Reliable SourcifyChina Factory Cutter Metal Machine: Your Ultimate Solution for Precision and Efficiency

Discover unparalleled reliability and efficiency with the SourcifyChina Factory Cutter Metal Machine. Elevate your manufacturing process with precision-engineered technology, ensuring exceptional performance and lasting durability for all your metal cutting needs.

Choosing SourcifyChina Factory for purchasing cutter metal machines from China ensures high-quality manufacturing. The factory adheres to strict international standards, guaranteeing reliable and durable machines that meet global expectations.

SourcifyChina offers competitive pricing without compromising on quality. By leveraging local resources and efficient manufacturing processes, they provide cost-effective solutions for buyers looking to maximize their investment.

Exceptional customer service is a hallmark of SourcifyChina. Buyers benefit from responsive support teams that assist with inquiries, troubleshooting, and after-sales services, ensuring a seamless purchasing experience from start to finish.

Another reason to choose SourcifyChina is their commitment to innovation. The factory continually invests in technological advancements, ensuring their metal cutting machines remain at the forefront of industry trends and advancements.

Moreover, SourcifyChina’s strategic location in China’s manufacturing hub allows for faster production and shipping times. This means buyers receive their orders promptly, reducing downtime and enabling quicker project execution.

In conclusion, SourcifyChina Factory stands out as a top choice for purchasing cutter metal machines due to its high quality, competitive pricing, excellent customer service, commitment to innovation, and strategic location. Buyers can be confident in their decision, knowing they are partnering with a reliable and forward-thinking manufacturer.

Cutter metal machines are essential for precision cutting and shaping of metal materials. Various types and options are available, each designed for specific tasks and materials, ranging from manual to advanced CNC machines.

– Manual Metal Cutters: Traditional hand-operated tools for simple, small-scale cutting tasks.

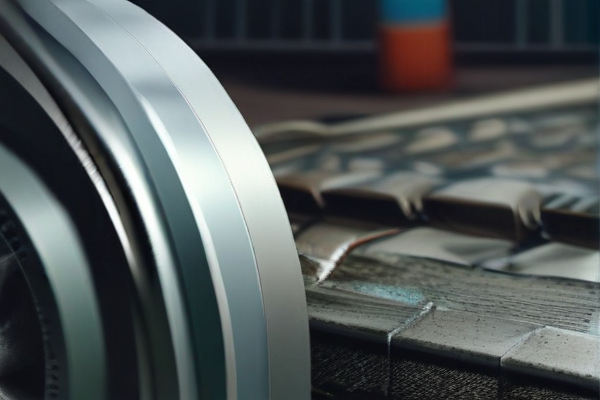

– Band Saws: Versatile machines for cutting various metals, offering both vertical and horizontal models.

– Cut-off Saws: Often used for straight cuts, also known as chop saws, best for hard metals.

– Plasma Cutters: Utilize an ionized gas to cut through thick metals with high precision.

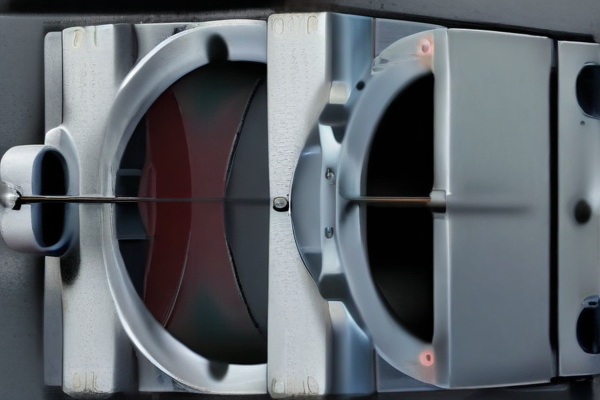

– Laser Cutters: Provide extremely accurate cuts using focused laser beams, ideal for intricate designs.

– Waterjet Cutters: Use high-pressure water mixed with abrasives, suitable for cutting without heat distortion.

– CNC Metal Cutters: Computer-controlled machines offering unparalleled accuracy and the ability to handle complex shapes and large-scale productions.

When selecting a cutter metal machine:

– Consider the type of metal being cut.

– Assess the required cutting speed and precision.

– Determine the scale of production.

– Evaluate maintenance requirements.

– Review safety features.

