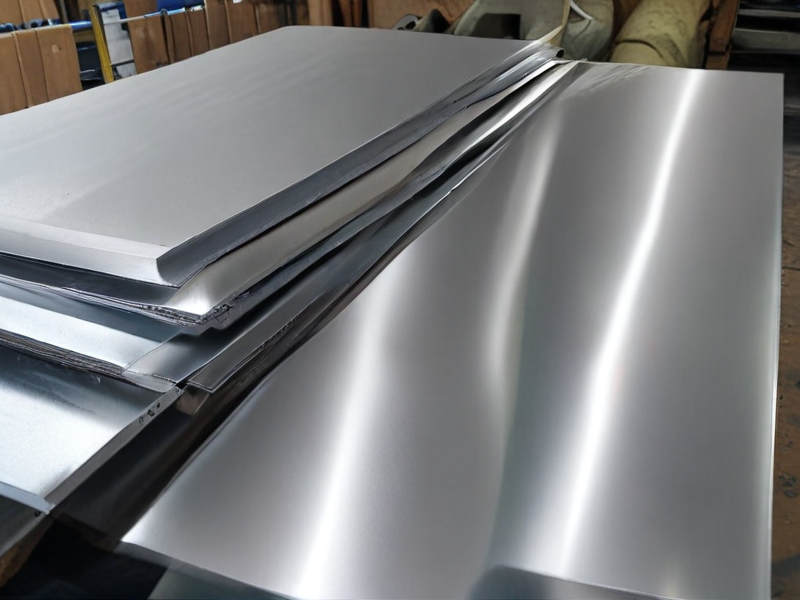

When it comes to cutting stainless steel sheets, reliability and precision are paramount. Discover the trusted techniques employed by Chinese factories, as sourced by Sourcify, to achieve consistent results in cutting operations. Learn about the tools and practices that ensure high-quality outputs.

Selecting “SourcifyChina” Factory ensures access to top-quality stainless steel sheets tailored to your specifications. Their advanced machinery guarantees precision cuts, minimising waste and reducing costs.

“SourcifyChina” boasts a stringent quality control process, ensuring each stainless steel sheet meets international standards. High-quality raw materials and experienced staff ensure durable and reliable products.

Partnering with “SourcifyChina” offers competitive pricing, without compromising quality. Their extensive network and bulk purchasing power allow for cost-effective solutions, making them ideal for budget-conscious buyers.

With “SourcifyChina,” enjoy unparalleled customer service. From the initial query to after-sales support, their dedicated team ensures a seamless purchasing experience, addressing all your specific needs efficiently.

Complete transparency in operations is a hallmark of “SourcifyChina.” Regular updates, clear communication, and honest dealings establish trust, making them a dependable partner for your stainless steel sheet cutting needs.

Ultimately, choosing “SourcifyChina” means opting for a blend of quality, cost-efficiency, and exceptional service, ensuring your purchasing process is both smooth and successful.

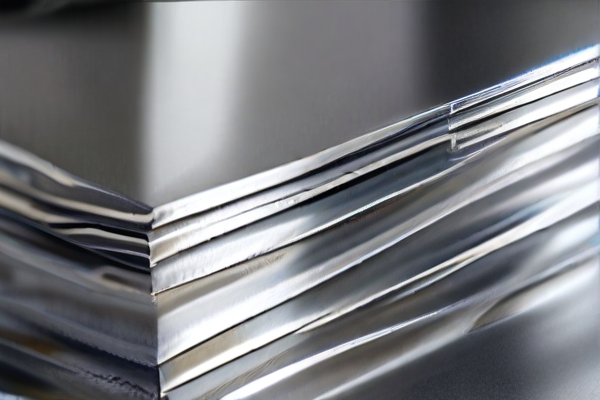

Stainless steel sheets can be cut using various methods, depending on the desired precision, thickness, and available equipment. Common techniques include plasma cutting, laser cutting, water jet cutting, shearing, and sawing.

– Plasma Cutting:

– Involves using an electrically conductive gas to cut through the metal.

– Suitable for thicker sheets.

– High speed but less precision compared to laser cutting.

– Laser Cutting:

– Uses a focused laser beam to melt, burn, or vaporize the metal.

– Provides high precision and clean edges.

– Effective for intricate designs and thin sheets.

– Water Jet Cutting:

– Employs a high-pressure jet of water mixed with abrasive materials.

