Choosing SourcifyChina Factory for purchasing copper plating metal from China ensures high-quality production standards. SourcifyChina’s strict quality control processes guarantee products meet international specifications, minimizing the risk of defects.

Their experienced team offers personalized customer service, assisting with product selection and logistics. This ensures a seamless purchasing experience from start to finish.

SourcifyChina provides competitive pricing without compromising on quality, making it a cost-effective solution for companies needing bulk purchases. They have established strong relationships with reliable suppliers, ensuring timely delivery.

With a robust infrastructure and advanced technology, SourcifyChina Factory is capable of handling large-scale orders efficiently. Their commitment to sustainability also ensures environmentally friendly production processes.

In conclusion, SourcifyChina Factory offers high-quality, competitively priced products with excellent customer service, making them the ideal choice for buyers seeking copper plating metal from China. Their expertise and reliability make the purchasing process efficient and hassle-free.

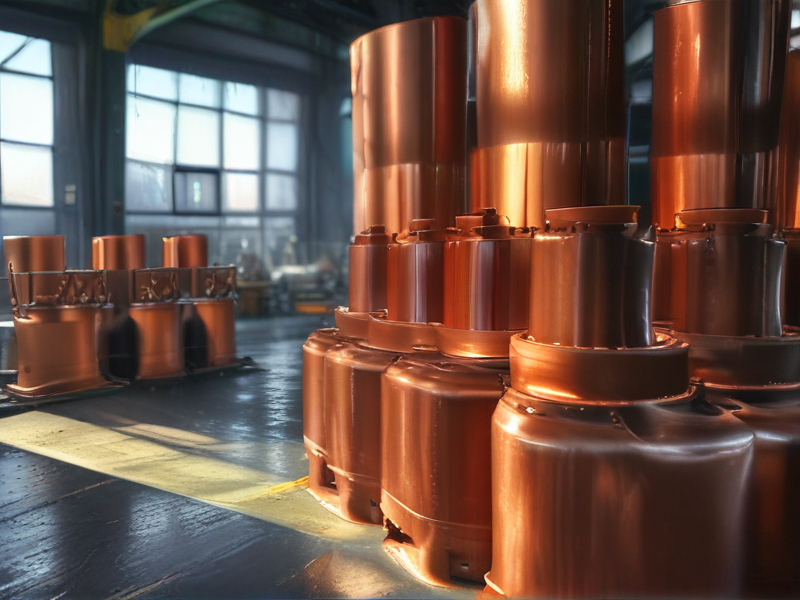

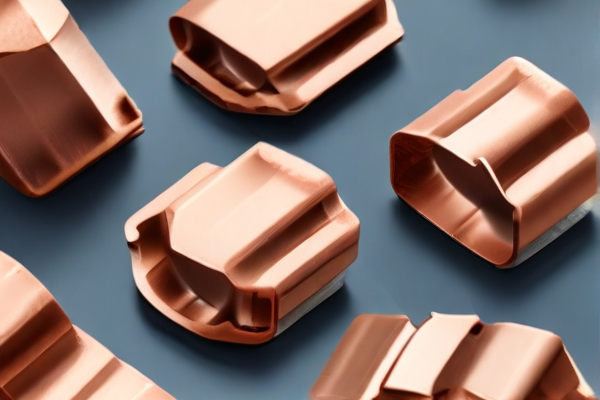

Copper plating metal involves the electrochemical process of depositing a thin layer of copper onto a substrate for improved conductivity, resistance to corrosion, and enhanced appearance. Various types and options exist to cater to specific industrial and decorative applications.

– Acid Copper Plating: Uses an acidic solution for a smoother and finer finish, ideal for engineering and decorative applications.

– Alkaline Copper Plating: Employs an alkaline solution, providing improved adhesion and corrosion resistance, often used as an undercoat.

– Electroless Copper Plating: A chemical reduction process, suitable for non-conductive substrates and complex geometries, often used in printed circuit boards.

– Bright Copper Plating: Involves additives to produce a shiny, mirror-like finish, common in decorative items.

– Matte Copper Plating: Results in a non-reflective, matte finish, useful in applications where glare is a concern.

– Strike Copper Plating: A thin initial layer to enhance adhesion for subsequent thicker coatings, critical for challenging substrates.

– Barrel Plating: Ideal for plating small, bulk items using a rotating barrel to ensure even coverage.

– Rack Plating: Best suited for larger or complex parts, where items are plated while mounted on racks for controlled application.

