Choosing SourcifyChina Factory for purchasing CNC fabricators from China ensures access to experienced professionals who understand the nuances of quality manufacturing and meet global standards. Their robust quality control mechanisms guarantee reliable and durable products.

SourcifyChina offers competitive pricing, helping buyers maximize their budget without compromising on quality. Their strategic location in China provides economical, timely logistics solutions, minimizing lead times and delivery costs.

The company’s dedication to customer satisfaction and tailored service means that buyers receive personalized solutions catered to their specific needs. Their responsive support team assists from inquiry to post-purchase, ensuring a seamless purchasing experience.

In conclusion, SourcifyChina Factory stands out for its commitment to quality, competitive pricing, and exceptional customer support. Choosing them for CNC fabricators ensures a reliable, efficient, and cost-effective partnership.

Computer Numerical Control (CNC) fabricators use automated machinery to produce precise components. Various types of CNC machines include milling, turning, laser cutting, and plasma cutting. Options available cater to diverse material requirements and production scales.

– CNC Milling Machines: Ideal for detailed, intricate components.

– CNC Turning Machines: Perfect for cylindrical parts.

– CNC Laser Cutters: Best for precise, high-speed cutting of thin materials.

– CNC Plasma Cutters: Suited for thicker metal materials.

– CNC Routers: Great for wood, plastic, and light metals.

– 5-Axis CNC Machines: Offers complex geometries, essential for advanced manufacturing.

– CNC Grinders: Provide fine finishing on hard materials.

– Water Jet Cutters: Utilize high-pressure water for cutting materials without thermal damage.

– CNC EDM (Electrical Discharge Machines): Excellent for hard metals and intricate shapes.

– CNC Lathes: Specialize in producing detailed cylindrical parts.

– CNC Drilling Machines: Focused on precise drilling tasks with tight tolerances.

– CNC Swiss Machines: Allow for extremely precise machining, suitable for small, complex parts.

– CNC Punching Machines: Used for punching holes in metal sheets.

– CNC Press Brake: Bends and shapes metal sheets with precision.

– CNC Wire Bending Machines: Designed for forming complex wire shapes.

Each machine type and option serves specific applications, ensuring efficiency, precision, and flexibility in manufacturing processes.

Computer Numerical Control (CNC) fabricators revolutionize manufacturing by automating intricate cutting, milling, and machining processes with superb accuracy. They are instrumental across numerous industries, enhancing productivity and precision.

– Aerospace: Crafting high-tolerance parts for aircraft and spacecraft.

– Automotive: Manufacturing engine blocks, gears, and custom components.

– Medical: Producing surgical instruments and prosthetic parts.

– Consumer Electronics: Creating enclosures and parts for gadgets.

– Construction: Cutting metal frames, structural components, and architectural elements.

– Custom Manufacturing: Making bespoke parts for specific industry needs.

– Prototyping: Rapid development of prototypes for testing and refinement.

– Jewelry: Precision crafting of intricate designs.

– Art and Sculpture: Producing metal and wood artworks.

– Shipbuilding: Forming complex ship components.

– Aviation: Building high-precision aviation machinery components.

– Renewable Energy: Manufacturing parts for wind turbines and solar power installations.

– Tool and Die Making: Creating molds and dies for various applications.

– Electronics: Producing circuit boards and electronic components.

– Robotics: Fabricating robotic parts and assemblies.

– Textile Equipment: Manufacturing parts for weaving and knitting machines.

– Oil and Gas: Precision parts for drilling equipment and refineries.

– Furniture: Custom and mass-produced fittings and fixtures.

– Military and Defense: Crafting durable, high-tolerance parts for defense equipment.

– Food Processing: Fabrication of processing equipment and machinery parts.

CNC fabricators drive innovation and efficiency in an array of fields, offering precise, customizable, and scalable solutions to meet ever-evolving industrial demands.

SourcifyChina CNC fabricators are reputable for their high-quality materials used in CNC machining. They offer metals like aluminum, steel, and titanium, known for their durability and versatility. These materials are chosen carefully to meet a range of industrial needs.

In addition to metals, SourcifyChina CNC fabricators also provide various plastics such as ABS, polycarbonate, and acrylic. These plastics are selected for their lightweight nature, durability, and resistance to environmental factors, making them suitable for various applications.

The company emphasizes the use of high-grade materials that ensure the longevity and reliability of the finished products. Quality control processes are stringent, ensuring that each material meets industry standards and specific customer requirements.

