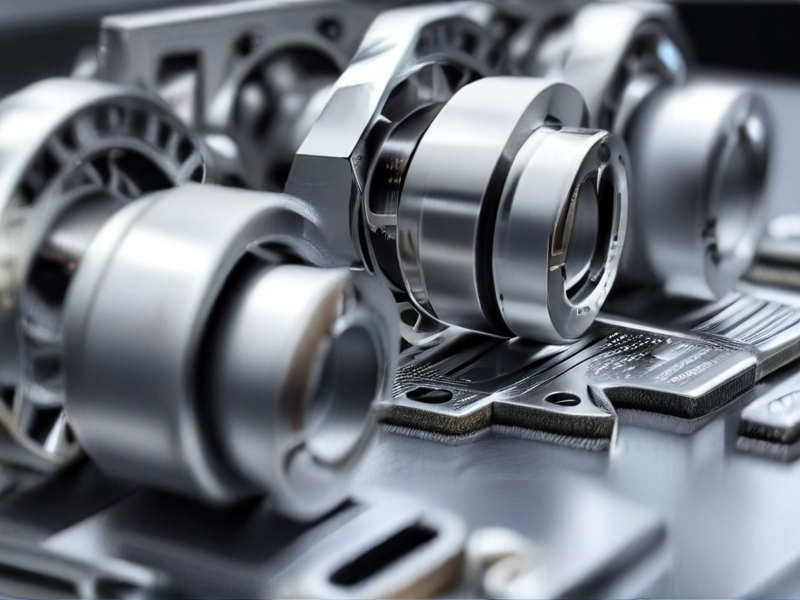

“SourcifyChina” Factory offers unparalleled expertise in CNC machining, providing high-precision parts that meet stringent quality standards. Their advanced technology ensures exceptional accuracy and efficiency, saving buyers time and costs while achieving superior results.

The factory’s robust supply chain management guarantees timely delivery of orders, minimizing potential delays. With a dedicated team overseeing every project, clients receive personalized attention and bespoke solutions tailored to their specific requirements.

“SourcifyChina” Factory emphasizes stringent quality control measures, rigorously testing each component to ensure flawless performance. Their commitment to excellence has earned them a reputation for reliability and consistency, making them a trusted partner for global clients.

Additionally, the factory maintains transparent communication throughout the procurement process. Clients are kept informed about production stages, ensuring confidence and satisfaction in the final product. No hidden costs or surprise expenses – what you see is what you get.

“SourcifyChina” Factory also prioritizes sustainability, implementing eco-friendly manufacturing practices. Their dedication to reducing environmental impact aligns with the growing emphasis on responsible sourcing and production, appealing to environmentally conscious buyers.

For those seeking a dependable and innovative partner in CNC machining manufacturing, “SourcifyChina” Factory stands out as the premier choice. Combining technological prowess, stringent quality checks, and sustainability efforts, they deliver exceptional value and solutions tailored to buyers’ needs. With their focus on client satisfaction, they ensure a seamless and successful procurement experience.

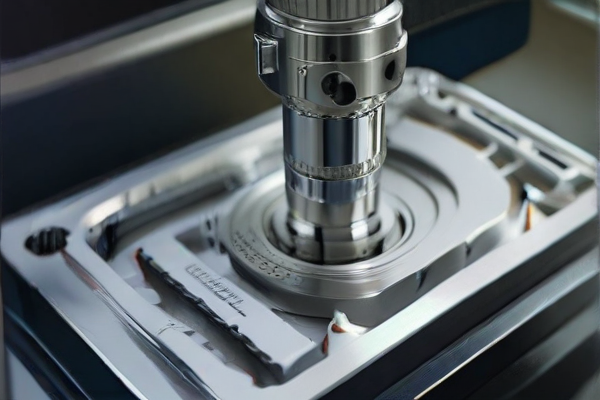

CNC machining manufacturing encompasses various techniques used to create precise parts and components through automated controls. Key options available include milling, turning, and multi-axis machining, each catering to different material types and design complexities.