Understanding these types and options helps in selecting the appropriate copper plating method to achieve the desired functional and aesthetic outcomes in various industries.

Copper plating metal finds extensive applications due to its excellent electrical conductivity, corrosion resistance, and aesthetic appeal. It is used in various industries ranging from electronics to automotive.

– Electronics: Enhances conductivity and reliability of circuit boards and connectors.

– Automotive: Provides corrosion resistance to automotive components, improving longevity.

– Plumbing: Used in fittings and fixtures to prevent corrosion and ensure sanitary conditions.

– Jewelry: Applied for its attractive finish and hypoallergenic properties.

– Aerospace: Helps in reducing friction and wear in aerospace components.

– Industrial Machinery: Utilized for its protective properties on mechanical parts.

– Coins and Medals: Used for its appealing look and durability.

– Medical Devices: Offers biocompatibility and reliability for implants and instruments.

– Heat Exchangers: Enhances thermal conductivity and resistance to oxidation.

– Marine Applications: Protects against harsh marine environments.

– Telecommunications: Improves signal transmission in various devices.

– Antique Restoration: Employed for aesthetic restoration and protection.

Each of these applications leverages the unique properties of copper, making it a valuable choice in diverse fields.

SourcifyChina’s copper plating metal is widely recognized for its high-quality finish and robust durability. The copper plating provides excellent corrosion resistance, ensuring the longevity and reliability of the metal in various applications. This top-tier material is especially beneficial in electrical and plumbing industries, where both aesthetic appeal and functional durability are crucial.

Moreover, the copper plating offers superior conductivity, making it an ideal choice for electrical components. It’s often used in manufacturing connectors, circuits, and other electronic parts. This ensures efficient electrical performance and enhanced product lifespan, aligning with the stringent requirements of modern technology.

In addition to its practical benefits, SourcifyChina’s copper plating metal is also visually appealing. The lustrous finish enhances the look of any product, adding a touch of sophistication and elegance. This aesthetic advantage makes it popular in decorative applications, contributing to the overall allure and marketability of finished goods.

SourcifyChina is committed to sustainability, using eco-friendly processes and materials in their copper plating. They prioritize reducing environmental impact while maintaining high standards of quality. This dedication to green manufacturing practices not only supports environmental conservation but also ensures that their products meet international regulatory standards.

SourcifyChina employs stringent quality control measures throughout its copper plating metal manufacturing process. Initially, raw materials undergo rigorous inspection to ensure they meet strict quality standards. This involves testing for purity, composition, and consistency.

The next phase involves precise cleaning and preparation of metal surfaces. Advanced technological methods remove impurities to optimize adhesion. This step is crucial for achieving a flawless copper layer. Specialists meticulously monitor each procedure to guarantee precision.

During the actual copper plating, the use of state-of-the-art machinery ensures even and consistent application. Automated systems maintain stable temperature and electric current, which are vital for an impeccable finish.

Post-plating, the materials are subjected to a series of tests, including thickness measurements and adhesion strength assessments. Only those that meet or exceed predefined criteria proceed to the final stage. This ensures each piece conforms to international standards.

Finally, each batch undergoes a detailed visual inspection and testing to identify any surface defects or inconsistencies. Products are then carefully packaged and stored to prevent damage. This comprehensive quality control ensures SourcifyChina’s copper-plated metals are of the highest standard, ready for global distribution.

SourcifyChina excels in providing top-notch copper plating services. Leveraging advanced techniques and state-of-the-art equipment, they ensure premium quality for diverse industrial applications. Their precision and attention to detail set them apart.

The company’s teams are proficient in handling both small and large-scale projects, maintaining consistent quality across all batches. Their expertise reduces lead times and ensures on-time delivery, making them a reliable partner.

Customer satisfaction is SourcifyChina’s priority, offering tailored solutions to meet specific requirements. Their flexibility in accommodating custom requests makes them stand out in the competitive market.

Sustainability is also a core value, with eco-friendly practices embedded in their operations. The firm adheres to stringent environmental standards, ensuring minimal waste and reduced ecological impact.

Overall, SourcifyChina’s copper plating capabilities are unmatched, combining quality, reliability, and sustainability. With a strong commitment to innovation and customer satisfaction, they continue to lead the industry, offering unparalleled service and expertise.

Copper plating offers numerous benefits for metals, enhancing their performance and extending their lifespan. This process involves applying a thin layer of copper to various substrates to improve their properties.

