Reliable

SourcifyChina: High-Quality Factory Parts for Bearing Solutions

SourcifyChina is a trusted provider for high-precision factory parts essential for bearings. Offering reliable and consistent quality, SourcifyChina ensures your machinery operates smoothly. Explore our comprehensive range of bearing parts tailored to meet diverse industrial needs.

High-Quality Assurance: SourcifyChina Factory stands out for its commitment to producing high-quality bearing parts. Each component undergoes rigorous testing to meet international standards, ensuring reliability and durability in various applications.

Competitive Pricing: By leveraging advanced manufacturing techniques and efficient resource management, SourcifyChina Factory offers competitive pricing. Buyers benefit from cost savings without compromising on the quality of the bearing parts.

Customized Solutions: Recognizing the diverse needs of different industries, SourcifyChina Factory provides customized solutions tailored to specific requirements. This flexibility ensures that clients receive parts that fit their unique applications perfectly.

Timely Delivery: SourcifyChina Factory is renowned for its punctual delivery schedules. With an efficient logistics network and streamlined production processes, buyers can trust that their orders will arrive on time, every time.

Excellent Customer Support: Offering outstanding customer service, SourcifyChina Factory ensures clear communication and support throughout the purchasing process. Their dedicated team is always ready to assist with inquiries, providing a seamless buying experience.

Comprehensive Inventory: The factory boasts a wide range of bearing parts, catering to various industries and applications. This extensive inventory allows buyers to find all necessary components in one place, simplifying the procurement process.

Sustainability Practices: Committed to environmental responsibility, SourcifyChina Factory implements sustainable manufacturing practices. By prioritizing eco-friendly processes, they help customers reduce their environmental footprint while ensuring high-quality products.

Proven Track Record: With years of experience and a solid reputation in the market, SourcifyChina Factory has earned the trust of numerous global clients. Their proven track record speaks volumes about their reliability and expertise.

In summary, choosing SourcifyChina Factory for purchasing bearing parts from China guarantees high-quality products, competitive pricing, and exceptional customer service. Their commitment to timely delivery, customized solutions, and sustainable practices positions them as a top choice for buyers worldwide.

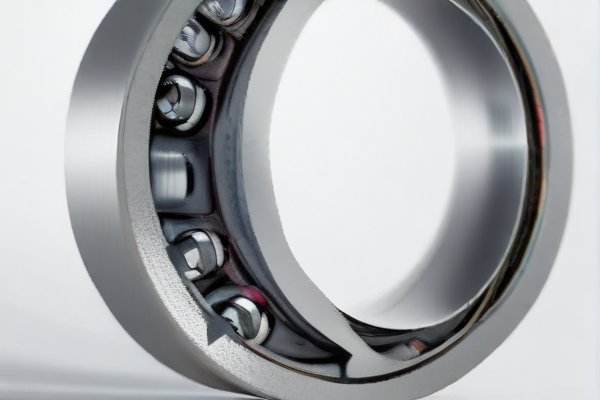

Bearings are mechanical components designed to reduce friction between moving parts. Essential bearing parts include raceways, balls or rollers, cages, and seals.

– Raceways: Inner and outer rings that form the pathway for rolling elements.

– Rolling Elements: Balls, cylinders, or needles that minimize friction.

– Cages: Maintain rolling element spacing and prevent contact.

– Seals: Keep out contaminants and retain lubricant.

Additional Options and Features:

– Shields: Similar to seals, but primarily protect against larger debris and dust.

– Lubrication Systems: Integral lubrication channels or grease fittings for maintenance.

– Retaining Rings: Securely position the bearing within the housing.

– Extended Inner Rings: Provide additional shaft support and improve alignment.

– Preloaded Bearings: Enhanced rigidity and minimized deflection through specific installation methods.

– Integral Sensors: Monitor speed, temperature, and vibration for predictive maintenance.

– Special Coatings: Applied to surfaces for corrosion resistance and extended life.

