1. Exceptional Quality Control: SourcifyChina ensures stringent quality control processes, assuring buyers of top-tier stainless steel brushing products. Their commitment to high standards reduces defects and enhances the durability of your purchases.

2. Competitive Pricing: The factory leverages cost-effective production methods and local sourcing to offer competitive prices. This ensures buyers receive high-quality products at reasonable rates, improving overall procurement efficiency.

3. Vast Experience: With years of industry experience, SourcifyChina understands the intricate demands of stainless steel brushing. Their expertise translates into reliable products tailored to meet diverse buyer specifications.

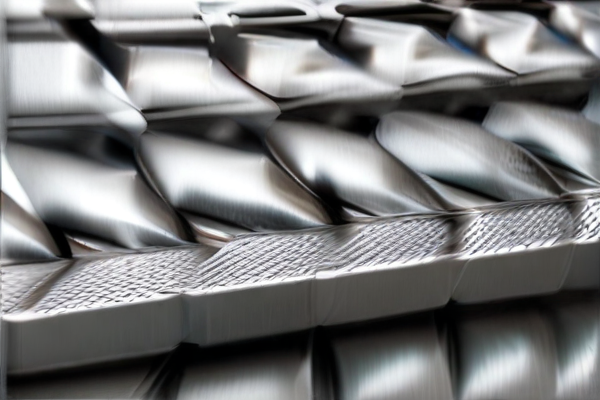

4. Advanced Technology: SourcifyChina employs cutting-edge technology for manufacturing stainless steel brushing. Their state-of-the-art machinery and innovative techniques guarantee precision and consistency in every batch produced.

5. Customized Solutions: Offering bespoke solutions, SourcifyChina caters to specific client needs. Whether it’s altering dimensions or adding special finishes, their customization services ensure unique and satisfactorily tailored products.

6. Sustainable Practices: Committed to eco-friendly manufacturing, SourcifyChina follows sustainable practices. They use recyclable materials and energy-efficient processes, thus supporting green initiatives and reducing their carbon footprint.

7. Timely Delivery: SourcifyChina values punctuality, ensuring timely delivery of orders. Their efficient logistics and well-coordinated supply chain operations minimize delays, assisting buyers in maintaining their project timelines.

8. Comprehensive Support: From inquiry to after-sales service, SourcifyChina provides comprehensive support. Their responsive customer service team is readily available to handle queries and resolve issues, enhancing the overall purchasing experience.

9. Positive Reputation: Highly regarded in the manufacturing industry, SourcifyChina has built a solid reputation for reliability and integrity. Positive client feedback underscores their commitment to exceeding buyer expectations.

10. Strong Partnerships: SourcifyChina has established robust relationships with reputable suppliers and partners. This network ensures a consistent supply of raw materials and streamlined operations, guaranteeing continued product excellence.

In conclusion, selecting SourcifyChina as your stainless steel brushing supplier ensures superior quality, affordability, customization, and eco-consciousness, supported by advanced technology and exceptional customer service.

