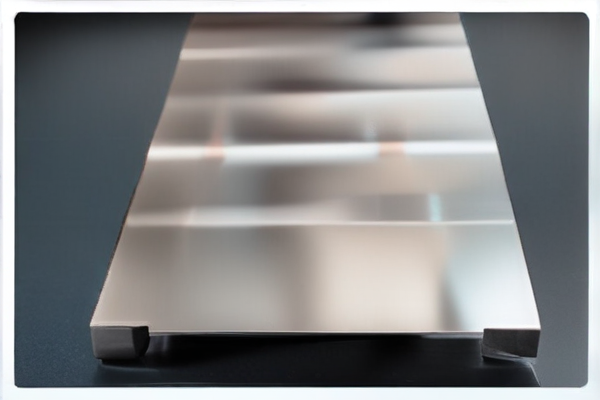

“SourcifyChina” Factory is the go-to for purchasing stainless steel sheets from China due to its high-quality materials and precision cutting technology. They ensure accurate dimensions and smooth edges, making further processing efficient.

Another advantage is their competitive pricing. “SourcifyChina” offers cost-effective solutions without compromising quality, benefiting businesses looking to optimize expenses while maintaining high standards.

Customer service is another hallmark. Their experienced team assists with customization and answers inquiries promptly, ensuring a seamless purchasing experience from order to delivery.

Lastly, “SourcifyChina” prioritizes timely delivery. They understand the importance of deadlines in manufacturing and are committed to meeting them, adding reliability to their list of strengths.

Choosing “SourcifyChina” Factory means choosing excellence, cost-efficiency, and reliable service for your stainless steel sheet cutting needs from China.

