Choosing SourcifyChina Factory provides buyers with a reliable source for high-quality stamped parts from China. With years of experience and a proven track record, the factory ensures precision and durability in every piece produced.

SourcifyChina’s state-of-the-art facilities leverage cutting-edge technology to meet exact specifications. Their dedicated team of skilled engineers and workers maintain rigorous standards, ensuring each stamped part meets industry requirements.

Competitive pricing is another advantage of choosing SourcifyChina Factory. By streamlining production processes and reducing waste, the factory offers cost-effective solutions without compromising on quality, making it an ideal partner for global buyers.

Moreover, SourcifyChina Factory values transparency and clear communication. From initial inquiry to final delivery, they provide timely updates, address concerns promptly, and ensure a smooth purchasing experience, building trust and long-term relationships.

In essence, SourcifyChina Factory combines quality, affordability, and excellent customer service. By choosing them, buyers can confidently source stamped parts that meet their exact needs, knowing they are backed by a dependable and efficient manufacturing partner.

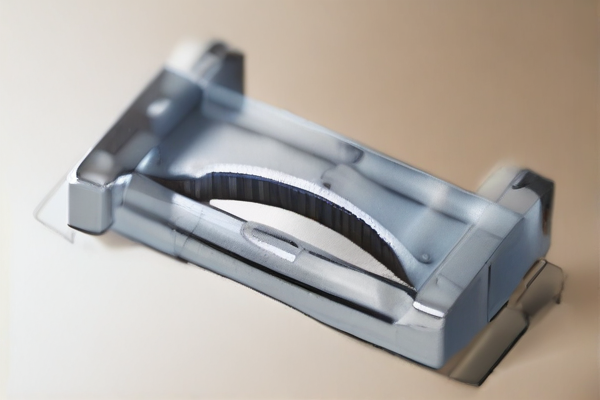

Stamped parts encompass a wide range of components created by pressing or stamping materials such as metal or plastic into specific shapes. These parts are essential in various industries due to their precision and efficiency.

– Progressive Die Stamping: Utilizes a series of dies to perform multiple cutting, bending, and punching operations.

– Transfer Die Stamping: Moves parts manually or automatically from one station to another for operations.

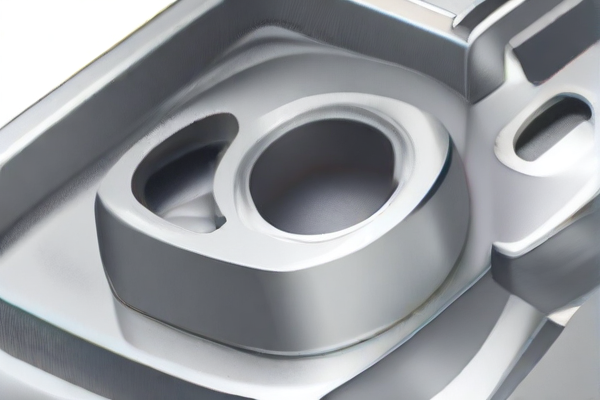

– Deep Draw Stamping: Forms the part through deep drawing techniques into a three-dimensional shape.

– Fine Blanking: Achieves high precision by shearing metal with minimal burrs or defects.

– Four-Slide Stamping: Involves tooling from four sides, ideal for intricate parts.

– Hot Stamping: Uses heat to shape strong, lightweight parts, primarily for automotive applications.

– Cold Stamping: Maintains material strength without applying heat, suitable for less complex shapes.

– Short-Run Stamping: Cost-effective for smaller production volumes.

– High-Speed Stamping: Produces large quantities at rapid rates, maintaining precision.

– Compound Die Stamping: Performs multiple operations in a single stroke for improved efficiency.

Options for materials include:

– Steel: Offers durability and versatility.

– Aluminum: Lightweight and resistant to corrosion.

– Copper: Excellent for electrical components.

– Brass: Good machinability and finish.

– Plastics: Used for lightweight and corrosion-resistant parts.

Industries served by stamped parts:

– Automotive: Body panels, brackets, and engine components.