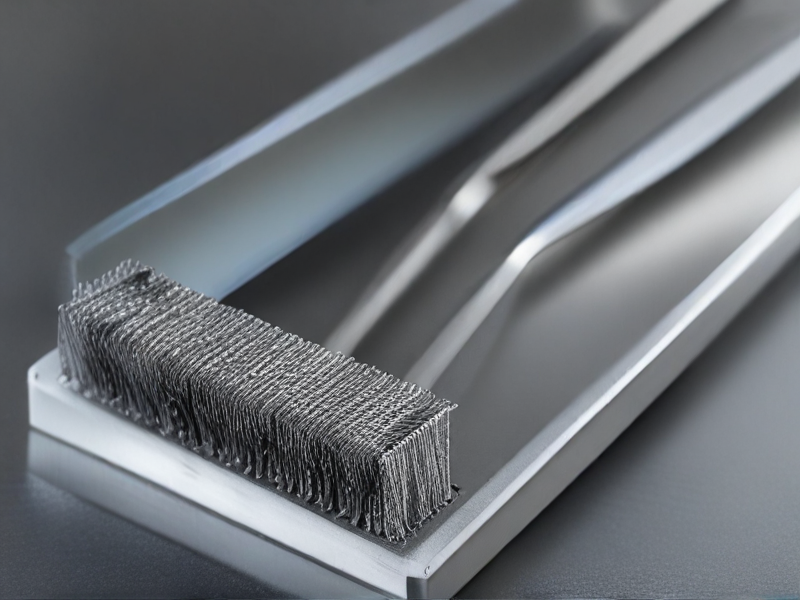

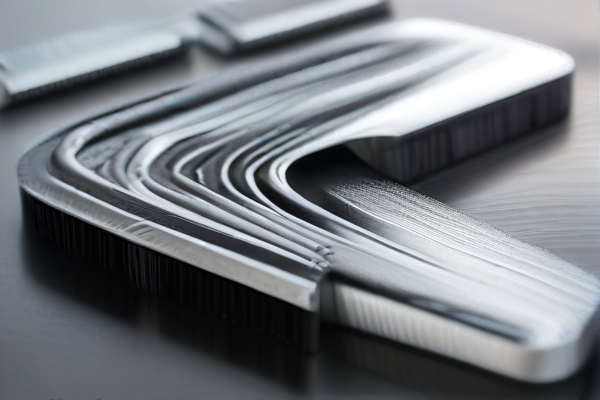

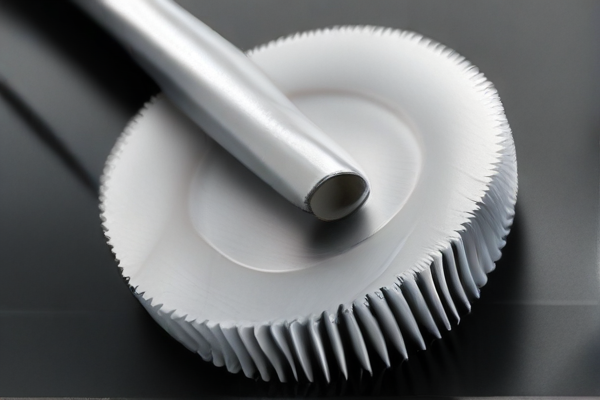

Stainless steel brushing is a technique to finish and enhance the surface of stainless steel, providing a distinctive texture and appearance. Common options include hand brushing, machine brushing, and automated brushing.

– Hand Brushing: Uses manual tools for detailed, intricate work.

– Machine Brushing: Employs bench-mounted or portable machines for consistent results.

– Automated Brushing: Involves CNC-controlled systems for high-volume and precision tasks.

– Brush Types: Choices include wire brushes, nylon brushes, and abrasive-impregnated brushes.

– Directionality: Techniques for unidirectional, cross-directional, and random patterns.

– Finishing Levels: From light brushing for subtle texture to heavy brushing for a pronounced effect.

– Pre-treatment: Surface cleaning and preparation, often required for optimal brushing results.

– Applications: Ideal for architectural, automotive, kitchen, and commercial uses.

– Advantages: Enhances aesthetic appeal, hides fingerprints, and improves resistance to corrosion.

– Drawbacks: May require maintenance to retain the finish over time.

– Surface Grades: Varying grades depending on the desired smoothness and texture.

– Customization: Tailorable to specific design requirements and preferences.

– Safety Measures: Essential to wear personal protective equipment (PPE) during the process.

– Cost Factors: Influenced by complexity, machine type, and labor involved.

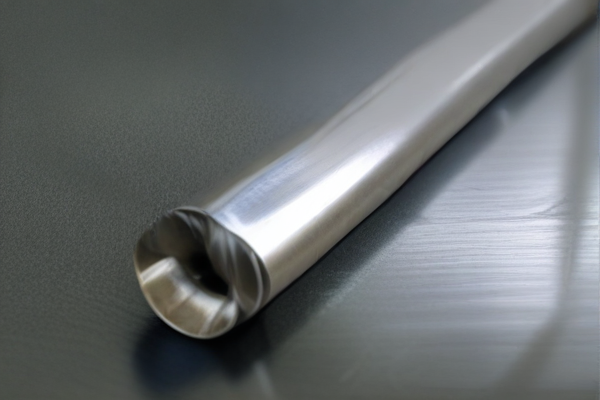

Stainless steel brushing is a finishing process that enhances the appearance and durability of stainless steel surfaces, providing a matte texture and reducing reflections. This technique is widely used across industries for both aesthetic and functional purposes.

