SourcifyChina is a leading procurement agency specializing in connecting buyers with top-quality machined parts manufacturers in China. Their network ensures cost-effective solutions without sacrificing quality.

With extensive industry experience, SourcifyChina guarantees streamlined purchasing processes. They handle negotiations, quality checks, and logistics to offer a hassle-free experience, saving clients time and effort.

SourcifyChina prioritizes transparency and reliability. Regular updates and thorough communication ensure buyers remain informed at all stages of the purchasing process, fostering trust and long-term relationships.

Their dedicated team of professionals provides personalized support, tailoring services to meet specific client requirements. This ensures each project is handled with meticulous attention to detail.

By choosing SourcifyChina, buyers gain a competitive edge in terms of cost-efficiency, quality, and service. SourcifyChina stands as the ideal partner for sourcing premium machined parts from China, ensuring each procurement is a success.

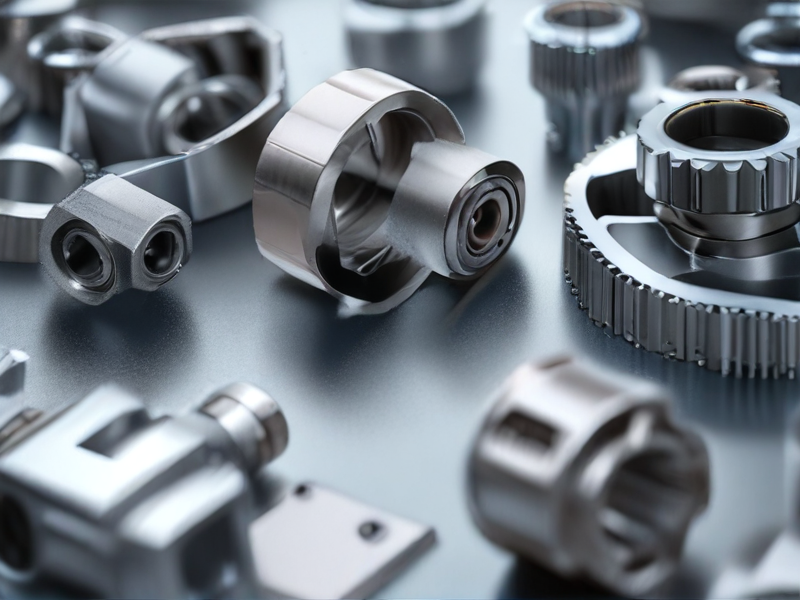

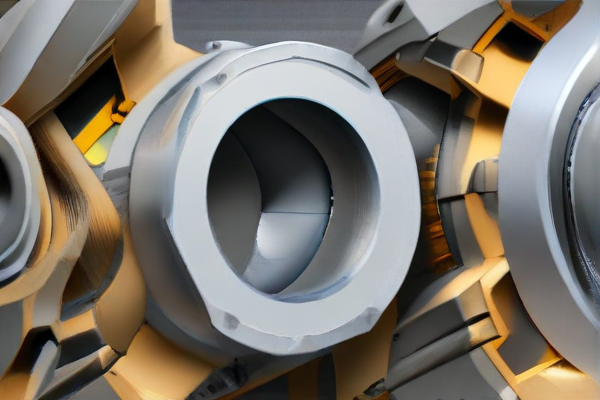

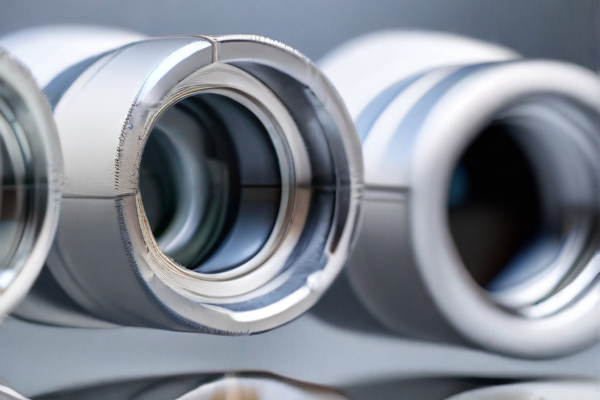

Machined parts are precision components produced using various machining processes. These parts can be made from metals, plastics, or composites, tailored for industries like automotive, aerospace, and medical.

