SourcifyChina Factory is a trusted partner for buyers seeking high-quality machining routers from China. With over a decade of experience, they offer competitive pricing, ensuring exceptional value for money without compromising on quality.

Buyers choose SourcifyChina for their state-of-the-art manufacturing facilities, equipped with the latest technology. Their skilled workforce ensures that each product meets international standards and rigorous quality controls.

SourcifyChina provides personalized customer service, assisting buyers through every step of the purchasing process. From initial enquiry to after-sales support, their dedicated team ensures seamless communication and satisfaction.

Timely delivery and reliable logistics are a key focus for SourcifyChina. They understand the importance of meeting deadlines and offer efficient shipping solutions to ensure products reach buyers promptly.

In summary, SourcifyChina Factory is ideal for purchasing machining routers due to their expertise, advanced manufacturing capabilities, competitive pricing, excellent customer service, and reliable logistics. They make the buying process seamless and efficient.

A machining router is a versatile tool used in woodworking, metalworking, and other material cutting applications. It comes in various types and offers many options based on precision, power, and functionality.

– CNC Routers: Computer Numerical Control routers, precise and programmable for complex tasks.

– Handheld Routers: Portable and versatile, commonly used by DIY enthusiasts.

– Fixed-Base Routers: Provide stability and precision, ideal for repetitive tasks.

– Plunge Routers: Allow vertical movement, perfect for deep cuts and intricate designs.

– Table-Mounted Routers: Mounted on a worktable, these offer better control and accuracy.

– Commercial Routers: Heavy-duty, designed for industrial use with high power and durability.

Options:

– Variable Speed Control: Adjusts cutting speed for different materials.

– Dust Collection Systems: Keeps the workspace clean by collecting debris.

– Interchangeable Bits: Offers versatility for various cutting tasks.

– Digital Readouts: Enhances precision with real-time data display.

– Ergonomic Handles: Improves comfort and reduces fatigue during prolonged use.

– Laser Guides: Provides improved accuracy with visual cutting paths.

– Soft Start Motor: Reduces startup torque for smoother operation.

These routers, based on the specific type and options chosen, cater to a range of requirements from casual hobbyist projects to industrial-scale operations.

A machining router is a versatile tool used for cutting, shaping, and carving various materials such as wood, plastic, and metal. It is commonly employed in industries ranging from furniture making to aerospace engineering.

– Woodworking: High precision in crafting furniture, cabinetry, and decorative items.

– Sign Making: Creating detailed signs and logos with intricate designs.

– Prototyping: Rapid development of component prototypes in engineering and design.

– Aerospace:Producing lightweight, precise components critical for aircraft.

– Automotive: Manufacturing customized vehicle parts and fine detailing.

– Plastic Fabrication: Cutting and shaping various types of plastics for industrial use.

– Metalworking: Engraving, cutting, and drilling metal parts with high accuracy.

– Jewelry Making: Detailed carving and engraving of materials like metals and stones.

– Model Building: Precision crafting for architectural and hobbyist models.

– Boat Building: Shaping and fitting wooden or composite materials for hulls and interiors.

– Education: Training students in machining and CNC operations.

– Art and Sculpture: Creating complex art pieces through precise routing techniques.

– Medical Equipment: Producing intricate components for medical devices.

– Electronics: Manufacturing circuit boards and enclosures with high precision.

– Instrument Making: Crafting detailed parts for musical instruments.

The machine’s adaptability and precision make it an indispensable tool across numerous fields, enhancing efficiency and innovation in both heavy-duty and low-volume tasks.

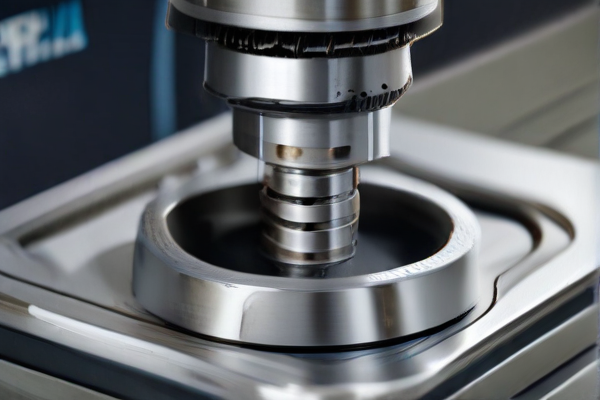

The “SourcifyChina Machining Router” is crafted from high-grade aluminum alloy, noted for its durability and strength. This metal ensures a lightweight yet robust structure, enhancing the machine’s operational efficiency and longevity.