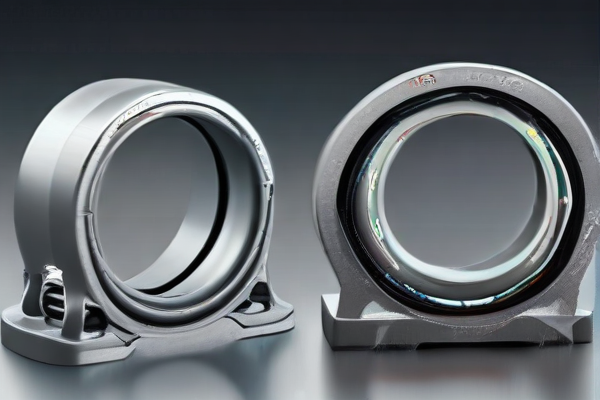

– Flanged Bearings: Eased mounting and alignment in complex assemblies.

– Back-to-back or Face-to-face Arrangements: Used in pairs to handle combined loads.

Understanding the options and configurations available for bearing parts can help tailor the selection to specific applications, enhancing performance and durability.

Applications for Parts of a Bearing

Parts of a bearing, such as the inner ring, outer ring, cage, and rolling elements, play critical roles in various industries by reducing friction and supporting loads. They are essential for the smooth operation of machinery and extending the lifespan of mechanical components.

– Inner Ring: Supports and stabilizes the entire bearing assembly, commonly used in electric motors and gearboxes.

– Outer Ring: Encases the bearing elements and allows for secure installation in housings; prevalent in automotive wheels.

– Cage (Retainer): Maintains separation and alignment of rolling elements, critical in high-speed applications like turbines.

– Rolling Elements: Reduce friction between rotating parts, widely used in applications like conveyor belts and bicycles.

Bearings and their parts are versatile and deeply integrated into machinery across many fields, ensuring efficiency and longevity.

The “SourcifyChina parts of a bearing” are crafted from high-quality steel, known for its exceptional durability and resistance to wear. This steel composition ensures the bearing’s longevity even under rigorous conditions.

A key material used is chrome steel, celebrated for its hardness and ability to withstand heavy loads. Chrome steel’s composition includes carbon and chromium, enhancing its strength and corrosion resistance.

Additionally, stainless steel is used for its excellent rust resistance, especially in environments exposed to moisture. This feature makes the bearing parts suitable for various applications, including those in wet or humid conditions.

Ceramic materials are also incorporated for their lightweight properties and high-temperature resistance. These ceramics reduce friction and enhance performance, making them ideal for high-speed applications.

Polymer materials are employed in certain bearing parts for their self-lubricating properties and resistance to chemicals. This helps in reducing maintenance and extending the bearing’s operational life.

Lastly, precision engineering in material selection and processing ensures that SourcifyChina bearing parts meet stringent quality standards. This meticulous attention to material and manufacturing processes guarantees reliable and efficient performance across various industrial applications.

SourcifyChina’s quality control process for bearing parts begins with stringent material selection. Only high-quality, durable materials meeting global standards are chosen to ensure longevity and performance.

Precision machining follows, using state-of-the-art CNC equipment to produce parts with exacting tolerances. This ensures each component fits perfectly, minimizing friction and wear.

Every part undergoes heat treatment to enhance hardness and durability. This step is crucial for withstanding the operational stresses bearings face in various applications.

Surface finishing is meticulously controlled to achieve smooth, polished surfaces, reducing friction and enhancing performance. This minimizes the risk of premature failure.

Finally, comprehensive testing and inspection are conducted. Advanced tools such as coordinate measuring machines (CMM) ensure every dimension and tolerance is met. Only those parts passing all tests proceed to assembly.

Meticulous documentation records each step, ensuring traceability and accountability throughout the production process. This allows for continuous improvement and swift resolution of any issues.

Customer feedback is actively sought and analyzed, driving ongoing enhancements. This commitment to quality promises bearings that meet or exceed client expectations, promoting long-term reliability and satisfaction.

SourcifyChina specializes in providing high-quality parts for bearings used in various industries. Their offerings include inner and outer rings, balls or rollers, cages, and seals. Every component is manufactured with precision to ensure optimal performance and longevity.

SourcifyChina takes pride in using advanced manufacturing techniques and high-grade materials like stainless steel and ceramic to produce durable bearing parts. This ensures that the bearings can withstand heavy loads and high speeds, making them suitable for demanding applications.

Customization is a key strength of SourcifyChina. They provide tailored solutions to meet specific client requirements. Whether it’s about modifying the dimensions or material composition, their team can deliver precise, customized parts without sacrificing quality.