Applications for stainless steel brushing:

– Kitchen Appliances: Provides a sleek, modern look for fridges, stoves, and dishwashers.

– Architectural Elements: Enhances the appearance of exterior and interior features such as railings, panels, and trim.

– Automotive Parts: Improves the look and resistance to corrosion of exhaust systems and decorative trims.

– Medical Equipment: Ensures a clean, smooth, and hygienic surface for surgical instruments and hospital fixtures.

– Consumer Electronics: Adds a sophisticated finish to smartphones, laptops, and other gadgets.

– Industrial Machinery: Offers a durable, low-maintenance finish for machine parts and components.

– Decorative Art: Used by artists and designers to achieve a specific artistic effect on sculptures and installations.

– Furniture: Provides a contemporary finish for tables, chairs, and other stainless steel furniture.

– Signage: Creates eye-catching and durable signs for commercial and residential use.

– Marine Applications: Enhances corrosion resistance and appearance of boat fittings and accessories.

Stainless steel brushing delivers both aesthetic appeal and increased durability, making it a versatile solution across numerous sectors.

SourcifyChina’s stainless steel brushing employs high-quality stainless steel, notable for its durability and resistance to corrosion. This makes it ideal for a variety of applications, from kitchenware to architectural elements. The material maintains its aesthetic appeal over time, providing a sleek, modern look that is easy to maintain.

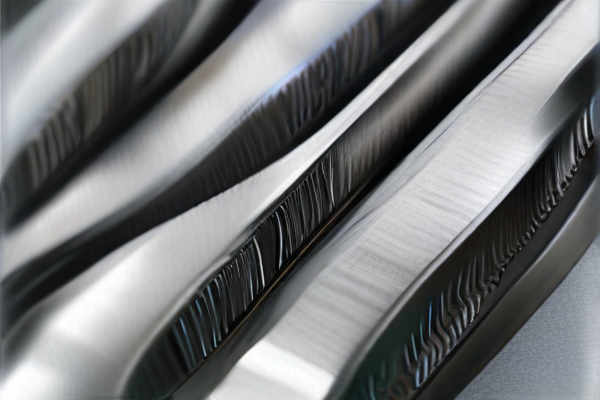

Stainless steel brushing involves creating a uniform finish with fine strokes, enhancing the material’s natural luster. The brushed finish not only adds to the visual appeal but also helps in concealing fingerprints and minor scratches, making it a practical choice for frequently used surfaces.

Additionally, SourcifyChina ensures that their stainless steel meets rigorous quality standards, providing both strength and flexibility. This allows the material to be easily shaped and customized without compromising its structural integrity. As a result, it can be adapted to a wide range of design specifications.

The ecological impact of stainless steel brushing is relatively low, as the material is recyclable and long-lasting. Choosing brushed stainless steel supports sustainability efforts by reducing the need for frequent replacements, contributing to resource conservation.

In summary, the stainless steel brushing process used by SourcifyChina produces a material that is not only aesthetically pleasing but also durable and practical. Its resistance to wear and tear, coupled with a sustainable profile, makes it an excellent choice for a variety of uses. This combination of features ensures that SourcifyChina’s products are both top-quality and eco-friendly.

SourcifyChina’s stainless steel brushing quality control process starts with carefully selecting high-quality raw materials. This ensures that the final product meets stringent industry standards and customer expectations.

The materials undergo rigorous inspection before production begins. This early-stage scrutiny guarantees that only defect-free materials are used, minimizing wastage and promoting efficiency in the manufacturing process.

Advanced machines are utilized for the brushing process, providing consistent texture and finish. These machines are regularly calibrated and maintained to ensure peak performance and reliability, resulting in a superior brushed stainless steel product.