In addition to aluminum alloy, key components are made from hardened steel, providing exceptional wear resistance. This material selection is crucial for tools exposed to constant friction and ensures precision and reliability in machining tasks.

The router also incorporates advanced composite materials for various fittings and external parts. These composites offer excellent resistance to environmental factors like corrosion, heat, and moisture, sustaining the machine’s integrity over time.

The combination of these materials not only bolsters performance but also simplifies maintenance. Reduced wear and tear and enhanced durability lower the frequency of part replacements, making the SourcifyChina Machining Router a cost-effective and reliable solution for various industrial applications.

SourcifyChina’s machining router quality control manufacturing process sets a high standard, ensuring each product meets precision and durability requirements. The process begins with material selection, where only top-grade metals are sourced, fostering robust end products.

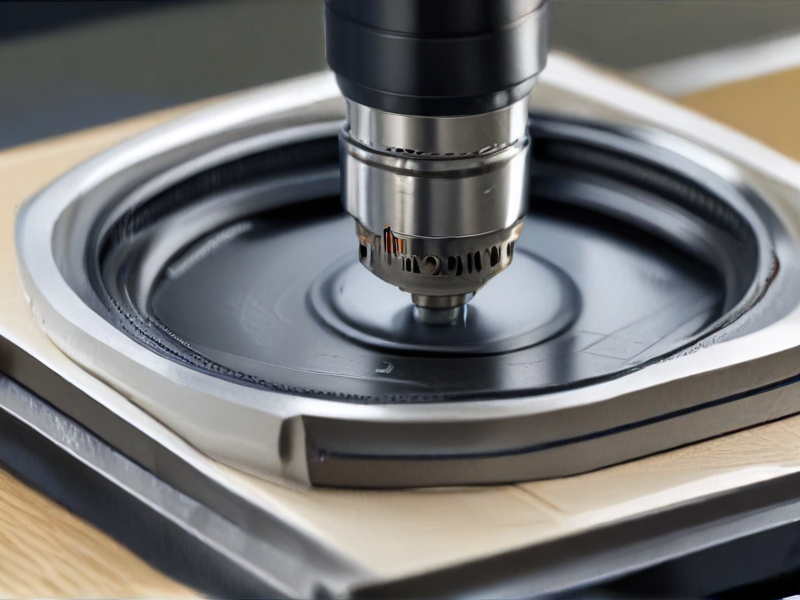

Next, advanced CNC machines execute cutting, drilling, and shaping tasks with exceptional accuracy. Continuous machine monitoring minimizes errors, showcasing SourcifyChina’s commitment to excellence. Each machine goes through a stringent calibration process to ensure optimal performance and reduced margins of error.

Next, machining accuracy is rigorously tested, using high-precision tools and Gauges to confirm exact measurements. Any deviations are immediately corrected, maintaining tight tolerances for parts.

Surface finishes are meticulously inspected for imperfections such as scratches, burrs, or rough edges. This ensures that each component not only functions flawlessly but also looks immaculate.

Additionally, assembled components undergo rigorous functional tests, simulating real-world operating conditions to verify performance. This stage identifies any potential weaknesses at an early stage.

Quality control engineers at SourcifyChina conduct final inspections, utilizing comprehensive checklists and visual assessments. This secondary verification ensures no detail is overlooked, and every product leaving the facility is up to par.

Documentation is a vital aspect of SourcifyChina’s quality control, where every stage of the process is recorded for traceability. This enables quick identification of any issues and promotes continuous improvement.

Feedback loops are a crucial part of the system, where data is analyzed to refine processes and eliminate recurring issues. This proactive approach drives constant enhancement in product quality.