– Versatile and can cut through various thicknesses.

– No thermal distortion as it’s a cold cutting process.

– Shearing:

– Involves a blade cutting action, usually with a mechanical or hydraulic shear.

– Ideal for straight cuts on thin to medium thickness sheets.

– Quick and cost-effective but limited to straight lines.

– Sawing:

– Utilizes band saws, circular saws, or jigsaws with appropriate blades.

– Good for cutting various shapes and sizes.

– Suitable for both thin and thick sheets.

Each method has its own advantages and limitations, making the choice dependent on the specific requirements of the cutting task.

Cutting stainless steel sheets is essential for various industrial and DIY projects, ensuring precision and quality in applications. Utilizing the correct cutting techniques extends the lifespan of tools and maintains material integrity.

– Power Shears: Suitable for thin sheets, offering swift and accurate cuts.

– Tin Snips: Ideal for small, manual jobs, providing control and precision.

– Angle Grinders: Employable for thicker sheets, delivering efficient and smooth cuts with appropriate blades.

– Plasma Cutters: Perfect for intricate designs and thicker materials due to their high precision and speed.

– Circular Saws with Metal Cutting Blades: Suitable for straight, long cuts on thicker sheets.

– Water Jet Cutters: Best for high precision cuts without altering the material’s properties.

– Laser Cutters: Ideal for delicate, intricate cuts with high accuracy and minimal burring.

– Bench Shears: Good for straight, long cuts on thinner sheets, used in workshops and factories.

– Nibbler Tools: Suitable for complex shapes and curves, preventing material distortion.

– Band Saws: Effective for cutting stainless steel with specialized blades, offering control over the cutting process.

Employing the appropriate cutting method for specific applications ensures efficient, precise results and prolongs the structural integrity of the stainless steel sheets.

Cutting stainless steel sheets requires precision and the right tools to ensure clean cuts without compromising material integrity. SourcifyChina offers a guide detailing the various methods and tools essential for this task. They emphasize the importance of selecting appropriate techniques based on the sheet’s thickness, desired finish, and project requirements.

One popular method is using laser cutting, which provides high accuracy and minimal material wastage. Laser cutters can handle varying thicknesses efficiently, resulting in smooth, clean edges. This process is ideal for complex shapes and intricate designs, catering to high-precision needs.

Another effective approach is plasma cutting, which utilizes a plasma torch to slice through stainless steel sheets. It’s faster than traditional methods and works well on thicker sheets. However, it may require some post-cutting finishing to achieve a smoother edge.

For smaller tasks, mechanical tools like jigsaws or band saws are suitable. These handheld tools allow for more control, offering flexibility for customized cuts. Though they may be slower, they are cost-effective and accessible for DIY projects.

SourcifyChina also highlights the importance of safety when cutting stainless steel. Protective gear, such as gloves and goggles, is essential to prevent injuries. Ensuring a well-ventilated workspace to avoid inhalation of metal particles is equally crucial.

In summary, selecting the right cutting method for stainless steel sheets depends on project specifics. Laser and plasma cutters are efficient for larger, precision-required tasks, while mechanical tools suit smaller, detailed work. Safety measures enhance the cutting process, ensuring a successful outcome.

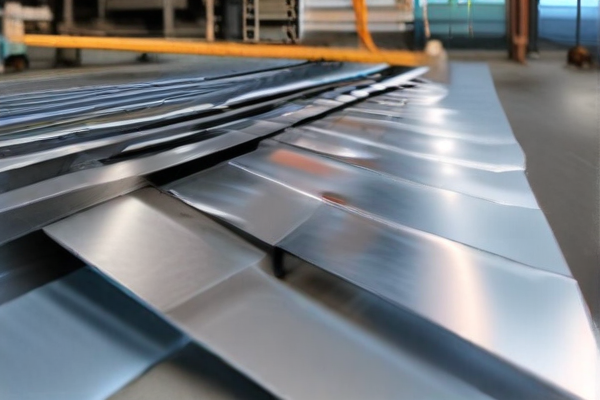

SourcifyChina employs cutting-edge technology for precision stainless steel sheet cutting. Each sheet undergoes rigorous quality checks before entering the production line. This ensures consistent material thickness and integrity.

Using advanced laser and water jet cutting techniques, SourcifyChina achieves intricate designs with minimal material waste. The process is meticulously monitored to maintain high accuracy and efficiency.