– Metals: Aluminum, steel, titanium

– Plastics: ABS, Delrin, PEEK

– Processes: CNC milling, turning, drilling

– Tolerances: High precision, typically ±0.001 inches

– Custom Designs: Specific to client requirements

– Surface Finishes: Anodizing, electroplating, powder coating

– Prototyping: Rapid prototyping for design validation

– Batch Production: Small to large volume manufacturing

– Quality Assurance: Inspections, testing for durability and compliance

Machined parts are essential components used across various industries, ensuring precision, durability, and functionality in manufacturing and engineering applications.

– Automotive Industry: Engine components, transmission parts, chassis, suspension systems.

– Aerospace: Aircraft frames, turbine blades, navigation systems.

– Medical Devices: Surgical instruments, prosthetic parts, diagnostic equipment.

– Electronics: Circuit board components, heat sinks, enclosures.

– Oil and Gas: Drill bits, pump components, valve systems.

– Construction: Heavy machinery parts, structural components.

– Consumer Goods: Appliance components, fitness equipment, furniture fittings.

– Defense: Weapon systems, military vehicles, communication equipment.

– Renewable Energy: Wind turbine components, solar panel mounts, hydroelectric parts.

– Robotics: Actuators, frame structures, sensor mounts.

SourcifyChina specializes in providing high-quality machined parts, utilizing a variety of materials tailored to specific industrial needs. Their selection includes stainless steel, aluminum, brass, and plastics, each chosen for its distinct properties and advantages.

Stainless steel parts offer exceptional strength and corrosion resistance, making them ideal for harsh environments. Aluminum, known for its lightweight and durability, is widely used in aerospace and automotive industries.

Brass is prized for its excellent machinability and conductivity, often employed in electrical and plumbing applications. Plastics, versatile and cost-effective, serve well in industries requiring lightweight and non-conductive components.

SourcifyChina ensures each material is rigorously tested for quality and performance, providing reliable and efficient solutions for diverse manufacturing needs. Their commitment to precision and excellence guarantees parts that meet stringent industry standards, supporting innovation and operational efficiency in various sectors.

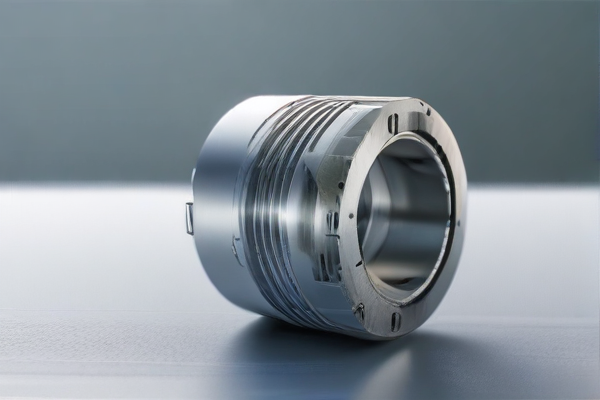

SourcifyChina maintains stringent quality control in its machined parts manufacturing process. Every step, from material selection to final assembly, is meticulously monitored. The use of high-grade raw materials is the norm, ensuring durability and precision.

Advanced machinery and cutting-edge technology play pivotal roles in their process. CNC machines and automated inspection tools minimize human error, delivering consistent, high-quality parts with tight tolerances. Regular equipment maintenance ensures optimal performance and longevity.

Skilled technicians oversee each phase, conducting thorough inspections and adhering to ISO standards. These professionals are trained to identify and rectify issues promptly, reducing defects and enhancing product reliability.

Final inspections involve rigorous testing, including stress and performance evaluations. Each part undergoes a meticulous examination to verify compliance with specified criteria. Any non-conforming components are either reworked or discarded, ensuring only top-quality parts reach customers.

Dedication to continuous improvement is evident through regular audits and feedback loops. Customer feedback drives enhancements, while internal reviews help pinpoint and address potential areas for improvement. This proactive approach ensures the quality remains consistently high.

In summary, SourcifyChina’s comprehensive quality control measures, from raw material selection to final inspection, underscore their commitment to excellence. The integration of advanced technology, skilled personnel, and continuous improvement protocols results in machined parts that meet and exceed industry standards. Their relentless focus on quality ensures customer satisfaction and reinforces their reputation for delivering superior products.