Key benefits of copper plating include:

– Corrosion Resistance: Protects metals from rust and oxidation.

– Conductivity: Improves electrical and thermal conductivity.

– Adhesion: Facilitates better adhesion of subsequent coatings.

– Aesthetic Appeal: Provides a smooth, attractive finish for decorative purposes.

– Wear Resistance: Increases durability and reduces material wear.

– Cost-Effectiveness: Economical for extensive industrial applications.

Copper plating not only boosts functional characteristics but also adds value to the treated materials, making it a versatile choice in various industries.

Copper plating is a widely used metal finishing technique known for its excellent conductivity, corrosion resistance, and aesthetic appeal. This process has numerous applications in various industries.

– Conductivity: Copper’s high electrical conductivity makes it ideal for electrical components and circuitry.

– Corrosion Resistance: Copper plating provides a protective layer that helps prevent rust and corrosion.

– Adhesion: Copper adheres well to both metallic and non-metallic surfaces, enabling versatile applications.

– Solderability: Facilitates excellent soldering, essential for electronic and manufacturing industries.

– Aesthetic Appearance: Offers a visually appealing reddish-brown finish, often used in decorative items.

– Cost-Effective: Relatively inexpensive compared to other precious metals like gold and silver.

– Thermal Conductivity: Efficient heat transfer makes it suitable for heat exchangers and cooling systems.

– Versatility: Can be used as a base layer for additional metal coatings, enhancing overall durability.

– Industrial Applications: Widely used in aerospace, automotive, telecommunications, and electronics sectors.

– Eco-Friendly: Copper is recyclable, making it a sustainable choice for various industries.

SourcifyChina specializes in delivering high-quality copper plating for a wide range of custom metal products. With advanced technology and skilled craftsmanship, they ensure precise finishes that enhance both aesthetic appeal and durability.

Their extensive experience allows them to handle projects of any size or complexity, catering to various industries including automotive, electronics, and consumer goods. Tailored solutions ensure each project meets stringent quality standards and client specifications.

SourcifyChina remains committed to sustainability, employing eco-friendly practices in copper plating. This dedication minimizes environmental impact while still achieving superior product quality and performance.

Clients benefit from SourcifyChina’s strong focus on innovation, competitive pricing, and fast turnaround times. Their dedicated customer service team guarantees smooth project execution from concept to completion.

SourcifyChina is a prominent player in the metal finishing industry, specializing in high-quality copper plating services. The company leverages advanced technology and a team of skilled professionals to deliver exceptional plating solutions tailored to a wide range of industrial applications. Offering unmatched precision and durability, SourcifyChina’s copper plating processes enhance the conductivity, corrosion resistance, and aesthetic appeal of metal components. Their state-of-the-art facilities and stringent quality control measures ensure that each project meets the highest industry standards. Committed to sustainability, SourcifyChina also employs environmentally friendly practices and materials, positioning itself as a responsible leader in the metal finishing sector. The company’s dedication to innovation, quality, and customer satisfaction makes it a go-to choice for businesses seeking reliable and efficient copper plating services in China and beyond.

Copper plating metal plays a crucial role in the aerospace, defense, and marine industries due to its excellent electrical conductivity, corrosion resistance, and thermal management properties. In the aerospace sector, copper plating is commonly used for components that require efficient heat dissipation and grounding. Aircraft electrical systems, including connectors and circuit boards, often employ copper plating to enhance conductivity and ensure reliable performance under extreme conditions. Additionally, the anti-corrosive nature of copper plating protects critical parts from oxidation and wear, thereby extending the lifespan and reliability of aerospace components, which are subject to significant stress and environmental challenges at high altitudes.

In the defense and marine industries, copper plating is integral for both operational efficiency and longevity of equipment. Military vehicles, ships, and submarines benefit from the anti-corrosive properties of copper, especially in marine environments where saltwater can rapidly degrade unprotected metals. Copper-plated components are essential in radar and communication systems, ensuring clear, uninterrupted signal transmission crucial for tactical operations. Furthermore, the robustness of copper-plated parts under harsh environmental conditions enhances the durability of weapon systems and other defense apparatus, thereby ensuring mission readiness and reducing maintenance costs. The application of copper plating in these fields underscores its indispensability in enhancing performance, reliability, and protection of critical systems and infrastructure.