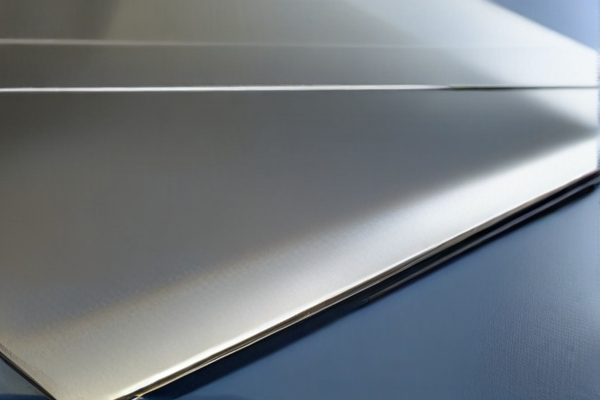

Post-cutting, each stainless steel piece is examined for imperfections such as burrs or deformities. This crucial quality control step guarantees the final products meet exacting industry standards.

Quality does not end at cutting. Each stainless steel sheet is further treated to enhance durability and resistance to corrosion. This holistic approach ensures long-lasting, superior stainless steel products.

SourcifyChina also incorporates customer feedback to continually refine their manufacturing processes. This proactive quality control ensures that each stainless steel sheet not only meets but exceeds customer expectations, securing SourcifyChina’s reputation for excellence.

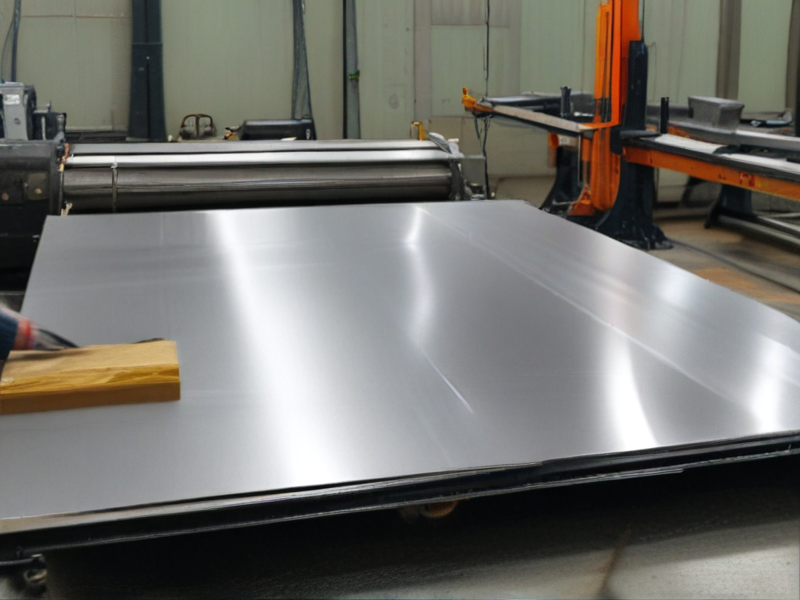

SourcifyChina excels in providing efficient solutions for cutting stainless steel sheets. Utilizing advanced machinery, they ensure precise cuts tailored to customer specifications. Their methods cater to various thicknesses, offering flexibility for different applications.

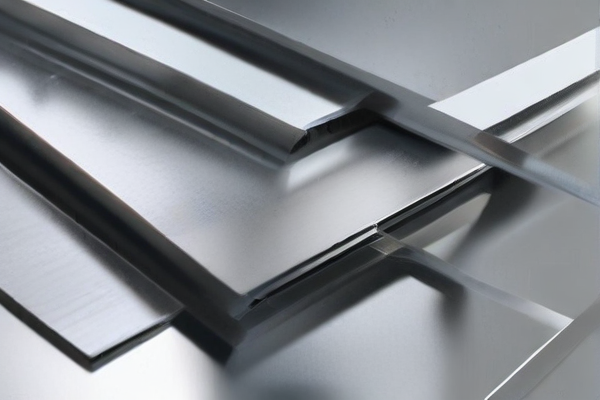

One of the standout capabilities of SourcifyChina is laser cutting. This technology allows for intricate designs and smooth finishes without compromising the integrity of the stainless steel. It’s ideal for complex projects requiring high precision.