In summary, SourcifyChina employs a meticulous quality control process, from material selection to final inspection, ensuring top-tier machining routers. Continuous monitoring, rigorous testing, and comprehensive documentation underpin their commitment to delivering superior products. This robust process assures clients that every machined product is of the highest standard, showcasing SourcifyChina’s dedication to quality and reliability.

SourcifyChina machining routers offer precision in various tasks, accommodating complex geometries with high accuracy. These machines excel in cutting, drilling, and routing operations, ensuring top-notch quality and repeatability for various industries.

With state-of-the-art technology, SourcifyChina enhances production efficiency. Its advanced features include programmable software, automatic tool changers, and real-time monitoring. These facets reduce downtime and guarantee rapid, consistent outputs.

Versatility is a hallmark of SourcifyChina machining routers. They cater to diverse materials—aluminum, wood, composites, and more. Adaptability ensures these routers meet the unique demands of multiple sectors, from automotive to aerospace.

Durability and reliability define SourcifyChina products. Manufactured with robust components, these routers endure heavy-duty usage while maintaining consistent performance. Longevity minimizes maintenance, heightening their cost-effectiveness.

Customer support from SourcifyChina is exceptional. Offering comprehensive training, easy access to spare parts, and prompt technical assistance, the company ensures optimal machine operation, maximizing user satisfaction and productivity.

In conclusion, SourcifyChina machining routers represent excellence in precision, efficiency, versatility, durability, and support. These attributes combine to deliver optimal performance and value.

A machining router offers numerous advantages in precision manufacturing, making it a staple in modern workshops. By automating and refining the craft, it substantially enhances productivity and product quality.

– Precision and Accuracy: Machining routers provide high levels of precision, ensuring that intricate designs and specifications are consistently adhered to.

– Efficiency and Speed: These machines significantly reduce the time required to complete tasks, improving overall workflow and productivity.

– Versatility: Capable of working with various materials such as wood, plastic, and metal, machining routers are adaptable to diverse manufacturing needs.

– Consistency: Automation ensures that repeated tasks produce uniform results, reducing errors and material waste.

– Cost-effectiveness: Though initially expensive, machining routers lower long-term costs by minimizing waste, reducing labor expenses, and enhancing efficiency.

– Complex Design Capability: The advanced technology allows for the creation of complex and multi-dimensional shapes that would be challenging to achieve manually.

– Safety: Automation reduces human involvement in dangerous tasks, improving workplace safety.

– Scalability: They can easily scale to meet increasing production demands, making them suitable for both small and large-volume manufacturing.

– Customization: Offers high flexibility in running different programs and settings to meet specific project requirements.

In summary, a machining router’s precision, efficiency, versatility, and ability to deliver consistent quality make it an indispensable tool in modern manufacturing. From reducing costs and material waste to enhancing safety and scalability, the benefits are vast and impactful.

A machining router is a versatile tool that provides precision in cutting, shaping, and carving various materials like wood, plastics, and metals. Its robust capabilities make it indispensable in both industrial and small-scale fabrication environments.

– Precision Cutting: Machining routers deliver high accuracy, making them ideal for detailed work.

– Versatility: They can handle a range of materials, including wood, plastic, and metals.

– Speed and Efficiency: Modern routers are designed for fast operation without compromising quality.

– Automation: Many routers come with CNC technology for automated and repeatable tasks.

– Durability: Industrial-grade routers offer long-lasting performance under heavy use.

– Ease of Use: Advanced models feature user-friendly interfaces and software.

– Safety Features: Equipped with safety mechanisms to protect operators.

– Customization: Allow for customizable settings to suit specific project requirements.

– Tool Compatibility: Compatible with various bits and attachments for different tasks.

– Dust Collection: Many routers come with dust collection systems to maintain a clean workspace.

– Ergonomics: Designed for comfort, reducing operator fatigue during extended use.

– Portability: Some models offer lightweight and portable options for easy transportation.

SourcifyChina offers specialized machining routers tailored to meet diverse custom product needs. With precision-engineered components, these routers deliver exceptional performance, ensuring high-quality finishes for various materials.