Skilled technicians supervise each stage of the process, from material selection to final inspection. Their expertise ensures that any deviations are promptly identified and corrected, maintaining high-quality standards throughout.

In the final stages, a comprehensive inspection is conducted to assess the finished product. This includes checking for uniformity, surface smoothness, and adherence to specified measurements, ensuring the final product meets all quality criteria.

The quality control team meticulously documents each step of the process. This documentation provides traceability and accountability, allowing for continuous improvement and prompt resolution of any issues that may arise.

Customer feedback is also considered vital in assessing product quality. Any concerns or suggestions from customers are taken seriously and incorporated into the quality control process, enhancing the overall product quality. By integrating meticulous quality control measures at every stage, SourcifyChina guarantees that their stainless steel brushing meets the highest standards of excellence.

SourcifyChina specializes in precision stainless steel brushing, delivering top-notch surface finishes. Their advanced equipment ensures consistent quality across diverse industrial applications, enhancing both aesthetics and functionality. Their experienced team masters fine-tuning the brushing technique to meet stringent requirements.

Boasting state-of-the-art facilities, SourcifyChina adheres to international standards. Their robust quality control guarantees each brushed stainless steel product meets client specifications. Tailored solutions and attention to detail set SourcifyChina apart in the competitive market.

The stainless steel brushing process at SourcifyChina significantly reduces the risk of corrosion due to the removal of surface imperfections. This not only improves durability but also extends the lifespan of the products.

Their end-to-end service, from initial consultation to final delivery, ensures customer satisfaction. SourcifyChina’s brushing capabilities cater to various industries including automotive, construction, and consumer goods. This holistic approach makes them a preferred partner for high-quality stainless steel finishes.

SourcifyChina’s commitment to innovation drives continuous improvement in their stainless steel brushing technology. Their dedication to eco-friendly practices ensures minimal environmental impact. By partnering with SourcifyChina, clients benefit from superior brushed stainless steel products backed by exceptional service and sustainable practices.

Stainless steel brushing stands out for its ability to enhance both the aesthetic and functional qualities of stainless steel surfaces. This technique offers multiple benefits that make it indispensable in various industries.

– Improves Surface Appearance:

Brushing creates a uniform, attractive finish that enhances the visual appeal of stainless steel.

– Increases Durability:

It strengthens the surface by removing imperfections, thereby reducing the risk of corrosion and wear.

– Enhances Cleanability:

A brushed finish is easier to clean and maintain, ideal for environments requiring high hygiene standards like kitchens and hospitals.

– Reduces Glare:

The matte finish generated by brushing reduces reflective glare, making it suitable for applications in bright environments.

– Improves Grip:

The textured surface of brushed stainless steel provides better grip and reduces slip risks.

– Hides Scratches:

Minor scratches and fingerprints are less visible on brushed surfaces, maintaining a cleaner appearance over time.

– Facilitates Welding and Fabrication:

Brushing can remove surface contaminants, improving the quality of welds and other fabrication processes.

– Environmentally Friendly:

The process generally involves fewer harmful chemicals compared to polishing, making it more eco-friendly.

In various sectors like automotive, architecture, and culinary, stainless steel brushing is highly valued for these advantages.

Brushed stainless steel is a popular finish that combines durability with a unique aesthetic. This finish provides a distinctive texture that hides scratches while maintaining a modern and sleek appearance.

Key Features of Stainless Steel Brushing:

– Aesthetic Appeal: Offers a sophisticated, matte finish that complements modern design schemes.

– Scratch Resistance: Minimizes the visibility of scratches and fingerprints.

– Durability: Maintains structural integrity while adding an extra layer of robustness.

– Ease of Maintenance: Simple to clean and maintain compared to other finishes.

– Versatility: Suitable for various applications, from kitchen appliances to architectural elements.

– Anti-Corrosive: Brushed stainless steel offers excellent resistance to rust and corrosion.

– Non-reflective: Provides a non-reflective surface, reducing glare in bright environments.