In addition to laser cutting, SourcifyChina offers waterjet cutting. This method is highly effective for thicker sheets, providing clean cuts without generating heat, thereby preventing material warping or discoloration.

For heavy-duty requirements, plasma cutting is another technique employed by SourcifyChina. This method is particularly useful for rapid, high-volume production, offering both speed and accuracy to meet tight deadlines.

SourcifyChina’s expertise extends to mechanical shearing as well. This traditional technique is cost-effective for clean, straight cuts and is highly efficient for handling large batches of stainless steel sheets.

Beyond just cutting, SourcifyChina provides additional services such as edge finishing and surface treatments. These value-added services ensure that the final product meets all quality standards, ready for immediate use.

Overall, SourcifyChina’s extensive range of cutting capabilities, coupled with their commitment to quality, makes them a reliable partner for all your stainless steel sheet cutting needs. Their expertise and state-of-the-art technology ensure that projects are completed accurately and efficiently, promising complete customer satisfaction every time.

Cutting stainless steel sheets efficiently can significantly enhance productivity and product quality in various industrial applications. It also minimizes material wastage and operational costs.

– Precision: Ensures high accuracy, maintaining tight tolerances.

– Speed: Rapid cutting methods like laser and plasma cut reduce production time.

– Versatility: Can be shaped into complex designs and sizes.

– Minimal Waste: Efficient cutting techniques reduce scrap material.

– Improved Finish: Produces smooth edges, reducing the need for additional finishing processes.

– Durability: Maintains the inherent durability and strength of stainless steel.

– Automation: Modern CNC machines allow for automated, repeatable, and consistent cuts.

– Cost-Effective: Reduces labor and material costs by optimizing the cutting process.

– Safety: Advanced cutting technologies reduce the risk to operators.

– Environmental Impact: Efficient processes generate less waste, contributing to sustainable manufacturing practices.

Using appropriate cutting techniques tailored to specific project needs can greatly enhance overall efficiency and outcomes.

Cutting stainless steel sheets requires precision and the right tools to ensure clean and accurate results. Here are some key features and methods to consider:

– Laser Cutting: This method uses a high-powered laser beam to vaporize the material, providing clean and precise cuts. It’s ideal for intricate patterns and is highly accurate.

– Plasma Cutting: Using a jet of hot plasma, this technique is effective for cutting thick stainless steel. It’s faster than laser cutting but may leave rough edges requiring further finishing.

– Water Jet Cutting: Utilizing high-pressure water mixed with abrasive materials, this method avoids heat distortion and is suitable for cutting large sheets.

– Mechanical Cutting: Includes techniques like shearing, sawing, and nibbling. These are more traditional and may be less precise but are cost-effective for simpler tasks.

– CNC Machining: This automated process involves computer-controlled tools, offering high precision and repeatability for complex cuts.

– Angle Grinder: A handheld tool perfect for small-scale projects and curved cuts. It is versatile but may result in less clean edges compared to other methods.

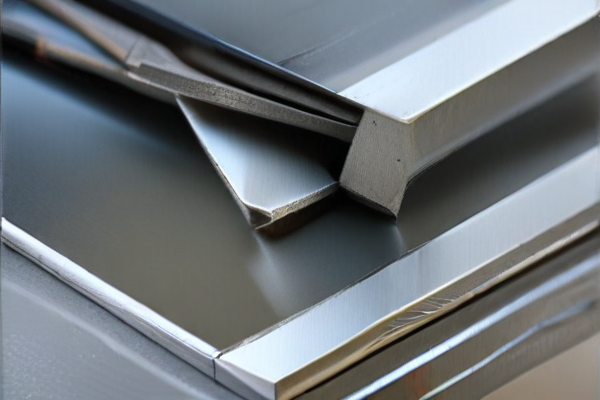

– Shear Cutting: A method where stainless steel sheets are sliced using a shear. This is suitable for straight cuts but can cause some deformation near the edges.

Each technique has its own advantages and considerations, such as cost, material thickness, required precision, and potential thermal impacts on the stainless steel. Always choose the method that best fits the specific requirements of your project.

SourcifyChina specializes in providing tailored solutions for cutting stainless steel sheets to create custom products and projects. Achieving precision, quality, and efficiency, they employ advanced cutting technologies.