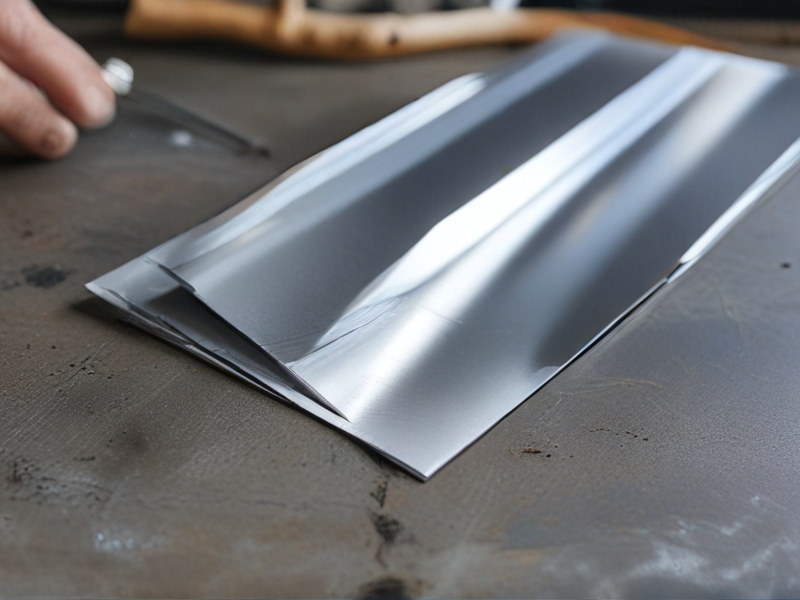

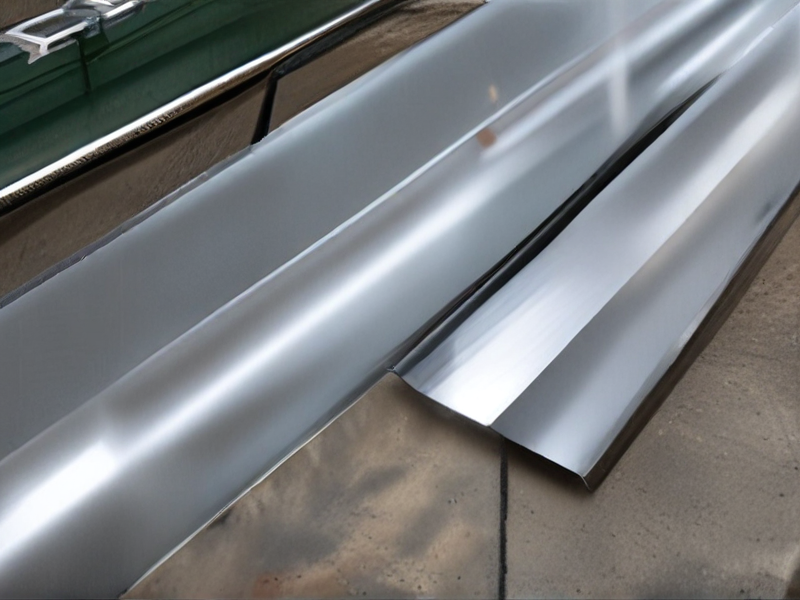

Cutting stainless steel sheets involves various methods suited for different needs and complexities. Techniques range from manual tools to advanced machinery, each offering unique advantages for precision, speed, and finish quality.

– Tin Snips: Simple, manual tool for thin sheets, ideal for small projects and straight or curved cuts.

– Power Shears: Faster than tin snips, suitable for medium to thin sheets, providing efficient and clean cuts.

– Angle Grinder: Versatile for both straight and curved cuts on thicker sheets; requires a steady hand and safety precautions.

– Circular Saw: Equipped with a specialized blade for stainless steel, it offers smooth, straight cuts on thicker sheets.

– Plasma Cutter: Fast and precise for cutting various thicknesses, best for intricate shapes and detailed work.

– Band Saw: Ideal for thicker sheets, offering control and precision, especially useful for straight cuts.

– Lasers Cutting: High-precision technique for detailed designs and complex shapes, used in professional settings.

– Water Jet Cutting: Uses high-pressure water mixed with abrasives, providing accurate and smooth cuts without heat distortion.

– Nibblers: Handheld or bench-mounted, great for making small, precise cuts on thin sheets with minimal material distortion.

Selecting the appropriate method depends on the sheet thickness, required precision, project scale, and available equipment.

Cutting stainless steel sheets precisely is critical for a wide range of industrial and DIY projects. Knowing how to effectively cut stainless steel ensures clean, accurate cuts and extends the life of your materials.

– Industrial Manufacturing: Custom fabrication, component creation, and prototyping.

– Construction: Bespoke fixtures, structural elements, and architectural finishes.

– Automotive: Custom parts, body repairs, and specialized components.

– Kitchen Appliances: Tailored fittings, custom countertops, and splashbacks.

– Art and Sculpture: Intricate designs, tailored shapes, and durable finishes.

– Aerospace: Precision components, structural elements, and specialized parts.

– Plumbing: Custom fittings, pipework, and installation components.

– Signs and Display: Custom signage, display elements, and advertising materials.

– Electronics: Enclosures, heat sinks, and custom components.

– Marine: Corrosion-resistant parts for boats, docks, and marine equipment.

Understanding how to cut stainless steel sheets can improve the efficiency, safety, and quality of your work, making it a valuable skill for numerous fields.

SourcifyChina explains the step-by-step process for cutting stainless steel sheets. They emphasize the importance of selecting the right tools for the job. Common options include shears, plasma cutters, and laser cutters. Shears are best for simple, straight cuts, while plasma and laser cutters are ideal for precision work.

Preparing the workspace is crucial. Ensure the area is clean and free from obstacles to prevent accidents. Proper safety gear, like gloves and goggles, is also essential to protect against sharp edges and metal sparks. Mark the cutting lines precisely using a scribe or marker.

The cutting technique depends on the tool used. When using shears, align the sheet properly to ensure a straight cut. For plasma or laser cutting, set the machine parameters according to the thickness and type of stainless steel. Smooth, steady motions will yield the best results and minimize rough edges.