– Compare cost vs capabilities.

A cutter metal machine is essential for precision cutting in various industries, providing streamlined operations and enhanced efficiency. Its applications are diverse and critical for numerous sectors.

– Manufacturing: Used to cut metal parts for machinery and equipment.

– Automotive: Precision cutting for car frames, components, and custom parts.

– Aerospace: Fabricating intricate parts requiring high precision and durability.

– Construction: Cutting beams, frames, and specialized metal fabrication.

– Metalworking: Creating custom metal designs, sculptures, and artisanal pieces.

– Shipbuilding: Customizing ship parts and intricate component fittings.

– Electronics: Precise cutting for enclosures, connectors, and circuit elements.

– Tool and Die Making: Producing high-precision tools and dies.

– Prototyping: Rapid production of prototypes for testing and development.

– Renewable Energy: Fabricating components for wind turbines and solar panel mounts.

– Medical Devices: Creating precise components for medical instruments and devices.

– Railway: Manufacturing rails, carriages, and supporting infrastructure.

– Heavy Machinery: Making large-scale industrial pieces for various equipment.

– Household Appliances: Crafting parts for everyday appliances and home tools.

– Art Installations: Custom metal pieces for art and design projects.

– Food and Beverage Industry: Producing parts for processing and packaging machinery.

– Oil and Gas: Cutting precise components used in refineries and rigs.

– Defense: Manufacturing parts for military vehicles and equipment.

– Agriculture: Producing farm machinery components.

The versatility of cutter metal machines ensures their indispensable role in these applications, boosting productivity and ensuring precision in production processes.