Copper plating is crucial in the automotive industry due to its excellent electrical conductivity and resistance to corrosion. In electrical systems, copper-plated components facilitate efficient power distribution and signal transmission, which are vital for the performance of modern vehicles. For instance, electrical connectors, terminals, and circuit boards in automotive electronics often use copper plating to ensure reliability and longevity. Additionally, in mechanical components like pistons, valves, and fasteners, copper plating provides a low-friction surface that reduces wear and improves durability. Given the automotive industry’s emphasis on efficiency and durability, copper plating plays a significant role in optimizing vehicle performance and extending component lifespan.

In the electronics industry, copper plating is indispensable due to its superior electrical and thermal conductivity. Printed circuit boards (PCBs), which are essential to almost all electronic devices, rely on copper plating to form conductive pathways that connect various components. This ensures efficient signal transmission and power distribution within the device, which is critical for functionality and performance. Furthermore, copper plating provides effective heat dissipation, preventing overheating in high-performance electronics such as computers, smartphones, and telecommunications equipment. The ability to reliably transfer data and manage heat makes copper-plated substrates a preferred choice in the ever-evolving field of electronics, where precision and dependability are paramount.

Copper plating metal plays a crucial role in the construction industry, offering multiple benefits that enhance the durability and functionality of building components. One of the primary applications is in reinforcing steel structures; copper plating provides a robust barrier against corrosion, extending the lifespan of steel bars used in concrete frameworks. This is particularly advantageous in coastal and industrial environments where structures are exposed to harsh conditions. Additionally, copper-plated fasteners and fixtures are commonly employed in construction to prevent rust, ensuring long-term stability and reduced maintenance costs. Copper’s inherent antimicrobial properties also make it a preferred choice for plumbing fixtures, reducing the incidence of bacterial contamination and enhancing water quality in both residential and commercial buildings.

In the realm of energy applications, copper plating metal is indispensable due to its excellent electrical conductivity. It is extensively used in the fabrication of electrical connectors and components in renewable energy systems such as solar panels and wind turbines. The efficient conduction of electricity is vital for minimizing energy losses and enhancing the overall efficiency of these systems. Furthermore, copper plating is pivotal in the production of batteries, particularly in the context of electric vehicles and portable electronic devices. The plated copper improves the performance and lifespan of battery electrodes, contributing to more reliable and longer-lasting energy storage solutions. Overall, copper plating continues to be a critical material in advancing energy technologies, promoting more sustainable and efficient energy utilization.

The industrial equipment sector extensively leverages copper plating for its exceptional electrical, thermal, and corrosion-resistant properties. In electrical applications, copper’s superior conductivity makes it indispensable in manufacturing circuit boards, connectors, and other components where efficient energy transfer is critical. Additionally, the manufacturing of heavy machinery often involves parts that must resist environmental wear and tear; copper plating offers a protective layer against corrosion and oxidation. This extends the lifespan of components used in harsh environments, such as mining operations and chemical processing plants, thereby ensuring operational reliability and reducing maintenance costs.

Moreover, the industrial equipment industry benefits from copper plating in terms of enhanced component strength and precision. Copper plating provides a malleable yet strong coating, enabling finer detailing in the production of intricate machine parts. This is particularly valuable in aerospace and automotive sectors, where the precision of components directly impacts safety and performance. Copper’s excellent bonding properties also facilitate the coating of complex geometries, ensuring comprehensive coverage and uniform thickness. Consequently, copper-plated components exhibit improved thermal management, reducing the risk of overheating in high-stress environments. Collectively, these attributes make copper plating an invaluable process in enhancing the durability and efficiency of industrial equipment.

Copper plating on medical devices offers a range of benefits, predominantly due to the metal’s exceptional antimicrobial and biocompatible properties. In clinical settings where sterile environments are paramount, copper’s ability to inhibit the growth of bacteria, viruses, and fungi is invaluable. Medical instruments such as surgical tools, wound dressings, and hospital touch surfaces like bed rails and door handles benefit from a copper plating layer that drastically reduces microbial contamination, thereby minimizing the risk of hospital-acquired infections. Additionally, copper’s biocompatibility ensures that it does not evoke adverse immune responses when in contact with human tissues, making it suitable for use in implants and other invasive medical devices.