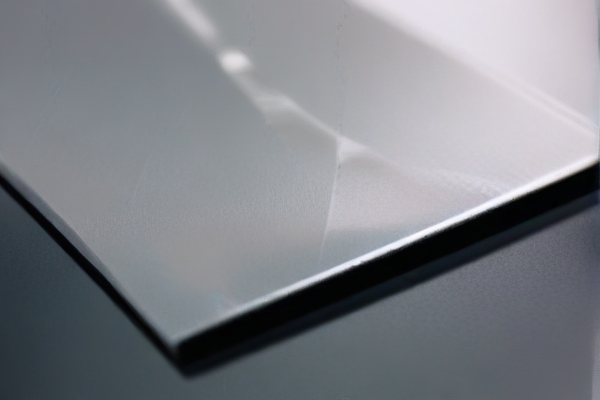

Cleaning up after cutting is equally important. Burrs and sharp edges should be filed down or sanded to avoid injuries. Inspect the cut pieces for accuracy and quality. Proper maintenance of cutting tools will prolong their lifespan and ensure efficient performance. With these steps, cutting stainless steel sheets becomes a straightforward task.

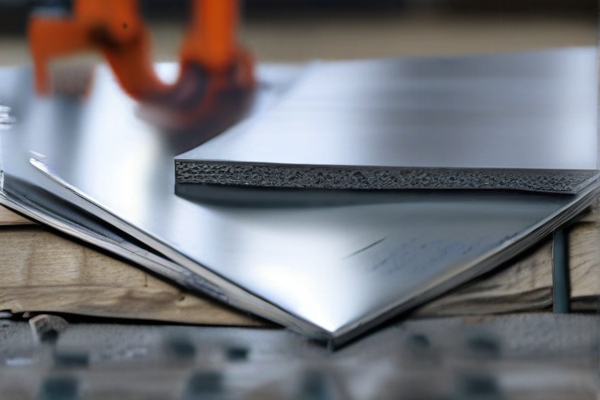

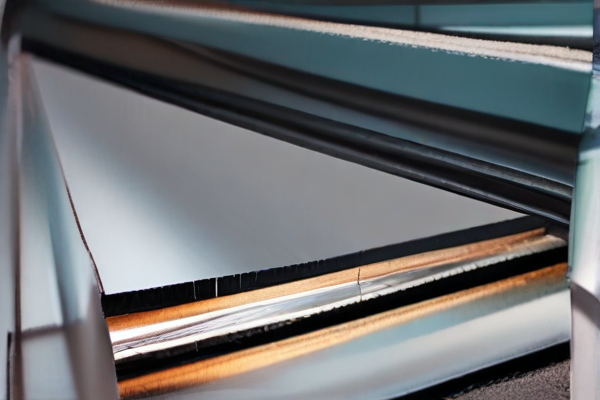

SourcifyChina employs advanced techniques to cut stainless steel sheets, ensuring precision and efficiency. The process starts with selecting premium-grade stainless steel, which guarantees durability and corrosion resistance. Laser cutting, plasma cutting, and waterjet cutting are the primary methods used, each chosen based on material thickness and end-use requirements.

Quality control is stringent at SourcifyChina, with multi-stage inspections integrated into the manufacturing process. Each cut is meticulously checked for accuracy using advanced measurement tools. The edges are then scrutinized for burrs or imperfections that might affect functionality or aesthetics.

To further ensure quality, SourcifyChina implements rigorous testing protocols. Samples from each batch undergo stress testing, corrosion resistance evaluation, and dimensional consistency checks. This ensures that every stainless steel sheet meets industry standards and customer specifications.

SourcifyChina also prioritizes environmental responsibility, employing eco-friendly practices in waste management and energy consumption. The company continuously invests in upgrading machinery and training staff, which reflects in enhanced quality and customer satisfaction.

In summary, the manufacturing process at SourcifyChina is a blend of precision, rigorous quality control, and sustainable practices. This comprehensive approach ensures that each stainless steel sheet not only meets but exceeds client expectations. As a result, SourcifyChina stands as a reliable partner in the metal fabrication industry, committed to delivering high-quality, precision-cut stainless steel sheets.

SourcifyChina boasts advanced capabilities in cutting stainless steel sheets, featuring precision technology that ensures clean and accurate cuts. Specialized machinery allows for custom shapes and sizes, meeting diverse industrial needs.

Their state-of-the-art laser cutting services handle varying thicknesses of stainless steel sheets with ease. This method offers high precision, smooth edges, and minimal material waste, enhancing overall efficiency.