– Consistency: Uniform finish that ensures a consistent appearance across different pieces.

– Hygienic: Smooth texture prevents the accumulation of dirt and bacteria.

– Eco-Friendly: Stainless steel is recyclable, contributing to sustainable practices.

Brushed stainless steel is a highly versatile and practical choice for a range of applications, providing both aesthetic and functional benefits.

SourcifyChina offers premium stainless steel brushing services for custom products and projects, ensuring top-notch quality and precision. Their expertise spans various industries, providing durable and aesthetically pleasing finishes.

Clients can customize the texture and appearance of their stainless steel items, enhancing both functionality and visual appeal. SourcifyChina’s advanced techniques ensure consistent and high-quality results.

The company supports a wide range of projects, from small-scale designs to large industrial applications, accommodating specific client requirements. Their team is skilled in managing complex orders efficiently.

With a commitment to excellence, SourcifyChina guarantees satisfaction through meticulous attention to detail and superior craftsmanship in every stainless steel brushing project they undertake.

SourcifyChina is a leading company specializing in the production and supply of high-quality stainless steel brushing solutions. With a robust presence in the metal finishing industry, SourcifyChina has garnered a reputation for its precision, durability, and innovative techniques in stainless steel brushing. The company prides itself on a comprehensive approach that includes sourcing premium materials, employing state-of-the-art machinery, and adhering to stringent quality control measures. This dedication ensures that their products meet the rigorous standards demanded by various industries such as automotive, construction, and electronics. Additionally, SourcifyChina is committed to sustainability, implementing eco-friendly practices within their manufacturing processes. Their team of skilled professionals works closely with clients to understand their unique requirements, providing customized solutions that enhance the aesthetic and functional properties of stainless steel components. As a customer-centric enterprise, SourcifyChina offers competitive pricing, timely delivery, and exceptional after-sales support, solidifying their position as a trusted partner in the global market.

Stainless steel brushing plays a crucial role in the aerospace, defense, and marine industries due to its ability to enhance the surface quality and performance of critical components. In the aerospace sector, the process is vital for ensuring that aircraft parts, such as engine components, airframes, and landing gears, maintain their strength and resistance to corrosion. The brushing method involves removing surface imperfections and contaminants, thereby improving the fatigue resistance and longevity of these parts. This is particularly important in aerospace applications where safety and reliability are non-negotiable. Additionally, brushed stainless steel surfaces offer reduced friction, which contributes to better aerodynamics and fuel efficiency.

In the defense and marine industries, stainless steel brushing is equally significant. Defense applications often demand materials that can withstand extreme conditions, including high stress, variable temperatures, and exposure to corrosive environments. Stainless steel components in military vehicles, weapons systems, and naval ships benefit from brushing as it ensures the removal of oxides and other debris that could compromise performance and durability. Similarly, in marine environments, the constant exposure to saltwater and harsh weather conditions can lead to rapid corrosion. Brushing stainless steel helps in creating a smoother, more resistant surface, which is essential for the longevity of marine structures like hulls, propellers, and rigging. The enhanced surface finish not only protects against corrosion but also reduces drag, contributing to improved operational efficiency.

Stainless steel brushing finds extensive application in the automotive industry, primarily for both aesthetic and functional purposes. The technique involves brushing stainless steel surfaces to create a uniform, satin-like finish that is both visually appealing and resistant to fingerprints and smudges. This is particularly valuable for interior and exterior components such as trim, grilles, and exhaust systems. The brushed finish not only enhances the vehicle’s overall aesthetics but also offers improved resistance to corrosion and wear, extending the lifespan of the components. Additionally, the texture created through brushing can improve the grip on surfaces like pedal covers, promoting safety. In high-performance and luxury vehicles, stainless steel brushing adds a touch of elegance and refinement, aligning with the premium image of these brands.