SourcifyChina’s diverse material offerings give clients the flexibility to select the most suitable options for their projects. This versatility aids in precise and efficient production, maintaining high standards across different industries and applications.

SourcifyChina CNC fabricators maintain rigorous quality control throughout their manufacturing process. They start by sourcing top-grade raw materials, ensuring the foundation of each product is of the highest quality. All materials undergo stringent inspections before production begins.

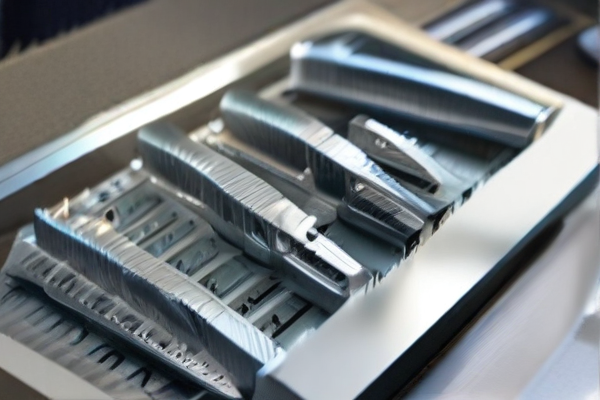

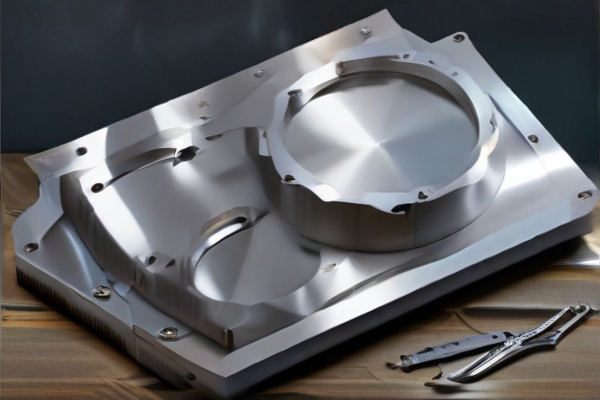

During the machining phase, each component is meticulously crafted using state-of-the-art CNC machines. These machines are regularly calibrated to ensure precise measurements and flawless finishes. Skilled operators continuously monitor the process to detect and correct any anomalies promptly.

Once machining is complete, products are meticulously inspected to meet exact specifications. Advanced dimensional and surface testing tools are utilized to ensure adherence to tight tolerances. Any defects identified are addressed immediately to maintain consistency and reliability.

Finally, a comprehensive final audit reviews all aspects of production, from materials to finished products. SourcifyChina implements continuous improvement practices, learning from each production run to enhance future quality and efficiency. This thorough quality control process ensures their clients receive the best possible components, meeting and often exceeding industry standards.

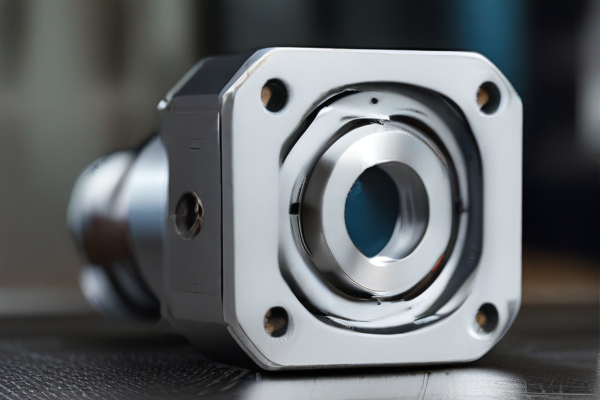

SourcifyChina CNC fabricators are leaders in precision manufacturing, providing state-of-the-art CNC machining services tailored to diverse industries. Their capabilities ensure high-quality production with exact specifications.

Specializing in both small and large-scale production runs, SourcifyChina boasts top-notch equipment and seasoned professionals. Their expertise allows them to handle intricate designs and complex geometries effortlessly.

Moreover, their cutting-edge machinery supports a variety of materials, including metals and plastics. This versatility makes them ideal partners for industries such as automotive, aerospace, and medical devices.

Their dedicated quality control team ensures each product meets stringent standards. Rigorous testing and inspection processes guarantee client satisfaction and compliance with global benchmarks.