In addition to laser cutting, SourcifyChina utilizes waterjet cutting for stainless steel. This technique enables intricate designs without thermal distortion, making it ideal for complex and delicate projects.

Plasma cutting is another essential service provided, especially for thicker stainless steel sheets. It guarantees quick and efficient processing, combining spee and accuracy to deliver quality results.

With a focus on innovation and customer satisfaction, SourcifyChina remains a leading provider of stainless steel cutting services. Their versatile approach ensures they can cater to any project requirements, delivering exceptional results every time.

Cutting stainless steel sheets efficiently can offer numerous benefits, including precision, cost-effectiveness, and improved work quality. Understanding the right techniques ensures you leverage these advantages fully.

– Precision: Proper cutting tools and techniques result in clean, accurate cuts, reducing material wastage.

– Cost-Effectiveness: Efficient cutting minimizes material loss and the need for additional tools or corrections.

– Time Savings: Quick and clean cuts streamline production processes, improving overall project timelines.

– Improved Safety: Using the right equipment reduces the risk of accidents and injuries.

– Versatility: Different cutting methods, such as laser cutting, water jet cutting, and plasma cutting, cater to various project needs.

– Material Integrity: Proper techniques help maintain the stainless steel’s structural integrity, ensuring durability and performance.

– Surface Finish: Clean cuts reduce the need for additional finishing processes, saving time and resources.

– Customization: Precise cutting allows for bespoke designs, fitting specific project requirements effortlessly.

These benefits underscore the importance of mastering the right techniques for cutting stainless steel sheets, ultimately enhancing both efficiency and quality in your projects.

Cutting stainless steel sheets requires precision and the right tools to achieve clean and accurate results without damaging the material. Here are some features to consider:

– Laser Cutting: Provides high precision and clean edges, ideal for intricate designs.

– Water Jet Cutting: Uses high-pressure water mixed with abrasive materials, suitable for thick sheets without thermal distortion.

– Plasma Cutting: Good for thick and thin sheets, though it may cause some material warping due to heat.

– Mechanical Sawing: Economical for simpler cuts, with options like hacksaws or band saws.

– Shearing: Effective for straight cuts, ideal for large sheets.

– CNC Machining: Offers high accuracy and consistency, especially for complex shapes.

– Angle Grinder: Useful for quick, rough cuts but may leave burrs needing additional finishing.

– Tin Snips: Best for small, simple, and manual cuts on thinner sheets.

– Nibbler Tools: Efficient for producing clean, precise cuts without edge deformation.

– Safety Gear: Protective equipment like gloves, goggles, and ear protection are critical for safety.

– Material Thickness: Choose the cutting method based on the thickness and type of stainless steel.

– Cutting Speed: Maintain appropriate cutting speeds to avoid overheating, especially in thermal methods.

– Edge Quality: Ensure post-cut treatments like deburring for a smooth finish.

– Tool Maintenance: Regularly maintain and sharpen cutting tools to ensure effective and safe operations.

– Budget and Scale: Consider cost-effectiveness and scale of the project for choosing the appropriate cutting method.

SourcifyChina specializes in providing top-quality stainless steel sheet cutting services for custom products and projects. Utilizing advanced machinery and skilled technicians, they ensure precise cuts tailored to your specifications. Their state-of-the-art laser and CNC cutting technologies guarantee high accuracy and minimal waste, making them a preferred choice for various industries.

For those involved in architectural design, automotive applications, or home improvement projects, SourcifyChina’s stainless steel cutting services offer unparalleled precision and durability. Their expertise ensures that each stainless steel sheet meets rigorous quality standards, providing a flawless finish that enhances the end product.

SourcifyChina also prioritizes customer satisfaction by offering personalized consultations to understand your specific needs. Their team of professionals works closely with clients to determine the most efficient cutting methods and materials, leading to highly customized and effective solutions.

Additionally, SourcifyChina’s robust project management capabilities facilitate timely deliveries and consistent quality control. By managing every aspect of the cutting process, from initial consultation to final delivery, they offer a seamless experience that tailors each project to the client’s unique requirements.