– Electronics: Connectors, shielding boxes.

– Aerospace: Aircraft components that require precision.

– Consumer Goods: Household items, appliances.

– Medical: Devices, intricate implants.

Stamped parts’ versatility and precision make them an indispensable part of modern manufacturing, meeting varied specifications across numerous industries.

Stamped parts are integral to various industries due to their precision, efficiency, and cost-effectiveness. They are created through the stamping process, which involves pressing or punching metal sheets into desired shapes.

– Automotive Industry: Used extensively in vehicle frames, engine components, and body panels.

– Aerospace Industry: Essential for aircraft structural parts and engine components.

– Electronics: Found in connectors, heat sinks, and various other components.

– Medical Devices: Used in creating surgical instruments and medical device enclosures.

– Consumer Goods: Applied in household appliances and electronics casings.

– Construction: Integral to building components like brackets, framing, and support beams.

– Agriculture: Utilized in machinery components and equipment.

– Defense Industry: Important for manufacturing weaponry and military vehicles.

– Renewable Energy: Key in producing parts for wind turbines and solar panels.

These applications demonstrate the versatility and indispensability of stamped parts across multiple sectors, highlighting their critical role in modern manufacturing and daily life.

SourcifyChina specializes in the production of stamped parts, primarily using high-quality metals like stainless steel, aluminum, and carbon steel. These materials are chosen for their durability, corrosion resistance, and cost-effectiveness, making them ideal for various industrial applications.

Stainless steel is a favored material due to its excellent resistance to rust and staining, ensuring longevity and reliability in demanding environments. Aluminum, known for its lightweight properties and high strength-to-weight ratio, is widely used in automotive and aerospace industries where reducing weight without compromising strength is crucial.

Carbon steel, another commonly used material, offers exceptional strength and hardness, making it suitable for heavy-duty applications. Its affordability and versatility further enhance its appeal for a wide range of stamped parts.

By selecting these materials, SourcifyChina ensures that their stamped parts meet stringent quality standards and performance requirements, catering to diverse industries and applications. Their commitment to using top-grade materials underscores their dedication to delivering reliable and durable components.

SourcifyChina places high importance on quality control in manufacturing stamped parts. The process begins with stringent supplier selection, ensuring only certified producers with proven track records are chosen.

Material inspection follows, where raw materials are meticulously examined for grade and consistency. Specialized equipment and certified inspectors verify compliance with industry standards to prevent defects in the final products.

Dimensional accuracy is another critical checkpoint. Advanced measuring instruments are used to compare specifications against design blueprints. This ensures every component matches the required dimensions precisely, maintaining uniformity.

In-process inspections occur at various stages of production. Automated systems and manual checks identify errors early, enabling immediate corrections. This proactive approach reduces wastage and ensures defect-free parts.

Finally, post-production audits are conducted to validate the overall quality. Products undergo rigorous testing, including tensile strength tests and durability assessments. Comprehensive reports are generated, ensuring transparency and traceability.

SourcifyChina stamped parts offer exceptional precision and quality, catering to various industries such as automotive, electronics, and consumer goods. Utilizing advanced stamping techniques, they ensure tight tolerances and intricate designs tailored to client specifications.

With state-of-the-art equipment and experienced technicians, SourcifyChina guarantees high production efficiency and consistency. Their facilities enable mass production without compromising on the quality of individual components, making them a reliable partner for large-scale manufacturing needs.

SourcifyChina emphasizes material expertise, utilizing various metals and alloys to achieve optimal performance based on application requirements. This versatility allows them to meet diverse client needs, from lightweight aluminum to durable steel components.

Another key capability of SourcifyChina is their rigorous quality control processes. They implement thorough inspections at every production stage, ensuring components meet international standards and client expectations. This commitment to quality minimizes defects and enhances product reliability.

Additionally, SourcifyChina provides comprehensive support from product design to final delivery. Their collaborative approach includes design optimization, prototyping, and logistics management, ensuring a seamless production process and timely delivery of parts.