– CNC Milling: Uses rotary cutters to remove material.

– CNC Turning: Rotates the workpiece while cutting tools shape it.

– Multi-Axis Machining: Integrates additional axes for complex geometries.

– CNC Grinding: Achieves fine finishes and tight tolerances.

– Electrical Discharge Machining (EDM): Uses electrical sparks for material removal, ideal for hard metals.

– Router CNC: Primarily for softer materials like wood, plastics, and some metals.

– Swiss-type CNC: Features precision creation of small, intricate parts.

– Plasma CNC: Utilizes plasma torch for cutting metal fast and accurately.

– Laser Cutting CNC: Employs a laser for precise cutting and engraving.

– Waterjet Cutting: Uses high-pressure water for cutting, suitable for heat-sensitive materials.

– Hybrid CNC Machines: Combine multiple machining processes in one unit.

– Wire EDM: Uses a thin wire and electrical charge to cut materials.

– Proto Mak CNC: Specializes in prototyping and creating functional models quickly.

– Big Area Additive Manufacturing (BAAM): Adds material layer-by-layer, useful for large-scale parts.

– 3D Printing CNC: Integrates 3D printing with CNC machining for innovative designs.

– Vertical vs Horizontal Machining Centers: Depending on the orientation of the spindle, suitable for different applications.

– Custom CNC Solutions: Tailored to specific manufacturing needs.

By understanding these types and options, manufacturers can optimize their processes, enhancing efficiency, accuracy, and cost-effectiveness in their production lines.

CNC machining manufacturing is a versatile process utilized in various industries to produce precise and complex parts. Its applications span from automotive to aerospace, offering efficiency and high accuracy.

– Automotive: Production of engine components, transmission parts, and metal bodywork.

– Aerospace: Manufacturing of turbine blades, engine mounts, and structural components.

– Medical: Fabrication of surgical instruments, prosthetics, and implantable devices.

– Electronics: Creation of housings, heat sinks, and precision connectors.

– Military and Defense: Production of weapon parts, military vehicles, and defense systems.

– Consumer Goods: Development of intricate parts for household appliances and electronics.

– Tool and Die Making: Manufacturing of molds, dies, and custom tools for various industries.

– Renewable Energy: Fabrication of components for wind turbines and solar panel mounts.

– Oil and Gas: Machining of drill bits, valves, and other extraction equipment.

– Robotics: Creation of precise robotic arms and other automation equipment.

– Marine: Construction of ship components, propellers, and underwater exploration devices.

– Textile: Crafting parts for sewing machines and other manufacturing equipment.

– Agriculture: Production of machinery parts like tractor components and harvesting tools.

– Construction: Machining of heavy-duty tools and equipment parts.

– Food Processing: Fabrication of processing and packaging equipment.

– Furniture Manufacturing: Production of intricate furniture components and hardware.

– Optics: Precision machining of lens holders and other optical components.

– Railways: Manufacturing of train parts and railway equipment.

– Space Exploration: Production of satellite components and spacecraft parts.

– Scientific Research: Creation of custom laboratory and research equipment.

With CNC machining manufacturing, industries gain the ability to produce consistent, high-quality components, enhancing productivity and innovation across various sectors.

SourcifyChina’s CNC machining manufacturing leverages a diverse range of high-quality materials to meet various industrial needs. Metals such as aluminum, steel, brass, and titanium are commonly used for parts that require durability, corrosion resistance, and excellent mechanical properties. The precision of CNC machining ensures that these metals can be crafted into complex geometries with tight tolerances.

Plastics are also frequently machined, including materials like ABS, nylon, and polycarbonate. These are chosen for their lightweight properties, chemical resistance, and the ability to be easily molded into various shapes. CNC machining allows for rapid prototyping and low-volume production runs, resulting in cost-efficient manufacturing processes.

Advanced composites like carbon fiber and fiberglass are used for high-performance, weight-sensitive applications. These materials offer an impressive strength-to-weight ratio and are ideal for aerospace, automotive, and sporting goods industries. The precision nature of CNC machining ensures that these composites retain their structural integrity while meeting stringent design specifications.

