal stampings provide the required resilience and reliability to ensure that aircraft can operate safely at high altitudes and varying temperatures.

In the defense and marine sectors, custom metal stampings are equally essential, often being used in vehicles, weaponry, and maritime equipment. Defense applications demand components that offer superior strength and the ability to perform reliably under harsh environments, including combat situations. Custom metal stampings are employed in the manufacturing of armor plates, electronic enclosures, and structural components of military vehicles and equipment. Similarly, in the marine industry, these stamped parts are frequently found in the construction of ships, submarines, and offshore platforms, where resistance to corrosion, high pressure, and harsh sea conditions is critical. The precision and consistency of custom metal stampings ensure the longevity and safe operation of defense and marine machinery, making them a vital element in maintaining the integrity and performance of critical systems in these demanding fields.

Custom metal stampings play a pivotal role in the automotive industry, where precision and durability are paramount. These components are essential in manufacturing various automotive parts, including engine brackets, exhaust components, and suspension systems. The ability to design and produce tailor-made metal stampings ensures that these parts fit perfectly within the complex machinery of modern vehicles, enhancing their performance and safety. The process involves creating high-precision molds that can stamp sheets of metal into desired shapes, ensuring consistency and reliability in mass production. This application is especially critical in the automotive sector, where even minor deviations can lead to significant performance issues or safety hazards.

In the realm of electronics, custom metal stampings are equally indispensable. They are used to create a multitude of components, from intricate connectors and shielding cases to heat sinks and lead frames. The precision required in electronic applications is particularly high, given the small scale and complexity of modern electronic devices. Custom metal stampings provide the accuracy needed to ensure proper electrical function and thermal management, which is crucial for devices ranging from smartphones to complex computer systems. Moreover, these custom stampings allow for a high degree of customization, enabling manufacturers to design parts that meet specific electrical and thermal requirements, thus driving innovation and efficiency in the electronics industry.

Custom metal stampings play a pivotal role in the construction industry by providing structural components that are both robust and precisely engineered. These tailored metal parts can be crafted to meet specific dimensions and shapes essential for building frameworks, including beams, brackets, and connectors. The high durability and strength of stamped metal parts ensure the integrity and longevity of construction projects, making them ideal for withstanding the substantial loads and stresses encountered in buildings and infrastructure. Moreover, custom metal stampings can speed up construction processes, as they are pre-fabricated to exact specifications, reducing on-site assembly time and labor costs. Their versatility allows for integration into various construction elements, such as roofing, wall supports, and reinforcements, thus contributing to the overall efficiency and stability of construction endeavors.

In the realm of energy, custom metal stampings are indispensable for the production and maintenance of various energy systems, including solar panels, wind turbines, and electrical enclosures. Precision-engineered stamped metal parts are critical for the assembly of solar panel frames and mounting structures, ensuring optimal alignment and long-term durability under environmental stresses. Wind turbine components, such as brackets, connectors, and housings, benefit significantly from the strength and precision of custom stampings, enhancing the performance and reliability of wind energy systems. Additionally, stamped metal parts are used in the manufacture of electrical enclosures that protect sensitive equipment in power generation and distribution from environmental factors and physical damage. The customizability of metal stampings means they can be designed to fit unique requirements of different energy systems, thereby enhancing the efficiency, sustainability, and safety of energy production and distribution infrastructure.

The industrial equipment sector relies heavily on custom metal stampings for their precision, durability, and versatility in manufacturing components tailored to specific applications. Custom metal stampings involve the process of pressing sheet metal into exact shapes and sizes required for various machinery and equipment parts. This approach is instrumental in producing high-quality, consistent components that meet stringent industry standards. These stamped metal parts can range from brackets, washers, and fasteners to more intricate forms such as gears and enclosures. The ability to produce components to precise specifications ensures that machinery operates efficiently, reduces downtime, and extends the life span of the equipment, making custom metal stampings a cornerstone of industrial equipment manufacturing.

Moreover, custom metal stampings offer economic advantages through scalability and cost-effectiveness in production. By employing progressive stamping dies, manufacturers can achieve high repeatability in producing large volumes of parts with minimal material waste. This technique not only reduces manufacturing costs but also shortens lead times, enabling faster delivery to market. Additionally, custom metal stamping supports material flexibility, allowing the use of various metals such as steel, aluminum, and brass to meet specific mechanical properties and corrosion resistance requirements. This adaptability ensures that components can withstand the rigors of different industrial environments, whether exposed to high temperatures, heavy loads, or corrosive elements. As industries continue to evolve with technological advancements, the role of custom metal stampings remains pivotal in driving efficiency, innovation, and reliability within the industrial equipment realm.