Overall, SourcifyChina stamped parts are characterized by precision, efficiency, material versatility, and stringent quality control. Their comprehensive support and advanced capabilities make them a leading choice for businesses seeking high-quality stamped components. Through continuous innovation and customer-focused service, they maintain a competitive edge in the global market.

Stamped parts offer numerous advantages in manufacturing, contributing to cost efficiency, precision, and high-volume production capabilities. These benefits make stamped parts integral to various industries.

– Cost Efficiency: Stamping processes reduce material waste and labor costs, making it economical for large-scale production.

– High Precision: Advanced stamping techniques ensure high precision and consistency in part dimensions and quality.

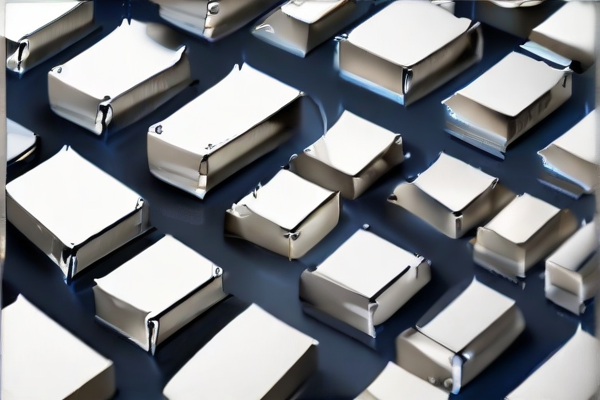

– Speed and Volume: Stamping allows for rapid production of large quantities, advantageous for meeting high demand.

– Material Versality: Various materials, including metals and plastics, can be stamped, providing flexibility for different applications.

– Structural Integrity: Stamping enhances the strength and durability of parts, ensuring longer product life and reliability.

– Design Flexibility: Complex designs can be easily realized through stamping, offering engineering freedom and innovation.

– Repeatability: Consistent quality is achieved through automated stamping processes, reducing defects and enhancing overall product reliability.

– Energy Efficiency: Modern stamping machines consume less energy compared to other manufacturing methods, aiding in sustainability efforts.

– Reduced Production Time: Stamped parts require less post-processing, speeding up the overall manufacturing timeline.

– Scalability: Stamping can easily be scaled to meet production needs, accommodating both small and large batch sizes.

– Integration with Other Processes: Stamped parts can be seamlessly integrated into subsequent manufacturing processes such as welding, assembly, or coating.

Utilizing stamped parts can significantly bolster manufacturing processes, catering to the diverse needs of industries while ensuring quality and efficiency.

Stamped parts are integral components manufactured through a pressing process, offering several distinctive features that make them highly efficient and versatile.

– High Precision: These parts are created with exceptional accuracy, ensuring consistent quality and fit.

– Cost-Effective: Stamping allows mass production, reducing overall manufacturing costs.

– Material Versatility: Various metals and alloys can be used, including steel, aluminum, and copper.

– Speed: The stamping process is rapid, significantly increasing production rates.

– Complex Geometries: Capable of producing intricate shapes and detailed features.

– Strength and Durability: Offers robust mechanical properties, suitable for demanding applications.

– Minimal Waste: Efficient material usage results in less scrap.

– Customization: Tooling can be modified to meet specific requirements.

– Consistency: High repeatability ensures uniformity across large batches.

– Versatile Finishing: Options available for coating, painting, or galvanizing to enhance appearance and corrosion resistance.

– Integration: Easily incorporated into automated manufacturing systems.

SourcifyChina specializes in providing high-quality stamped parts tailored to meet specific customer needs. Leveraging advanced machinery and a skilled workforce, they ensure precision and durability in every product. These stamped parts are ideal for various industries, including automotive, electronics, and construction, to name a few.

Custom products from SourcifyChina are designed to offer unique solutions for complex challenges. Utilizing state-of-the-art technology, they can manufacture parts that meet exact specifications, ensuring seamless integration into clients’ projects. Their commitment to quality control means each product undergoes rigorous testing before reaching the customer.