By choosing SourcifyChina, you gain access to a comprehensive range of services that ensure your custom stainless steel products are cut to perfection. Whether for large-scale manufacturing or small, specialized projects, their cutting-edge technology and customer-focused approach ensure superior results every time.

SourcifyChina is a premier company specializing in the precise cutting of stainless steel sheets for various industrial applications. Employing advanced technology and state-of-the-art machinery, SourcifyChina ensures high-quality, accurate cuts that meet stringent industry standards. The company utilizes techniques such as laser cutting, waterjet cutting, and plasma cutting to cater to diverse requirements, delivering results with superior finish and minimal wastage. With a team of experienced professionals, SourcifyChina prides itself on its commitment to excellence, quick turnaround times, and unparalleled customer service. By leveraging innovation and expertise, the company provides tailored solutions that address the unique needs of its clients, making it a trusted partner in the stainless steel processing industry.

Cutting stainless steel sheets is a vital process in the aerospace, defense, and marine industries, where precision and durability are paramount. Various methods such as laser cutting, plasma cutting, and water jet cutting are employed to ensure the stainless steel sheets meet the stringent specifications required in these sectors. Laser cutting utilizes focused beams of light to achieve high precision cuts, making it ideal for aerospace components that demand minimal tolerances and high quality. Plasma cutting, by ionizing gas to create a high-temperature plasma arc, offers a faster alternative for thicker sheets, often used in the manufacture of robust defense equipment. Water jet cutting, which employs a high-pressure stream of water mixed with abrasive particles, provides a cold cutting process, preventing thermal distortion and thus preserving the inherent properties of the stainless steel, crucial in marine applications where material fatigue and corrosion resistance are critical.

In aerospace engineering, components fabricated from stainless steel sheets must endure extreme stresses and environmental conditions, necessitating cuts that maintain structural integrity and aerodynamic performance. Similarly, in the defense industry, the precision cutting of stainless steel sheets is integral to producing components that meet rigorous safety and operational standards, including those for armored vehicles and weapon systems. The marine industry, on the other hand, relies on accurately cut stainless steel for the construction of ships and underwater vessels, where material strength and resistance to corrosive seawater are essential. Each of these high-stakes environments demands cutting techniques that not only provide precise and clean edges but also maintain the metal’s physical properties to ensure long-term reliability and safety.

Stainless steel sheet cutting is a crucial process in the automotive industry where precision and durability are paramount. In automotive applications, the steel sheets are often utilized for fabricating body panels, exhaust systems, and various structural components. The cutting methods employed can range from laser cutting to plasma cutting and water jet cutting. Laser cutting offers high precision and smooth edges, essential for parts that require exact dimensions and a flawless finish. Plasma cutting is favored for its ability to rapidly slice through thicker sheets, reducing production times for robust components like chassis parts. Water jet cutting, although slower, is preferred for intricate designs and when there’s a necessity to avoid thermal distortion, ensuring the structural integrity of the material.

In the electronics sector, stainless steel sheets are commonly used in the manufacturing of device enclosures, heat sinks, and structural frames for various equipment. The delicate and intricate nature of these components necessitates cutting methods that can maintain high levels of precision and avoid any form of material deformation. Laser cutting is often employed due to its capability to produce fine, detailed cuts with minimal thermal impact, making it ideal for circuits and small structural parts. For applications requiring minimal heat, such as components for semiconductor manufacturing equipment, water jet cutting is often the go-to method as it ensures a cold-cutting process that preserves the metallurgical properties of stainless steel. Both these cutting methods support the high demands for reliability, accuracy, and quality in the production of electronic components.

When it comes to the construction industry, the precision and quality of cuts in stainless steel sheets are pivotal for achieving durable and aesthetically pleasing structures. Cutting methods such as laser cutting, plasma cutting, and mechanical methods like using circular saws or tin snips cater to different project needs. Laser cutting, for instance, offers unparalleled precision and is ideal for intricate designs and high-volume tasks, although it requires more sophisticated equipment and safety measures. Plasma cutting provides a balance between precision and speed, making it suitable for both on-site adjustments and prefabrication stages. Mechanical methods, while less precise, are often the cost-effective choice for simple cuts and are more accessible for smaller jobs. Each method has its own set of advantages and limitations, and selecting the right technique is crucial for optimizing efficiency and ensuring the structural integrity of the construction project.