In the realm of electronics, stainless steel brushing is equally significant, especially for devices requiring a sleek, modern appearance combined with durability. Consumer electronics such as smartphones, laptops, and kitchen appliances often feature brushed stainless steel surfaces. This finish provides a sophisticated look that appeals to consumers while maintaining practical benefits such as scratch resistance and ease of cleaning. The brushing process also ensures that electronic devices can withstand daily handling and use without degrading in quality. Additionally, for industrial electronics and components used in harsh environments, the added resistance to corrosion and wear offered by brushed stainless steel is invaluable. By combining aesthetic appeal with functional resilience, stainless steel brushing ensures that electronic products not only look good but are built to last.

Stainless steel brushing in construction enhances both the aesthetic and functional qualities of buildings and infrastructure. The brushing process imparts a uniform, matte finish to the steel, which not only elevates the visual appeal with a modern, sleek look but also improves the material’s resistance to corrosion and wear. This makes it ideal for high-traffic areas and external architectural features exposed to the elements, such as facades, handrails, and cladding. Additionally, brushed stainless steel’s non-reflective surface minimizes glare, making it a practical choice for structures where light reflection could be an issue, such as in urban environments with numerous glass and steel buildings.

In the energy sector, stainless steel brushing is crucial for equipment and structures that must withstand harsh operational environments. The brushing process helps to reduce surface roughness, thereby minimizing the adherence of contaminants and facilitating easier cleaning and maintenance. This is particularly important in energy applications such as oil and gas pipelines, nuclear reactors, and renewable energy installations, where material integrity and cleanliness are paramount. Moreover, the improved corrosion resistance due to brushing ensures longevity and reliability of components, reducing downtime and maintenance costs. The enhanced surface properties also contribute to better performance in high-temperature and high-pressure environments, essential for energy production and distribution systems.

Stainless steel brushing is a widely adopted surface treatment technique in the industrial equipment sector due to its ability to enhance both aesthetic appeal and functional properties. This process involves using abrasive brushes to create a unidirectional satin finish that not only improves the visual quality of stainless steel components but also augments their resistance to wear and corrosion. Such a finishing technique is essential in industries like food and beverage, pharmaceuticals, and chemical processing, where maintaining hygiene and ensuring long service life are critical. The brushed finish helps in reducing the likelihood of bacterial accumulation, making it easier to clean and sanitize equipment like tanks, valves, and piping systems that come in direct contact with consumable products.

Apart from hygiene-related benefits, the stainless steel brushing technique also adds to the durability and resilience of industrial equipment employed in harsh environments. In sectors like oil and gas, marine, and construction, where equipment is regularly exposed to extreme conditions, a brushed finish provides an additional layer of protection against corrosive elements such as saltwater and industrial chemicals. Furthermore, this treatment reduces the visibility of surface scratches and abrasions, thereby prolonging the aesthetic and functional integrity of the equipment. The improved surface toughness ensures that critical components such as offshore drilling rigs, structural supports, and heavy machinery remain reliable over extended periods, minimizing downtime and maintenance costs. Overall, stainless steel brushing serves as a valuable process in enhancing the longevity, safety, and efficiency of industrial equipment across various sectors.

Stainless steel brushing is a crucial surface finishing process in the manufacturing of medical devices. This technique involves using abrasive brushes to remove surface contaminants, such as rust, scale, and other impurities, from stainless steel parts. By meticulously cleaning and polishing the metal surface, brushing enhances the corrosion resistance and fatigue strength of medical devices, such as surgical instruments and implants. This is particularly important in the medical field where devices must withstand harsh environments, including bodily fluids and sterilization processes, without degrading. The improved finish helps in ensuring that the medical devices are durable and safe for extended and repeated use within the human body.

Moreover, stainless steel brushing also plays a significant role in ensuring biocompatibility and reducing the risk of infections. A smooth and clean surface minimizes the potential for bacterial adhesion and biofilm formation, which are common sources of post-operative infections. Additionally, the process helps in improving the aesthetic appearance of medical devices, making them more acceptable in clinical settings. The enhanced surface finish achieved through brushing also aids in the precise functioning of surgical tools, providing better grip and maneuverability for surgeons. Overall, stainless steel brushing is an indispensable process in the fabrication of high-quality, reliable, and safe medical devices, contributing significantly to patient safety and healthcare outcomes.