Their expertise lies in creating bespoke solutions for both small-scale and large-scale projects. Whether it’s intricate designs or large volume productions, SourcifyChina’s machining routers cater to all complexities and specifications.

The company prides itself on using cutting-edge technology to enhance efficiency and precision. Their routers are equipped with advanced features, making them capable of handling the most demanding machining tasks with ease.

SourcifyChina also provides extensive customization options. Clients can specify exact requirements, from tool dimensions to operational capabilities, ensuring the routers perfectly align with project needs.

Additionally, their robust customer support ensures seamless integration and operation of the custom routers. They offer consultation, installation, and maintenance services, providing a comprehensive solution to any machining challenge.

The commitment to quality and customer satisfaction positions SourcifyChina as a reliable partner for custom machining solutions. Their dedication to innovation and precision engineering makes them a preferred choice in the industry.

In conclusion, choosing SourcifyChina for your machining router needs guarantees high performance and adaptability. Their custom products and thorough support services facilitate successful project execution, making them a top contender in the machining industry. Their routers not only meet but often exceed customer expectations, making them a wise investment for any machining project.

SourcifyChina Machining Router is a leading manufacturing enterprise renowned for its high-precision machining services and sophisticated router solutions. Leveraging cutting-edge technology and advanced machinery, the company specializes in creating bespoke components that meet the exacting demands of various industries, including aerospace, automotive, and electronics. With a focus on quality and cost-efficiency, SourcifyChina employs stringent quality control measures and innovative manufacturing techniques to ensure each product aligns with international standards. The company prides itself on its customer-centric approach, offering tailored solutions that cater to the nuanced requirements of their global clientele. Furthermore, their dedication to sustainable practices and ethical sourcing underscores their commitment to corporate responsibility. Through continuous improvement and investment in technological advancements, SourcifyChina Machining Router consistently delivers superior products that help customers achieve operational excellence.

Machining routers hold a pivotal role in the Aerospace, Defense, and Marine industries, offering precise and efficient solutions for cutting, shaping, and drilling various materials, including metals, composites, and plastics. In aerospace, these advanced machinery tools are essential in the manufacture of lightweight yet strong components, such as airframe structures and engine parts. The demand for complex geometries and tight tolerances in aircraft components is rigorously met by machining routers, ensuring high performance and safety standards. Furthermore, the aerospace sector relies heavily on the router’s ability to handle high-performance materials like titanium and carbon fiber composites, which are crucial for reducing weight and increasing fuel efficiency.

In the defense sector, machining routers are indispensable for producing a wide range of critical components, from weapon systems to intricate electronic housings used in radar and communication equipment. The precision and repeatability of these routers ensure that parts meet exacting military specifications, which are vital for the functionality and reliability of defense systems. Similarly, the marine industry benefits from these advanced machining processes in the development of ship hulls, propellers, and other structural elements. Routers enable the machining of large, intricate parts used in naval vessels and commercial ships, improving performance and longevity in harsh marine environments. The versatility and accuracy of machining routers thus play an essential role in advancing innovation and operational efficiency across these high-stakes industries.

A machining router is an invaluable tool in the automotive industry, where precision and customization are paramount. This versatile machine can sculpt and shape various components such as dashboard panels, body parts, and intricate engine components with high accuracy. Utilizing computer numerical control (CNC) technology, these routers are capable of producing complex geometries and ensuring consistent quality across production runs. In the automotive realm, the ability to swiftly prototype and modify parts contributes to accelerated development cycles and enhanced innovation. Additionally, machining routers facilitate the use of lightweight, high-strength materials like composites and aluminum, which are essential for improving vehicle performance and fuel efficiency.

In the electronics industry, machining routers play a crucial role in manufacturing and prototyping circuit boards, enclosures, and other intricate components. With the proliferation of compact and highly integrated devices, the demand for precisely machined parts has grown exponentially. These routers can deftly mill out the fine traces and pathways required for printed circuit boards (PCBs), ensuring reliable electrical connectivity and signal integrity. Moreover, custom electronic casings and housings can be meticulously crafted, providing both aesthetic appeal and functional protection. The adaptability of machining routers to handle various materials—from plastics to metals—empowers electronics manufacturers to experiment with novel designs and swiftly bring cutting-edge products to market.