SourcifyChina also prides itself on rapid turnaround times without sacrificing quality. Efficient workflows and advanced technology facilitate on-time delivery, a critical factor in today’s fast-paced business environment.

For customized projects, their skilled engineers offer design assistance and prototyping services. This collaborative approach helps clients refine their concepts and achieve optimal results.

In summary, SourcifyChina CNC fabricators stand out for their technical prowess, material versatility, stringent quality control, and customer-focused solutions. They are a reliable partner for industries demanding precision and efficiency.

Benefits of CNC Fabricators

CNC fabricators have revolutionized the manufacturing industry by enhancing precision, efficiency, and scalability. Their advanced capabilities offer numerous advantages.

– Precision and Accuracy: CNC fabricators are known for their high level of accuracy, ensuring consistent and repeatable results. This minimizes errors and reduces material waste.

– Increased Efficiency: Automation in CNC machines significantly reduces production time. They can operate continuously, improving throughput rates and meeting tight deadlines.

– Complex Designs: CNC fabricators can easily handle intricate and complex designs that would be challenging and time-consuming with manual methods.

– Scalability: Whether it’s a prototype or a large production run, CNC fabricators can scale operations seamlessly to meet various production demands.

– Material Versatility: They can work with a wide range of materials, including metals, plastics, and composites, making them suitable for diverse applications.

– Cost-Effectiveness: Reduced labor costs and minimized material wastage translate into significant cost savings over time.

– Safety: Automated processes reduce the need for manual handling, thereby lowering the risk of workplace injuries and enhancing overall safety.

– Consistent Quality: With minimal human intervention, CNC fabricators maintain consistent quality across all manufactured units, ensuring high customer satisfaction.

– Integration with Digital Technologies: CNC machines can easily integrate with CAD/CAM software, streamlining the transition from design to fabrication and enabling quick modifications to designs.

In summary, CNC fabricators offer unmatched precision, efficiency, and versatility, making them indispensable in modern manufacturing. Their ability to produce complex designs quickly and accurately while keeping costs low leads to improved productivity and competitive advantage.

CNC fabricators have revolutionized manufacturing with their precision and efficiency. These machines offer numerous features that streamline production, reduce errors, and enhance customization capabilities for various industries.

– High Precision: CNC machines provide extremely accurate cuts, ensuring that each part meets exact specifications.

– Automation: Automated control of tools and operations reduces the need for manual intervention, minimizing human error.

– Versatility: Capable of working with a variety of materials, including metals, plastics, and composites.

– Consistency: Reliable and repeatable results improve quality and maintain uniformity across large production runs.

– Complex Geometries: Capable of producing intricate designs and complex geometries that would be challenging to achieve manually.

– Time Efficiency: Fast processing speeds accelerate production timelines, making it possible to meet tight deadlines.

– Customization: Easy to reprogram for different tasks, allowing for quick adaptability to new designs and specifications.

– Safety: Enhanced safety features protect operators, reducing the risk of workplace injuries.

– Cost-Effective: Long-term cost savings through reduced waste, lower labor costs, and minimized downtime.

– Integration: Compatibility with CAD software streamlines the design-to-production workflow, ensuring seamless transitions from digital models to physical parts.

By leveraging these features, CNC fabricators play a critical role in modern manufacturing, supporting industries from aerospace to automotive with efficient and high-quality production solutions.

SourcifyChina CNC fabricators excel in delivering custom products tailored to meet specific requirements. Utilizing advanced machinery and technology, they ensure precision and quality in every component they produce. From intricate designs to large-scale projects, their expertise spans across a variety of industries.

Their dedicated team collaborates closely with clients to understand their vision and specifications. This personalized approach guarantees that every project is executed flawlessly, meeting both deadlines and quality standards. Whether it’s prototyping or full-scale production, SourcifyChina stands out for its attention to detail and commitment to excellence.

The fabricators at SourcifyChina are adept at working with a wide range of materials, including metals, plastics, and composites. This versatility allows them to cater to diverse needs, providing solutions for automotive, aerospace, medical, and consumer products. Their state-of-the-art CNC machines ensure that even the most complex designs are manufactured with utmost accuracy.

Innovation is at the core of SourcifyChina’s operations. By continually investing in the latest technology and training, they stay ahead of industry trends, offering cutting-edge solutions to their clients. This forward-thinking approach not only enhances productivity but also translates to cost-effective manufacturing processes, benefiting clients across the board.