Stainless steel brushing is a vital technique in machining and manufacturing, primarily employed to enhance the surface finish and aesthetic appeal of stainless steel components. The process involves using a brush with abrasive bristles to create a uniform, satin-like texture on the metal surface. This not only improves the visual quality but also removes minor imperfections, scales, and contaminants that may have formed during earlier stages of production. In manufacturing, brushed stainless steel is often chosen for its ability to maintain a clean and polished look with minimal maintenance, making it ideal for applications in the automotive, aerospace, and consumer goods industries where both functionality and appearance are crucial.

In addition to aesthetic improvements, stainless steel brushing plays a significant role in the functional performance of components. The process can enhance the corrosion resistance of stainless steel by removing surface impurities that could lead to rust formation. Moreover, brushed surfaces tend to be less reflective, reducing glare and making the material more suitable for environments where light reflection can be problematic, such as in kitchen appliances or architectural elements. The controlled roughness imparted by brushing also improves adhesion properties for subsequent coatings or finishes, which is beneficial in various industrial applications. Overall, stainless steel brushing is a versatile and essential process that contributes to both the visual and functional optimization of stainless steel products in machining and manufacturing.

Sure, here are some FAQs with answers for manufacturing “stainless steel brushing quality work from SourcifyChina Factory”:

Q1: What types of stainless steel can be brushed at SourcifyChina Factory?

A1: SourcifyChina Factory is experienced in brushing various grades of stainless steel, including 304, 316, and 430. Each type is handled with care to ensure a consistent and high-quality brushed finish.

Q2: What is the typical lead time for a stainless steel brushing project?

A2: The lead time varies depending on the project size and complexity but generally ranges from 1 to 3 weeks. For precise timelines, please contact our customer service team with project details.

Q3: Can SourcifyChina handle custom brushing patterns?

A3: Yes, SourcifyChina Factory offers customization for brushing patterns. Whether you need straight-line, cross-hatch, or other specific designs, our skilled technicians can accommodate your requirements.

Q4: What are the quality control measures in place at SourcifyChina?

A4: SourcifyChina implements stringent quality control procedures, including surface inspections, thickness measurements, and adhesion tests, to ensure that every piece of brushed stainless steel meets industry standards.

Q5: Do you offer polishing and brushing combination services?

A5: Absolutely. SourcifyChina can provide both polishing and brushing services to achieve the desired finish and texture on stainless steel surfaces, allowing for a customized appearance and improved aesthetics.

Q6: What is the maximum size of stainless steel sheets that can be brushed?

A6: SourcifyChina Factory can handle stainless steel sheets up to 2000mm in width and 6000mm in length. For larger or specialized dimensions, please contact our team for further assistance.

Q7: How do you handle surface defects during the brushing process?

A7: Our technicians meticulously inspect each sheet for defects such as scratches or blemishes. Any identified issues are addressed immediately to ensure a flawless brushed finish.

Q8: Is there a minimum order quantity (MOQ) for brushed stainless steel?

A8: The MOQ depends on the specific project but typically starts at 500 kg. For smaller orders, please consult with our sales team for customized solutions.

Manufacturing brushed stainless steel involves a meticulous process to achieve the desired finish. Here are some key tips, specifically from SourcifyChina factory:

1. Material Selection: Begin with high-quality stainless steel to ensure durability and an even brushing pattern. 304 and 316 grades are commonly used for their corrosion resistance and strength.

2. Surface Preparation: Clean the stainless steel surface thoroughly to remove any dirt, oil, or contaminants. This ensures a uniform finish and prevents defects.

3. Brushing Techniques:

– Abrasive Pads: Use non-woven abrasive pads or wheels. These create a consistent and controlled finish.

– Directional Brushing: Apply the brush strokes in one direction to achieve a uniform look. Cross-brushing can create a patchy appearance.

– Grit Selection: Start with a coarser grit (e.g., 120) to remove surface imperfections, then progress to finer grits (e.g., 240, 320) for a smooth finish.