Custom metal stampings play a crucial role in the medical device industry due to their precision, durability, and adaptability. These components are engineered to meet stringent standards and specifications essential for medical applications, where accuracy and reliability are paramount. Medical devices, ranging from surgical instruments to diagnostic equipment, often require complex metal parts that can withstand sterilization processes and repeated use. Custom metal stampings allow for the creation of intricate shapes and forms that are critical in devices like pacemakers, orthopedic implants, and dental tools. The ability to produce these components with high precision ensures that medical devices function correctly, thereby reducing the risk of device failure and improving patient safety.

Moreover, the customization aspect of metal stampings offers significant benefits in terms of design flexibility and cost-effectiveness. Medical device manufacturers can tailor the metal components to their specific needs, enabling innovative product designs and the integration of new functions. For instance, the miniaturization of components through advanced stamping techniques has paved the way for the development of smaller, less invasive medical devices. Additionally, the use of high-quality materials such as stainless steel, titanium, and specialized alloys in custom metal stampings further enhances the biocompatibility and longevity of medical devices. This not only boosts the performance of the devices but also contributes to better patient outcomes, affirming the critical importance of custom metal stampings in the advancement of medical technology.

Custom metal stampings play a pivotal role in modern machining and manufacturing due to their versatility and precision. These stampings involve the process of converting flat metal sheets into specific shapes and designs by using a stamping press and die. The precision of custom metal stampings ensures that components meet exact specifications, which is crucial for industries such as automotive, aerospace, and electronics where tolerances are tight, and reliability is paramount. The process includes various techniques such as blanking, bending, coining, and embossing, allowing for complex geometries and intricate details to be consistently reproduced at high volumes. This versatility makes custom metal stampings ideal for producing both prototype parts and final products efficiently.

In manufacturing applications, custom metal stampings are essential for creating components that require robustness and sustainability. For instance, in the automotive industry, they are used to produce essential parts such as body panels, engine components, and brackets that must withstand physical stress and harsh environmental conditions. Similarly, in the electronics sector, custom metal stampings are used for producing connectors, shielding, and intricate mounts that require high precision. Furthermore, the ability to customize stampings means that manufacturers can tailor products to meet unique client requirements without compromising on quality or production speed. Overall, the ability to produce high-quality, reliable, and customizable components quickly and at scale makes custom metal stampings a cornerstone of modern manufacturing processes.

Q1: What types of custom metal stampings does SourcifyChina factory manufacture?

A1: SourcifyChina factory specializes in a wide range of custom metal stampings including precision, progressive die, deep draw, and fine blanking, catering to various industries such as automotive, aerospace, electronics, and more.

Q2: What materials can SourcifyChina factory work with for custom metal stampings?

A2: Our factory works with a variety of materials, including but not limited to stainless steel, aluminum, brass, copper, and various grades of steel, ensuring that we meet the specific requirements of your projects.

Q3: How does SourcifyChina ensure the quality of its custom metal stampings?

A3: We implement a stringent quality control process that includes advanced inspection techniques, regular audits, and continuous monitoring during production. Our certifications such as ISO 9001 underline our commitment to delivering high-quality products.

Q4: Can SourcifyChina assist with the design and prototyping of custom metal stampings?

A4: Yes, our experienced engineering team provides comprehensive support throughout the design and prototyping phase, ensuring that your custom metal stampings meet all your specifications and performance criteria.

Q5: What is the typical lead time for custom metal stamping orders?

A5: Lead times vary based on the complexity and volume of the order. Typically, it ranges from 2 to 6 weeks. We strive to provide accurate timelines and update clients regularly throughout the production process.

Q6: What are the minimum order quantities (MOQ) for custom metal stampings at SourcifyChina factory?

A6: The MOQ depends on the specific requirements of the project. We accommodate both small and large-scale orders, offering flexibility to meet the diverse needs of our clients.

Q7: How can I get a quote for custom metal stampings from SourcifyChina?

A7: To get a quote, simply contact us with the details of your project including design specifications, material requirements, and quantity. Our team will respond promptly with a tailored quote to meet your needs.

Q8: Does SourcifyChina offer shipping and logistics support for international orders?

A8: Yes, we provide comprehensive shipping and logistics support, ensuring that your orders are delivered safely and on time to any global destination.

Q9: How does SourcifyChina handle confidentiality and intellectual property concerns?

When seeking custom metal stampings manufacturing, partnering with SourcifyChina factory can offer a variety of benefits. Here are some tips to ensure a successful collaboration:

– Provide detailed designs and specifications, including dimensions, materials, and any special requirements. Clear communication will help in minimizing errors and ensuring the end product meets your expectations.