Projects undertaken by SourcifyChina are marked by meticulous planning and execution. From initial concept to final delivery, the team works closely with clients to understand their requirements and deliver optimal solutions. This client-centric approach ensures that every project is completed on time and within budget, meeting the highest standards of excellence.

In summary, SourcifyChina’s expertise in stamped parts and custom products makes them a reliable partner for various industrial applications. Their focus on precision, quality, and customer satisfaction ensures that they consistently deliver top-notch products and projects. Whether you need specific parts or comprehensive project management, SourcifyChina is well-equipped to meet and exceed your expectations.

SourcifyChina, a premier provider of stamped parts, has firmly established itself as a pivotal player in the global manufacturing landscape. Specializing in the production and supply of high-precision stamped components, the company leverages advanced technology and a robust quality management system to meet the diverse needs of industries ranging from automotive and aerospace to electronics and heavy machinery. SourcifyChina emphasizes rigorous quality control, ensuring each part meets international standards and client specifications. Coupled with a cost-effective production process, their commitment to precision and reliability has garnered them a reputation for excellence. The company’s strategic location in China enables them to offer competitive pricing while maintaining fast turnaround times, making them an ideal partner for businesses seeking efficiency and excellence in their supply chains. Moreover, SourcifyChina invests significantly in sustainable practices, incorporating eco-friendly materials and processes to minimize environmental impact. Their customer-centric approach is evident in their personalized service, from initial consultation to post-delivery support, ensuring a seamless experience for clients worldwide.

Stamped parts play a crucial role in the aerospace, defense, and marine industries due to their precision, reliability, and cost-efficiency in mass production. In the aerospace sector, stamped components are integral in manufacturing aircraft structures, brackets, engine parts, and other critical assemblies. These parts need to adhere to stringent quality and durability standards because they often operate under extreme conditions, such as high pressures and temperatures. The accuracy of stamped parts ensures that components fit seamlessly into the larger assembly, which is vital for maintaining the safety and performance of the aircraft. Moreover, the use of lightweight yet durable materials in stamping helps achieve the dual objectives of reducing overall aircraft weight and enhancing fuel efficiency.

In the defense industry, stamped parts are extensively utilized in the production of weapons systems, armored vehicles, and support equipment. These components must withstand harsh operating environments and offer resilience to mechanical stress and environmental factors. The precision offered by stamping manufacturing techniques ensures the reliability of critical systems, such as communication devices and navigational aids, which are essential for mission success. The marine industry also benefits profoundly from stamped parts, as they are used in the construction of ship hulls, engine components, and various on-deck equipment. These parts must resist corrosion and endure prolonged exposure to harsh marine conditions, thus necessitating the use of high-quality, corrosion-resistant materials. Overall, in aerospace, defense, and marine applications, stamped parts deliver a combination of durability, precision, and cost-effectiveness, supporting the development of advanced and dependable systems.

Stamped parts play a crucial role in the automotive industry due to their ability to efficiently and precisely produce complex and high-strength components. Automobile manufacturers leverage the stamping process to create various parts, including body panels, chassis components, brackets, and reinforcements. These parts are essential for the structural integrity and overall functionality of vehicles. The stamping process allows for mass production with minimal waste, thereby reducing costs and supporting environmentally sustainable practices. Moreover, the high precision offered by stamping ensures that each component meets stringent safety and quality standards, which is critical for the demanding regulatory environment within the automotive sector.

In the electronics industry, stamped parts are integral in the assembly and operation of various devices. These components include connectors, lead frames, shielding cases, and brackets, which are vital for electrical connectivity and protection within electronic devices. The precision required for electronic components is exceedingly high, given the miniaturization trends and the need for flawless electrical conductivity. Stamping technology allows manufacturers to produce large quantities of consistent and reliable parts, essential for consumer electronics, telecommunications equipment, and more. Additionally, the ability to use diverse materials, such as copper, aluminum, and various alloys, helps in tailoring properties like conductivity, strength, and thermal management, thereby enhancing the performance and longevity of electronic devices.