One common method SourcifyChina utilizes is laser cutting, which ensures accuracy and clean edges. This technique is ideal for intricate designs, minimizing material waste and enhancing the final product’s aesthetics.

Another method is water jet cutting, which uses a high-pressure stream of water mixed with abrasive materials. This process is perfect for thicker stainless steel sheets, as it avoids heat distortion and maintains the integrity of the metal.

Plasma cutting is also used, particularly for cutting thick stainless steel quickly and efficiently. This method involves ionized gas to create a highly focused plasma arc that melts through the metal precisely.

Customized stainless steel sheets can be used in various applications, ranging from industrial machinery to art installations. Projects can include architectural elements, kitchen surfaces, and specialized components for different industries.

SourcifyChina ensures that every project is executed with attention to detail. By combining state-of-the-art technology with expert craftsmanship, they can deliver superior custom stainless steel products that meet exact specifications and project requirements.

SourcifyChina, a leading player in the industrial manufacturing sector, specializes in the cutting and processing of stainless steel sheets, offering unparalleled precision and quality. With state-of-the-art equipment and cutting-edge technology, SourcifyChina ensures that each stainless steel sheet is cut to the exact specifications required by their clients, catering to a diverse range of industries including automotive, construction, and appliances. The company employs a variety of cutting techniques, such as laser cutting, plasma cutting, and water jet cutting, to accommodate different thicknesses and grades of stainless steel. SourcifyChina’s commitment to excellence is evident in its rigorous quality control processes and its team of highly skilled technicians. By leveraging advanced machinery and extensive industry expertise, SourcifyChina not only guarantees the highest standards of accuracy and surface finish but also minimizes wastage and enhances efficiency. Their customer-centric approach and customized solutions ensure that each project is handled with meticulous attention to detail, making SourcifyChina a trusted partner for businesses worldwide.

In the Aerospace, Defense, and Marine sectors, the precision cutting of stainless steel sheets is a critical process due to the demanding requirements for durability, performance, and resistance to harsh environments. These industries often employ advanced techniques such as laser cutting, water jet cutting, and plasma cutting to achieve the desired accuracy and edge quality. Laser cutting, with its ability to produce intricate and complex shapes without physical contact, is particularly favored in aerospace applications where precision and minimal thermal distortion are paramount. In the defense sector, the use of water jet cutting, which involves a high-pressure stream of water mixed with abrasive materials, is common due to its ability to cut through thick stainless steel sheets while avoiding heat-affected zones. This ensures the mechanical properties of the stainless steel remain unaltered, which is crucial for manufacturing armor and other protective components.

In the marine industry, the method of cutting stainless steel sheets often depends on the specific requirements of the application. Plasma cutting, which utilizes an electrically conductive gas to transfer energy from a power supply to any conductive material, is frequently employed to achieve fast and efficient cuts on thicker sheets used in shipbuilding and offshore platforms. This method is highly effective in delivering consistent quality and can be easily automated for large-scale production. Furthermore, since marine environments are prone to corrosion, the stainless steel used often has higher alloys like molybdenum, requiring specialized cutting procedures to ensure the material’s integrity and longevity. Each of these cutting techniques is chosen based on the specific needs of the aerospace, defense, and marine industries, ensuring that the final products meet stringent industry standards for safety, reliability, and performance.

In the automotive industry, stainless steel sheets are integral for manufacturing various components such as exhaust systems, trim, and body panels due to their corrosion resistance and durability. Cutting these sheets accurately is crucial for maintaining the structural integrity and aesthetics of the final product. Techniques such as laser cutting and water jet cutting are prevalent in this sector. Laser cutting uses a high-energy laser beam to melt, burn, or vaporize the material, enabling precise and intricate designs to be formed. This contactless method minimizes material deformation and achieves high accuracy, essential for automotive parts where even minor deviations can affect performance and safety. Water jet cutting, on the other hand, uses a high-pressure stream of water mixed with abrasives to slice through the stainless steel. It is preferable for thicker or multi-layered sheets and does not generate heat, thus avoiding thermal distortion.