In the energy sector, efficient and precise cutting of stainless steel sheets is critical for the production and maintenance of equipment such as pipelines, reactors, and storage tanks. These components demand high precision and durability to withstand extreme conditions and prevent energy loss or hazards. Laser cutting stands out in this context for its accuracy and ability to handle complex shapes and thick materials without compromising the integrity of the steel. Plasma cutting can be employed for its speed and cost-effectiveness, especially in scenarios where quick fabrication or emergency repairs are needed. Mechanical methods are often reserved for less demanding situations or initial phases of manufacturing where fine precision is not paramount. The versatility and properties of stainless steel, combined with the appropriate cutting technique, ensure the optimized performance and longevity of energy infrastructure, thereby contributing to safer and more efficient energy production and distribution.

The industrial equipment industry employs a variety of techniques for cutting stainless steel sheets, each method tailored to match the specific requirements of the task. One commonly used technique is plasma cutting, which utilizes an accelerated jet of hot plasma to slice through stainless steel with high precision. This method is particularly effective for cutting thick stainless steel sheets and can be automated for enhanced efficiency and consistency. In industrial settings, CNC (Computer Numerical Control) plasma cutting machines are often employed, allowing for intricate patterns and designs to be executed swiftly and accurately. Another prevalent method is laser cutting, where a high-powered laser beam melts, burns, or vaporizes the metal along a focused line. Laser cutting is renowned for its clean edges and minimal material wastage, making it ideal for applications demanding high precision and fine detailing.

Water jet cutting represents another robust technique implemented within the industrial equipment sector for stainless steel sheet processing. This method uses a high-pressure stream of water, sometimes mixed with abrasive materials, to cut through the stainless steel. One of the main advantages of water jet cutting is that it does not generate heat, thereby minimizing thermal distortion and preserving the intrinsic properties of the stainless steel. Additionally, it is an environmentally friendly option as it generates minimal hazardous waste and does not produce harmful fumes. Each cutting method offers its unique benefits and is selected based on factors such as material thickness, desired finish, and production volume. By leveraging these advanced cutting technologies, the industrial equipment industry ensures precise, efficient, and sustainable processing of stainless steel sheets, catering to a broad range of applications from automotive and aerospace to construction and medical devices.

Medical device manufacturing often requires precise and clean cutting of stainless steel sheets, which are commonly used due to their durability, corrosion resistance, and biocompatibility. Cutting stainless steel sheets for medical devices, such as surgical tools, implants, or diagnostic equipment casings, demands methods that ensure minimal contamination, exact dimensions, and smooth edges. Laser cutting and waterjet cutting are two advanced techniques employed in the industry. Laser cutting utilizes a high-energy beam to vaporize the metal along a precise path, providing high accuracy and control, essential for intricate designs or small components. Waterjet cutting, on the other hand, employs a high-pressure stream of water mixed with abrasive materials to slice through the steel, offering the advantage of no thermal distortion and maintaining the material’s structural integrity.

The stringent quality control and precision requisite in medical device manufacturing necessitate the use of these cutting technologies. The laser cutting method provides superior precision and is advantageous for creating complex patterns with minimal material waste, which is critical in producing cost-effective medical devices. Meanwhile, waterjet cutting is highly valued for its ability to cut thicker sheets and different materials without altering their inherent properties, which is crucial when manufacturing devices that require both metal and non-metal parts. Both these methods enhance the overall efficiency and product quality, ensuring that medical devices meet strict regulatory standards. Efficient and precise stainless steel sheet cutting not only streamlines production but also ensures that the end products are safe, reliable, and effective for medical use, ultimately contributing to improved healthcare outcomes.

Cutting stainless steel sheet is a critical operation in both machining and manufacturing, requiring precision and optimal techniques to maintain the material’s integrity and finish. The nature of stainless steel, known for its durability and resistance to corrosion, often makes it challenging to cut due to its hardness and toughness. Common methods employed include laser cutting, water jet cutting, plasma cutting, and mechanical shearing. Laser cutting provides a high precision solution with the benefit of a clean cut and minimal heat-affected zones, ideal for intricate designs and thin sheets. Water jet cutting, which utilizes a high-pressure stream of water mixed with abrasive materials, cuts through stainless steel without generating heat, making it perfect for thicker sheets where thermal distortion is a concern.