The company also excels in quality assurance. Rigorous testing protocols are employed to ensure that each part meets international standards. This commitment to quality helps in minimizing downtime and improving overall operational efficiency for their clients.

In conclusion, SourcifyChina supplies superior bearing parts that are known for their durability, precision, and customization. Their commitment to quality and customer satisfaction makes them a preferred partner for businesses seeking reliable and efficient bearing solutions.

Bearings are crucial components in machinery, significantly enhancing efficiency, durability, and reliability by reducing friction and wear between moving parts.

Benefits of Bearing Parts:

– Ball Bearings:

– Reduce rotational friction.

– Enable smooth motion and high-speed application.

– Require minimal lubrication and maintenance.

– Roller Bearings:

– Handle high radial loads.

– Suited for heavy-duty applications.

– Longer service life with improved load distribution.

– Needle Bearings:

– Compact design allows for space-saving solutions.

– High load-carrying capacity for their size.

– Ideal for oscillating applications.

– Thrust Bearings:

– Manage axial loads efficiently.

– Prevent premature wear in axial-loaded applications.

– Provide stable performance under axial pressure.

– Cage (Retainer):

– Maintains consistent spacing of rolling elements.

– Reduces friction and wear of rolling elements.

– Enhances grease retention, reducing maintenance.

– Seals and Shields:

– Protect bearing from contamination.

– Retain lubricant within the bearing structure.

– Extend bearing life through environmental protection.

– Inner and Outer Rings:

– Provide stable housing for rolling elements.

– Sustain high loads and offer precision for moving parts.

– Form a robust boundary for efficient load transfer.

– Lubrication:

– Minimizes metal-to-metal contact and wear.

– Reduces heat and extends bearing life.

– Improves overall efficiency and reliability of machinery.

Each of these bearing parts plays a vital role in ensuring the mechanical system’s performance, longevity, and efficiency, making them indispensable in various industrial applications.

Bearings are essential components in machinery, enabling rotational or linear movement while reducing friction and wear. Key features of bearing parts ensure their efficacy and longevity.

– Inner Ring: This component fits onto the shaft and rotates with it, providing a smooth raceway for rolling elements.

– Outer Ring: Encases the inner ring and rolling elements, typically stationary, fitting into the housing.

– Rolling Elements: Usually balls or rollers, they minimize friction and wear by carrying the load between the inner and outer rings.

– Cage (Retainer): Holds and evenly spaces the rolling elements, preventing them from clumping and improving movement efficiency.

– Seals/Shields: Protect the bearing internals from contaminants like dust and moisture, enhancing operational lifespan.

– Lubrication: Crucial for reducing friction and wear; can be grease or oil, often pre-applied or requiring periodic maintenance.

– Raceways: Precision-ground surfaces on the inner and outer rings where rolling elements roll, crucial for smooth motion.

Understanding these features is key for selecting the right bearing for specific applications, ensuring optimal performance and durability.

SourcifyChina specializes in sourcing and supplying a wide variety of bearing parts, ensuring high quality and reliability for various industrial applications. These components include bearing balls, rollers, and cages, each designed to meet stringent performance standards.

Tailored solutions are a cornerstone of SourcifyChina’s offerings. By understanding unique project requirements, the company delivers custom products that fit specific needs, providing unparalleled precision and functionality. Their expertise spans across different material choices and configurations.

Versatility is key at SourcifyChina. They cater to diverse sectors, from automotive to heavy machinery, ensuring that every client receives parts that enhance performance and longevity. This adaptability sets them apart.

Innovative approaches drive their product development. By incorporating the latest technology and engaging in continuous improvement, SourcifyChina remains at the forefront of bearing part manufacturing. This commitment to innovation ensures clients receive top-tier products.

In addition to supplying parts, SourcifyChina offers comprehensive project support. From initial consultation to final delivery, their expert team provides guidance, ensuring seamless integration of components into clients’ systems. They also assist with troubleshooting and optimize operational efficiency.

SourcifyChina’s commitment to quality is evidenced by rigorous testing protocols. Each part undergoes meticulous inspection, guaranteeing compliance with industry standards and customer specifications. This attention to detail minimizes failure rates and extends product life cycles.

Competitive pricing combined with exceptional quality makes SourcifyChina a preferred partner. By leveraging economies of scale and efficient supply chain management, they offer cost-effective solutions without sacrificing performance. This approach creates significant value for clients.