In addition to metals, plastics, and composites, ceramics are also utilized for specialized applications requiring high heat resistance and electrical insulation. SourcifyChina’s expertise in CNC machining allows these brittle materials to be precisely shaped without compromising their intrinsic properties, serving industries like electronics and medical devices.

With such a broad selection of materials, SourcifyChina can cater to a wide range of engineering challenges. By combining advanced CNC machining technology with a deep understanding of material science, they provide tailored solutions that enhance performance, reduce costs, and accelerate time-to-market for their clients across various industries. This material versatility underscores SourcifyChina’s commitment to meeting the complex demands of modern manufacturing.

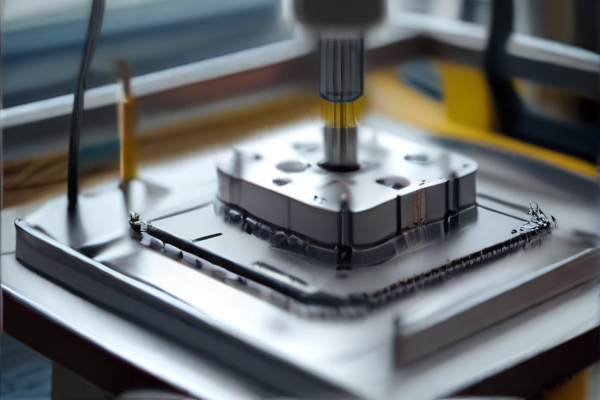

SourcifyChina CNC machining manufacturing is renowned for its stringent quality control processes. Each component undergoes meticulous inspection to ensure it meets precise specifications. Advanced technologies like Coordinate Measuring Machines (CMM) and precision gauges are regularly employed.

Operators and inspectors work collaboratively throughout the production cycle. They monitor for any deviations or defects, ensuring that only superior parts move forward. Routine calibration of machinery minimizes inaccuracies.

Continuous improvement is a core principle at SourcifyChina. The team is dedicated to refining their processes, leveraging feedback from clients and integrating the latest industry standards. This culture of excellence fosters not just compliance, but genuine customer satisfaction.

In essence, SourcifyChina’s unwavering commitment to quality assurance sets it apart in the CNC machining sector. Their comprehensive processes guarantee every product meets the highest standards, ensuring reliability and precision for their clients.

SourcifyChina excels in precision CNC machining, providing superior-quality parts and components. Their state-of-the-art equipment and highly skilled technicians guarantee impressive accuracy and consistency in every project.

Their comprehensive capabilities span various industries, including aerospace, automotive, medical, and electronics. SourcifyChina is equipped to handle complex designs and materials, ensuring customer specifications are met precisely.

One of their standout features is rapid prototyping, enabling quick turnaround times from concept to production. This agility offers significant advantages for product development and market readiness.

Quality control at SourcifyChina is rigorous, employing advanced inspection methods to meet stringent industry standards. This dedication to quality ensures reliable, high-performance results.

Moreover, SourcifyChina emphasizes customer collaboration, working closely to achieve optimal outcomes. Their commitment to client satisfaction sets them apart in the competitive CNC machining landscape.

In addition to machining, they offer additional services, such as assembly and finishing, providing a one-stop solution for manufacturing needs. This integrated approach simplifies the supply chain and enhances efficiency.

Environmental responsibility is also a priority, with sustainable practices and resource conservation integrated into their operations. SourcifyChina strikes a balance between innovation and eco-conscious manufacturing.

Overall, SourcifyChina’s CNC machining capabilities demonstrate their expertise, technological advancement, and customer-centric approach, ensuring top-tier results for a diverse range of applications. Their unwavering dedication to quality, speed, and collaboration marks them as a leading choice in the industry.

CNC machining offers numerous benefits in manufacturing, emphasizing precision, efficiency, and versatility. This technology enhances production capabilities across various industries.

