## Reliable Source for High-Quality Laser Cut Acrylic Sheets: Discover SourcifyChina Factory

Discover the unparalleled reliability and quality of laser cut acrylic sheets from SourcifyChina Factory—your trusted source for precision-crafted materials perfect for diverse applications. Explore custom solutions and exceptional service today.

SourcifyChina Factory stands out for its unparalleled expertise in producing high-quality laser-cut acrylic sheets. With advanced technology and precision manufacturing, they ensure products meet international standards, delivering durability and flawless finish.

Customer satisfaction is prioritized through rigorous quality control and timely delivery. From bespoke designs to bulk orders, SourcifyChina meets diverse needs seamlessly.

Their competitive pricing, without compromising quality, offers significant cost savings for buyers. This economic advantage makes them an ideal partner for global businesses seeking reliable manufacturing solutions.

Responsive customer service and dedicated support teams ensure smooth communication and efficient problem-solving. Buyers are assured of a hassle-free purchasing experience, cultivating long-term business relationships.

Complete transparency and ethical practices underline SourcifyChina’s commitment to integrity. Buyers can trust in the factory’s consistent efforts to adhere to sustainable and responsible manufacturing processes.

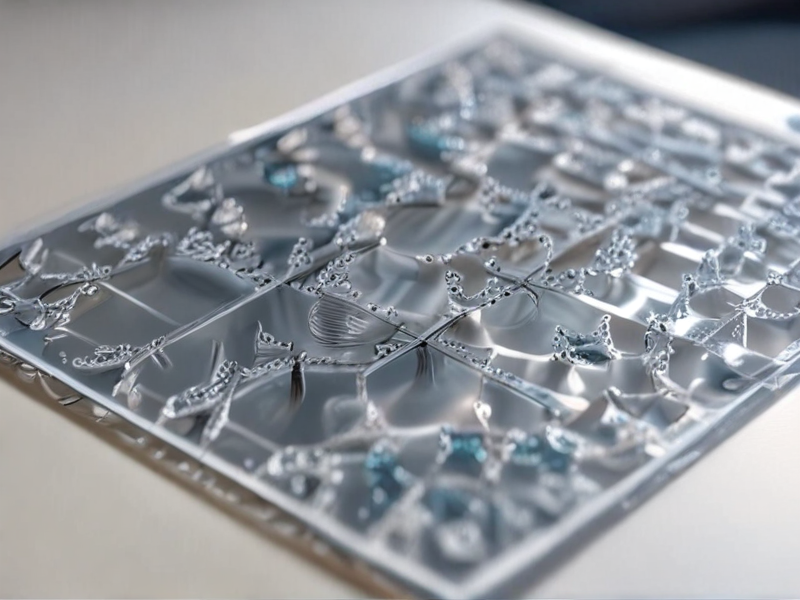

Laser cut acrylic sheets are versatile materials used in various applications, from decorative elements to functional components. Options include different thicknesses, colors, finishes, and degrees of transparency, catering to specific needs.