In the construction industry, machining routers are indispensable tools used for precision cutting, shaping, and engraving of materials such as wood, plastic, and composite materials. These routers empower craftsmen to create intricate designs and structures with a high degree of accuracy, enhancing both the aesthetic and functional qualities of construction projects. For instance, detailed moldings, custom cabinetry, and elaborate architectural designs can be achieved more efficiently and with greater consistency using CNC (computer numerical control) routers. The automation and precision provided by these tools significantly reduce labor costs and material waste, while also speeding up the production process. This allows construction professionals to execute complex tasks that would be extremely difficult or time-consuming using traditional manual methods.

In the energy sector, machining routers play a crucial role in the production and maintenance of various components essential to renewable energy technologies. For example, the fabrication of wind turbine blades and solar panel frameworks often involves the use of high-performance materials like carbon fiber composites and specialized plastics. CNC routers can precisely cut and shape these materials into the complex geometries required for optimal performance. Moreover, in the realm of energy storage, machining routers are used to produce battery casings and other vital components with meticulous precision, ensuring the efficiency and safety of energy storage systems. As the demand for renewable energy solutions grows, the ability to rapidly and accurately manufacture the necessary components using machining routers becomes increasingly vital, emphasizing the importance of these tools in advancing sustainable energy initiatives.

The industrial equipment sector has significantly benefited from the advanced capabilities of machining routers, particularly in precision manufacturing and high-volume production settings. These versatile machines, typically computer numerical control (CNC) operated, are celebrated for their ability to perform intricate cuts on various materials, including metals, plastics, composites, and wood. Machining routers have become indispensable in industries such as aerospace, automotive, and electronics, where precision and consistency are paramount. By automating complex cutting tasks, they significantly reduce manual labor, enhance accuracy, and speed up production times. Moreover, their integration with CAD (Computer-Aided Design) software allows for the seamless transition from digital design to physical product, ensuring that end products meet the exact specifications required for high-stakes applications.

Beyond precision and productivity, the adoption of machining routers in the industrial sector fosters greater innovation and sustainability. These machines support additive manufacturing processes and can efficiently handle materials that would otherwise be difficult or impossible to work with using traditional methods. Their ability to minimize material waste through precise cuts and optimized nesting strategies is particularly beneficial for cost-saving and environmental strategies. Furthermore, machining routers often form part of smart manufacturing initiatives, where they are incorporated into interconnected systems that leverage IoT (Internet of Things) for real-time monitoring and adaptive controls. This interconnectedness not only maximizes machine uptime and productivity but also provides valuable data analytics for continuous improvement. Overall, the application of machining routers represents a cornerstone in the evolution of industrial manufacturing, driving advancements in quality, efficiency, and sustainability.

Machining routers, commonly referred to as CNC (Computer Numerical Control) routers, play a pivotal role in the medical devices industry, enabling the production of highly precise and complex components. These devices are instrumental in the fabrication of various medical instruments, implants, and equipment enclosures. The critical need for accuracy and consistency in the medical field is well-supported by CNC routers, which can adhere to stringent tolerances and exact specifications. For example, components for surgical instruments, such as handles and clamps, benefit from the precision routing offers, ensuring they function safely and effectively. Additionally, CNC routers are used to create custom-fit prosthetics and orthotic devices, improving patient comfort and outcomes by producing components tailored to individual anatomical requirements.

Furthermore, machining routers facilitate the efficient production of medical device prototypes and small-batch manufacturing, which is essential for developing new technologies and personalized medical solutions. The ability to rapidly iterate and refine designs using CNC technology accelerates the innovation cycle in medical device development. For instance, dental labs use machining routers to produce custom dental implants, crowns, and bridges with remarkable accuracy. The high speed and automation capabilities of CNC routers also reduce production costs and time, making advanced medical solutions more accessible. Overall, the integration of machining routers in medical device manufacturing translates into better-quality products, enhanced patient care, and streamlined production processes.

