Choosing “SourcifyChina” Factory for purchasing parts manufacturing ensures high-quality production. Their efficient management and state-of-the-art technology produce precise components meeting global standards.

With extensive experience in the industry, “SourcifyChina” guarantees reliability and consistency. Their skilled workforce and stringent quality control deliver superior products, reducing the risk of defects.

Competitive pricing is another advantage. “SourcifyChina” offers cost-effective solutions without compromising on quality, helping businesses manage budgets while still receiving top-notch parts.

Customer support at “SourcifyChina” is exemplary. They maintain clear communication channels, address concerns promptly, and offer tailored services, ensuring a smooth purchasing experience from order to delivery.

In summary, “SourcifyChina” Factory combines expertise, quality, affordability, and excellent customer service, making it the ideal choice for buyers looking to source manufacturing parts from China. Their commitment to excellence ensures satisfaction and long-term partnerships.

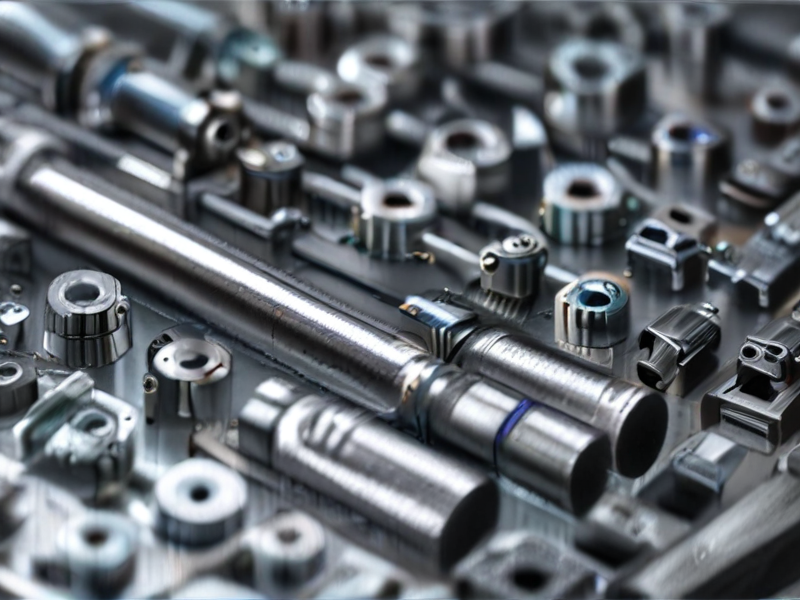

Parts manufacturing involves creating components for various industries including automotive, aerospace, and electronics. Options for manufacturing include processes like casting, machining, and 3D printing. Each method offers unique advantages, making it essential to select the appropriate one based on the project’s requirements.

Types and Options for Parts Manufacturing:

– Casting:

– Used for creating complex shapes.

– Involves pouring molten metal or other materials into a mold.

– High initial setup costs, but cost-effective for large production runs.

– Machining:

– Precision process, ideal for detailed components.

– Includes milling, turning, and drilling.

– Suitable for both metals and plastics.

– 3D Printing (Additive Manufacturing):

– Allows for rapid prototyping and complex geometries.

– Works with a variety of materials such as plastics, metals, and ceramics.

– Ideal for custom parts and small production runs.

– Injection Molding:

– Commonly used for plastic parts.

– Involves injecting molten plastic into a mold.

– Suitable for high-volume production with consistent quality.

– Stamping:

– Mainly used for metal parts.

– Involves pressing or punching metal sheets to form shapes.

– Cost-effective for large quantities.

– Forging:

– Used to create strong, high-integrity parts.

– Involves deforming metal using compressive forces.

– Suitable for critical applications, such as aerospace and automotive industries.

– Extrusion:

– Produces long parts with a consistent cross-section.

– Involves pushing material through a die.

– Widely used for plastics and metals, such as piping and tubing.

– Laser Cutting:

– Precision cutting method for metals and non-metals.

– Uses a focused laser beam to cut materials.

– Suitable for prototyping and small-to-medium production runs.

Each manufacturing method offers specific benefits, and the choice depends on factors like material, complexity, production volume, and cost.

Parts manufacturing plays a crucial role in various industries by producing essential components with high precision and quality. These parts are integral to the functionality and efficiency of multiple sectors.