Furthermore, copper plating enhances the durability and functionality of medical devices. Copper’s excellent electrical conductivity improves the performance of electronic components in diagnostic equipment, such as MRI machines and other imaging tools. Its thermal conductivity also aids in the efficient dissipation of heat, which is critical in maintaining the operational stability of complex medical apparatus. The malleability and ductility of copper allow for intricate designs and consistent coatings, ensuring that devices function reliably under the stringent conditions of medical use. By combining these material advantages, copper plating not only enhances the longevity and efficiency of medical devices but also plays an essential role in maintaining a hygienic and safe healthcare environment.

Copper plating, a process in which a layer of copper is deposited on the surface of a metal or other material, is integral in numerous machining and manufacturing applications. In the realm of machining, copper plating is particularly valued for its excellent electrical conductivity, corrosion resistance, and malleability. This process enhances the surface of workpieces, making them more compatible with various operations, such as grinding, cutting, and forming. Additionally, copper’s superior thermal conductivity aids in dissipating heat efficiently during machining processes, thereby extending the lifespan of both the tools and the workpieces. The uniformity of the copper layer ensures minimal friction and wear on the equipment, reducing maintenance costs and improving operational efficiency.

In manufacturing, copper plating is widely used in industries such as electronics, automotive, and aerospace. In the electronics industry, copper-plated components are essential for creating reliable and efficient circuit boards, connectors, and switches. The automotive sector relies on copper plating to enhance the durability and conductivity of parts like connectors, brake rotors, and bushings. In aerospace, copper plating is employed to improve the stability and conductivity of various critical components under extreme environmental conditions. Beyond these applications, copper plating is also used to create aesthetically pleasing finishes on household items and consumer electronics. Additionally, the antibacterial properties of copper make it a desirable option for medical equipment and surfaces exposed to high-touch public environments. Overall, copper plating extends the functionality, durability, and appeal of a wide range of machined and manufactured products.

Sure! Here are some frequently asked questions (FAQ) with answers regarding copper plating metal quality work from SourcifyChina factory.

Q1: What types of metals can you copper plate?

A1: SourcifyChina factory specializes in copper plating on various metals, including steel, aluminum, brass, and stainless steel. We ensure high-quality adhesion and finish for each metal type.

Q2: What is the thickness range of copper plating you offer?

A2: We offer copper plating thickness ranging from 5 microns up to 100 microns, depending on the specific requirements of your project. Custom thickness can also be accommodated upon request.

Q3: How do you ensure the quality of the copper plating?

A3: Quality is ensured through a series of inspections and tests, including adhesion tests, thickness measurements, and visual inspections. SourcifyChina follows strict industry standards and uses advanced equipment to guarantee high-quality results.

Q4: Can you provide custom finishes for copper-plated items?

A4: Yes, we offer a variety of custom finishes, including matte, satin, and bright gloss. We can also provide additional treatments such as passivation and protective coatings as per your requirements.

Q5: What is the typical lead time for copper plating services?

A5: The lead time varies depending on the volume and complexity of the order. Typically, it ranges from 1 to 3 weeks. We also offer expedited services for urgent requirements.

Q6: Do you provide samples before mass production?

A6: Yes, we can provide samples for approval before proceeding with mass production. This ensures that the final product meets your expectations and specifications.

Q7: What are your minimum order quantities (MOQ) for copper plating services?

A7: Our minimum order quantity varies based on the project, but typically starts at 100 pieces. For custom or specialized projects, please contact us for more details.

Q8: Are your copper plating processes environmentally friendly?

A8: SourcifyChina is committed to sustainability. We utilize eco-friendly chemicals and processes, and we adhere to all environmental regulations to minimize our impact on the environment.

Q9: How does SourcifyChina handle shipping and delivery?

A9: We offer various shipping options including air, sea, and express courier services. Our team ensures careful packaging to prevent any damage during transit and tracks shipments to provide timely deliveries.

Q10: What payment methods do you accept?

When considering copper plating metal manufacturing, particularly from SourcifyChina factory, there are several tips to ensure a smooth and successful process. Here are some key pointers:

1. Quality Assurance: Verify that SourcifyChina employs robust quality control measures. Request information on their quality management systems and certifications, such as ISO 9001.

2. Material Sourcing: Ensure the factory sources high-quality raw materials. Copper purity and the base metals to be plated are crucial for the final product’s durability.

3. Process Expertise: Inquire about the expertise and experience of their technicians in copper plating processes like electroplating, electroless plating, and immersion plating.

4. Customization Capabilities: Confirm that SourcifyChina can handle custom requirements regarding thickness, uniformity, and specific surface finishes.