Machining routers, integral tools in the realm of manufacturing, have transformed the landscape of material processing, especially in industries requiring precision and efficiency. Primarily utilized for cutting, shaping, and milling various materials such as wood, plastics, and metals, they are fundamental to achieving intricate designs, detailed engravings, and complex component fabrication. The versatility of machining routers allows manufacturers to execute tasks with a high level of accuracy and repeatability, reducing human error and increasing productivity. Advanced computer numerical control (CNC) routers further enhance these capabilities by automating the machining process, enabling the production of highly consistent parts and complex geometries that would be difficult to achieve manually.

In manufacturing applications, machining routers play a crucial role in optimizing workflow and minimizing waste. Their ability to execute detailed and repetitive tasks makes them indispensable in sectors like automotive, aerospace, and furniture making. By incorporating routers into production lines, manufacturers can significantly cut down on lead times, streamline operations, and ensure a high degree of precision in end products. Additionally, routers contribute to cost savings by maximizing material utilization and reducing the need for additional finishing processes. Their integration with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems allows for seamless transitions from design to production, ensuring that the final product aligns precisely with the initial design specifications, ultimately leading to high-quality, reliable, and innovative manufacturing outputs.

Certainly! Here are the FAQs for “machining router quality work from SourcifyChina factory”:

Q: What types of materials can SourcifyChina handle for machining router work?

A: SourcifyChina is capable of handling a wide array of materials, including metals (like aluminum, steel, and brass), plastics, and composites. We tailor our services to meet specific material requirements.

Q: How does SourcifyChina ensure the quality of machining router work?

A: Quality assurance at SourcifyChina involves rigorous inspections, advanced machinery, and adherence to international standards (ISO 9001). Our QA team performs meticulous checks at every stage of production.

Q: What are the lead times for machining router projects?

A: Lead times vary based on project complexity and volume. Generally, we provide an initial lead time estimate upon reviewing the project requirements. Typically, small to medium-sized projects take 2-4 weeks.

Q: Can SourcifyChina work with custom designs?

A: Yes, SourcifyChina specializes in custom machining router work. Clients can submit their designs through CAD files or detailed drawings, and we will provide a feasibility analysis and cost estimate.

Q: What file formats are accepted for design submissions?

A: We accept various file formats, including .DWG, .DXF, .STEP, .IGES, and PDF drawings. If you have a different format, please contact us for compatibility.

Q: Are there minimum order requirements?

A: While SourcifyChina can accommodate both small and large orders, discussing project specifics with our team will help determine any minimum order requirements applicable.

Q: What is the pricing structure for SourcifyChina’s machining router services?

A: Pricing is project-specific and depends on factors like material, complexity, volume, and lead time. We provide competitive quotes tailored to meet client needs after evaluating the project details.

Q: How can I place an order with SourcifyChina?

A: You can place an order by contacting our sales team via email or through our website’s contact form. We will guide you through the requirements, documentation, and payment processes.

Q: Does SourcifyChina offer post-production support?

A: Yes, we offer post-production support including assembly, finishing services like anodizing or painting, and logistics management to ensure your products reach their destination safely.

Q: How can I track the progress of my order?

When considering sourcing machining routers from SourcifyChina Factory, strategic planning is crucial for high-quality products and cost efficiency. Here are some condensed tips to guide you:

1. Research and Vetting:

– Investigate SourcifyChina’s industry reputation and verify certifications like ISO.

– Request sample products to assure quality before committing to bulk orders.

2. Customization and Design:

– Clearly communicate your specific requirements and modifications.

– Provide detailed design specs or collaborate with their engineering team for bespoke solutions.

3. Material and Component Quality:

– Confirm the grade of materials used (e.g., aluminium, carbide) to ensure durability.

– Opt for high-quality bearings and motors to enhance router performance and longevity.

4. Production Capabilities:

– Verify the factory’s production capacity to meet your volume needs.

– Understand the lead times to plan your supply chain efficiently.

5. Quality Control:

– Establish stringent quality assurance protocols. Request regular quality checks and reports.

– Utilize third-party inspections to mitigate risks of defects.

6. Cost Management:

– Get detailed quotes encompassing all expenses, including shipping and customs.