Customer satisfaction is a priority, reflected in their responsive service and after-sales support. SourcifyChina builds lasting relationships through reliable delivery, prompt communication, and a straightforward procurement process.

In summary, SourcifyChina excels in providing custom bearing parts and comprehensive project support. Their focus on quality, innovation, and customer-centric solutions makes them an industry leader. Choose SourcifyChina for reliable, tailored bearing components that drive success in diverse applications.

SourcifyChina is a renowned and pioneering enterprise specializing in the manufacturing and supply of bearing components. With an unwavering commitment to quality, precision, and efficiency, the company stands as a trusted partner in the mechanical engineering and automotive sectors. SourcifyChina’s product lineup encompasses a comprehensive range of bearing parts including rolling elements, cages, seals, and raceways—all engineered to meet the rigorous demands of modern machinery. Leveraging advanced manufacturing technologies and stringent quality control processes, the company ensures that its components offer superior durability, reduced friction, and enhanced performance. Moreover, SourcifyChina prides itself on its ability to provide customized solutions tailored to the specific needs of its clients, thus fostering long-term partnerships and fostering innovation. By integrating sustainability practices and keeping pace with technological advancements, SourcifyChina not only contributes to the operational excellence of its clientele but also advances the broader goals of ecological responsibility and industrial modernization.

Bearings are fundamental components within Aerospace, Defense, and Marine applications due to their vital role in reducing friction and wear between moving parts, thereby enhancing efficiency and operational longevity. In aerospace, bearings are critically placed in engines, landing gear, and control systems. The rolling elements (balls, rollers), races, and cage of these bearings are engineered to withstand extreme temperatures, vibrations, and loads. Their precision ensures reliability and safety in aircraft, helping maintain stability and maneuverability during flight. The aerospace bearings must also meet stringent regulatory standards and undergo rigorous testing to mitigate the risk of failure in mission-critical scenarios.

In the defense sector, bearings are utilized in a plethora of high-stakes applications, such as in tanks, amphibious vehicles, missile systems, and radar units. The components — including the inner and outer races, rolling elements, and cages — must be fabricated from robust materials like stainless steel or ceramics to endure harsh environments, high speeds, and heavy loads. Bearings in defense applications often feature advanced coatings and lubricants to enhance corrosion resistance and performance under extreme conditions. Similarly, the marine industry relies heavily on durable bearings in propulsion systems, navigation aids, and various onboard machinery. These bearings must operate flawlessly under intense pressure, saltwater exposure, and varying thermal conditions, ensuring the seamless and efficient functioning of marine vessels. The precise design and material composition of bearing parts are central to their ability to perform reliably in such demanding applications.

Bearings are quintessential components in both automotive and electronics applications, performing vital functions by reducing friction between moving parts and enhancing efficiency. In the automotive sector, bearings are omnipresent—from the engine and transmission to the suspension and steering systems. Tapered roller bearings, for instance, are deployed in wheel hubs to withstand axial and radial loads, ensuring smooth wheel rotation. Needle roller bearings are often utilized in the transmission to facilitate seamless gear changes while minimizing wear and tear. Ball bearings, renowned for their versatility, are used in multiple settings, such as in alternators and electric motors, to enhance rotational performance and durability, thereby bolstering overall vehicle reliability and performance.

In the realm of electronics, miniature and precision ball bearings play a critical role in ensuring the smooth operation of various devices. For instance, in cooling fans of computers and servers, ball bearings are employed to ensure efficient dissipation of heat by providing reliable and prolonged operation. Hard disk drives also utilize miniature ball bearings to support the rapid and precise rotation of the disk platters, thereby ensuring data stability and accessibility. Brushless DC motors, which are prevalent in modern electronics such as drones and cameras, incorporate ball bearings to reduce operational noise and extend the motor’s lifespan. Overall, the integration of appropriate bearings in electronics not only enhances device performance but also ensures longevity and reliability, essential for meeting the high standards of modern technology.

In the construction industry, the parts of a bearing play a crucial role in the functionality and longevity of heavy machinery and structural components. The inner and outer rings, balls or rollers, and the cage—each meticulously engineered—enable smooth motion and reduce friction in mechanical systems. For instance, cranes, bulldozers, and other heavy equipment rely on bearings to handle the immense loads and stresses they encounter. Robust bearing parts ensure these machines operate efficiently, reducing downtime and maintenance costs. This efficiency translates into faster project completion times and improved safety on construction sites, as reliable bearings minimize the likelihood of sudden machinery failures that could pose significant hazards.