In manufacturing applications, choosing the right method to cut a stainless steel sheet is crucial for both efficiency and end-quality. Mechanical cutting, such as using power shears or saws, is preferred for straight cuts in thicker sheets, though it requires meticulous setup to avoid damaging the material. Plasma cutting offers a balance of speed and precision, particularly useful for large-scale fabrications. Each method comes with its own set of parameters that need adjustment based on stainless steel grade and sheet thickness. For instance, adjusting the laser power or water jet pressure ensures clean cuts and reduces waste. Ultimately, selecting the appropriate cutting technique not only ensures operational efficiency but also contributes to producing high-quality, precise products in fields ranging from automotive to aerospace manufacturing.

Sure! Here is a list of FAQs with answers for manufacturing quality stainless steel sheets from SourcifyChina factory:

Q1: What types of stainless steel sheets can SourcifyChina provide?

A1: SourcifyChina offers various grades of stainless steel sheets, including 304, 316, 430, among others. Each grade has its specific properties suitable for different applications, ensuring the best quality for any project.

Q2: How does SourcifyChina ensure the quality of their stainless steel sheets?

A2: SourcifyChina adheres to strict quality control measures throughout the manufacturing process. This includes using certified raw materials, conducting regular inspections, and utilizing advanced machinery to produce precise and durable products.

Q3: What methods does SourcifyChina use to cut stainless steel sheets?

A3: SourcifyChina employs state-of-the-art cutting technologies such as laser cutting, plasma cutting, and water jet cutting. These methods provide clean, precise cuts while minimizing material waste and maintaining the structural integrity of the stainless steel sheet.

Q4: Can SourcifyChina customize the size and thickness of stainless steel sheets?

A4: Yes, SourcifyChina offers customization options for size, thickness, and finish based on the client’s requirements. Their flexible manufacturing capabilities ensure that they can meet specific project needs efficiently.

Q5: What are the lead times for orders from SourcifyChina?

A5: Lead times can vary based on the quantity and complexity of the order. Typically, standard orders are processed and shipped within 2 to 4 weeks. It’s best to contact SourcifyChina for a precise timeline.

Q6: Does SourcifyChina provide finishing services for stainless steel sheets?

A6: Yes, SourcifyChina offers various surface finishing options including polishing, brushing, and coating to enhance the appearance and performance of stainless steel sheets according to customer specifications.

Q7: How can I place an order or get a quote from SourcifyChina?

A7: Interested customers can contact SourcifyChina via their official website or direct email. They provide prompt responses and detailed quotations based on project specifications.

Q8: Are SourcifyChina’s stainless steel sheets compliant with international standards?

A8: Absolutely, SourcifyChina ensures that all their stainless steel products meet international standards such as ASTM, ISO, and EN, guaranteeing quality and reliability.

Certainly! Cutting stainless steel sheets from SourcifyChina factory requires precision and careful planning. Here are some tips to ensure you do it effectively:

1. Choose the Right Tool: For clean cuts, consider tools like laser cutters, plasma cutters, or stainless steel shears, depending on the thickness. Laser cutters are ideal for high precision, while plasma cutters work well for thicker sheets.

2. Safety First: Always wear protective gear, including gloves, safety goggles, and a face shield. Ensure your workspace is well-ventilated and free from inflammable materials.

3. Measure and Mark: Use a quality ruler and scribing tool to mark where the cut will be. Double-check measurements to avoid costly mistakes.

4. Secure the Sheet: Clamp the stainless steel sheet tightly on a stable workbench. This prevents movement during cutting, ensuring a straight, clean cut.

5. Select the Right Cutting Speed and Power: For laser and plasma cutters, adjust the speed and power settings according to the sheet’s thickness and material grade. Too much power can cause heat deformation, while too little may result in an incomplete cut.

6. Cut Gradually: If using a manual tool like an angle grinder or jigsaw, make several shallow passes instead of trying to cut through in one go. This reduces the risk of warping and ensures a smoother edge.