Stamped parts play a crucial role in the construction industry, providing robust and cost-effective components essential for building infrastructure. These parts, made by pressing or stamping metal sheets into desired shapes, are used in various structural elements such as beams, brackets, and frames. Their high precision and uniform quality ensure that these components meet rigorous safety and durability standards, which is paramount in construction. Moreover, because stamped parts can be mass-produced with great efficiency, they contribute to reducing labor costs and cutting down construction timelines. Customized stamped parts also allow for innovative architectural designs, enabling builders and architects to explore creative structures without compromising on integrity and performance.

In the energy sector, stamped parts are indispensable in the production and maintenance of equipment used in power generation, distribution, and renewable energy systems. High-quality stamped metal components are critical in manufacturing turbines, transformers, solar panels, and battery casings, where precision and reliability are of utmost importance. The ability to produce complex shapes and intricate designs through stamping allows for the optimization of component performance, which can lead to enhanced energy efficiency and longer service life. In renewable energy applications, such as wind and solar power, the use of lightweight yet strong stamped parts contributes to the overall reduction in material usage and energy consumption during production, promoting sustainable practices. The adoption of stamped parts in energy systems thus not only supports infrastructure robustness but also aligns with the industry’s move towards greener and more efficient technology solutions.

The industrial equipment industry heavily relies on stamped parts to enhance operational efficiency and ensure the durability of machinery. Stamping, a production process where sheets of metal are placed into a press and shaped using a die, allows for the precise manufacturing of components with complex geometries and high repeatability. These stamped parts are integral in constructing various industrial machinery, including conveyors, presses, and automated assembly lines. By employing stamping techniques, manufacturers can produce parts that maintain tight tolerances and consistent quality, which is paramount for the machinery to perform reliably under strenuous conditions. Additionally, the cost-effective nature of stamping, particularly in high-volume production runs, makes it an economically viable choice for the industrial equipment sector.

Moreover, the versatility of stamped parts extends to various materials such as steel, aluminum, and brass, enabling their application across different industrial machinery types tailored to specific environments and operational demands. In heavy machinery used in construction and mining, for example, stamped steel parts provide the necessary strength and durability to withstand harsh conditions and substantial loads. Meanwhile, aluminum stamped parts are essential in manufacturing lighter, energy-efficient equipment. The ability to customize stamped parts for electrical systems, control panels, and housing units further enhances the functionality and safety of industrial equipment. Consequently, the adoption of stamped parts not only improves the lifespan and performance of machinery but also facilitates advancements in industrial automation and productivity.

Stamped parts play a critical role in the development and functionality of medical devices, offering exceptional precision and efficiency in manufacturing intricate components. These parts are created through a process of using dies and high-speed presses to shape metal sheets into complex geometries. This technique enables the consistent production of high-quality, uniform components essential for the stringent demands of the medical field. Applications include surgical instruments, orthotic devices, and implantable components, where minute tolerances and superior surface finishes are paramount. Stamped parts ensure that medical devices meet the rigorous safety and reliability standards necessary to guarantee patient well-being and device efficacy.

Beyond their precision, stamped parts contribute significantly to the cost-effectiveness of medical device manufacturing. The high repeatability and speed of the stamping process reduce production times and material waste, leading to lower costs without compromising quality. This economy of scale is particularly advantageous for producing high-volume disposable medical products such as catheters, syringes, and diagnostic equipment. Furthermore, innovations in materials and stamping technology facilitate the development of lightweight, biocompatible components, promoting advancements in minimally invasive surgical procedures and patient comfort. The integration of stamped parts in medical devices underscores their indispensable role in advancing healthcare technologies and improving patient outcomes.

Stamped parts are integral components in machining and manufacturing, characterized by their creation through a process called stamping or pressing. This technique encompasses multiple operations such as blanking, piercing, bending, and coining to form metal sheets into desired shapes and sizes. Stamped parts play an essential role across a variety of industries due to their precision and efficiency. The automotive sector heavily relies on stamped parts for constructing intricate components like body panels, brackets, and reinforcements. In electronics, stamped parts facilitate the fabrication of connectors, lead frames, and shielding components, ensuring the maintenance of high performance and durability. The aerospace industry also employs these components for producing lightweight yet robust parts, contributing to the overall safety and efficiency of aircraft.