5. Lead Times: Discuss and agree upon lead times. Understanding their production schedule will help in planning your supply chain more effectively.

6. Environmental Compliance: Ensure that the factory adheres to local environmental regulations and utilizes eco-friendly processes and waste management practices.

7. Sample Products: Request samples of past work to evaluate the quality and finish of their copper plating. This helps in setting your expectations and refining specifications.

8. Communication: Establish clear and open lines of communication. Language can be a barrier, but a dedicated point of contact who speaks fluent English can alleviate misunderstandings.

9. Cost Analysis: Analyze costs, including shipping, tariffs, and potential hidden fees. Ensure that the quoted price aligns with your budget and project requirements.

10. Reviews and References: Check reviews or ask for references from previous clients. Feedback from others can provide insights into the reliability and quality of the factory’s work.

By focusing on these key areas, you can secure a reliable partnership with SourcifyChina for your copper plating needs.

Sure, here is an FAQ list for sourcing copper plating metal from SourcifyChina factory:

1. What is the minimum order quantity (MOQ) for copper plating metal?

The minimum order quantity is usually specified in the product listing. For custom orders, you can contact SourcifyChina’s sales department to get specific information about MOQ.

2. How long does it take to fulfill an order?

Order fulfillment times can vary based on order size and customization requirements. Typically, standard orders are fulfilled within 2-4 weeks, while custom orders may take longer. It’s best to confirm with the factory for precise lead times.

3. Can I request samples before placing a bulk order?

Yes, SourcifyChina offers sample requests for a nominal fee. You can discuss sample availability and associated costs with the sales team.

4. What are the payment terms?

SourcifyChina generally accepts T/T (Telegraphic Transfer) and L/C (Letter of Credit) as payment methods. Specific payment terms can be negotiated with the sales representative.

5. Are the copper plating materials RoHS compliant?

Yes, SourcifyChina ensures that their copper plating materials meet international standards, including RoHS compliance. Certification documents can be provided upon request.

6. Can I customize the copper plating thickness and specifications?

Absolutely. SourcifyChina offers customization options for copper plating thickness, dimensions, and other specifications based on your project requirements.

7. How is shipping handled?

Shipping can be arranged through various methods like sea freight, air freight, or courier services. SourcifyChina works with several logistics partners to ensure timely and cost-effective delivery.

8. What after-sales support is available?

SourcifyChina provides comprehensive after-sales support, including technical assistance and quality claim options in case of any discrepancies in the order.

9. Is there a warranty on the copper plating metal?

Warranties can vary depending on the product and specific terms of the purchase agreement. Typically, SourcifyChina offers warranties against manufacturing defects.

10. How can I contact SourcifyChina for more information?

You can reach SourcifyChina through their official website’s contact form, email, or phone number provided in their contact details section.

Sourcing copper plating metal from a supplier like SourcifyChina requires a strategic approach to ensure quality, cost-effectiveness, and reliability. Here are some tips:

1. Verify Supplier Credentials:

– Check the factory’s certifications, such as ISO or RoHS, to ensure they meet international standards.

– Request samples to assess material quality and plating finish.

2. Clear Specifications:

– Provide detailed specifications including thickness, size, purity level, and intended application of the copper plating metal.

– Use technical drawings if necessary to avoid miscommunication.

3. Compare Quotes:

– Obtain quotes from multiple suppliers to benchmark prices.

– Ensure that the quotes include all costs such as shipping, customs duties, and any additional processing fees.

4. Quality Control:

– Establish quality assurance protocols with the supplier, including inspection and testing procedures.

– Consider third-party inspection services for an unbiased quality check before shipment.

5. Lead Times and Production Capacity:

– Discuss lead times and the factory’s production capacity to ensure they can meet your demand.

– Plan for potential delays and confirm the delivery schedule.

6. Payment Terms:

– Negotiate favorable payment terms that protect both parties, such as a deposit upfront and the balance upon successful inspection.

– Use secure payment methods and possibly an escrow service for added protection.

7. Communication:

– Maintain clear and consistent communication through a single point of contact.

– Use video calls, emails, and project management tools to keep track of progress and address issues promptly.

8. Long-Term Relationship:

– Build a relationship with the supplier by visiting the factory if possible.

– Foster a partnership based on mutual trust and regular feedback to improve future orders.

By following these tips, you’ll increase your chances of sourcing high-quality copper plating metal efficiently and effectively from SourcifyChina.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.