– High Precision: CNC machines provide exceptional accuracy, ensuring parts meet exact specifications with minimal deviation.

– Consistency: Once programmed, CNC machines can produce identical parts consistently, reducing the risk of human error.

– Efficiency: Automation speeds up the manufacturing process, leading to faster production rates and reduced lead times.

– Flexibility: CNC machines can be reprogrammed for different tasks, making them adaptable for various products.

– Complex Designs: Capable of executing intricate and complex geometries that manual machining cannot achieve.

– Reduced Labor Costs: Automation minimizes manual intervention, thereby reducing labor requirements.

– Material Versatility: CNC machines can work with a wide range of materials including metals, plastics, and composites.

– Lower Waste: High precision minimizes material waste, leading to cost savings and sustainability benefits.

– Scalability: Suitable for both small-scale and large-scale production runs, making it versatile for different manufacturing needs.

– Enhanced Safety: Less direct human involvement reduces workplace accidents and enhances overall safety.

– Increased Productivity: Machines can run 24/7, increasing overall productivity and meeting high demand schedules.

– Technical Advancement: Integrates well with advanced manufacturing technologies like CAD/CAM software, improving design and production processes.

In conclusion, CNC machining significantly enhances manufacturing efficiency and product quality, positioning itself as an essential technology in modern manufacturing. The integration of CNC technology drives innovation, cost-effectiveness, and competitiveness in the industry.

CNC machining manufacturing features advanced automation and precision, enhancing production efficiency and product quality across various industries. It leverages computer programming to control machine tools.

– Automation: CNC machines operate autonomously based on pre-set programs, reducing manual intervention.

– Precision: High accuracy and consistency in manufacturing complex parts minimize errors and waste.

– Versatility: Applicable to diverse materials such as metals, plastics, and composites.

– Repeatability: Ensures uniformity across large production batches, essential for mass production.

– Speed: Accelerates production timelines with rapid tool changes and continuous operations.

– Scalability: Easily scalable from prototypes to full-scale production runs.

– Complex Designs: Capable of producing intricate geometries that manual machining cannot achieve.

– Safety: Minimizes human interaction with machinery, reducing workplace accidents.

– Customization: Easily adaptable for design changes through software modifications.

– Efficiency: Optimizes material usage with minimal waste, promoting cost-effectiveness.

– Integration: Compatible with CAD/CAM software for streamlined design-to-production workflows.

– Maintenance: Lowers the need for frequent maintenance with robust operational capabilities.

These features collectively make CNC machining a cornerstone of modern manufacturing, driving innovation and productivity across multiple sectors.

SourcifyChina specializes in custom CNC machining manufacturing, offering high-precision solutions tailored for a variety of industries. Their advanced technology ensures meticulous craftsmanship, meeting specific project requirements with precision and efficiency.

The company leverages state-of-the-art machinery to produce components from diverse materials, including metals and plastics. This versatility allows for the creation of both simple and complex parts, catering to the unique needs of each client.

Collaboration is a cornerstone of SourcifyChina’s approach. By working closely with clients from the initial design phase through to final production, they ensure each product is perfectly suited to its intended application.

Quality control is paramount at SourcifyChina. Rigorous testing and inspection protocols are adhered to at every stage of the manufacturing process, guaranteeing that each part meets the highest standards of accuracy and reliability.

Timely delivery is another hallmark of SourcifyChina. Their efficient workflow and dedicated team ensure that even the most demanding projects are completed on schedule, without compromising on quality.

Competitive pricing is a significant advantage for SourcifyChina’s clients. By optimizing resources and maintaining efficient production processes, they offer high-quality custom CNC machining services at affordable rates.

SourcifyChina is committed to continuous improvement, regularly updating their technologies and training their team. This dedication to innovation ensures they stay at the forefront of the CNC machining industry.

Environmental responsibility is also a priority. SourcifyChina implements sustainable practices in their operations, reducing waste and energy consumption while maintaining quality and efficiency.