SourcifyChina specializes in providing high-quality machined parts with precision and reliability. Their state-of-the-art facilities ensure components meet rigorous standards for various industries, including automotive, aerospace, and medical devices.

Utilizing advanced CNC machines and skilled technicians, SourcifyChina delivers intricate parts with tight tolerances. Their capabilities include milling, turning, grinding, and complex multi-axis machining, guaranteeing accurate and consistent results.

They prioritize quality control through comprehensive inspection processes, employing cutting-edge metrology equipment. This commitment to excellence ensures each part adheres to exact specifications and industry standards.

SourcifyChina offers custom solutions tailored to clients’ specific needs. Their engineering team collaborates closely with customers from design to production, providing expert guidance and support.

Furthermore, SourcifyChina emphasizes cost-efficiency and timely delivery, leveraging streamlined processes and robust supply chain management. This approach enables them to maintain competitive pricing without compromising quality or deadlines.

In addition, SourcifyChina’s dedication to sustainability is evident in their environmentally conscious manufacturing practices. They focus on reducing waste and optimizing resource usage, contributing to a greener future.

With a global customer base, SourcifyChina provides comprehensive logistical support, ensuring seamless international shipping and reliable delivery. Their commitment to customer satisfaction drives continuous improvement and innovation in their services.

Overall, SourcifyChina’s machined parts capabilities encompass precision, quality, and efficiency, making them a trusted partner for diverse manufacturing needs. Their integrated approach ensures that clients receive exceptional products and services every time.

Machined parts offer numerous benefits that enhance the efficiency, precision, and reliability of manufacturing processes. Their advantages include:

– High Precision: Machined parts are produced with tight tolerances, ensuring consistent and accurate dimensions.

– Durability: These parts are often made from high-quality materials, leading to greater longevity and resistance to wear.

– Customization: Machining allows for the creation of bespoke parts tailored to specific requirements.

– Efficiency: Automated machining processes reduce production time and labor costs.

– Scalability: Easily adaptable to both small-scale and mass production.

– Consistency: Automated processes ensure uniformity across large batches of parts.

– Reduced Waste: Precision machining minimizes material waste, promoting cost savings and sustainability.

Machined parts are essential components in various industries, offering precision, durability, and customization. These parts are created through processes like milling, turning, and drilling, allowing for intricate designs and tight tolerances.

Key Features of Machined Parts:

– Precision: High accuracy in dimensions and shapes.

– Surface Finish: Smooth and consistent finishes achieved through fine machining.

– Durability: Strong and resilient materials that withstand wear and tear.

– Customization: Tailored designs to meet specific requirements.

– Tight Tolerances: Consistent and reliable performance.

– Complex Geometries: Ability to produce intricate and detailed shapes.

– Material Versatility: Compatibility with metals, plastics, and composites.

– Repeatability: Consistent quality in large production runs.

– Cost-Effectiveness: Efficient production methods for reducing costs.

– Quality Control: Rigorous inspection processes ensure high standards.

SourcifyChina specializes in providing top-quality machined parts tailored to meet the precise requirements of diverse industries. Utilizing cutting-edge technology and meticulous craftsmanship, they deliver custom machined products that ensure high performance and reliability.

The company stands out for its ability to handle complex projects, offering end-to-end solutions from initial design consultations to final quality inspections. This comprehensive approach guarantees that each component aligns perfectly with clients’ specifications and industry standards.

SourcifyChina takes pride in its team of skilled engineers and technicians who thrive on delivering precision and excellence in every project. Their expertise ensures that even the most intricate designs are executed flawlessly.

Beyond just manufacturing, SourcifyChina offers value-added services such as prototype development, assembly, and testing. These services help clients streamline their production processes and bring innovative products to market faster.

Customer satisfaction is a top priority at SourcifyChina. Their commitment to building long-term relationships is evident through their transparent communication, flexible solutions, and timely delivery schedules. Each project is approached with a mindset of collaboration and innovation.

In summary, SourcifyChina is a trusted partner in the manufacturing industry, known for its exceptional custom machined parts and comprehensive project management services. Their dedication to quality, precision, and customer satisfaction continues to drive their success, making them an invaluable resource for industries worldwide.