SourcifyChina’s commitment to quality is evident in their rigorous inspection and testing protocols. Each product undergoes stringent checks to ensure it meets the highest standards of durability and performance. This meticulous attention to detail minimizes errors and maximizes customer satisfaction, establishing SourcifyChina as a trusted partner in CNC fabrication.

In conclusion, SourcifyChina CNC fabricators are leaders in custom product manufacturing, combining precision engineering with innovative technology. Their client-focused approach, material versatility, and unwavering commitment to quality make them an exemplary choice for any project. Trust SourcifyChina to deliver exceptional results every time.

SourcifyChina CNC Fabricators is a premier manufacturer renowned for its precision-driven, high-quality CNC machining services. Based in China, the company distinguishes itself through state-of-the-art technology and a commitment to unparalleled craftsmanship. Specializing in a diverse range of industries — from automotive to aerospace and medical devices — SourcifyChina ensures that each product delivered meets stringent international standards. Leveraging an expert team of engineers and advanced machinery, including multi-axis CNC milling and turning centers, the company excels in producing complex components with exacting tolerances. SourcifyChina’s robust quality assurance protocols, paired with its cost-competitive solutions and swift turnaround times, have solidified its reputation as a trusted partner for clients around the globe who seek reliable and innovative manufacturing capabilities. Through continuous investment in technology and skills development, SourcifyChina CNC Fabricators remains at the forefront of the CNC machining industry, making it a go-to source for precision engineering needs.

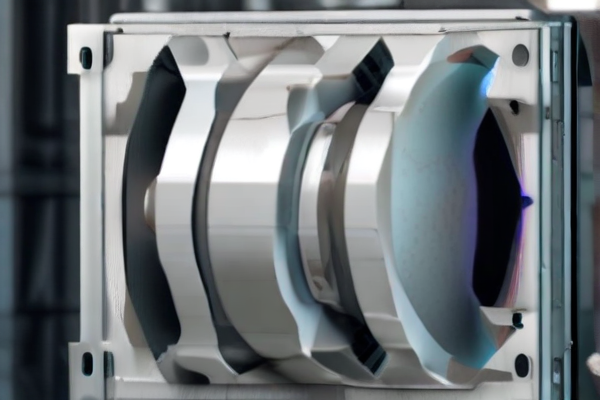

Aerospace, defense, and marine industries are sectors that demand precision, reliability, and durability, all of which are paramount to their operational integrity. CNC (Computer Numerical Control) fabricators play a crucial role in meeting these stringent requirements. In aerospace engineering, CNC machines are used to craft complex components like turbine blades, structural airframe members, and intricate engine parts. The materials often worked on include lightweight, high-strength alloys such as titanium and specialized composites, which require meticulous machining to exact specifications. The precision and repeatability of CNC machining ensure that each component adheres to the highest quality standards, which is critical for maintaining the safety and performance of aircraft.

In the realm of defense, CNC fabricators contribute significantly to the production of advanced weaponry, military vehicles, and communication systems. These applications often involve the machining of robust materials like hardened steels and specialty alloys that can withstand extreme conditions. CNC technology enables the production of intricate parts for missile systems, radar components, and armored vehicle structure with unparalleled accuracy and consistency, essential for mission-critical applications where failure is not an option. Similarly, in marine applications, CNC fabricators are relied upon to create parts for ship engines, propellers, and hull components. The marine environment demands materials that resist corrosion and wear; CNC fabricators ensure these materials are shaped with precision to provide reliable and efficient performance in challenging oceanic conditions. By leveraging the capabilities of CNC machines, these industries can achieve the highest levels of performance and reliability in their specialized applications.

CNC fabricators have revolutionized the automotive industry by providing unparalleled precision and efficiency in the manufacturing of intricate and critical components. In an environment where accuracy is paramount, CNC machining enables the production of engine parts, transmission components, and intricate body parts with sub-millimeter precision. This high level of accuracy not only helps in enhancing the performance and safety of vehicles but also drastically reduces production times and costs. The ability to replicate complex designs consistently ensures that each part meets stringent quality standards, contributing to the reliability and longevity of automotive products. Moreover, CNC fabricators are essential in the rapid prototyping phase, allowing engineers to test and refine new designs swiftly, accelerating the development of innovative automotive technologies.