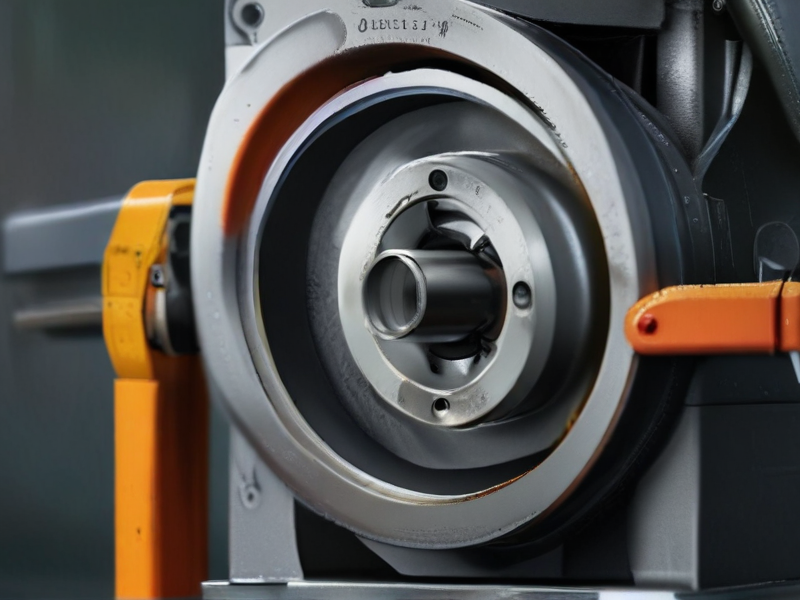

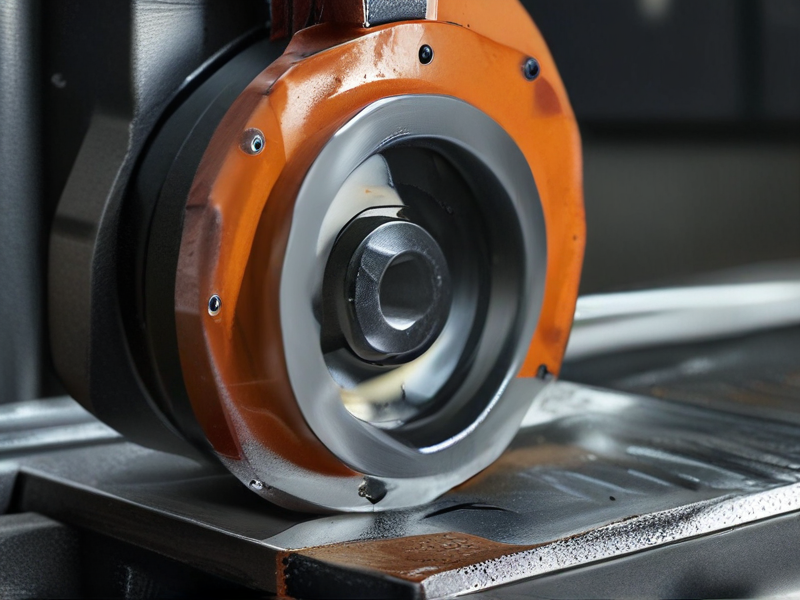

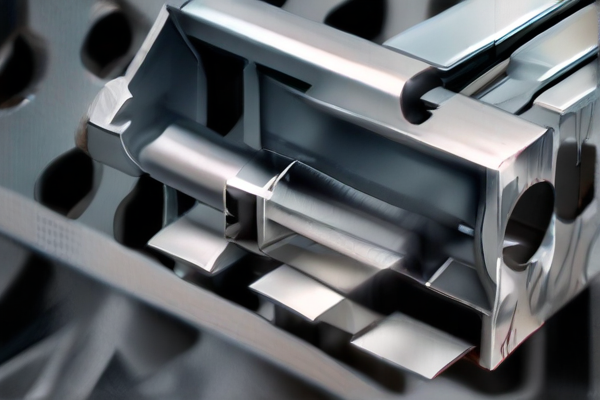

The “SourcifyChina Cutter Metal Machine” is constructed primarily from high-grade stainless steel and aluminum, ensuring durability and resistance to wear and corrosion. This choice of materials allows for precision and longevity in various industrial applications.

The machine also incorporates cutting-edge carbide and diamond-tipped cutting tools. These materials are known for their exceptional hardness and ability to maintain sharpness over prolonged use, enabling efficient and accurate cutting operations on a wide range of metals.

The frame and structural components are made from reinforced steel with a weather-resistant coating. This not only enhances the machine’s durability but also provides stability during high-speed operations, reducing vibrations and increasing precision.

Additionally, the machine utilizes advanced electronic components encased in heavy-duty plastic and metal housings. These materials protect against environmental factors such as dust and moisture, ensuring reliable long-term performance.

Overall, the selection of materials in the “SourcifyChina Cutter Metal Machine” highlights a commitment to quality and precision. These choices ensure the machine is robust, efficient, and capable of meeting the rigorous demands of modern metal cutting tasks.

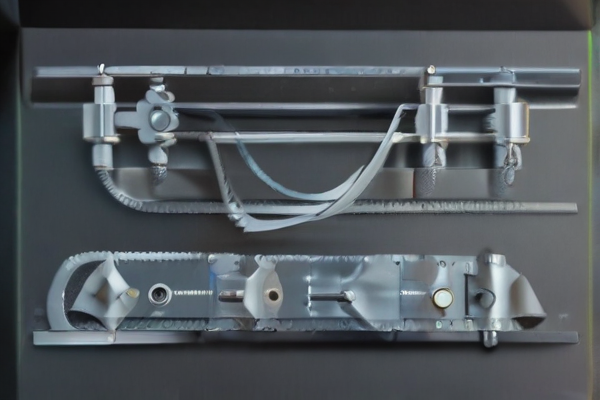

The quality control manufacturing process of the SourcifyChina cutter metal machine begins with raw material inspection. Each batch of metal is tested for strength, durability, and conformity to specifications.

Next, the assembly process follows strict guidelines. Skilled technicians use precision tools to assemble machine components, ensuring alignment and operational efficiency. Automated systems check for discrepancies.

During production, each machine undergoes rigorous testing. Performance tests simulate real-world conditions to validate functionality. Any unit showing defects is recalibrated or replaced.

Final inspection involves a comprehensive review. Parameters like cutting accuracy, machine stability, and noise levels are assessed. Only units meeting all criteria are approved for shipping.

The process culminates with customer feedback collection. Insights lead to continuous improvement, enhancing machine reliability and customer satisfaction. This meticulous quality control guarantees that every SourcifyChina cutter metal machine meets the highest standards.