SourcifyChina Machined Parts is a distinguished provider of precision-engineered components, specializing in high-quality CNC machining services. Catering to a diverse range of industries including automotive, aerospace, electronics, and medical devices, the company is renowned for its commitment to excellence and precision. Utilizing state-of-the-art equipment and advanced technology, SourcifyChina ensures that every part meets stringent quality standards and customer specifications. Their skilled team of engineers and machinists is adept at handling complex projects, from prototyping to full-scale production runs. By leveraging a robust supply chain network and rigorous quality control processes, SourcifyChina delivers reliable, cost-effective solutions that help clients achieve their production goals efficiently. Dedicated to innovation and customer satisfaction, SourcifyChina Machined Parts stands out as a trusted partner for businesses seeking superior machining capabilities and exceptional service.

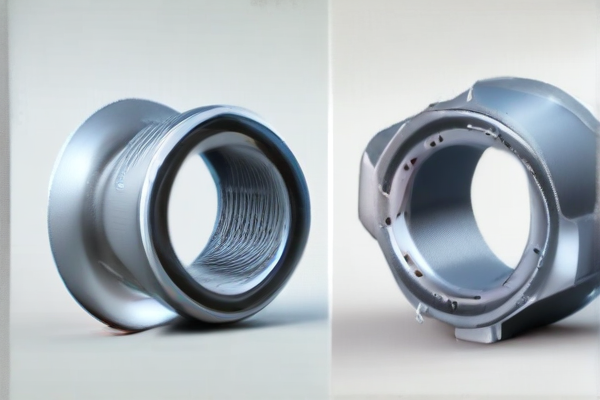

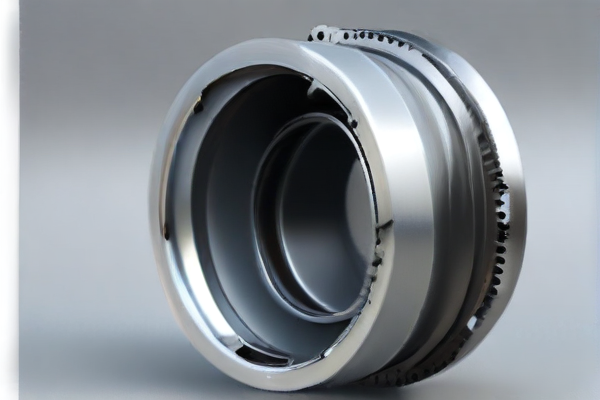

Machined parts play a crucial role in the aerospace, defense, and marine industries, where precision, reliability, and durability are paramount. In aerospace, these parts are essential in the construction of aircraft and spacecraft components such as engine parts, landing gear, and structural elements. The high precision and tight tolerances required in aerospace applications necessitate the use of advanced machining techniques to ensure that parts can withstand extreme conditions such as high temperatures, pressure, and mechanical stress. Materials like titanium, aluminum, and composite alloys are commonly used due to their strength-to-weight ratio and resistance to corrosion, which are vital for maintaining the performance and safety of aerospace vehicles.

In the defense and marine sectors, machined parts are integral to the functionality and longevity of various systems. In defense, these components are used in the manufacturing of weapons, vehicles, and communication equipment, where exact specifications and robust construction are critical to operational success. Machined parts in marine applications, such as propeller shafts, engine components, and hull fittings, must endure harsh maritime environments, including saltwater corrosion and fluctuating pressures. The ability to produce highly accurate and resilient parts ensures that military and marine vessels can operate effectively and safely under demanding conditions. Advanced machining technologies, including CNC machining and additive manufacturing, are often employed to meet the stringent requirements of these industries, providing the necessary precision and material performance.

Machined parts are pivotal in the automotive industry, where precision and reliability are paramount. These components are integral to the construction of various vehicle systems, including engines, transmissions, and suspension systems. For example, engine blocks, cylinder heads, and crankshafts are often produced using CNC (Computer Numerical Control) machining, ensuring high accuracy and consistency. The stringent demands for performance and safety in the automotive sector necessitate the use of machined parts that can withstand extreme conditions and wear. Moreover, with the advent of electric vehicles (EVs), the need for precise and reliable machined parts has only increased, as these vehicles require intricate components for their electric drivetrains and battery systems.