In the electronics sector, CNC fabricators play a crucial role in the production of highly detailed and miniaturized components that are fundamental to modern electronic devices. The capabilities of CNC machinery allow for the precise fabrication of circuit boards, enclosures, and connectors with intricate patterns and tolerances that are otherwise challenging to achieve through traditional methods. This precision is vital for the functionality and performance of electronic devices, ranging from consumer electronics like smartphones and laptops to critical components in medical equipment and aerospace electronics. Additionally, CNC fabrication supports the trend of miniaturization in electronics, enabling the development of smaller, yet more powerful and complex devices. By ensuring consistency and high-quality output, CNC fabricators help drive innovation and maintain the rigorous standards necessary in the fast-evolving electronics industry.

CNC fabricators have revolutionized the construction industry by enhancing precision, reducing waste, and significantly cutting down production times. In construction, these computer-controlled machines are used to create intricate parts and components with exceptional accuracy. This automation minimizes human error and ensures consistent quality, making it ideal for producing steel beams, concrete molds, and custom architectural elements. Additionally, CNC technology facilitates the prefabrication of complex structures that can be quickly assembled on-site, thus expediting the construction process and reducing labor costs. The ability to produce highly detailed and uniform components also supports innovative architectural designs, enabling the construction of modern, aesthetically-pleasing buildings that adhere to stringent safety standards.

In the energy sector, CNC fabricators play a critical role in the manufacturing and maintenance of complex machinery and infrastructure essential for various forms of energy production, including wind, solar, and fossil fuels. For instance, precision machining is vital for creating the highly specialized parts used in turbines for wind farms and hydroelectric plants. Similarly, solar panel frames and mounting hardware benefit from the exacting tolerances achievable through CNC fabrication. In the oil and gas industry, CNC-machined components are essential for pipelines, drilling equipment, and refining processes, where durability and precision are paramount. By ensuring the reliability and performance of energy-producing systems, CNC fabricators contribute to the efficiency and sustainability of the global energy supply chain, facilitating advancements and innovations that drive the sector forward.

The industrial equipment industry has seen transformative changes with the application of CNC (Computer Numerical Control) fabricators. These advanced machines bring precision, efficiency, and scalability to manufacturing processes that were previously labor-intensive and prone to human error. CNC fabricators automate the cutting, drilling, milling, and machining of materials such as metal, wood, and plastic with high accuracy. They are widely used in producing complex industrial components like gears, engine parts, and custom fasteners. Their ability to execute intricate designs with minimal manual intervention greatly reduces production time and costs, contributing to the overall competitiveness of the industrial equipment sector.

Moreover, CNC fabricators support customization and flexibility, allowing manufacturers to quickly adapt to changing market demands and customer specifications. They integrate seamlessly with computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, enabling precise replication of design prototypes and efficient mass production. As a result, industries such as automotive, aerospace, and heavy machinery are able to maintain high standards of quality and reliability while scaling up production to meet global demand. Additionally, the data-driven nature of CNC technology facilitates predictive maintenance, ensuring minimal downtime and prolonging the lifespan of both the machines and the components they produce. In essence, the widespread adoption of CNC fabricators in the industrial equipment industry sets new benchmarks for productivity, quality, and innovation.

Computer Numerical Control (CNC) fabricators play a crucial role in the medical device industry, enabling the precise and efficient production of high-quality components and instruments. CNC technology allows for the meticulous creation of intricate parts used in a variety of medical applications, from surgical instruments to orthopedic implants. The precision machining offered by CNC fabricators ensures that each component meets stringent industry standards and tolerances, essential for ensuring patient safety and device efficacy. With the ability to work with diverse materials such as biocompatible metals and polymers, CNC machines are indispensable in producing components that meet the demanding requirements of medical devices.

In addition to their precision, CNC fabricators bring significant enhancements in productivity and consistency to the medical device manufacturing process. Automated machining reduces the likelihood of human error, leading to higher reliability and repeatability in production. This is particularly important in the medical field where even slight deviations can have serious implications. Furthermore, CNC fabricators are capable of rapid prototyping, enabling swift iterations and improvements in device design. This accelerates development cycles and allows for faster time-to-market for new medical innovations. Consequently, CNC technology not only ensures the high quality of medical devices but also supports continuous innovation and improvement within the industry.