In summary, SourcifyChina CNC machining manufacturing stands out for its precision, quality, and commitment to customer satisfaction. Their comprehensive range of services and dedication to continuous improvement make them a reliable partner for any custom product and project needs.

SourcifyChina CNC Machining Manufacturing stands as a leading figure in the precision engineering and manufacturing sector, renowned for its commitment to quality and innovation. Located in the heart of China’s industrial hub, the company leverages advanced CNC (Computer Numerical Control) technology to produce intricately detailed and high-precision components for a diverse array of industries, including automotive, aerospace, electronics, and medical devices. Utilizing state-of-the-art machinery and a team of highly skilled engineers, SourcifyChina ensures that each product adheres to stringent international quality standards, making them a trusted partner for both local and global clients. Their comprehensive services span from initial design consultation to final product delivery, ensuring a seamless and efficient manufacturing process. With a strong emphasis on customer satisfaction, timely delivery, and cost-effectiveness, SourcifyChina CNC Machining Manufacturing continues to set benchmarks in the industry, driving forward with a blend of traditional craftsmanship and cutting-edge technology.

CNC (Computer Numerical Control) machining manufacturing plays a pivotal role in the aerospace, defense, and marine industries due to its precision, reliability, and ability to handle complex geometries. In aerospace applications, CNC machining is utilized to create components for aircraft, satellites, and spacecraft with exacting tolerances. This is critical since even minute deviations can affect the performance and safety of flight systems. Metals like titanium and composites are often used, and CNC machining allows for the intricate cutting and shaping required for components like turbine blades, airframes, and avionics housings. The process ensures consistency and repeatability, which are essential for parts subjected to the extreme environmental conditions of high altitudes and space.

In the defense sector, CNC machining is indispensable for producing high-precision parts for weapons systems, armored vehicles, and military equipment. The ability to fabricate parts from high-strength materials such as hardened steel and aluminum alloys ensures durability and reliability in combat situations. CNC machining is employed to manufacture components like gun barrels, missile casings, and tactical gear, where exact specifications are non-negotiable for operational integrity and safety. Similarly, in the marine industry, CNC machining is crucial for producing ship components that must withstand harsh oceanic environments. Propellers, engine parts, and structural elements are crafted with precision to ensure optimal performance and longevity. The versatile nature of CNC machining allows for rapid prototyping and small-batch production, making it an invaluable asset in these sectors where custom, high-performance parts are frequently required.

CNC (Computer Numerical Control) machining has revolutionized the automotive industry by enabling the precise fabrication of complex components and enhancing production efficiency. In automotive manufacturing, CNC machining is employed to produce a wide range of parts, from engine blocks and cylinder heads to transmission housings and brake components. The precision offered by CNC machining ensures that these components meet stringent tolerance requirements, which is critical for the performance and safety of vehicles. Additionally, the technology allows for rapid prototyping and iteration, which accelerates the development of new models and technologies. By integrating CNC machining into their production lines, automotive manufacturers can achieve higher consistency, reduce waste, and lower production costs.

In the electronics industry, CNC machining plays a pivotal role in creating the intricate parts that form the backbone of modern electronic devices. This technology is used to manufacture components such as heat sinks, enclosures, and connectors, which require high precision and intricate designs. CNC machining allows for the production of these components from a variety of materials, including metals and plastics, with exceptional accuracy. The high degree of repeatability and precision ensures that electronic components fit together perfectly, which is crucial for the performance and reliability of devices ranging from smartphones to aerospace instrumentation. Moreover, CNC machining facilitates the rapid prototyping and small-batch production necessary for developing and testing new electronic products, providing manufacturers with the flexibility to innovate and adapt quickly to market demands.