In the realm of energy applications, bearing components are indispensable in both traditional and renewable energy systems. Turbines, whether in power plants, wind farms, or hydroelectric dams, require highly specialized bearings to support their shafts and enable smooth rotational motion. The precision and durability of bearing parts such as races, rolling elements, and cages are essential for maintaining operational stability and optimizing energy conversion processes. For example, in wind turbines, high-quality bearing parts reduce friction and wear, enabling the turbines to convert wind energy into electrical power more efficiently. In hydroelectric systems, the continuous rotation of turbines under varying loads and speeds demands bearings with exceptional resilience and reliability, ensuring long-term energy production with minimal interruptions. The overall performance and sustainability of energy systems heavily depend on the quality and integrity of their bearing components.

In the industrial equipment sector, bearings play a pivotal role due to their unique ability to reduce friction between moving parts, thereby enhancing performance and longevity. Bearings consist of essential components like the outer ring, inner ring, rolling elements (such as balls or rollers), retainer or cage, and seals. The outer and inner rings form the raceways, in which the rolling elements seamlessly rotate, providing a smooth motion with minimal resistance. In heavy machinery, this minimizes wear and tear, ensuring reliable operation under high loads and varying speeds. The retainer keeps the rolling elements evenly spaced, ensuring consistent load distribution and operational stability. Seals prevent contaminants from entering the bearing, thereby ensuring longevity and reducing maintenance needs.

In manufacturing, construction, automotive, and aerospace sectors, the precise application of bearing parts ensures the efficiency and safety of equipment from conveyors to power generators and beyond. For instance, in high-speed machinery, the choice of rolling elements—be it balls for lighter loads or cylindrical rollers for heavy ones—can significantly impact performance. The material of the rings and rolling elements, often high-strength steel or ceramics, is chosen for durability and resistance to extreme conditions such as high temperatures and corrosive environments. Furthermore, specialized seals can be employed to protect the bearings from dust and moisture, crucial in industries like mining and agriculture. By optimizing each part of a bearing to meet specific operational conditions, industries achieve superior machine efficiency, reduced downtime, and ultimately, cost savings.

Medical devices frequently incorporate bearings to ensure smooth, reliable, and precise movement in various mechanical components. In life-saving equipment such as MRI machines, surgical robots, and ventilators, the parts of a bearing—comprising the inner and outer rings, rolling elements (balls, rollers, etc.), and cage—work collaboratively to reduce friction and enable seamless rotational or linear motion. The inner ring usually attaches to the rotating shaft, while the outer ring is set within the machine housing, allowing movement to be transferred efficiently and accurately. For instance, in an MRI machine, bearings help the rotating components produce high-resolution images by maintaining the precise alignment and reducing operational noise. The rolling elements, such as balls or rollers, positioned between the rings further enhance the stability and low-friction operation, ensuring that critical medical devices perform consistently under stringent conditions.

The cage, or bearing retainer, plays a crucial role by maintaining the positions of the rolling elements, preventing them from clustering together, and ensuring even load distribution. This meticulous design is particularly vital in surgical robots where precise movements are paramount; any unexpected friction or misalignment could compromise the accuracy of a procedure. By utilizing high-quality bearing parts, manufacturers can create medical devices that operate with minimal wear and tear, leading to longer-lasting and more reliable machines. Furthermore, material choices for bearings in medical applications often involve stainless steel or ceramic to meet the rigorous demands of hygiene and corrosion resistance. These materials also offer the added advantage of biocompatibility, thus supporting the stringent safety and reliability requirements inherent to the field of medical technology.

Machining plays a critical role in the manufacturing of bearing parts, where precision and durability are of utmost importance. The primary components of bearings—inner rings, outer rings, cages, and rolling elements (balls or rollers)—must adhere to strict tolerances and finishes to ensure optimal performance and longevity. Advanced machining techniques such as turning, grinding, and honing are employed to achieve the desired specifications. CNC (Computer Numerical Control) machines have revolutionized this process by offering unparalleled accuracy and repeatability, thus reducing human error and accelerating production times. Additionally, materials like high-grade steel, ceramics, and polymers are often used to fabricate these components, each requiring specialized machining methods to handle their unique properties effectively.