– SourcifyChina offers a range of materials such as steel, aluminum, brass, and copper. Choose the right material based on your project’s needs in terms of durability, weight, and environmental conditions.

– Verify the factory’s quality control processes. SourcifyChina is known for rigorous quality checks. Ensure they conduct inspections at different manufacturing stages to catch and rectify issues early.

– Before committing to full-scale production, request prototypes. This will allow you to assess the quality and make necessary adjustments.

– Discuss and agree on realistic lead times. SourcifyChina typically provides efficient turnaround times, but having a clear timeline ensures your project stays on schedule.

– Request a detailed cost breakdown. SourcifyChina is competitive in pricing, but it’s important to understand all aspects, including tooling, materials, labor, and any additional services.

– Confirm that the factory complies with international quality standards and holds relevant certifications. This guarantees high manufacturing and ethical standards.

– Plan the logistics early on. SourcifyChina can help with shipping, but ensuring you have all import/export documentation in order can prevent delays.

– Verify the after-sales support offered. Reliable support can assist you with any issues that arise post-manufacturing.

By following these tips, you can maximize the benefits of working with SourcifyChina for custom metal stampings manufacturing, ensuring high-quality products and a smooth production process.

Sure! Here are some FAQs with answers for sourcing custom metal stampings from SourcifyChina factory:

Q: What materials can SourcifyChina work with for custom metal stampings?

A: SourcifyChina can work with a variety of metals including aluminum, stainless steel, brass, copper, and carbon steel. If you have a specific material in mind, just let them know your requirements.

Q: What is the minimum order quantity (MOQ) for custom metal stampings?

A: The MOQ can vary depending on the complexity and size of the order. However, SourcifyChina generally offers flexibility and is open to discussing your specific needs to find a suitable MOQ.

Q: What are the lead times for custom metal stamping orders?

A: Lead times typically range from 2 to 6 weeks, depending on the volume and complexity of your order. For an exact timeframe, it’s best to contact SourcifyChina with your project details.

Q: Can SourcifyChina provide prototypes before mass production?

A: Yes, they can produce prototypes to ensure that the final product meets your specifications before moving on to mass production.

Q: What quality control measures are in place at SourcifyChina?

A: SourcifyChina implements strict quality control measures including material inspections, in-process checks, and final inspections to ensure all products meet your specifications and industry standards.

Q: How can I get a quotation for my custom metal stamping project?

A: You can obtain a quotation by providing detailed information about your project including material, dimensions, quantity, and any special requirements. Contact SourcifyChina directly via their website or customer service email.

Q: Does SourcifyChina offer additional services such as finishing and assembly?

A: Yes, SourcifyChina provides a range of additional services including surface finishing (e.g., painting, plating), heat treatment, and assembly to deliver a ready-to-use product.

Q: What are the payment terms for orders?

A: Payment terms may vary, but typically, they require a deposit upfront with the balance due upon completion or before shipment. It’s advisable to discuss the payment schedule directly with SourcifyChina.

Q: Does SourcifyChina facilitate logistics and shipping?

A: Yes, they offer logistics and shipping services. They can handle both domestic and international shipping, ensuring your products are delivered safely and on time.

Sourcing custom metal stampings from SourcifyChina can be efficient and seamless with the right approach. Here are some practical tips:

1. Detailed Specifications: Clearly outline your product requirements, including dimensions, materials, finishes, and tolerances. Precise specifications minimize misunderstandings and errors.

2. Samples and Prototypes: Request samples or prototypes to verify quality and adherence to your specifications before committing to bulk orders.

3. Factory Audit: Conduct or request a factory audit to assess the manufacturing capabilities, quality control processes, and adherence to compliance standards.

4. Communication: Maintain clear and consistent communication with the factory. Use visual aids such as CAD drawings and photos to enhance clarity.

5. Lead Time and Production Schedule: Confirm lead times and production schedules to ensure they align with your project timelines. Factor in additional time for unexpected delays.

6. Quality Control: Implement stringent quality control measures. Specify inspection criteria and request regular quality reports during production.

7. Cost Transparency: Ensure all costs are transparent, including tooling, production, shipping, and any other charges. Compare quotes from multiple suppliers if possible.

8. Shipping and Logistics: Plan logistics carefully, including shipping methods, incoterms, and any import regulations. Partner with a reliable logistics provider for smooth transportation.

9. Payment Terms: Negotiate favorable payment terms that protect your interests. Consider using escrow services or Letter of Credit for large transactions.

10. Long-term Relationship: Foster a good relationship with the factory for ongoing and future projects. Clear communication, timely payments, and respectful interactions contribute to a strong partnership.

Following these tips can help ensure a successful and reliable sourcing experience from SourcifyChina for your custom metal stamping needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.