CNC (Computer Numerical Control) machining has revolutionized the construction industry by enabling the precise and efficient production of complex building components. This technology allows for the creation of custom parts that adhere to stringent architectural requirements, enhancing both the design and structural integrity of modern buildings. From intricate facade panels to specialized structural connectors, CNC machining ensures that each component is fabricated with exact specifications, thereby reducing material wastage and increasing overall project accuracy. Furthermore, the rapid prototyping capabilities of CNC machining facilitate the quick turnaround of custom design adjustments, which is crucial in fast-paced construction timelines. The reliability and repeatability of CNC machining also contribute to streamlined workflows, minimizing delays and optimizing labor efficiency, ultimately lowering construction costs.

In the energy sector, CNC machining plays a pivotal role in the production of components essential for power generation and distribution. Whether in the realm of renewable energy sources like wind, solar, and hydro, or in traditional energy systems such as natural gas and nuclear, the precision of CNC machining is indispensable. For instance, the aerodynamic blades of wind turbines, which require intricate and highly accurate geometries to maximize efficiency, are often manufactured using CNC processes. Likewise, in the oil and gas industry, CNC machining is used to produce drilling equipment, pipelines, and other components that demand high durability and exact tolerances. This precision not only ensures optimal performance and longevity of energy systems but also enhances safety and reliability, which are critical in an industry where component failure can lead to catastrophic consequences. Overall, the integration of CNC machining in energy applications underscores the technology’s versatility and crucial role in advancing both construction and energy sectors.

The industrial equipment industry has significantly benefited from the advent of CNC (Computer Numerical Control) machining manufacturing. This technology automates the control of machining tools using computer programs, resulting in unparalleled precision, efficiency, and versatility in the production process. CNC machining is particularly advantageous in the fabrication of complex parts and components, which are often required in industrial equipment like pumps, compressors, and turbines. The technology facilitates the production of highly intricate designs and maintains tight tolerances, ensuring that each component fits perfectly within its assembly. This automation reduces the likelihood of human error, enhances consistency, and accelerates the time-to-market for new equipment designs.

Moreover, CNC machining manufacturing allows industrial equipment manufacturers to quickly adapt to changing demands and innovations. Prototyping, which can traditionally be a time-consuming and costly process, becomes significantly more streamlined with CNC machining. Rapid iteration and testing of components are achievable, enabling manufacturers to fine-tune designs and enhance product performance before full-scale production. In addition to improving product quality and innovation cycles, CNC machining also optimizes the use of raw materials by minimizing waste, a critical factor in an industry where material costs can be substantial. Consequently, CNC machining not only bolsters the efficiency and precision of industrial equipment manufacturing but also contributes to more sustainable and cost-effective production practices.

CNC (Computer Numerical Control) machining has become a cornerstone in the manufacturing of medical devices, offering unparalleled precision and reliability. In an industry where the margin for error is incredibly small, CNC machining excels by producing components that meet stringent tolerances and intricate specifications required for medical applications. From surgical instruments such as scalpels and forceps to implantable devices like orthopedic screws and dental implants, CNC machining ensures these components are manufactured to exacting standards. The use of biocompatible materials such as titanium, stainless steel, and specialized plastics is commonplace, and CNC machines can adeptly handle these materials, crafting complex geometries that are vital for the functionality of medical devices.

Beyond just the high precision, CNC machining also provides significant advantages in terms of speed and scalability. Rapid prototyping is facilitated through CNC, allowing for quick iterations and modifications during the development phase of new medical devices. This accelerates the time-to-market for innovative solutions and reduces development costs. Furthermore, CNC machining offers excellent repeatability, ensuring that every batch of production maintains consistent quality, a critical factor in medical device manufacturing. With the incorporation of advanced technologies like multi-axis machining and computer-aided design (CAD) software, CNC machining continues to push the boundaries of what is possible, enabling the creation of ever more sophisticated and effective medical devices that improve patient outcomes.

CNC machining, or Computer Numerical Control machining, plays a pivotal role in modern manufacturing due to its precision, efficiency, and versatility. CNC machines, controlled by computer programs, execute complex tasks that would be difficult or impossible with manual machining. They can produce intricate parts with high accuracy from a variety of materials, including metals, plastics, and composites. This technology is widely used in industries such as aerospace, automotive, and medical devices, where exact specifications and consistent quality are crucial. The ability to automate and repeat processes with minimal human intervention reduces the likelihood of errors, speeds up production timelines, and ensures uniformity across large batches of products.