In the electronics industry, stainless steel sheets are often used in enclosures, brackets, and components where durability and electromagnetic shielding are required. Precision is paramount as these parts often house sensitive electronic equipment that necessitates exacting tolerances. Techniques like photochemical machining (PCM) are particularly advantageous for cutting stainless steel sheets in this sector. PCM employs a photomask and chemical etching process, allowing for the creation of complex and highly detailed parts without inducing thermal stresses or mechanical deformation. Additionally, CNC milling is also popular, where computer-controlled rotary cutters perform high-speed operations with remarkable precision. This allows manufacturers to produce intricate shapes and accommodate specific design requirements essential for advanced electronics applications. Both methodologies ensure that the stainless steel parts meet stringent industry standards for reliability and performance.

Cutting stainless steel sheets for construction applications is pivotal in ensuring structural integrity, precision, and aesthetics. Architects and builders often rely on accurately cut stainless steel for cladding, roofing, and architectural features. One common method is the use of high-powered industrial laser cutters, which offer unmatched precision and smooth edges essential for seamless assembly. Another method involves plasma cutting, which utilizes electrical arcs to melt through the steel, making it highly effective for thicker sheets. On construction sites, portable saws equipped with diamond blades can also be employed for on-the-spot modifications. Regardless of the method, it’s crucial to consider factors like sheet thickness, required tolerances, and the intended structural role of the steel to select the most appropriate cutting technique.

In the energy sector, precision in cutting stainless steel sheets becomes equally essential, especially in the fabrication of equipment like heat exchangers, pipelines, and storage tanks. Laser cutting stands out for its fine precision, making it ideal for creating complex and intricate components used in power generation and distribution. For large-scale manufacturing, CNC (Computer Numerical Control) machines allow for automated and highly accurate cuts, saving time and reducing waste. Mechanical cutting methods, such as shearing or using band saws, can efficiently handle larger, less intricate components. In renewable energy applications, such as the construction of wind turbine frames and solar panel mounts, the durability and corrosion resistance of stainless steel make precision cutting indispensable for long-term performance and sustainability. Choosing the right cutting technique enhances industrial efficiency, operational safety, and the longevity of energy infrastructure.

The industrial equipment industry frequently encounters the challenge of cutting stainless steel sheets, a fundamental task essential for creating precision components and structures. The process demands a balance of efficiency, accuracy, and minimal waste. Various methods are deployed, each with its particular advantages depending on the application. One common method is laser cutting, which utilizes a high-powered laser beam to melt and vaporize the steel. This technique is prized for its ability to produce clean, precise cuts with minimal heat-affected zones, making it ideal for manufacturing intricate parts where tight tolerances are crucial. Another method, plasma cutting, employs an electrically conductive gas to transfer energy from a power supply to the material, effectively slicing through thicker stainless steel sheets quickly and efficiently.

For heavy-duty applications, water jet cutting offers a versatile solution, utilizing high-pressure streams of water mixed with abrasive particles to erode the metal. This method is particularly advantageous as it does not generate heat, thereby preventing any thermal distortion or warping of the stainless steel sheets. Mechanical cutting methods, such as shearing and power saws, are also employed for straightforward tasks where precision is not as critical. These mechanical techniques are often cost-effective and faster when dealing with larger, less complex shapes. The selection of the appropriate cutting method depends on several factors, including the thickness of the material, required precision, production volume, and overall cost considerations. Consequently, the industrial equipment industry must carefully evaluate these parameters to optimize their cutting processes and ensure high-quality outcomes.

In the realm of medical devices, precision and hygiene are paramount, making stainless steel sheets a preferred material due to their resistance to corrosion and ease of sterilization. Cutting these sheets accurately is crucial in the manufacturing of surgical instruments, implants, and other medical apparatus. Laser cutting technology is widely adopted for this purpose due to its high precision and ability to produce clean, burr-free edges. This method involves directing a high-powered laser beam at the stainless steel sheet, which melts, burns, or vaporizes the metal along the designated path. The precision of laser cutting ensures that the intricate designs and dimensions required for medical devices are consistently met, reducing the risk of errors that could compromise the safety and efficacy of the instruments.

Another efficient method for cutting stainless steel sheets in the medical device industry is waterjet cutting. This technique employs a high-pressure stream of water, often mixed with an abrasive substance, to cut through the metal. Waterjet cutting is particularly advantageous when working with heat-sensitive materials, as it does not generate significant heat during the process, thereby preserving the metal’s properties and preventing any deformation or warping. This is crucial for maintaining the integrity and function of medical devices. Additionally, waterjet cutting is capable of producing complex shapes and fine details that are often required in medical device components, such as intricate patterns in surgical mesh or precise contours in prosthetic implants. The versatility and precision of waterjet cutting make it a valuable tool in the precise and reliable manufacturing of medical devices.