In the electronics industry, machined parts play a critical role in the production of devices ranging from consumer electronics to industrial equipment. Components such as heat sinks, enclosures, and connectors are often manufactured using machining techniques to achieve the necessary precision and durability. For instance, the heat sinks used in computers and other electronic devices are typically machined from aluminum or copper to enhance thermal management and prevent overheating. Additionally, the miniaturization trend in electronics requires highly precise and intricate machined parts to fit into compact assemblies without compromising functionality. This precision is essential in ensuring the reliability and longevity of electronic devices, which are increasingly integral to modern life.

Machined parts play a crucial role in the construction industry, where precision, durability, and reliability are paramount. These components are utilized in a variety of applications, from the structural framework of buildings to the intricate mechanisms within construction equipment. For instance, machined parts such as gears, shafts, and bearings are essential in cranes and excavators, ensuring smooth operation and efficiency. Additionally, custom-fabricated metal parts are often used in creating robust connections between structural elements, enhancing the integrity and safety of buildings. The precision offered by machined parts allows for tight tolerances and high-quality finishes, which are critical in achieving the stringent standards required in construction projects.

In the energy sector, machined parts are indispensable for the maintenance and operation of various energy systems, including renewable and non-renewable sources. Wind turbines, for example, rely on precision-machined components such as rotor hubs, gearboxes, and generator shafts to convert wind energy into electricity efficiently. Similarly, in the oil and gas industry, machined parts like valves, pumps, and drilling equipment components are essential for the safe and effective extraction and processing of hydrocarbons. The reliability of these parts is crucial, as failures can lead to significant operational downtimes and financial losses. Furthermore, in the realm of nuclear energy, high-precision machined parts are used in reactor components and safety systems, where exact specifications and material properties are critical for safe operation. Thus, the role of machined parts in the energy sector underscores their importance in ensuring the efficiency, safety, and longevity of energy-producing systems.

The industrial equipment industry relies heavily on machined parts for its manufacturing processes, ensuring precision, durability, and efficiency in various applications. Machined parts, produced through processes like milling, turning, and grinding, are essential in creating components with tight tolerances and complex geometries that are crucial for machinery performance. These parts are used in equipment ranging from heavy-duty construction machines to intricate robotic arms, facilitating the assembly and operation of diverse industrial systems. Their precision manufacturing ensures that each component fits seamlessly with others, reducing wear and tear, and enhancing the lifespan and reliability of the equipment.

Moreover, the use of machined parts in the industrial equipment sector significantly contributes to innovation and customization. Advanced computer numerical control (CNC) machining allows for the production of highly specialized components tailored to specific industrial applications, from custom gears and shafts to intricate housings and fittings. This flexibility supports the development of bespoke machinery tailored to unique operational requirements, driving efficiency and productivity. Furthermore, the high-quality finishes and materials used in machined parts ensure they can withstand the rigorous demands of industrial environments, including exposure to extreme temperatures, pressures, and corrosive substances. Consequently, machined parts are indispensable in maintaining the operational integrity and advancement of the industrial equipment industry.

Machined parts play a crucial role in the development and functionality of medical devices, providing precision, reliability, and customization required for various medical applications. These parts are fabricated through processes such as CNC (Computer Numerical Control) machining, which ensures high accuracy and consistency. For example, surgical instruments, prosthetics, and orthopedic implants often rely on machined components to meet exact specifications, ensuring they function correctly within the human body. The precision machining allows for the creation of complex geometries and tight tolerances essential for the effectiveness and safety of these devices. Furthermore, materials used in these machined parts, such as titanium, stainless steel, and medical-grade plastics, are chosen for their biocompatibility, strength, and durability, making them suitable for prolonged use within the body.

In addition to their structural applications, machined parts are integral in the production of diagnostic and therapeutic equipment. Devices such as MRI machines, CT scanners, and infusion pumps incorporate machined components to ensure their operational integrity and longevity. The precision and customization capabilities of machining processes enable the creation of intricate parts necessary for the sophisticated mechanisms within these devices. Moreover, the adaptability of machining allows for rapid prototyping and iterative development, which is critical in advancing medical technology and responding to evolving clinical needs. By providing high-quality, reliable, and customizable components, machined parts significantly contribute to the advancement and efficacy of modern medical devices, enhancing patient care and outcomes.