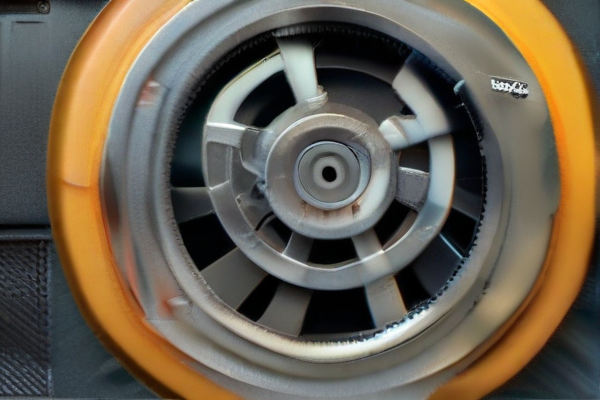

The SourcifyChina cutter metal machine boasts precision and durability, offering exceptional performance in metal fabrication. With a robust design, it is ideal for industrial applications, ensuring consistent, high-quality cuts across various metal types.

Equipped with advanced CNC technology, this machine allows for intricate and complex designs, exceeding the standards of traditional cutting methods. Efficient and reliable, it minimizes waste and maximizes production quality, making it a cost-effective solution for businesses.

The cutter features user-friendly controls and software integration, enabling seamless operation and programming. This simplifies the workflow, reduces training time, and enhances overall productivity.

With high-speed cutting capabilities, the SourcifyChina machine delivers rapid turnaround times without compromising accuracy. Its versatility supports diverse projects, from large-scale manufacturing to custom construction, catering to a wide range of industry needs.

A key feature is its safety mechanisms, including automatic shut-offs and protective barriers, ensuring operator safety and reducing the risk of accidents. This aligns with modern safety standards and regulations, offering peace of mind.

Maintenance is straightforward thanks to its modular components and accessible design, enhancing longevity and reducing downtime. Regular upkeep becomes manageable, ensuring continuous, optimal performance for extended periods.

In conclusion, the SourcifyChina cutter metal machine is a comprehensive tool designed to meet the rigorous demands of metalworking. Its precision, speed, and safety features make it a valuable asset, driving efficiency and quality in any production environment. Whether for large-scale operations or intricate custom work, this machine stands out for its robust capabilities and user-centric design.

Cutting metal machines offer significant advantages in various industries by providing precision, efficiency, and reliability. These machines streamline the process of cutting metal, enhancing both productivity and safety.

– Precision: Metal cutting machines ensure high accuracy, essential for creating intricate designs and maintaining product quality.

– Efficiency: They speed up production times by performing cuts faster than manual methods, reducing labor costs.

– Consistency: Automated systems provide uniform cuts, ensuring each part is identical to the next, which is critical in mass production.

– Versatility: Capable of handling various types of metals, from steel to aluminum, making them suitable for diverse applications.

– Safety: Reduced human involvement minimizes the risk of accidents, promoting a safer work environment.

– Cost-effective: Long-term investment leading to lower operational costs due to reduced waste and rework.

– Customization: Programmable settings allow for easy adjustments, catering to specific project requirements.

– Environmental Impact: Precision cutting reduces material wastage, leading to more sustainable operations.

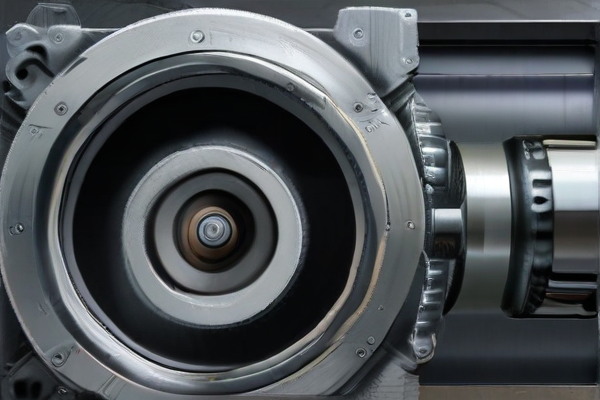

A cutter metal machine, commonly referred to as a metal cutting or machining tool, is essential for precision cutting, shaping, and finishing of metal components in various industries. These machines come with several advanced features designed to enhance efficiency and precision.

– High Precision: Advanced controls and fine-tuning capabilities allow for precise cuts, ensuring high-quality finishes.

– Durability: Built with robust materials to withstand the rigors of cutting tough metals.

– Versatility: Capable of handling various types of metal, including steel, aluminum, and titanium.