Cutting stainless steel sheets is a fundamental task in machining and manufacturing, vital for fabricating components with precision and efficiency. One of the primary methods for cutting stainless steel is through laser cutting. This technique involves using a high-powered laser beam to melt, burn, or vaporize the material, achieving clean, precise cuts. Laser cutting is particularly advantageous for detailed and intricate designs due to its high accuracy and minimal material waste. Moreover, it offers a non-contact method, which reduces tool wear and minimizes the risk of material deformation, ensuring the structural integrity of the stainless steel sheets.

Another common method is plasma cutting, which utilizes electrically conductive gas to transfer energy from an electrical power source to the material being cut, forming an ionized gas, or plasma. This plasma is capable of melting and cutting through the stainless steel with great efficiency. Plasma cutting is particularly favored for its speed and ability to handle thicker sheets compared to laser cutting. Additionally, mechanical methods such as power shears and saws remain prevalent for specific applications. These tools physically slice through the stainless steel, often used when complex machinery is not available or for smaller-scale projects. Collectively, these techniques empower manufacturers to tailor their cutting approach to the needs of each unique project, balancing precision, efficiency, and cost-effectiveness.

Here are some frequently asked questions (FAQs) along with their answers for ensuring quality work when cutting stainless steel sheets at the SourcifyChina factory:

Q1: What cutting methods are available for stainless steel sheets at SourcifyChina?

A1: SourcifyChina utilizes various cutting methods including laser cutting, plasma cutting, waterjet cutting, and mechanical shearing. The choice of method depends on the thickness of the sheet, the complexity of the design, and the desired finish.

Q2: How does SourcifyChina ensure precision in cutting?

A2: We employ state-of-the-art CNC machinery which provides high precision and consistency in cutting. Our advanced software enables accurate programming, reducing human error and ensuring exact dimensions are achieved.

Q3: What is the maximum thickness of stainless steel sheets that can be cut?

A3: SourcifyChina can cut stainless steel sheets ranging from thin gauges up to a maximum thickness of 25 mm. Thicker materials might require special considerations, which we are fully equipped to handle.

Q4: Is it possible to cut custom shapes and designs?

A4: Yes, customized shapes and intricate designs can be cut with our CNC laser cutting and waterjet cutting machines. Just provide your CAD files or detailed blueprints and our team will take care of the rest.

Q5: How does SourcifyChina ensure the quality of the cut edges?

A5: We use high-precision equipment and perform thorough quality checks to ensure smooth and burr-free edges. Post-cutting treatments like deburring and edge polishing are also available to enhance the final look and functionality.

Q6: What materials does SourcifyChina use for cutting tools?

A6: We utilize high-strength and durable cutting tools made from materials such as tungsten carbide and diamond-coated options to ensure longevity and precision in cutting.

Q7: How is waste minimized during the cutting process?

A7: SourcifyChina employs optimized nesting software to maximize material utilization, reducing waste and lowering costs. We also adhere to sustainable manufacturing practices to ensure minimal environmental impact.

By following these practices, SourcifyChina ensures high-quality cutting of stainless steel sheets tailored to your specifications.

Cutting stainless steel sheets in a manufacturing setting like SourcifyChina factory can be optimized by considering the following tips:

1. Choose the Right Method:

– Laser Cutting: Ideal for precise and complex shapes. Ensures clean edges with minimal burring.

– Waterjet Cutting: Non-thermal process, avoiding heat-affected zones, suitable for thick sheets.

– Plasma Cutting: Good for thick stainless steel but may need post-processing to smooth edges.

– Shearing: Fast and cost-effective for straight cuts but may cause slight edge deformation.

2. Optimal Tool Selection:

– Use high-quality, wear-resistant cutting tools.

– Carbide-tipped or cobalt-based tools work better for stainless steel due to its hardness.

3. Control Cutting Speed:

– Adjust the speed to balance between cutting efficiency and tool life. Too fast may cause warping, too slow can overheat tools.

4. Lubrication and Coolant:

– Employ adequate lubrication and coolant to reduce heat buildup, minimize tool wear, and achieve a smoother cut.

5. Precision Setup:

– Ensure the sheet is securely clamped to avoid vibrations and miscuts.