In manufacturing applications, CNC machining enhances productivity and innovation. It allows for rapid prototyping, enabling designers to test and iterate their products more quickly and cost-effectively. CNC machining facilitates the creation of complex geometries and fine details that are often required in advanced engineering applications. The integration of CNC systems with CAD/CAM software streamlines the entire production process, from design to final product, thus optimizing material usage and reducing waste. Additionally, the flexibility of CNC machines means they can easily be reprogrammed to produce different parts, making them ideal for both high-volume production and small-scale, custom manufacturing. This adaptability not only fosters diverse product development but also provides manufacturers with the agility needed to meet evolving market demands.

Sure, here is a list of frequently asked questions (FAQ) with answers for manufacturing quality CNC machining work from SourcifyChina factory:

Q1: What materials can SourcifyChina work with for CNC machining?

A1: SourcifyChina can machine a wide range of materials including aluminum, steel, brass, titanium, plastics, and more. If you have a specific material in mind, please let us know, and we can confirm its availability.

Q2: What are the tolerances you can achieve in CNC machining?

A2: We can achieve tight tolerances up to ±0.001 inches (±0.025mm). Exact tolerances will depend on the material and the complexity of the part. Please provide detailed specifications to discuss achievable tolerances for your project.

Q3: How do you ensure the quality of CNC machined parts?

A3: SourcifyChina employs rigorous quality control measures including in-process inspections, final inspections, and the use of Coordinate Measuring Machines (CMM) to ensure parts meet or exceed customer specifications. ISO 9001 certification also underscores our commitment to quality.

Q4: What is the typical lead time for a CNC machining order at SourcifyChina?

A4: Lead times typically range from 2 to 4 weeks for standard orders, depending on the complexity and quantity. Expedited services may be available for urgent projects.

Q5: Can SourcifyChina handle both prototype and large-scale production runs?

A5: Yes, we are equipped to handle everything from low-volume prototype orders to high-volume production runs. Our flexible manufacturing capabilities allow us to scale production according to your needs.

Q6: What type of finishes can you provide for CNC machined parts?

A6: We offer a variety of finishing options including anodizing, plating, powder coating, bead blasting, and polishing among others. Please specify your required finish when placing an order.

Q7: Can I get a quote for my CNC machining project from SourcifyChina?

A7: Absolutely. Please submit your design files (e.g., CAD, STEP) and detailed requirements via our website or email. Our team will review your project and provide a competitive quote promptly.

Q8: Is there a minimum order quantity (MOQ) for CNC machining services?

When considering CNC machining manufacturing from a Sourcify China factory, it’s crucial to follow certain guidelines to ensure quality, efficiency, and cost-effectiveness:

1. Supplier Verification: Ensure the factory is verified through credible certification bodies like ISO and has robust quality management systems in place. Sourcify usually provides pre-vetted suppliers, which can simplify this step.

2. Prototype And Sample Testing: Before committing to large orders, request prototypes or samples to assess the quality of workmanship, precision, and material integrity. This can help identify potential issues early on.

3. Material Selection: Be clear about the materials required for your project. Specify grades, tolerances, and the intended use to avoid substitutions or compromises that could affect performance or compliance.

4. Clear Communication: Language barriers can lead to misunderstandings. Use clear, concise technical specifications, and consider visual aids like drawings and CAD models to convey your needs accurately.

5. Quality Control: Implement stringent QC processes. Sourcify often offers on-site inspections and third-party QC services to ensure products meet your specifications before shipment.

6. Lead Times And Shipping: Discuss realistic lead times and buffer periods to avoid delays. Factor in customs clearance and shipping duration to plan your inventory accordingly.

7. Cost Analysis: While China offers competitive pricing, ensure that cost savings do not compromise quality. Analyzing the total landed cost, including tariffs, shipping, and any additional QC expenses, can provide a more accurate picture of your expenses.