– Automation: Many modern machines are equipped with CNC (Computer Numerical Control) systems for automated, high-speed operations.

– Efficiency: Designed to optimize cutting speed while maintaining accuracy, reducing operational time.

– Safety Features: Incorporated safety systems such as emergency stop buttons and protective guards to ensure operator safety.

– Ease of Use: User-friendly interfaces and software make it easier for operators to program and operate machines.

– Coolant System: Built-in coolant systems to manage heat generated during cutting, extending tool life and maintaining quality.

– Low Maintenance: Requires minimal maintenance due to advanced engineering and quality components.

– Adaptability: Can be integrated with other machinery and tools for a seamless workflow in manufacturing setups.

Investing in a cutter metal machine with the above features enhances productivity and ensures high-quality outcomes, making it a valuable asset in modern manufacturing and engineering environments.

SourcifyChina offers expertly crafted cutter metal machines, tailored to your specific requirements. Our custom-built products ensure precision and efficiency for industrial applications. Each machine undergoes rigorous quality checks to meet international standards.

Designed for performance, our machines incorporate advanced technology for unparalleled cutting accuracy. From intricate patterns to large-scale projects, SourcifyChina’s solutions are versatile and reliable. Our commitment to innovation means you’re getting the best in modern machinery.

Whether for automotive, aerospace, or construction sectors, our custom products cater to a diverse range of industries. Our team collaborates with clients to fine-tune machines that align with unique specifications and operational challenges.

The integration of user-friendly interfaces makes our cutter metal machines simple to operate and maintain. Training programs and comprehensive customer support ensure that your team can maximize productivity effortlessly.

Choose SourcifyChina for your custom metal cutting needs. We prioritize your project’s success by delivering machines that not only meet but exceed expectations. Experience seamless execution and high-quality results with every project you undertake.

SourcifyChina Cutter Metal Machine, a leading enterprise in the heavy machinery industry, is dedicated to producing high-quality metal cutting equipment and solutions tailored to various industrial needs. With years of expertise and cutting-edge technology, the company designs and manufactures a wide array of metal cutting machines, including CNC plasma cutters, laser cutters, and waterjet cutters, ensuring precision, efficiency, and durability. Their commitment to innovation is reflected in constant upgrades and the integration of advanced features, catering to the evolving demands of the manufacturing sector. SourcifyChina prides itself on providing exceptional customer support, from initial consultation through installation and ongoing maintenance, ensuring optimal performance and customer satisfaction. By prioritizing sustainability, the company also emphasizes eco-friendly practices and materials in their production processes. With a global reach, they have established a strong presence across various markets, testament to their reliability and excellence in the metal cutting machinery domain.

In the aerospace and defense industries, the utilization of cutter metal machines is pivotal for the fabrication of high-precision components. These machines are employed to create complex, lightweight, and durable parts required in aircraft and defense equipment. The exacting standards of these sectors necessitate the use of advanced cutter metal machines that can handle materials like titanium, aluminum, and high-strength alloys. The ability to produce parts with tight tolerances ensures that they can withstand the rigorous demands of flight and combat scenarios, where failure is not an option. Furthermore, the efficiency and accuracy of these machines contribute significantly to the overall performance and safety of aircraft and military hardware, making them indispensable in these fields.

In the marine industry, cutter metal machines play a crucial role in the construction and maintenance of ships and offshore structures. These machines are used to cut, shape, and finish metal components that form the backbone of marine vessels and rigs, such as hulls, bulkheads, and engine parts. Given that marine environments subject equipment to harsh conditions including high salinity and pressure, the precision and durability afforded by these machines are essential for ensuring operational efficiency and longevity. Additionally, cutter metal machines are integral to the repair and retrofitting of maritime vessels, enabling them to meet evolving safety and performance standards. The adoption of cutting-edge metal cutting technologies in shipyards and marine manufacturing facilities underscores the growing importance of precision engineering in navigating the challenges of modern marine applications.

Cutter metal machines, also known as metal cutting machines, play an essential role in the automotive industry, significantly contributing to manufacturing precision components and parts. These machines are instrumental in fabricating complex components such as engine blocks, transmission systems, and chassis parts. With advanced capabilities such as Computer Numerical Control (CNC), these machines ensure highly accurate and consistent cuts, essential for maintaining the stringent quality standards of automotive manufacturing. High-speed cutting allows for efficient mass production, while precise repeatability ensures that each component meets exacting specifications. Consequently, cutter metal machines help automotive manufacturers achieve a balance between high-volume output and uncompromised quality, crucial for the performance and safety of vehicles.