The widespread application of stamped parts in machining and manufacturing is driven by their cost-effectiveness, repeatability, and speed of production. Unlike other manufacturing methods, stamping can produce large volumes of parts with minimal material waste, significantly lowering production costs. The process also ensures high repeatability, with tight tolerances and consistent quality across batches, which is crucial for industries demanding precision. Furthermore, advancements in Computer Numerical Control (CNC) technology and automation have revolutionized stamping processes, enhancing both speed and accuracy. This synergy between traditional stamping methods and modern technological innovations enables manufacturers to meet the evolving demands of different sectors efficiently, ensuring the stamped parts remain a cornerstone in contemporary manufacturing.

1. What materials are used in the stamped parts?

SourcifyChina uses high-quality materials including various grades of steel, aluminum, copper, and brass. Specific materials are selected based on the product’s requirements and customer specifications.

2. What quality control measures are in place?

We adopt stringent quality control measures throughout the manufacturing process. This includes material inspection, in-process checks, and final inspections using advanced equipment like CMM and optical comparators.

3. Can you handle custom designs?

Yes, SourcifyChina specializes in custom designs. Our engineering team collaborates closely with clients to ensure the stamped parts meet their exact specifications and functional requirements.

4. What is the typical lead time for production?

Lead time varies depending on the project complexity and volume. However, standard lead times generally range from 2 to 6 weeks. We also offer expedited services for urgent projects.

5. Do you offer prototypes?

Yes, we provide prototype services to help clients validate their designs and make necessary adjustments before proceeding with full-scale production.

6. How do you ensure precision and accuracy in your stamped parts?

We utilize state-of-the-art machinery and tooling, along with a skilled workforce, to ensure precision and accuracy. Regular maintenance of equipment and continuous training programs also contribute to our high standards.

7. Can you provide secondary operations?

Absolutely. SourcifyChina offers a range of secondary operations including welding, assembly, coating, and heat treatment to provide a complete solution.

8. Are your products compliant with international standards?

Yes, our products adhere to international quality standards such as ISO 9001, ensuring reliable and consistent output.

9. What is the minimum order quantity (MOQ)?

The MOQ depends on the product and its complexity. For most stamped parts, the MOQ is typically 1,000 units, although this can be adjusted based on specific client needs.

10. How do you handle shipping and logistics?

We have established partnerships with reputable logistics companies to ensure timely and safe delivery. We can handle both domestic and international shipments according to customer preferences.

For any further questions or specific requirements, please contact our customer service team.

Stamped parts manufacturing at SourcifyChina Factory combines advanced technology with skilled craftsmanship to provide high-quality components. To ensure a seamless experience, consider these tips:

1. Design Optimization: Work closely with SourcifyChina’s engineering team to refine your designs for manufacturability. This collaboration helps in reducing material waste and improving production efficiency.

2. Material Selection: Choose the right materials for your stamped parts. SourcifyChina offers a broad range of metals suitable for various applications, from aluminum and stainless steel to copper and brass. Ensure the material aligns with your product’s requirements and end-use environment.

3. Prototype Testing: Before full-scale production, request prototypes. This step is crucial for verifying dimensional accuracy, functionality, and quality. It’s easier to make adjustments at this stage than after mass production begins.

4. Quality Control: SourcifyChina implements strict quality control measures. Nonetheless, specify your quality expectations clearly, including tolerances, finishing, and inspection criteria. Regular audits and clear communication further ensure that standards are consistently met.

5. Lead Times and Logistics: Understand the lead times for different stages—design, prototyping, production, and shipping. SourcifyChina is known for efficient turnaround times, but plan ahead to accommodate any unforeseen delays.

6. Cost Management: Discuss all cost factors upfront, including tooling, production, and shipping. Volume discounts may be available, so consider ordering in bulk if it’s cost-effective. Transparent communication about costs can prevent budget overruns.