Manufacturing the parts of a bearing involves not only sophisticated machining but also stringent quality control measures to meet industry standards. Bearings are essential in reducing friction between moving parts in machinery, and even minimal deviations can lead to significant failures. Hence, post-machining processes such as surface treatment, heat treatment, and coating are applied to enhance their wear resistance and operational lifespan. Inspection techniques like Coordinate Measuring Machines (CMM) and non-destructive testing are employed to ensure that each part meets the desired specifications. Furthermore, advancements in additive manufacturing (3D printing) are beginning to make an impact, allowing for the rapid prototyping of custom bearing designs. This holistic approach ensures that the final product delivers high performance, reliability, and efficiency in various applications ranging from automotive to aerospace and industrial machinery.

1. What types of bearing parts does SourcifyChina factory manufacture?

SourcifyChina specializes in manufacturing a wide range of bearing parts including inner and outer rings, rollers, cages, and seals. These components are produced to meet various industry standards and customized specifications.

2. What materials are used in the production of bearing parts at SourcifyChina?

The factory utilizes high-grade materials such as stainless steel, chrome steel, and ceramics. Each material is selected based on the specific requirements of the bearing part to ensure durability and performance.

3. How does SourcifyChina ensure the quality of its bearing parts?

Quality is ensured through a rigorous inspection process involving advanced testing equipment and adherence to ISO certification standards. Each part undergoes dimensional accuracy checks, hardness testing, and surface finish evaluations.

4. Can SourcifyChina handle custom orders for bearing parts?

Yes, SourcifyChina offers custom manufacturing services to meet unique customer specifications. This includes special dimensions, materials, and treatments based on client needs.

5. What is the lead time for an order at SourcifyChina?

Lead times vary depending on the complexity and volume of the order. Typically, standard parts are delivered within 4-6 weeks, while custom orders might take longer.

6. Does SourcifyChina provide samples before full production runs?

Yes, samples can be provided for approval before commencing full-scale production. This helps ensure the final product meets all client specifications and quality standards.

7. How does SourcifyChina handle international shipping and logistics?

SourcifyChina partners with reputable logistics companies to offer reliable international shipping. They handle all documentation and customs clearance, ensuring timely delivery to your destination.

8. Are there minimum order quantities (MOQ) at SourcifyChina?

Yes, MOQs vary depending on the part type and customization level. For detailed information, it’s best to contact their sales team directly.

9. What post-sales support does SourcifyChina offer?

SourcifyChina provides comprehensive post-sales support including technical assistance, replacement parts, and addressing any quality concerns promptly.

10. How can I request a quote from SourcifyChina?

Quotes can be requested through their website or by contacting their sales team via email. Provide detailed specifications and quantities for an accurate quote.

Certainly! When dealing with parts of bearing manufacturing from SourcifyChina factory, here are some key tips to ensure quality and efficiency:

1. Material Selection: Choose high-quality materials like stainless steel, ceramic, or specialized composites based on the specific bearing application. Ensure the factory adheres to material standards to avoid premature failure.

2. Precision Machining: SourcifyChina prides itself on precision. Confirm that the factory employs advanced CNC machines to achieve tight tolerances and smooth finishes essential for bearing performance.

3. Heat Treatment: Proper heat treatment processes like quenching and tempering enhance the hardness and fatigue resistance of bearing parts. Verify that the factory has controlled heat treatment capabilities.

4. Surface Finish: Polishing and grinding techniques should be employed to achieve ultra-smooth surfaces, reducing friction and wear. Look for facilities offering superfinishing processes.

5. Quality Control: Rigorous inspection methods, including CMM (Coordinate Measuring Machine) and surface roughness testers, should be in place to ensure all parts meet specifications. Ask for detailed inspection reports.

6. Coatings and Lubrication: Select appropriate coatings (e.g., anti-corrosion, anti-friction) and lubrication methods to extend bearing life. Ensure that the factory can provide specialized treatments if required.

7. Assembly Expertise: Proper assembly techniques, including correct alignment and interference fits, are critical. Inspect the factory’s assembly protocols and workforce expertise.