In the field of electronics, cutter metal machines are equally indispensable. They are used to shape and resize metal components that form the backbone of various electronic devices, from printed circuit boards (PCBs) to enclosures and heat sinks. The precision offered by modern cutter metal machines enables the creation of intricate patterns and designs required for advanced electronic components. Fine cuts and intricate detailing are critical for the miniaturization of electronic devices, making these machines essential for the production of compact and efficient electronics. Additionally, the ability to work with different metals and thicknesses broadens the machine’s application, facilitating innovation in the design and functionality of electronic gadgets. Consequently, cutter metal machines not only enhance production efficiency but also drive technological advancements in the electronics sector.

The cutter metal machine has revolutionized the construction industry by significantly enhancing efficiency, precision, and safety. In construction applications, this versatile machine is used to cut through various metals, including steel beams, pipes, and reinforcing bars, which are essential in building robust structures. Its ability to make precise cuts minimizes material wastage and ensures components fit together seamlessly. Advanced models equipped with computer numerical control (CNC) capabilities can execute complex cuts with high accuracy, which is crucial for bespoke architectural designs and intricate building frameworks. Additionally, the machine’s portability allows it to be employed directly at construction sites, reducing the need for transporting heavy materials back and forth, thus saving time and labor costs.

In the energy sector, cutter metal machines play a pivotal role in the fabrication and maintenance of infrastructure such as pipelines, wind turbines, and power plant components. These machines are vital for constructing and repairing pipelines that transport oil, natural gas, and other resources. Precise cutting is essential to ensure that welded joints are secure and leak-free, thereby enhancing the safety and efficiency of the energy distribution network. In the realm of renewable energy, cutter metal machines are used to manufacture components for wind turbines and solar panel frameworks, where precision is vital for optimal performance and alignment. By facilitating the creation of high-quality, durable components, cutter metal machines help drive innovation and sustainability in the energy sector, contributing to the development of more efficient and reliable energy systems.

The industrial equipment industry heavily relies on cutter metal machines for precision and efficiency in various manufacturing processes. These machines are designed to handle a variety of metals, from steel to aluminum, ensuring accurate cuts and shapes critical for creating components that meet exact specifications. In sectors such as automotive, aerospace, and construction, cutter metal machines facilitate the fabrication of essential parts, ranging from engine blocks to structural frameworks. Their ability to perform clean cuts with minimal waste not only enhances production speed but also improves the overall cost-efficiency, making them indispensable in mass production environments.

Moreover, cutter metal machines play a pivotal role in prototyping and custom manufacturing. Advanced CNC (Computer Numerical Control) versions of these machines allow for meticulous control over cutting operations, enabling the creation of intricate and customized designs. This precision is vital for industries like medical device manufacturing, where components must adhere to stringent regulatory standards. Additionally, the integration of automated cutter metal machines helps reduce human error, improve worker safety, and streamline workflows. As technology advances, these machines are becoming more sophisticated, incorporating laser and plasma cutting capabilities to expand their versatility and application scope even further. Thus, cutter metal machines are a cornerstone in the industrial equipment landscape, driving innovation and efficiency across various sectors.

Medical devices rely heavily on precision and accuracy, particularly in their manufacturing processes. One critical tool in this regard is the “cutter metal machine.” This sophisticated piece of equipment is designed for the precise cutting and shaping of various metals used in medical devices. From surgical instruments like scalpels and forceps to components for diagnostic machines, the cutter metal machine ensures each piece meets stringent quality and safety standards. Advanced features such as computer numerical control (CNC) technology allow for highly accurate cuts down to micrometric precision. This level of accuracy is essential for ensuring that medical devices function correctly, thereby safeguarding patient health and improving clinical outcomes.

Additionally, cutter metal machines contribute significantly to the innovation and development of new medical devices. As the medical field continually evolves, there is a constant demand for smaller, more efficient, and more complex devices. Cutter metal machines facilitate the rapid prototyping and development of these devices, offering the capability to work with diverse metals and alloys, including titanium and stainless steel, known for their biocompatibility and durability. By enabling swift, precise, and repeatable production, these machines significantly reduce the time and cost associated with bringing new medical technologies to market. The combination of precision, versatility, and efficiency makes cutter metal machines indispensable in the medical device manufacturing industry, ultimately contributing to better healthcare solutions and improved patient outcomes.