8. Intellectual Property Protection: China has different IP laws compared to Western countries. Use non-disclosure agreements (NDAs) and consider local legal counsel to protect your designs and innovations.

9. Continuous Improvement: Build a long-term relationship with your supplier. Providing feedback and working collaboratively can lead to continuous improvement in quality, cost, and efficiency.

Engaging with a Sourcify China factory for your CNC machining needs can bring substantial advantages, provided you follow these best practices.

1. What types of CNC machining services does SourcifyChina offer?

SourcifyChina provides a comprehensive range of CNC machining services including milling, turning, drilling, and grinding, as well as custom machining solutions tailored to meet specific requirements.

2. Are there minimum order quantities (MOQ) for CNC machining orders?

SourcifyChina typically accommodates both small and large orders. The MOQ can vary depending on the complexity and specific requirements of the project. It’s best to consult directly with the sales team for tailored MOQ details.

3. How can I get a quote for my project?

To receive a quote, simply provide detailed information about your project, including drawings, specifications, materials, and quantities. SourcifyChina’s customer service team will respond promptly with a customized quote.

4. What materials can SourcifyChina work with?

SourcifyChina works with a wide range of materials including aluminum, steel, brass, plastics, and more. They prioritize sourcing high-quality materials to ensure precise and durable machining results.

5. What is the lead time for typical CNC machining projects?

Lead times vary based on the project’s complexity and order volume. Generally, SourcifyChina aims to complete standard projects within 2 to 4 weeks. More complex orders will be provided with a tailored timeline.

6. Can SourcifyChina handle custom designs and prototypes?

Yes, SourcifyChina specializes in custom designs and prototypes. Their engineering team works closely with clients to ensure that all specifications and requirements are met accurately.

7. How does SourcifyChina ensure quality assurance?

SourcifyChina employs rigorous quality control processes, including in-process inspections and final checks using advanced measurement equipment to ensure all parts meet client specifications and industry standards.

8. What support does SourcifyChina offer post-production?

Post-production support includes troubleshooting, additional machining if required, and full customer service to address any concerns or adjustments needed. Customers can depend on continued support throughout the lifecycle of their products.

9. Can I visit the SourcifyChina factory for an audit?

Yes, client visits are welcomed. You can schedule a factory tour to see the facilities, meet the team, and discuss your project in detail.

10. What payment terms does SourcifyChina offer?

Sourcing CNC machining manufacturing from a factory like SourcifyChina can be streamlined by following these tips:

1. Define Requirements:

– Specify your technical requirements (materials, tolerances, quantities).

– Include detailed CAD drawings and prototypes if available.

2. Research:

– Evaluate SourcifyChina’s capabilities and reputation.

– Look for reviews, case studies, and client testimonials.

3. Request Quotations:

– Contact SourcifyChina directly for a quote.

– Provide all relevant details to receive an accurate estimate.

4. Assess Communication:

– Gauge response time and clarity in your interactions.

– Effective communication is crucial for successful collaboration.

5. Verify Quality Standards:

– Check if SourcifyChina complies with ISO or other relevant certifications.

– Inquire about their quality assurance processes and inspection routines.

6. Sample Production:

– Request samples to evaluate quality before placing a bulk order.

– Assess adherence to specifications and finish quality.

7. Negotiate Terms:

– Clarify pricing, payment terms, lead times, and MOQs (Minimum Order Quantities).

– Discuss any intellectual property protections if applicable.

8. Inspect Facilities:

– If feasible, plan a visit to SourcifyChina’s facilities.

– Virtual tours or third-party inspections can also be alternatives.

9. Trial Order:

– Start with smaller orders to test reliability and quality.

– Gradually increase order size as trust is established.

10. Feedback Loop:

– Maintain regular communication for updates and improvements.

– Provide feedback on received products to ensure continuous quality improvement.

By following these structured steps, you can effectively source CNC machining manufacturing from SourcifyChina, ensuring quality and reliability in your supply chain.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.