– Thickness Options

– Ranges: 1mm to 25mm

– Common: 3mm, 5mm, 8mm

– Color Choices

– Transparent

– Opaque

– Translucent

– Specialty colors like fluorescent or mirrored

– Finish Types

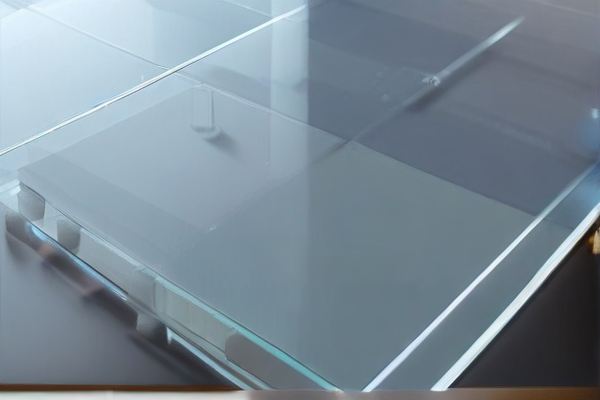

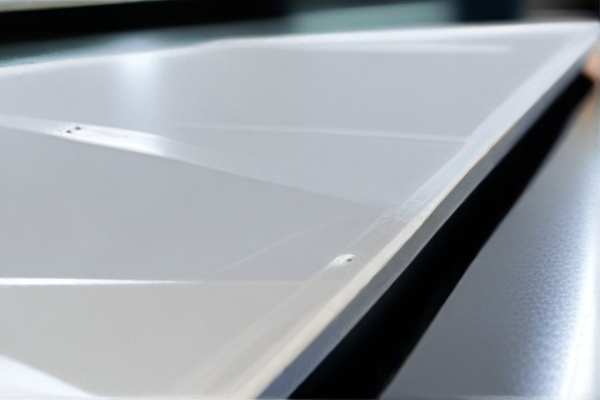

– Glossy

– Matte

– Textured

– Transparency Levels

– Clear

– Frosted

– Tinted

– Specialty Types

– UV-resistant

– Anti-static

– Scratch-resistant

– Application Areas

– Signage

– Displays

– Interior design

– Prototyping

– Art and craft

– Processing Options

– Engraving

– Etching

– Cutting shapes

– Drilling holes

– Benefits

– Precise

– Repeatable

– Customizable

– Durable

– Considerations

– Melting point

– Brittleness

– Cost

While laser cut acrylic sheets are highly customizable and functional, appropriate selection among the different types, thicknesses, and finishes ensures optimal results for specific applications. They can be tailored to meet aesthetic needs as well as practical requirements, making them widely used in both industrial and creative projects.

Laser cut acrylic sheets have various applications due to their precision and aesthetic appeal. These versatile materials find use across different industries, offering both functional and decorative benefits.

– Signage: Perfect for creating eye-catching signs and displays for businesses.

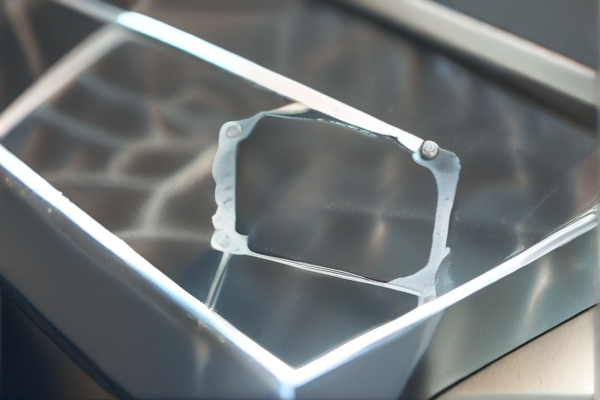

– Architectural Models: Used in the creation of detailed and accurate architectural models.

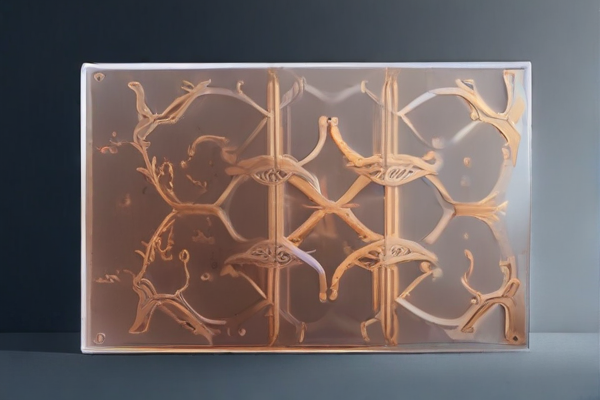

– Decorative Elements: Ideal for intricate decorative panels, wall art, and custom nameplates.

– Prototyping: Useful in rapid prototyping to produce precise and functional models.

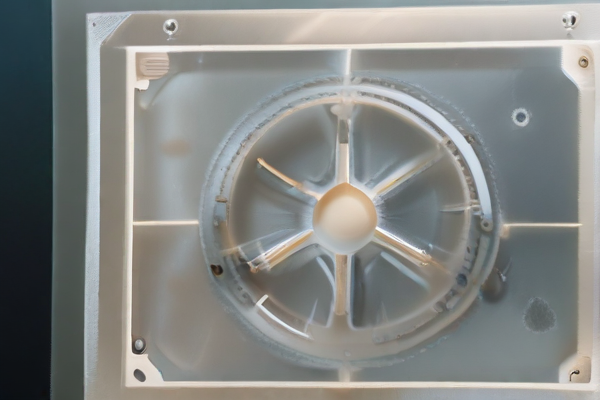

– Lighting: Utilized in light fixtures and diffusers for a modern, sleek appearance.

– Furniture: Employed in designing contemporary furniture pieces.

– Retail Displays: Enhances the aesthetic and functionality of point-of-sale displays.

– Jewelry: Essential for crafting custom, intricate jewelry and fashion accessories.

– Engraving: Excellent for creating detailed engravings for various applications.

– Awards and Trophies: Used to make customized awards and recognition items.

– Protective Barriers: Utilized for creating sneeze guards and other protective barriers.

– Educational Tools: Helpful in the production of teaching aids, models, and interactive displays.

– Automotive: Applied in custom automotive interiors and components.