Cutter metal machines are indispensable tools in the realms of machining and manufacturing, providing precision and efficiency in the shaping and modification of metal components. These machines operate using a variety of cutting tools, including milling cutters, drills, and lathes, to precisely remove material from a workpiece, creating finished parts that meet exact specifications. In industries such as automotive, aerospace, and heavy machinery, the ability to produce high-precision metal parts is critical. Cutter metal machines enable the production of intricate geometries and fine tolerances that are necessary for complex assemblies and reliable mechanical performance. The incorporation of computer numerical control (CNC) technology in these machines has further enhanced their capabilities, allowing for automated, repeatable, and high-speed machining processes, which significantly reduce production times and operational costs.

Beyond traditional manufacturing, cutter metal machines are also pivotal in prototyping and custom manufacturing applications. The flexibility and adaptability of these machines allow engineers and designers to rapidly produce prototypes directly from CAD models, facilitating iterative testing and design refinement. This capability is particularly beneficial in research and development scenarios, where fast turnaround times can accelerate the innovation cycle. Moreover, in custom manufacturing, where bespoke components are often required in limited quantities, cutter metal machines provide the precision and versatility to meet unique customer specifications without the need for extensive retooling or setup changes. By streamlining both the development and production processes, cutter metal machines continue to be essential assets in modern machining and manufacturing ecosystems, driving advancement and efficiency across various industrial sectors.

Sure, here’s a list of FAQs with answers for manufacturing “cutter metal machine quality work from SourcifyChina factory”:

1. What types of cutter metal machines does SourcifyChina manufacture?

SourcifyChina manufactures a variety of cutter metal machines including laser cutters, plasma cutters, and CNC metal cutting machines, each designed to meet specific industrial requirements.

2. What materials can SourcifyChina’s cutter metal machines process?

Our machines can process a wide range of materials such as stainless steel, aluminum, copper, brass, and other metal alloys with precision and efficiency.

3. How does SourcifyChina ensure the quality of its cutter metal machines?

We implement stringent quality control measures at every stage of manufacturing, from raw material selection to final assembly. Each machine undergoes rigorous testing to ensure it meets international standards.

4. Are the machines compatible with various industrial applications?

Yes, our cutter metal machines are highly versatile and can be used in various industries including automotive, aerospace, construction, and metal fabrication.

5. What is the lead time for receiving a cutter metal machine from SourcifyChina?

The lead time varies depending on the model and customization requirements, but typically ranges from 4 to 8 weeks. We always strive to deliver within the promised timeframe.

6. Do you offer customization options for the machines?

Absolutely, we offer customization options to tailor the machines to your specific needs, including changes in size, power, and additional features.

7. What kind of after-sales support does SourcifyChina provide?

We offer comprehensive after-sales support, including installation assistance, training, maintenance services, and technical support to ensure optimal performance.

8. Are there any certifications for SourcifyChina’s cutter metal machines?

Our machines are certified to meet international standards such as CE, ISO9001, and other relevant certifications, ensuring high quality and compliance.

9. How can I place an order with SourcifyChina?

You can place an order by contacting our sales team through our website, phone, or email. We will provide a detailed quotation and guide you through the ordering process.

10. What payment methods does SourcifyChina accept?

We accept multiple payment methods including T/T (Telegraphic Transfer), L/C (Letter of Credit), and other internationally recognized payment options.

Certainly! Here are some tips for sourcing metal cutter machines from SourcifyChina factory:

1. Research Thoroughly: Start by understanding the specific needs of your project. Metal cutters come in various forms like laser, plasma, and waterjet cutters. Identify the right technology for your requirements.

2. Verify Credibility: Check SourcifyChina’s credentials and customer reviews. A reputable factory should have positive testimonials and a track record of delivering quality machinery.

3. Request Detailed Quotations: Don’t just settle for price. Ask for comprehensive quotes that include machine specifications, shipping costs, warranties, and after-sale services.

4. Quality Control: Ensure the factory has robust quality control measures. You can request ISO certifications or schedule a virtual tour of their production facility.