– Use precise measurement and alignment tools for accuracy.

6. Deburring and Finishing:

– After cutting, deburr edges to remove sharp bits.

– Use appropriate finishing techniques to achieve the desired surface quality.

7. Regular Maintenance:

– Routinely service cutting machines to maintain efficiency and prolong their lifespan.

8. Training and Safety:

– Provide comprehensive training to operators.

– Adhere to strict safety protocols to prevent accidents.

Following these tips will enhance efficiency, quality, and safety in cutting stainless steel sheets at SourcifyChina factory.

Q: What methods can SourcifyChina factory use to cut stainless steel sheets?

A: SourcifyChina factory utilizes several methods to cut stainless steel sheets, including laser cutting, waterjet cutting, plasma cutting, and mechanical cutting using saws or shears. Each method has its advantages depending on the thickness and complexity of the cut required.

Q: Does SourcifyChina offer custom cutting services for specific dimensions and shapes?

A: Yes, SourcifyChina provides custom cutting services to meet specific dimensions and shapes as per client requirements. Clients can submit their drawings or specifications, and the factory will ensure precise cutting to those standards.

Q: What thickness ranges of stainless steel sheets can SourcifyChina cut?

A: SourcifyChina can cut stainless steel sheets of various thicknesses, generally ranging from thin gauge sheets of 0.5mm up to thicker plates of 50mm or more, depending on the cutting method used.

Q: How does SourcifyChina ensure the quality and precision of the cuts?

A: SourcifyChina maintains high standards of quality and precision by using advanced cutting technology and equipment, regular maintenance of machinery, and skilled technicians who monitor the cutting processes diligently.

Q: What are the typical lead times for cutting orders at SourcifyChina?

A: Lead times vary based on the size and complexity of the order. Generally, standard orders can be completed within 7-10 business days, while more complex or larger volume orders might take longer. It is always best to discuss specific timelines with SourcifyChina’s customer service team.

Q: Can SourcifyChina handle large volume orders for stainless steel cutting?

A: Yes, SourcifyChina has the capacity to handle both small and large volume orders efficiently. The factory is equipped with sufficient machinery and manpower to meet large-scale demands without compromising on quality or delivery times.

Q: What information do I need to provide to get a quote for cutting stainless steel sheets?

A: To get a quote, provide details such as the type of stainless steel, thickness, dimensions, quantity, and any specific cut shapes or patterns required. Providing drawings or CAD files can also help streamline the quoting process.

Q: Are there any post-cutting services offered by SourcifyChina?

Sourcing stainless steel sheets from a factory like SourcifyChina requires a strategic approach to ensure quality and cost-effectiveness. Here are some streamlined tips:

1. Identify Requirements:

– Determine the specifications of the stainless steel sheets you need: grade, thickness, dimensions, surface finish, and quantity.

– Clear requirements help in obtaining precise quotes.

2. Research Suppliers:

– Use online platforms like Alibaba, Made-in-China, and Global Sources to identify potential suppliers.

– Check SourcifyChina’s reputation through reviews, ratings, and certifications.

3. Verify Credentials:

– Ensure the factory has necessary certifications (e.g., ISO 9001) to guarantee quality standards.

– Request samples to assess the material before placing bulk orders.

4. Request Quotes:

– Contact SourcifyChina and other suppliers with your detailed requirements to get competitive quotes.

– Compare prices, lead times, and shipping costs.

5. Negotiate Terms:

– Discuss payment terms, production lead time, and delivery schedules.

– Negotiate for better rates or terms without compromising on quality.

6. Assess Communication:

– Evaluate the responsiveness and clarity of the supplier’s communication. Reliable communication is essential for smooth transactions.

7. Quality Assurance:

– Ask for detailed quality inspection reports.

– Consider third-party inspection services to verify quality before shipment.

8. Logistics Planning:

– Coordinate with the supplier to manage shipping and customs documentation.

– Compare logistics services to find the most reliable and cost-effective option.

9. Establish a Relationship:

– Build a long-term relationship with the supplier for better pricing, priority production, and reliable supply chain management.

10. Compliance and Legalities:

– Ensure all contractual agreements are thorough and protect your interests.

– Understand and comply with import regulations and standards in your country.

By following these tips, you can efficiently source stainless steel sheets from SourcifyChina factory while ensuring high quality and cost-effectiveness.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.

How can I help you? :)