CNC fabricators play an instrumental role in the machining and manufacturing industries, providing precision, efficiency, and consistency that traditional methods often lack. Computer Numerical Control (CNC) technology allows for the automation of machine tools, wherein a computer controls the movements and operations of machinery, such as lathes, mills, routers, and grinders. This automated control ensures that each part produced meets exact specifications, with tolerances often within micrometers. The digital nature of CNC systems also reduces human error, ensuring high-quality output regardless of the batch size. The capability to quickly switch between different tasks and prototypes means CNC fabricators are vital in both mass production settings and specialized, custom manufacturing scenarios.

Beyond mere production, CNC fabricators greatly enhance manufacturing application versatility and material efficiency. Precision machining facilitated by CNC technology allows for the creation of complex geometries and intricate designs that manual processes can’t achieve. This opens up possibilities in diverse industries, including aerospace, automotive, healthcare, and electronics, where parts often require stringent specifications and exceptional material properties. Additionally, CNC fabricators optimize material usage by minimizing waste through exact cutting paths and efficient nesting of parts. This not only reduces material costs but also contributes to sustainable manufacturing practices. The integration of advanced software for design and simulation further supports innovation, allowing engineers and designers to rapidly iterate and refine products before they hit the production floor. Thus, CNC fabricators are essential in driving forward the capabilities and efficiencies of modern machining and manufacturing.

Certainly! Below are some frequently asked questions (FAQs) with answers for manufacturing CNC fabricators with quality work from SourcifyChina factory:

—

Q1: What types of CNC services does SourcifyChina provide?

A1: SourcifyChina offers a wide range of CNC services, including milling, turning, drilling, and precision cutting, all tailored to meet specific client requirements.

Q2: How does SourcifyChina ensure the quality of their CNC fabrication?

A2: SourcifyChina employs strict quality control measures, including thorough inspections and advanced testing equipment, to ensure each product meets or exceeds industry standards.

Q3: What materials can SourcifyChina work with in CNC fabrication?

A3: SourcifyChina works with a variety of materials, including metals like aluminum, steel, and titanium, as well as plastics and composites.

Q4: How quickly can SourcifyChina complete a CNC fabrication project?

A4: The completion time for a CNC fabrication project varies depending on complexity and volume. However, SourcifyChina is known for offering competitive lead times without compromising quality.

Q5: Can SourcifyChina handle custom CNC fabrication orders?

A5: Yes, SourcifyChina specializes in custom CNC fabrication services, tailoring each project to the client’s unique specifications and requirements.

Q6: What is the minimum order quantity (MOQ) for CNC services at SourcifyChina?

A6: The MOQ for CNC services can vary based on the project, but SourcifyChina is flexible and caters to both small and large orders to suit customer needs.

Q7: Are there any certifications held by SourcifyChina that verify their quality standards?

A7: SourcifyChina holds various industry-standard certifications like ISO 9001, ensuring consistent quality and reliable processes in their manufacturing services.

Q8: How does SourcifyChina handle design confidentiality?

A8: SourcifyChina takes confidentiality seriously, employing secure data handling protocols and non-disclosure agreements (NDAs) to protect client designs and intellectual property.

Q9: Does SourcifyChina provide prototypes before mass production?

A9: Yes, SourcifyChina offers prototyping services to help clients validate their designs before proceeding to large-scale production, ensuring the final product meets their expectations.

Q10: How can I get a quote for my CNC fabrication project with SourcifyChina?

Partnering with a CNC fabricator like SourcifyChina can significantly enhance your manufacturing efficiency and product quality. Here are some tips to make the most out of this partnership:

1. Clear Communication: Establish a strong communication channel to convey your product specifications, design requirements, and quality standards. Use detailed CAD drawings and 3D models to eliminate misunderstandings.

2. Quality Control: Ensure the factory adheres to stringent quality control measures. Regularly request samples and consider third-party inspections to verify consistency and precision.

3. Material Selection: Discuss the best materials for your product with the CNC fabricator. SourcifyChina has access to a wide range of materials; their expertise can guide you in selecting the most durable and cost-effective options.

4. Production Capabilities: Understand the factory’s production capabilities and limitations. Ensure they have the necessary machinery and technology to meet your requirements, whether it’s for prototyping or large-scale production.

5. Lead Times: Clarify lead times upfront. Be realistic about production and shipping durations to avoid delays. Set milestones and deadlines to keep the project on track.

6. Cost Consideration: While outsourcing to China can be cost-effective, it’s vital to factor in shipping, taxes, and potential tariffs. Request detailed quotations to understand the full cost implications.