– Packaging: Provides premium packaging options for high-end products.

– Home Decor: Used in creating unique home decor items like tabletop decorations and frames.

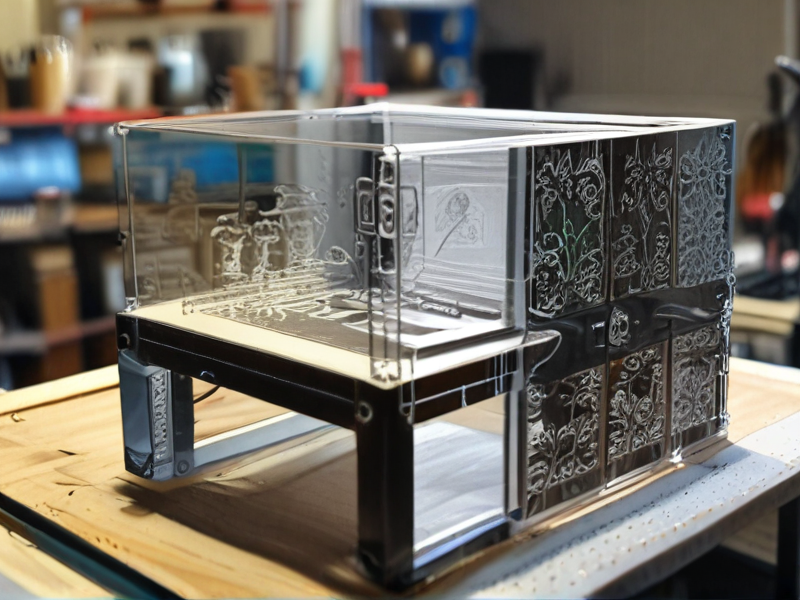

– Electronics: Essential for fabricating custom enclosures and components in electronics.

Innovative and adaptable, laser cut acrylic sheets continue to open doors for design and functionality advancements across numerous sectors.

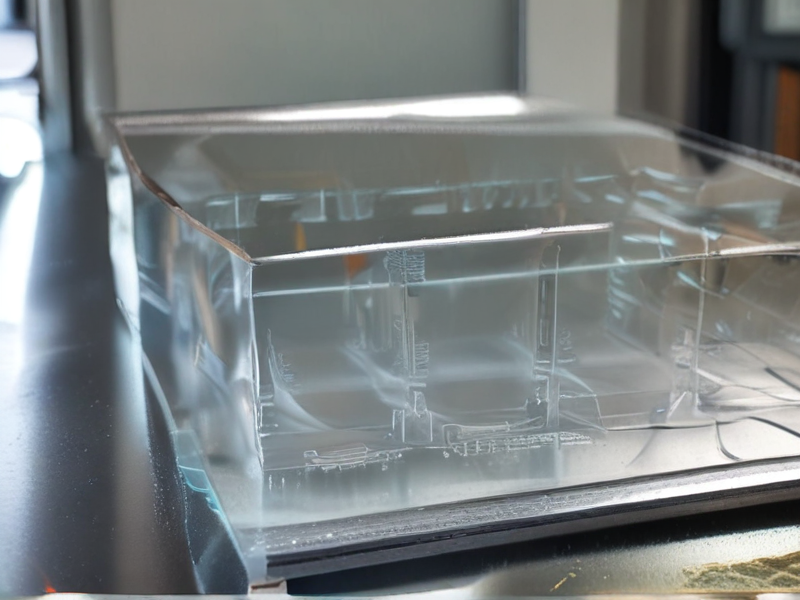

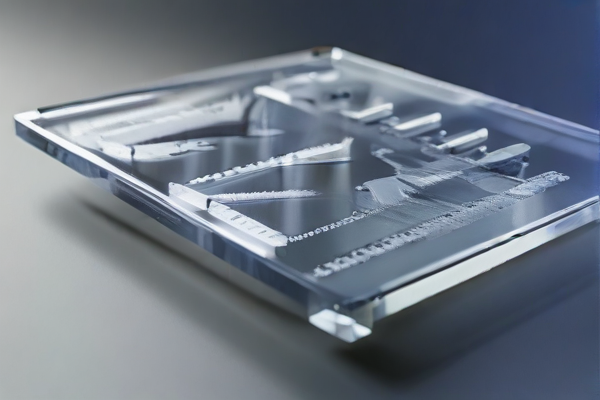

SourcifyChina laser-cut acrylic sheets are crafted from high-quality polymethyl methacrylate (PMMA), known for its exceptional clarity and durability. These sheets offer a crystal-clear appearance, often surpassing glass in transparency. Ideal for both indoor and outdoor applications, the material is UV-resistant, ensuring that it doesn’t yellow or degrade over time.