8. Customization Capabilities: If you need custom bearings, check SourcifyChina’s capacity for bespoke designs. Clear communication and collaborative design processes are key.

9. Logistics and Lead Time: Consideration of lead times and logistics is crucial, especially when dealing with international vendors. Ensure the factory can meet your deadlines and has reliable shipping practices.

10. Sustainability Practices: Lastly, inquire about the factory’s environmental practices. Sustainable manufacturing processes are increasingly important in global supply chains.

By focusing on these aspects, you can ensure that the parts of bearing manufacturing from SourcifyChina factory meet your technical requirements and quality standards.

FAQ: Sourcing Parts of a Bearing from SourcifyChina Factory

Q1: What types of bearing parts can I source from SourcifyChina factory?

A1: SourcifyChina factory specializes in a wide range of bearing parts including inner rings, outer rings, balls, rollers, cages, and seals. We can also accommodate custom specifications based on your requirements.

Q2: How do I request a quote for bearing parts?

A2: You can request a quote by visiting our website, filling out the online form with your specifications, or directly contacting our sales team via email or phone. Detailed drawings and material specifications will help expedite the process.

Q3: What are the minimum order quantities (MOQs) for bearing parts?

A3: The MOQs vary depending on the type of bearing part and customization requirements. Our sales team will provide specific MOQs during the quoting process.

Q4: What materials are available for bearing parts?

A4: We offer a variety of materials including stainless steel, chrome steel, carbon steel, and ceramics. Each material has its own advantages, which we can explain based on your application needs.

Q5: Can you provide custom bearing parts?

A5: Yes, we offer custom manufacturing services. You can provide your own designs and specifications, and we will ensure the parts meet your precise requirements.

Q6: What is the lead time for orders?

A6: Lead times depend on the complexity of the parts and order volume. Generally, standard parts take 2-4 weeks, while custom parts may require 6-8 weeks. Detailed timelines will be provided during the quote process.

Q7: How do you ensure the quality of bearing parts?

A7: Quality assurance is a priority for us. We follow strict ISO certification standards, and each part undergoes rigorous inspection before shipment. We also provide material certification and inspection reports upon request.

Q8: What are the payment terms?

A8: Our payment terms are typically 30% upfront and 70% before shipment. We accept various payment methods including wire transfer, L/C, and PayPal.

Q9: Can you handle international shipping?

A9: Yes, we ship globally. We work with reliable shipping partners to ensure timely and safe delivery of your order.

Sourcing parts of a bearing from SourcifyChina requires strategic planning and careful execution. Here are some key tips:

1. Define Requirements: Clearly specify the type, dimensions, materials, tolerances, and quantities of the bearing parts you need. This helps in conveying exact requirements to the supplier, ensuring they understand your needs precisely.

2. Research Suppliers: SourcifyChina connects buyers with verified Chinese manufacturers. Use their platform to find factories specializing in bearing components. Review their profiles, certifications, and customer feedback.

3. Request Quotes: Solicit detailed quotations from multiple suppliers. Compare not only the prices but also the quality of materials, production capabilities, lead times, and minimum order quantities (MOQs).

4. Validate Capabilities: Ensure the factory can meet your technical specifications and quality standards. Ask for samples or visit the factory (if practical) to assess their production facilities, QA processes, and overall reliability.

5. Negotiate Terms: Discuss and negotiate terms to get the most favorable pricing, payment terms, and delivery schedules. Ensure there are clear agreements on these aspects to avoid misunderstandings later.

6. Order Samples: Before placing a bulk order, request samples to verify the quality. Test these samples rigorously to ensure they meet your performance standards.

7. Quality Assurance: Set up a stringent quality assurance protocol. Clearly communicate your quality expectations and consider employing third-party inspections to verify the parts before shipment.

8. Logistics Planning: Plan the logistics carefully, considering shipping methods, costs, and customs procedures. SourcifyChina may offer support with logistics, leveraging their expertise to smooth out the process.

9. Maintain Communication: Keep open lines of communication with the supplier. Regular updates can help manage timelines and quickly address any issues that may arise.

10. Build Relationships: Establish a positive, long-term relationship with the supplier. This can lead to better terms, priority service, and collaborative problem-solving in future transactions.

Effective sourcing is about precision, thorough vetting, and clear communication. By following these steps, you can ensure a successful partnership with SourcifyChina.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.