7. Legal Protection: Protect your intellectual property by ensuring appropriate legal agreements are in place. Non-disclosure agreements (NDAs) and manufacturing contracts can safeguard your designs and innovations.

8. Sustainability: Inquire about the factory’s sustainability practices. Many customers now value eco-friendly production, and partnering with a manufacturer who prioritizes this can enhance your brand’s reputation.

9. Cultural Sensitivity: Respect cultural differences in business practices. Understanding and adapting to these can foster better relationships and smoother negotiations.

By following these tips, you can ensure a productive and mutually beneficial partnership with SourcifyChina’s CNC fabricators.

Certainly! Here are some frequently asked questions (FAQs) about sourcing CNC fabricators from SourcifyChina factory:

1. What is SourcifyChina?

SourcifyChina is a manufacturing and sourcing platform that connects businesses with reliable factories in China, including CNC fabricators. They streamline the process to ensure quality products and timely delivery.

2. Why should I source CNC fabricators from SourcifyChina?

SourcifyChina ensures that you get access to verified and high-quality CNC fabrication services. They pre-vet factories for quality and reliability, offer competitive pricing, and provide support throughout the manufacturing process.

3. How do I start a CNC fabrication project with SourcifyChina?

To start, simply visit the SourcifyChina website and submit a request for quotation (RFQ) detailing your project requirements. A SourcifyChina representative will then get in touch with you to discuss your needs.

4. What materials can SourcifyChina CNC fabricators work with?

SourcifyChina CNC fabricators can work with a wide range of materials including metals (e.g., aluminum, steel, brass) and plastics (e.g., ABS, PVC, PTFE).

5. Are there minimum order quantities (MOQ) for CNC fabrication?

The minimum order quantity depends on the specific factory and project requirements. SourcifyChina works with you to match you with a factory that can meet your MOQ needs.

6. What quality control measures are in place?

SourcifyChina employs stringent quality control processes, including pre-production inspections, in-process checks, and final inspections before shipment, ensuring that your specifications are met.

7. How long does it take to complete a CNC fabrication order?

Lead times vary depending on the complexity and volume of the order. Typically, a CNC fabrication project may take anywhere from a few weeks to a couple of months. SourcifyChina will provide a more accurate timeline upon evaluating your project.

8. What are the payment terms?

SourcifyChina offers flexible payment terms, which are typically discussed and agreed upon during the contract negotiation stage. Common terms include initial deposits with balance payments upon completion.

9. How is shipping handled?

SourcifyChina can handle shipping and logistics to ensure your CNC fabricated products are delivered to your destination. They offer various shipping options based on your timeframe and budget.

10. Who do I contact for support?

Sourcing CNC fabricators from “SourcifyChina factory” can streamline your manufacturing process and cut costs. Here are some concise tips to help you navigate this effectively:

1. Research Thoroughly:

– Look up “SourcifyChina factory” on trusted platforms like Alibaba, Global Sources, or direct company websites.

– Check reviews and ratings from previous clients for insights on reliability and quality.

2. Define Requirements:

– Clearly outline your CNC machining needs, including material type, precision level, and volume.

– Provide detailed drawings or CAD files to avoid miscommunication.

3. Verify Capabilities:

– Confirm the factory’s expertise in your specific industry and material.

– Inquire about their CNC machine types, tolerances, and quality control processes.

4. Request Samples:

– Ask for prototype samples to assess the quality firsthand.

– Use these samples to validate if the factory meets your precision and quality expectations.

5. Negotiate Terms:

– Discuss payment terms, lead times, and production schedules.

– Clarify the logistics, including shipping costs and responsibilities.

6. Quality Assurance:

– Establish a quality control plan, including in-process inspections and final audits.

– Consider hiring a third-party inspection service for unbiased quality checks.

7. Legal and Compliance:

– Ensure the factory complies with local and international regulations.

– Check for certifications like ISO to guarantee standardized processes.

8. Clear Communication:

– Maintain regular communication throughout the production cycle.

– Use tools like emails, video calls, and instant messaging for real-time updates.

9. Long-term Relationship:

– Build a relationship based on trust and mutual benefit.

– Periodically review performance and provide feedback for continuous improvement.

By following these steps, you can efficiently source from SourcifyChina factory, ensuring high-quality CNC fabrication for your projects.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.