The laser-cutting process guarantees precision and smooth edges, making the acrylic sheet suitable for intricate designs and complex shapes. This high level of accuracy is particularly useful for projects requiring detailed aesthetic elements, such as signs, displays, and decorative items.

Additionally, the material is lightweight yet robust, which makes it easy to handle and install. Its impact resistance is significantly higher than that of glass, reducing the risk of breakage during transportation and installation. Because of its versatile nature, it can be used in various industries, including architecture, automotive, and retail.

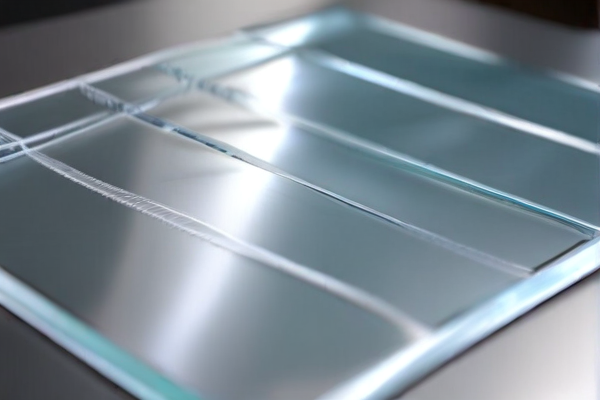

Furthermore, SourcifyChina’s laser-cut acrylic sheets are available in a variety of thicknesses and colors, allowing for customization to meet specific project needs. These sheets can be easily drilled, sawed, and machined without chipping or cracking, making them a versatile choice for many applications.

In summary, SourcifyChina laser-cut acrylic sheets offer an excellent balance of durability, clarity, and customization options. Their high-quality composition and precision cutting make them an ideal material for a wide range of applications, providing a reliable solution for both decorative and functional uses. These features make SourcifyChina laser-cut acrylic sheets a preferred choice for professionals seeking quality and versatility.

SourcifyChina employs a meticulous quality control process in the manufacturing of their laser cut acrylic sheets. Starting with the selection of premium raw materials, each batch undergoes rigorous inspection before entering production.

Advanced laser cutting technology ensures precision and accuracy in each cut. The machinery is regularly calibrated and maintained to uphold the highest standards of performance, minimizing errors and defects.

Post-cutting, acrylic sheets are thoroughly inspected for any discrepancies such as uneven edges, cracks, or impurities. These checks are crucial in maintaining the integrity and appearance of the final product.

A dedicated team conducts random sample testing to verify consistency across production batches. This step helps in identifying any variations and implementing corrective measures promptly.

Final inspections include verifying dimensions, smoothness, transparency, and strength of the acrylic sheets. Each sheet must pass these stringent tests before being approved for shipping.

Continuous feedback and improvements are integral to SourcifyChina’s quality control. Customer feedback is invaluable, guiding future enhancements and ensuring that only top-quality products reach the market.

By adhering to these comprehensive quality control measures, SourcifyChina guarantees that their laser cut acrylic sheets meet industry standards and customer expectations, reinforcing their commitment to excellence.

SourcifyChina offers precision laser-cutting capabilities for acrylic sheets, delivering highly accurate and intricate designs. The advanced laser technology ensures precise cuts, enhancing aesthetics and functionality.

These acrylic sheets come in various thicknesses and colors, catering to diverse project requirements. The versatility of acrylic allows for broad applications, from signage to bespoke interior elements.

The company commits to rapid production times while maintaining high-quality standards. This efficiency is crucial for businesses needing quick turnarounds without compromising the integrity of the final product.

SourcifyChina also offers customizable options, allowing clients to achieve their exact specifications. Detailed etching and intricate patterns can be easily incorporated.

Moreover, SourcifyChina emphasizes sustainability by using eco-friendly materials and reducing waste through efficient laser-cutting techniques. This aligns with modern environmental considerations.

The finished products are durable and resistant to wear, ensuring longevity. The precision of laser cutting also enables seamless integration of components in complex assemblies.

Customer support is an integral part of their service, assisting clients from the initial design phase to the final delivery. This holistic approach ensures client satisfaction and project success.

In summary, SourcifyChina’s laser-cut acrylic sheets offer precision, variety, and customization. The company’s commitment to quality, speed, and sustainability makes it a trusted partner for diverse applications.

Laser-cut acrylic sheets offer precision and versatility, making them ideal for various applications. Their benefits span from aesthetic appeal to durability and cost-efficiency.

– Precision and Accuracy: Laser cutting delivers precise and clean edges, ensuring high-quality finishes without manual interventions.