4. Equipment: Use specialized brushing machines for large-scale production. Hand-held tools can be used for smaller, detailed work. Ensure the equipment is maintained regularly to avoid inconsistencies.

5. Speed and Pressure: Maintain consistent speed and pressure during the brushing process. Too much pressure can cause unevenness, while too little may not produce the desired texture.

6. Quality Control: Inspect the brushed finish under proper lighting. Look for uniformity in texture and appearance. Address any irregularities immediately to maintain high quality.

7. Post-Processing: After brushing, clean the surface to remove any residual abrasive particles. Apply a protective coating if necessary to enhance durability and resistance to fingerprints.

8. Safety: Ensure workers wear appropriate safety gear, including gloves and masks, to protect against metal particles and dust.

Following these tips from SourcifyChina factory can help achieve a high-quality brushed stainless steel finish, suitable for various applications from kitchen appliances to architectural elements.

Q: What types of stainless steel brushing finishes do you offer?

A: SourcifyChina offers a variety of stainless steel brushing finishes, including satin, brushed, and mirror finishes. Each type can be customized according to your specifications.

Q: Can you provide custom sizes and shapes?

A: Yes, we can customize stainless steel brushing products to meet your specific size and shape requirements. Please provide detailed drawings or specifications.

Q: What is your minimum order quantity (MOQ)?

A: The MOQ varies depending on the product type and customization needs. Typically, the MOQ starts at 500 units. Contact us for more details.

Q: What materials do you use for stainless steel brushing?

A: We use high-quality stainless steel grades such as 304, 316, and 430, ensuring durability and performance based on your application needs.

Q: How do you ensure the quality of your products?

A: SourcifyChina employs strict quality control measures, including material inspections, process monitoring, and final product testing. We adhere to international standards like ISO and ASTM.

Q: Can I get a sample before placing a bulk order?

A: Yes, we offer samples for you to evaluate our quality and finish. Sample costs and shipping fees apply and can be refunded upon bulk order confirmation.

Q: What is your lead time for production?

A: The lead time varies based on order size and customization requirements but typically ranges from 20 to 30 days. We prioritize timely delivery without compromising quality.

Q: Do you offer shipping and logistics services?

A: Yes, we provide comprehensive shipping and logistics services, including air freight, sea freight, and express delivery. We can handle customs clearance and other documentation requirements.

Q: What payment methods do you accept?

A: We accept various payment methods, including bank transfers, Letter of Credit (L/C), and PayPal. Payment terms are usually 30% upfront and 70% before shipment.

Q: How do I place an order?

A: To place an order, contact our sales team with your requirements. We will provide a detailed quote and guide you through the ordering process, including customization options and payment terms.

Sourcing “stainless steel brushing” from SourcifyChina factory can be streamlined with these tips:

1. Research and Verify:

– Conduct thorough research on SourcifyChina’s reputation.

– Check reviews and ratings from other clients.

– Verify the factory’s certifications, such as ISO standards.

2. Clear Communication:

– Clearly specify your requirements, including type, size, and finish of the stainless steel brushing.

– Use precise technical drawings and specifications.

3. Samples and Prototypes:

– Request samples to evaluate the quality.

– Ensure the samples meet your specifications before placing a bulk order.

4. Quality Control:

– Implement strict quality control measures.

– Arrange for third-party inspections to verify the quality of the products before shipment.

5. Cost and Payment Terms:

– Get detailed quotations, including all costs (manufacturing, shipping, taxes).

– Negotiate favorable payment terms; consider using a Letter of Credit for large orders.

6. Lead Time and Delivery:

– Confirm the lead time and ensure it aligns with your project timeline.

– Discuss and agree on shipping methods and logistics to avoid delays.

7. Contracts and Agreements:

– Draft a detailed contract outlining all terms, including quality standards, lead times, and penalties for non-compliance.

– Ensure all agreements are in writing and signed by both parties.

8. Ongoing Communication:

– Maintain regular communication with the factory to monitor production progress.

– Use project management tools to track the status of your order.

By following these steps, you can effectively source stainless steel brushing from SourcifyChina, ensuring quality and timely delivery.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.