Machined parts play a crucial role in the machining and manufacturing industries, where precision and efficiency are paramount. These parts are created using various machining processes such as turning, milling, drilling, and grinding, which involve the removal of material from a workpiece to achieve desired shapes and dimensions. The versatility of machined parts is evident in their application across a wide range of sectors, including automotive, aerospace, medical devices, and electronics. In the automotive industry, for instance, machined components are essential in the production of engine blocks, transmission parts, and suspension systems, ensuring high performance and reliability. Similarly, the aerospace industry relies on machined parts for critical components such as turbine blades, landing gear, and structural elements, where precision and durability are non-negotiable.

The manufacturing application of machined parts extends to the customization and rapid prototyping of components, enabling manufacturers to meet specific requirements and innovate swiftly. Advanced computer numerical control (CNC) machines have revolutionized the production of machined parts, offering high precision, repeatability, and the ability to handle complex geometries with ease. This technological advancement has significantly reduced production time and costs while improving the quality of the final products. Moreover, the integration of machining with additive manufacturing techniques, such as 3D printing, has opened new avenues for creating hybrid parts that combine the strengths of both processes. This synergy enhances the functional capabilities of machined parts, making them indispensable in modern manufacturing practices.

FAQ for Machined Parts Quality Work from SourcifyChina Factory

Q: What types of machined parts can SourcifyChina manufacture?

A: SourcifyChina specializes in producing a variety of machined parts, including CNC machined parts, turned parts, drilled parts, and milled parts. We cater to various industries like automotive, aerospace, medical, and electronics.

Q: How does SourcifyChina ensure the quality of its machined parts?

A: Quality is our top priority. We use advanced machinery and adhere to strict quality control procedures, including ISO certification standards. Each part undergoes rigorous inspection, including coordinate measuring machine (CMM) checks, to ensure it meets customer specifications.

Q: Can SourcifyChina handle custom machining projects?

A: Yes, we can. SourcifyChina is equipped to handle custom machining projects based on client specifications. We work closely with our clients to understand their unique requirements and provide tailored solutions.

Q: What materials can you machine?

A: We work with a wide range of materials such as aluminum, steel, stainless steel, brass, copper, and various types of plastic. If you have specific material requirements, we can source and machine them accordingly.

Q: What is your production capacity?

A: SourcifyChina has a large-scale manufacturing facility with multiple CNC machines and advanced equipment, allowing us to handle both small and large production runs efficiently.

Q: How do you handle shipping and logistics?

A: We offer comprehensive shipping and logistics services. Our team ensures that your machined parts are packaged securely and delivered on time, whether domestically or internationally.

Q: What is your turnaround time for machined parts?

A: Turnaround times vary depending on project complexity and volume, but we strive to meet deadlines while maintaining high-quality standards. Typically, lead times range from a few days to several weeks.

Q: Can I request a sample before full production?

A: Yes, we offer prototyping services. Clients can request samples before moving to full production to ensure the parts meet their expectations and specifications.

Q: How do I get a quote for my machining project?

A: To get a quote, you can contact us via our website or email, providing detailed drawings, specifications, and quantity requirements. Our team will respond promptly with a competitive quote.

When considering machined parts manufacturing from SourcifyChina factory, here are key tips to ensure a successful partnership:

1. Assess Capabilities: Verify the factory’s machining capabilities, including CNC machining, milling, turning, and finishing processes. Ensure they can meet your specific technical requirements.

2. Quality Standards: Confirm that SourcifyChina adheres to international quality standards such as ISO 9001. Request information on their quality control processes and inspection methods.

3. Material Expertise: Ensure the factory has experience working with the materials you require, be it metals, plastics, or composites. This expertise is crucial for producing parts that meet your specifications.

4. Communication: Establish clear lines of communication. Effective communication is essential for discussing design specifications, lead times, and any potential issues that may arise during production.

5. Prototyping Services: Check if the factory offers prototyping services. This can help in verifying the design and functionality before committing to full-scale production.