– Versatility: Suitable for a wide range of applications including signage, display cases, and custom art, due to its adaptability.

– Durability: Acrylic sheets are resistant to weather and UV rays, imparting long-lasting durability.

– Aesthetic Appeal: Available in various colors and finishes, they enhance visual aesthetics.

– Cost-Efficiency: Reduced material waste and minimal need for post-processing lower production costs.

– Ease of Maintenance: Easy to clean and maintain, acrylic sheets retain their clarity and appearance over time.

– Safety: Unlike glass, acrylic does not shatter, reducing the risk of injury.

These attributes make laser-cut acrylic sheets an excellent choice for both commercial and personal projects.

Laser-cut acrylic sheets are versatile materials perfect for precision-cut projects, offering unparalleled accuracy, smooth edges, and intricate detailing.

– Precision and Accuracy: Laser cutting technology ensures high precision, allowing intricate designs with minimal tolerance errors.

– Smooth Edges: The laser melts the edges of the acrylic as it cuts, resulting in smooth, polished finishes without additional processing.

– Customizable Shapes: Complex geometries and detailed patterns can be easily achieved, catering to both functional and decorative purposes.

– Material Efficiency: Minimized waste due to accurate cuts and nesting capabilities, which maximize material utilization.

– Durability: Acrylic is a strong material, resistant to impact, weather, and UV light, making laser-cut pieces suitable for various indoor and outdoor applications.

– Aesthetic Appeal: Available in various colors and finishes, laser-cut acrylic can add a stylish touch to projects like signage, displays, and art.

– Reduced Lead Time: Automation of the laser-cutting process reduces production times, enabling faster project completion.

– Versatility: Suitable for diverse industries such as retail, construction, interior design, and more.

– Cost-Effective: Reduced need for additional finishing work and efficient use of materials can lower overall production costs.

Laser-cut acrylic sheets are an excellent choice for projects demanding precision, durability, and aesthetic flexibility.

SourcifyChina specializes in providing high-quality, laser-cut acrylic sheet custom products and projects. Their precision-cutting services cater to a variety of industries, ensuring each piece meets exact specifications.

Their advanced laser cutting technology produces intricate designs with exceptional accuracy. This process results in smooth, polished edges and detailed features that enhance the final product’s overall appearance and functionality.

SourcifyChina offers a wide range of acrylic sheets in various colors, thicknesses, and finishes. This versatility allows clients to select materials that perfectly match their project’s requirements, ensuring a tailored solution for every need.

Customization options include engraving, cutting, and shaping to fit specific design elements or branding needs. Clients can submit their designs or work with SourcifyChina’s experienced team to develop unique and innovative solutions.

Their commitment to quality is evident in every product, from simple promotional items to complex architectural models. By maintaining high standards, SourcifyChina ensures durability and aesthetic appeal in all their offerings.

In addition to their superior products, SourcifyChina provides excellent customer service. Starting from initial consultation to final delivery, they offer support at every stage. This ensures a smooth and efficient process.

International shipping is available, making SourcifyChina’s custom laser cut acrylic solutions accessible to clients worldwide. They prioritize timely delivery while maintaining the highest quality standards throughout the production process.

SourcifyChina is a distinguished provider specializing in high-quality laser-cut acrylic sheets, renowned for its precision, reliability, and innovative designs. Catering to a diverse clientele, the company excels in producing custom acrylic solutions that cater to various industries, including signage, displays, and construction. Employing advanced laser cutting technology, SourcifyChina ensures every acrylic sheet meets stringent quality standards, delivering products that boast exceptional clarity, durability, and intricate detailing. Their dedicated team works closely with clients to understand their unique requirements, offering tailored solutions and continuous support throughout the production process. In addition to their top-notch products, SourcifyChina is committed to sustainable practices, using environmentally-friendly materials and energy-efficient methods. This dedication to excellence and sustainability has established SourcifyChina as a trusted and reliable partner in the world of acrylic manufacturing.

Laser-cut acrylic sheets are increasingly being adopted in the aerospace industry due to their versatility, precision, and durability. These sheets are used in the production of lightweight components, such as control panels, cockpit instrument covers, and interior finishes. Their ability to withstand high stress and maintain optical clarity makes them ideal for cabin windows and light covers. Moreover, the precise laser-cutting process ensures that each piece meets stringent aerospace standards, thereby enhancing the overall safety and performance of aircraft. By reducing the weight of components without compromising structural integrity, laser-cut acrylic sheets contribute to fuel efficiency and cost-effectiveness in aerospace applications.