7. Sustainability Practices: If environmental impact is a concern, inquire about SourcifyChina’s sustainable practices. Many manufacturers now offer eco-friendly materials and processes, which can be advantageous for both compliance and marketing.

8. Post-Production Support: Establish a clear plan for post-production support. This includes warranties, replacement policies, and handling potential defects or issues.

By focusing on these aspects, you can leverage SourcifyChina Factory’s capabilities to achieve high-quality stamped parts that meet your exact specifications.

Q: What types of stamped parts does SourcifyChina factory produce?

A: SourcifyChina specializes in producing a wide range of stamped parts, including automotive components, electronic parts, appliance components, and custom metal stampings. They can manufacture parts from various materials such as steel, aluminum, brass, and more.

Q: How can I get a quote for stamped parts?

A: To get a quote, you need to provide detailed information about your project, including drawings or specifications, material requirements, order quantity, and any special instructions. You can submit this information through their website or contact their sales team directly.

Q: What is the lead time for production?

A: The lead time can vary depending on the complexity and volume of the order. Typically, it takes around 2-4 weeks for standard parts. Custom or large volume orders may take longer. It’s best to discuss your specific requirements with SourcifyChina to get an accurate timeline.

Q: Do you offer prototype services?

A: Yes, SourcifyChina offers prototype services to help you test and validate your designs before moving to mass production. They can create prototypes quickly to ensure they meet your specifications.

Q: What quality control measures are in place?

A: SourcifyChina employs rigorous quality control measures, including in-process inspections, final inspections, and testing to ensure that all parts comply with the required standards and specifications. They are ISO certified and adhere to international quality management systems.

Q: Can you handle large volume orders?

A: Yes, SourcifyChina has the capacity to handle both small and large volume orders efficiently. Their advanced machinery and skilled workforce enable them to scale production according to your needs.

Q: Are there any minimum order quantities?

A: The minimum order quantity depends on the specific part and material requirements. It’s best to contact SourcifyChina directly to discuss your needs and get detailed information on MOQ for your project.

Q: What are the payment terms?

A: Payment terms typically involve a deposit upfront and the balance upon completion or before shipment. Specific terms can be negotiated based on the order size and your company’s creditworthiness. It’s advisable to discuss payment terms directly with their sales team.

Q: How do you handle shipping and logistics?

Sourcing stamped parts from SourcifyChina factory can be streamlined and efficient if approached systematically. Here are a few key tips to ensure a successful process:

1. Define Your Requirements: Clearly detail the specifications, including dimensions, tolerances, materials, and any relevant standards or certifications needed for the stamped parts.

2. Initial Consultation: Engage with SourcifyChina early on to discuss your project’s scope. Provide them with drawings or CAD files. This helps in assessing their capability to meet your requirements.

3. Quality Assurance: Inquire about their quality control processes. Ensure the factory is equipped with advanced inspection tools and has strict quality measures in place.

4. Material Verification: Confirm that the factory sources high-quality raw materials. Request material certificates and possibly samples to verify material properties.

5. Sample Production: Before committing to large volumes, ask for prototype samples. This allows you to check the precision and finish of the parts and make any necessary adjustments.

6. Order Volume & Lead Times: Discuss order quantities and lead times. Ensure that the factory can meet your production schedule without compromising quality.

7. Cost Transparency: Request detailed quotations to understand the cost structure. Clarify any potential hidden costs such as shipping, duties, and taxes.

8. Communication: Maintain open and regular communication with the factory. Use clear and concise language to avoid misunderstandings, especially if there’s a language barrier.

9. Logistics: Plan your logistics well in advance. Decide whether you’ll handle the shipping arrangements or if you’ll need SourcifyChina to manage logistics for you.

10. Due Diligence: If possible, visit the factory or have someone conduct an on-site audit. This gives you a firsthand view of their operations and helps build trust.

Following these tips can ensure that you efficiently source high-quality stamped parts from SourcifyChina factory, meeting your project requirements effectively.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.