6. Lead Times and Scalability: Discuss lead times and ensure they align with your project timelines. Also, confirm that the factory can scale production up or down based on your needs.

7. Cost Transparency: Obtain detailed quotes that include all potential costs (material, labor, tooling, shipping, etc.). Transparent pricing helps avoid hidden costs and ensures budget adherence.

8. Factory Visits: If possible, visit the factory to inspect their facilities and meet the team. This can provide valuable insights into their operations and build trust.

9. References and Reviews: Seek references or reviews from previous clients to gauge the factory’s reliability and performance.

10. Logistics and Shipping: Discuss logistics and ensure the factory can manage the shipping of parts to your location efficiently and cost-effectively.

By considering these factors, you can optimize your collaboration with SourcifyChina for machined parts manufacturing.

FAQ: Sourcing Machined Parts from SourcifyChina Factory

1. What types of machined parts can SourcifyChina provide?

SourcifyChina offers a wide range of machined parts, including CNC machined components, precision parts, and custom-made parts from various materials like metals and plastics.

2. How does SourcifyChina ensure the quality of the machined parts?

SourcifyChina maintains high-quality standards by implementing rigorous quality control processes, including in-process inspections, final inspections, and the use of advanced measurement equipment.

3. What is the typical lead time for receiving machined parts?

Lead times vary depending on the complexity and quantity of the parts ordered. Generally, it ranges from 2 to 6 weeks from order confirmation to delivery.

4. Can SourcifyChina handle both small and large volume orders?

Yes, SourcifyChina is equipped to handle both small and large volume orders, providing flexibility to meet different production needs.

5. What materials can SourcifyChina work with?

SourcifyChina can machine parts from a variety of materials, including aluminum, stainless steel, brass, copper, plastics, and more.

6. How do I get a quote for my machined parts project?

To get a quote, you can submit your design files (CAD drawings or specifications) through the SourcifyChina website or contact their sales team directly. Provide details about the materials, quantities, and any special requirements.

7. Does SourcifyChina offer prototyping services?

Yes, SourcifyChina provides prototyping services to help you develop and test your designs before committing to full-scale production.

8. What are the payment terms and options?

SourcifyChina typically requires a deposit with the balance due upon completion. They accept various payment methods, including wire transfers, PayPal, and credit cards.

9. How does SourcifyChina handle shipping and logistics?

SourcifyChina coordinates shipping and logistics to ensure timely delivery. They work with reliable carriers and offer various shipping options to meet your needs.

10. What if I have an issue with my order?

If you encounter any issues, SourcifyChina’s customer service team is available to assist you. They will work to resolve any problems quickly and efficiently to ensure your satisfaction.

Sourcing machined parts from SourcifyChina factory can be efficient and cost-effective if approached correctly. Here are some tips:

1. Define Specifications Clearly:

Provide detailed drawings, material specifications, tolerances, and finish requirements. Clear documentation helps avoid misunderstandings and ensures the factory can meet your needs.

2. Request Samples:

Before placing a large order, ask for samples to evaluate the quality and adherence to your specifications. This helps in identifying any potential issues early.

3. Verify Capabilities:

Ensure the factory has the necessary machinery and expertise to produce your parts. This includes CNC machines, quality control processes, and relevant industry certifications.

4. Communicate Regularly:

Maintain open and frequent communication with the factory. Regular updates on production progress can help mitigate delays and quality issues.

5. Quality Control:

Implement a robust quality control process. This can include third-party inspections or on-site visits to the factory to ensure the parts meet your standards.

6. Negotiate Terms:

Discuss payment terms, delivery schedules, and any potential penalties for delays. Clear agreements can prevent future disputes.

7. Intellectual Property Protection:

Secure agreements that protect your designs and intellectual property. Consider non-disclosure agreements (NDAs) and other legal protections.

8. Logistics Planning:

Plan for shipping and customs. Understanding import regulations and choosing the right shipping method can save time and costs.

9. Build Relationships:

Developing a good relationship with the factory can lead to better service, preferential pricing, and smoother operations.

10. Feedback Loop:

Provide feedback on received parts and any issues encountered. Constructive feedback helps improve future orders and establishes a collaborative partnership.

By following these tips, you can enhance the efficiency and reliability of sourcing machined parts from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.