In the defense sector, laser-cut acrylic sheets are utilized for various purposes, including protective barriers and transparent armor. The sheets’ clarity and durability make them suitable for periscope systems, gunsights, and other optical devices that require both visibility and robustness. Laser cutting allows for creating intricate shapes and designs that align with the specific needs of advanced military equipment. Similarly, in marine environments, laser-cut acrylic sheets are employed in the construction of boat windows, hatches, and instrument panels due to their resistance to UV rays and saltwater corrosion. Their non-yellowing property ensures long-lasting visibility and aesthetic appeal, making them a reliable choice for both surface and underwater applications. The precision and adaptability of laser-cut acrylic sheets thereby enhance the efficiency and effectiveness of aerospace, defense, and marine operations.

Laser-cut acrylic sheets have revolutionized the automotive industry by providing precision and flexibility in manufacturing various components. Interior elements such as dashboards, instrument clusters, and decorative trims benefit immensely from the use of laser-cut acrylic due to its clarity, strength, and ease of customization. Automotive designers can achieve intricate details and seamless finishes that meet both aesthetic and functional requirements. Additionally, acrylic’s lightweight nature contributes to overall vehicle efficiency by reducing weight without compromising durability. This material also excels in exterior applications such as lighting fixtures and custom emblems, where precise cuts and consistent quality are paramount.

In the realm of electronics, laser-cut acrylic sheets are indispensable for creating custom enclosures, housings, and panels. The ability to achieve high precision with laser cutting technology ensures that intricate designs and tight tolerances are met, which is crucial for delicate electronic components. Acrylic offers excellent electrical insulation properties, making it a reliable choice for protective covers and mounting structures in sensitive equipment. Furthermore, its versatility allows for the production of aesthetically pleasing and functional elements such as transparent display windows, LED diffusers, and customized control panels. The material’s resilience and clarity enhance the visual appeal and durability of electronic devices, making it a preferred choice for both consumer electronics and specialized industrial applications.

In the construction industry, laser-cut acrylic sheets have emerged as a versatile and innovative material utilized in various applications. Due to their precision and adaptability, these sheets are frequently employed for creating customized architectural elements, such as decorative panels, room dividers, and intricate window designs. Architectural firms have adopted laser-cut acrylic for its ability to provide clean, accurate cuts that enhance the aesthetic appeal of buildings. Furthermore, the material’s lightweight yet durable nature allows for easier installation and handling compared to traditional glass. These qualities make laser-cut acrylic an attractive option for modern construction projects, where both functionality and design are paramount.

In the energy sector, laser-cut acrylic sheets play a crucial role in the development of solar panels and other renewable energy technologies. Due to their optical clarity and resistance to UV light, these sheets are often used as protective covers for photovoltaic cells, ensuring maximum sunlight penetration while safeguarding the sensitive components underneath. Additionally, their customizability allows engineers to design specific shapes and configurations tailored to improve energy conversion efficiency. Beyond solar applications, laser-cut acrylic is also utilized in the production of energy-efficient light fixtures and smart windows. These applications benefit from the material’s high transmission of light and its capacity to be laser-cut to precise specifications, optimizing both performance and design.

The industrial equipment industry increasingly relies on laser-cut acrylic sheets for their durability, precision, and versatility. This technologically advanced method ensures that the acrylic sheets are cut with unparalleled accuracy, which is crucial for creating components that require exact specifications. For instance, laser cut acrylic is used in the manufacture of intricate gears, custom enclosures, and protective guards for machinery. Its robustness allows it to withstand the rigors of industrial environments while offering a lightweight alternative to traditional materials like metal and glass. This adaptability makes laser-cut acrylic sheets a preferred choice for industries ranging from automation and robotics to packaging and material handling.

Additionally, the aesthetic and functional benefits of laser-cut acrylic sheets cannot be overlooked. The clean, polished edges produced by laser cutting eliminate the need for further finishing processes, reducing production time and costs. Furthermore, acrylic’s excellent light transmission properties make it ideal for safety shields and covers in equipment where visibility is crucial. Its resistance to UV light and chemicals ensures long-lasting performance, reducing the need for frequent replacements. These properties combined make laser-cut acrylic an invaluable resource in the industrial equipment sector, promoting efficiency, safety, and innovation across various applications.

Medical devices benefit greatly from the application of laser-cut acrylic sheets due to their precision, durability, and versatility. Acrylic is a biocompatible material, making it suitable for various medical uses, including surgical tools, diagnostic equipment, and protective barriers. The laser-cutting process ensures that these acrylic components are manufactured with high accuracy, often necessary for intricate designs and detailed specifications. This precision is critical in medical settings where even the smallest discrepancy can affect the efficacy and safety of a device. The smooth edges produced by laser cutting also reduce the risk of contamination and make cleaning easier, essential attributes in maintaining the sterility of medical instruments.