– Negotiate favorable terms without compromising on quality.

7. After-Sales Support:

– Ensure robust after-sales service, including warranty, spare parts, and technical support.

– Confirm training availability for your team on maintenance and operation.

8. Communication and Coordination:

– Maintain clear and regular communication to avoid misunderstandings and delays.

– Employ a local agent or third-party sourcing company if necessary for better coordination and oversight.

These steps help ensure that your collaboration with SourcifyChina Factory will be effective and mutually beneficial.

Sure! Below is a list of FAQs with answers related to sourcing a machining router from SourcifyChina factory:

1. What types of machining routers does SourcifyChina offer?

SourcifyChina offers a range of machining routers, including CNC routers, 3-axis, 4-axis, and 5-axis routers, as well as specialized models for different materials like wood, metal, and plastics.

2. Can SourcifyChina customize a machining router to my specifications?

Yes, SourcifyChina provides customization services. You can specify your requirements, and they will work with you to design and manufacture a router that meets your specific needs.

3. What is the lead time for a machining router order from SourcifyChina?

The lead time varies depending on the model and level of customization. Generally, it ranges from 2 to 8 weeks. It’s best to confirm with the factory for an accurate timeline.

4. What are the payment terms for ordering machining routers from SourcifyChina?

SourcifyChina typically requires a 30% deposit before starting production, with the remaining 70% due before shipment. They accept various payment methods, including wire transfer and L/C.

5. Does SourcifyChina provide a warranty for their machining routers?

Yes, SourcifyChina offers a standard one-year warranty on their machining routers, covering parts and labor. Extended warranties may also be available upon request.

6. How can I ensure the quality of the machining router before placing a bulk order?

You can request a sample unit or visit the factory for an inspection. Additionally, SourcifyChina can provide detailed quality inspection reports and certifications upon request.

7. What support and training does SourcifyChina provide?

SourcifyChina offers comprehensive support, including installation guidance, maintenance manuals, and remote technical assistance. Training programs for operating the machines can also be arranged.

8. How is shipping handled for international orders?

SourcifyChina can manage shipping logistics, offering options like FOB, CIF, or DDP. They partner with reliable freight companies to ensure timely and safe delivery.

9. What are the main markets SourcifyChina services?

SourcifyChina exports machining routers worldwide, with major markets including North America, Europe, Southeast Asia, and Australia.

Sourcing a machining router from SourcifyChina factory can be simplified by following these tips:

1. Research and Verify: Start by researching SourcifyChina. Verify the factory’s credibility through online reviews, industry forums, and testimonials. Make sure they have a good reputation for quality and reliability.

2. Specify Requirements: Clearly outline your machining router specifications. Include details like size, material, performance metrics, and any customization needs. This ensures you receive accurate quotes and avoids misunderstandings.

3. Request Samples: Always request samples before making a bulk purchase. Evaluate the sample’s quality, build, and performance to ensure it meets your standards.

4. Assess Communication: Effective communication is crucial. Ensure the factory’s representatives are responsive, transparent, and proficient in English (or another language you’re comfortable with).

5. Factory Audit: If possible, conduct an on-site or third-party audit to assess the factory’s production capabilities, quality control measures, and working conditions. This step is vital for large orders.

6. Quality Assurance: Discuss the factory’s quality control processes. Ensure they adhere to international standards and can provide necessary certifications.

7. Negotiation: Price negotiation is expected in China. Use your research and sample evaluations to negotiate a fair price. Consider the total cost, including shipping, taxes, and duties.

8. Payment Terms: Clarify payment terms to protect your interests. Arrange a payment schedule that allows for initial deposits, balanced with milestones, and final payments upon successful delivery.

9. Logistics & Shipping: Collaborate on logistics, including packaging, shipping methods, and timelines. Ensure the factory can handle the proper documentation and customs requirements.

10. Contracts: Draft a clear, detailed contract that includes all agreed-upon terms, conditions, timelines, and penalties for non-compliance.

By following these steps, you can effectively source a high-quality machining router from SourcifyChina, minimizing risks and ensuring a smooth transaction.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.