7. Cool Down the Metal: Cutting generates heat, which can warp the steel. Utilize cooling methods like a water jet or allow pauses in between cuts to cool down the metal.

8. Deburring: After cutting, the edges will be sharp and may have burrs. Use a deburring tool or a file to smooth out these edges for safety and a professional finish.

By following these tips, you can achieve precise and clean cuts on stainless steel sheets from SourcifyChina factory, suitable for various industrial and manufacturing applications.

Q1: What is the best method for cutting stainless steel sheets?

A1: The best methods for cutting stainless steel sheets are laser cutting, plasma cutting, water jet cutting, and mechanical cutting such as shearing or sawing. Each method has its advantages depending on the thickness and precision required.

Q2: Does SourcifyChina factory provide custom cutting services?

A2: Yes, SourcifyChina factory offers custom cutting services tailored to your specific requirements, utilizing advanced machinery like laser cutters and water jet cutters to achieve precise results.

Q3: What thickness range can SourcifyChina handle?

A3: SourcifyChina can manage stainless steel sheets ranging from very thin (0.5mm) to thick plates (50mm), ensuring high-quality cuts regardless of the sheet thickness.

Q4: What tolerances can SourcifyChina achieve with their cutting processes?

A4: SourcifyChina can achieve tight tolerances, typically within ±0.1mm for laser cutting and even finer depending on the precision requirements of your project.

Q5: How long does it typically take to complete a cutting order?

A5: Lead times can vary based on the complexity and volume of the order. Generally, SourcifyChina aims to complete standard orders within 5-7 business days.

Q6: Can SourcifyChina handle bulk orders for cutting stainless steel sheets?

A6: Yes, SourcifyChina is well-equipped to handle both small and bulk orders efficiently, ensuring timely delivery without compromising quality.

Q7: What type of stainless steel grades can SourcifyChina cut?

A7: SourcifyChina can process a wide range of stainless steel grades, including common ones like 304 and 316, as well as specialized grades upon request.

Q8: What information do I need to provide for a cutting quote?

A8: To obtain a quote, provide details like the type of stainless steel, thickness, dimensions, quantity, and the preferred cutting method, along with any specific tolerances or finishing requirements.

Q9: Are there any special considerations for cutting stainless steel sheets?

A9: It’s important to consider the grade and thickness of the stainless steel, desired edge quality, and specific application to determine the best cutting method. SourcifyChina’s experts can assist in identifying the most suitable approach.

Sourcing stainless steel sheets and understanding how to cut them efficiently can be pivotal for your projects. SourcifyChina is an excellent factory partner for such needs. Below are some tips:

1. Specify Requirements: Clearly define the grade, thickness, size, and finish of the stainless steel sheets. This information helps the factory provide accurate quotes and ensures you get the right material.

2. Supplier Verification: Conduct thorough research on SourcifyChina. Check reviews, request samples, and ask for references from other clients to ensure reliability and quality.

3. Communicate Needs: Establish open communication channels. Discuss your cutting requirements, such as laser cutting, water jet, plasma cutting, or shearing, depending on your desired precision and edge finish.

4. Quality Checks: Ensure the factory follows quality assurance processes. Request inspection reports and consider third-party inspections.

5. Lead Time and Logistics: Clarify the lead times for production and delivery. Discuss logistics and shipping options to ensure timely and cost-effective delivery.

6. Cost Analysis: Compare quotes from SourcifyChina with other suppliers. Factor in material, cutting costs, and shipping to make a well-rounded decision.

7. Sustainability: Ask about the factory’s sustainability practices. This can be crucial for companies focusing on eco-friendly operations.

Cutting Techniques:

– Laser Cutting: Offers high precision and is suitable for intricate designs.

– Water Jet Cutting: Provides a smooth finish and is ideal for heat-sensitive materials.

– Plasma Cutting: Efficient for thick sheets but may require secondary finishing.

– Shearing: Fast but may leave rough edges requiring deburring.

By following these steps and maintaining clear communication with SourcifyChina, you can efficiently source and cut stainless steel sheets tailored to your specific project needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.

How can I help you? :)