Furthermore, laser-cut acrylic sheets are utilized in creating custom enclosures and housings for medical devices. These enclosures protect sensitive electronics and components from environmental factors, ensuring reliability and longevity. The clear acrylic allows for easy monitoring of embedded systems without the need to disassemble the device, facilitating quick assessments and troubleshooting. Additionally, acrylic’s optical clarity makes it ideal for light-guiding applications within medical diagnostics tools, enabling accurate readings and observations. Thus, the integration of laser-cut acrylic not only enhances the functional aspects of medical devices but also contributes to improving patient safety and care quality through superior design and material efficacy.

Laser cutting of acrylic sheets has revolutionized the machining and manufacturing industries by offering precise, intricate, and clean cuts that are difficult to achieve with traditional cutting methods. In machining, laser technology allows for the production of high-quality components with minimal waste, as the focused laser beam can cut acrylic sheets with extreme accuracy. This precision enables the design and creation of highly detailed parts, such as gears, enclosures, and aesthetic elements, which are essential in industries ranging from automotive to consumer electronics. Moreover, the non-contact nature of laser cutting reduces the risk of material deformation, ensuring the integrity and dimensional accuracy of the final product.

In manufacturing, laser-cut acrylic sheets are widely utilized due to their versatility and efficient processing capabilities. The speed and efficiency of laser cutting enable mass production of components with consistent quality, which is critical for meeting the demands of large-scale manufacturing operations. Additionally, laser cutting supports rapid prototyping, allowing manufacturers to quickly turn around design iterations and bring products to market faster. The ability to precisely cut and engrave acrylic sheets also supports custom manufacturing, making it possible to produce tailored solutions for clients with unique requirements. Overall, the application of laser-cut acrylic sheets in machining and manufacturing offers a blend of precision, efficiency, and flexibility that enhances product quality and accelerates production timelines.

1. What is the typical lead time for manufacturing laser cut acrylic sheets?

The typical lead time for manufacturing laser cut acrylic sheets at SourcifyChina factory ranges from 7 to 14 days, depending on the order volume and complexity of the design.

2. What types of acrylic sheet thicknesses are available for laser cutting?

SourcifyChina factory offers a wide range of acrylic sheet thicknesses for laser cutting, typically from 1mm to 20mm. Custom thicknesses can also be accommodated upon request.

3. How precise is the laser cutting process at SourcifyChina factory?

The laser cutting process at SourcifyChina factory is highly precise, achieving tolerances as tight as ±0.1mm. This ensures accurate and consistent quality for all laser cut acrylic products.

4. Can SourcifyChina factory handle custom designs and complex patterns?

Yes, SourcifyChina factory is equipped with advanced laser cutting technology and skilled technicians capable of handling custom designs and intricate patterns with high precision.

5. What file formats are accepted for custom laser cutting designs?

SourcifyChina factory accepts various file formats for custom laser cutting designs, including AI, DXF, and SVG files. Customers are advised to contact the factory for specific file preparation guidelines.

6. Is color customization available for laser cut acrylic sheets?

Yes, SourcifyChina factory offers a variety of standard and custom colors for laser cut acrylic sheets. Color customization can be discussed during the order process.

7. How does SourcifyChina factory ensure the quality of laser cut acrylic sheets?

SourcifyChina factory ensures quality by utilizing state-of-the-art laser cutting machines, conducting thorough inspections, and adhering to strict quality control protocols throughout the production process.

8. What are the shipping options for international customers?

SourcifyChina factory offers various shipping options for international customers, including express courier services, air freight, and sea freight. Shipping costs and transit times vary based on the destination and selected shipping method.

9. Are there any minimum order quantities for laser cut acrylic sheets?

SourcifyChina factory usually does not impose strict minimum order quantities, allowing flexibility for both small-scale and large-scale orders. However, pricing may be more cost-effective for bulk purchases.

10. Can I request samples before placing a full order?

Certainly! Here are some tips for successful laser cut acrylic sheet manufacturing from SourcifyChina factory:

1. Material Selection: Choose high-quality acrylic sheets to ensure precision and durability. SourcifyChina offers various thicknesses and colors to suit different applications.

2. Design Precision: Ensure your design files are in vector format (like .AI, .DXF, or .SVG) for accurate laser cutting. Double-check measurements and consider tolerance for a seamless fit.

3. Communication: Maintain clear and detailed communication with SourcifyChina. Specify details like material type, thickness, and finishing touches to avoid errors.