5. Customization Options: Often, factories can modify machines to better suit your needs. Discuss potential customization upfront to avoid any last-minute surprises.

6. Sample Testing: If possible, request a sample or a demonstration of a similar machine. This can provide a tangible sense of the machine’s performance and build quality.

7. After-Sales Support: Inquire about the availability of spare parts and technical support. A reliable after-sales service can significantly reduce downtime in case of malfunctions.

8. Lead Times and Shipping: Understand the manufacturing and shipping timelines. Plan your order well in advance to accommodate any potential delays.

9. Cultural and Language Barriers: Working with international suppliers can sometimes be challenging due to language barriers. Consider hiring a translator or using Sourcify’s local agents to facilitate smoother communication.

10. Legal and Payment Terms: Ensure that all terms and conditions are clearly outlined in the contract. Opt for secure payment methods such as Letters of Credit (LC) or escrow services to protect your investment.

By following these tips, you can ensure a smooth and efficient procurement process with SourcifyChina for your metal cutter machine needs.

Certainly! Here is a list of frequently asked questions (FAQ) with answers for sourcing a cutter metal machine from SourcifyChina factory:

Q1: How can I place an order for a cutter metal machine?

A1: To place an order, visit our website and select the desired model. You can also contact our sales team directly via email or phone for personalized assistance.

Q2: What are the payment terms?

A2: We accept various payment methods including T/T (Telegraphic Transfer), L/C (Letter of Credit), and PayPal. For larger orders, we may require a 30% deposit with the balance due before shipment.

Q3: What is the lead time for delivery?

A3: The standard lead time is 4-6 weeks from the date the order is confirmed and payment is received. Lead times may vary depending on the machine specifications and current production schedule.

Q4: Do you offer customization?

A4: Yes, we offer customization options to meet specific requirements. Please provide detailed specifications when you contact us, so we can accommodate your needs.

Q5: What is the warranty period?

A5: Our cutter metal machines come with a 1-year warranty on parts and labor. Extended warranty options are available upon request.

Q6: How do you handle quality control?

A6: We have stringent quality control measures in place, including rigorous testing and inspection at each production stage. Certifications such as ISO and CE further ensure product quality.

Q7: Can I visit the SourcifyChina factory?

A7: Yes, factory visits are welcome. Please contact us to schedule an appointment. We can also provide virtual tours if an in-person visit is not feasible.

Q8: What are the shipping options?

A8: We offer various shipping options including sea freight, air freight, and express courier services. Shipping costs depend on the delivery location and the shipping method chosen.

Q9: Do you provide after-sales support?

A9: Yes, we provide comprehensive after-sales support including installation guidance, technical support, and maintenance services. You can reach our support team via email or phone.

Q10: Are spare parts readily available?

A10: Spare parts are readily available and can be shipped promptly. We recommend keeping essential spare parts on hand to minimize downtime.

Sourcing a cutter metal machine from SourcifyChina factory can be streamlined if you follow these tips:

1. Research Thoroughly: Use platforms like Alibaba or Made-in-China to locate SourcifyChina. Read reviews and ratings.

2. Define Specifications: Clearly outline your machine requirements, such as cutting capacity, precision level, and power source.

3. Request Quotations: Contact SourcifyChina directly for quotations. Provide detailed specifications to receive accurate pricing.

4. Verify Credentials: Ensure SourcifyChina’s credibility. Check their business license, quality certifications, and industry experience.

5. Sample Orders: Request a sample or a smaller batch order to assess the machine’s quality and manufacturing standards before committing to a large order.

6. Negotiate Terms: Discuss payment terms, delivery schedule, and warranty conditions. Negotiate to find a mutually beneficial agreement.

7. Third-party Inspection: Hire a third-party inspection service to review the machines before shipment to ensure they meet your requirements.

8. Understand Logistics: Discuss logistics and shipping details to avoid misunderstandings. Know the Incoterms (EXW, FOB, CIF, etc.) being used.

9. After-sales Support: Ensure that the factory provides after-sales support and a clear returns policy if the machines encounter issues.

10. Formal Agreement: Draft a detailed contract outlining terms, specifications, delivery dates, and penalties for non-compliance.

By following these tips, you can effectively source a reliable cutter metal machine from SourcifyChina factory while minimizing risks and ensuring quality.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.