4. Sample Request: Before bulk production, request a sample to verify the quality and accuracy of the cut. This saves time and resources in the long run.

5. Optimization: Utilize nesting techniques to optimize material usage and reduce waste. SourcifyChina’s experts often provide insights on how to best arrange your designs.

6. Lead Time: Discuss and agree on lead times. Consider both manufacturing and shipping durations to ensure your project timeline is met.

7. Quality Control: Ask about SourcifyChina’s quality control processes. Inquire if they offer inspection reports or can conduct third-party inspections.

8. Finishing Options: Explore various finishing options, such as polishing, engraving, or painting, to enhance your product’s aesthetic and functionality.

9. Environmental Considerations: Ensure that the factory follows environmental standards for waste management and energy efficiency, reflecting sustainable manufacturing practices.

10. Cost Efficiency: Compare quotes and services from SourcifyChina with other suppliers. Ensure that you are getting competitive pricing without compromising on quality.

By following these tips, you can ensure a smooth and successful collaboration with SourcifyChina for your laser cut acrylic sheet needs.

Frequently Asked Questions (FAQ) for Sourcing Laser Cut Acrylic Sheets from SourcifyChina Factory

Q: What types of acrylic sheets does SourcifyChina offer?

A: SourcifyChina provides a diverse range of acrylic sheets, including clear, colored, frosted, and mirrored options. They also offer custom thicknesses and sizes to meet specific project needs.

Q: What is the minimum order quantity (MOQ) for laser-cut acrylic sheets?

A: The MOQ varies based on the specifications of the order. For custom laser-cut designs, the MOQ typically starts at 50 sheets, but it’s best to contact SourcifyChina directly for precise details.

Q: Can I get a sample before placing a large order?

A: Yes, SourcifyChina can provide samples of their acrylic sheets. It’s recommended to specify your requirements, so the sample accurately reflects the final product.

Q: What is the lead time for orders?

A: The lead time depends on the order size and customization level. Generally, standard orders take about 2-4 weeks, while custom orders may take longer. Confirm the timeline with the factory when placing your order.

Q: How are the acrylic sheets packaged for shipping?

A: SourcifyChina ensures safe packaging by wrapping sheets in protective film and using sturdy cartons or wooden crates to prevent damage during transit.

Q: What are the payment terms?

A: SourcifyChina typically requires a deposit upfront, with the balance paid before shipment. They accept various payment methods, including wire transfers, PayPal, and Western Union.

Q: Do you offer design services for custom laser cutting?

A: Yes, SourcifyChina has an in-house design team to assist with custom laser cutting. Provide your specifications or design files for a tailored solution.

Q: How can I track my order after it’s shipped?

A: After your order is shipped, SourcifyChina will provide tracking details and shipping documentation for you to monitor the delivery status.

Q: Are there any certifications for the acrylic sheets?

A: SourcifyChina’s acrylic sheets comply with international standards and are certified for quality and safety. Specific certifications can be provided upon request.

Q: How do I get a quote for my order?

Sourcing “laser cut acrylic sheet” from SourcifyChina factory can be streamlined by following these tips:

1. Research and Identify Needs: Clearly define the specifications of the acrylic sheets you need, including thickness, color, size, and type of laser cutting.

2. Visit SourcifyChina’s Website: Explore their official website to understand their offerings, capabilities, and services. Look for any relevant case studies or testimonials.

3. Request Samples: Before committing to a bulk order, request samples to evaluate the quality of the acrylic sheets and the precision of the laser cutting.

4. Communicate Clearly: Reach out to SourcifyChina with a detailed inquiry. Mention specific requirements like dimensions, quantity, and any customization needs. Clear communication reduces misunderstandings.

5. Check Certifications: Ensure the factory has necessary certifications such as ISO9001 for quality management. This assures you of their commitment to consistent quality.

6. Assess Lead Time and Costs: Inquire about the production lead times and detailed cost breakdowns. Confirm if there are any hidden fees, such as shipping or handling charges.

7. Negotiate Terms: Discuss payment terms, minimum order quantities (MOQs), and potential discounts for bulk orders. It’s often possible to negotiate better terms with direct manufacturers.

8. Review Quality Control Procedures: Ask about their quality control measures to ensure the products meet your specified standards. Reliable factories should have stringent QC processes.

9. Check Logistics and Shipping: Confirm the logistics and shipping processes. Understand the delivery timelines and the shipping methods offered.

10. Establish a Relationship: Building a strong relationship with the supplier can lead to better service and potential cost savings in the future.

By following these tips, you can efficiently source laser cut acrylic sheets from SourcifyChina with confidence in quality and service.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.