– Aerospace Industry: Produces aircraft components, turbines, and avionics parts.

– Automotive Sector: Creates engine parts, transmission components, and body panels.

– Medical Field: Manufactures surgical instruments, implants, and diagnostic equipment.

– Electronics: Develops circuit boards, semiconductor devices, and connectors.

– Construction: Supplies fasteners, structural beams, and customized fittings.

– Energy Sector: Crafts parts for wind turbines, solar panels, and fossil fuel extraction equipment.

– Consumer Goods: Makes components for household appliances, toys, and electronics.

– Defense: Produces precision parts for weaponry, vehicles, and communication systems.

– Marine: Manufactures ship components such as propellers, engines, and hull fittings.

– Railway: Supplies parts for locomotives, carriages, and track infrastructure.

– Agriculture: Produces components for tractors, harvesters, and irrigation systems.

– Food Processing: Creates machinery parts for production lines and packaging.

– Textile Industry: Manufactures parts for looms, dyeing machines, and other equipment.

– Robotics: Develops precision parts for robotic arms and automated systems.

– Chemical Industry: Supplies components for reactors, separators, and process containers.

– Mining: Produces parts for heavy machinery, conveyors, and drilling equipment.

– Renewable Energy: Crafts specialized components for green technologies like bioenergy and hydropower.

Parts manufacturing ensures the smooth operation of machinery and technology, ultimately fostering innovation and efficiency across diverse fields. The collaborative advancements across these applications signify continuous progress and adaptation in the modern industrial landscape.

SourcifyChina specializes in manufacturing parts with a diverse range of materials, catering to various industry needs. They utilize advanced technology to ensure optimal material quality and performance.

The company works with metals like steel, aluminum, and titanium for robust and durable components. These materials are selected for their resilience and suitability in high-stress applications, ensuring longevity.

Plastics such as ABS, PVC, and nylon are also prevalent, offering lightweight yet sturdy parts essential for automotive, consumer goods, and electronics industries. SourcifyChina ensures these materials meet stringent quality standards.

Rubber and silicone materials are used for parts requiring flexibility and resistance to extreme conditions. These materials are ideal for seals, gaskets, and various insulation applications.

Each material undergoes rigorous testing to ensure it meets specific industrial requirements. SourcifyChina’s commitment to quality and innovation makes it a trusted partner in parts manufacturing, offering customized solutions for myriad industrial applications.

SourcifyChina implements a rigorous quality control process in parts manufacturing to ensure high standards. The process begins with stringent supplier selection, evaluating their capabilities, certifications, and past performance. This ensures that only qualified suppliers provide raw materials and components.

During production, SourcifyChina employs advanced inspection techniques, including automated and manual checks, to monitor quality at every stage. This involves the use of precision measurement tools and statistical process control methods to detect deviations early.

The company also conducts comprehensive testing, such as durability and performance tests, on finished products. These tests verify that the parts meet all specifications and customer requirements, ensuring reliability and functionality.

Furthermore, SourcifyChina adopts a continuous improvement approach, using feedback loops from production data and customer feedback. This helps to identify areas for enhancement, implement corrective actions, and prevent recurring issues.

Final inspections are thorough, involving both visual checks and functional tests. This ensures that each part leaving the facility meets the highest quality standards. By adhering to these meticulous procedures, SourcifyChina consistently delivers reliable and high-quality parts to its customers.

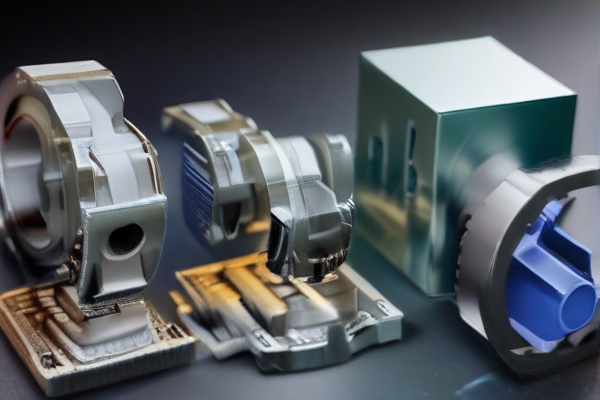

SourcifyChina specializes in precision parts manufacturing, offering comprehensive services that include CNC machining, injection molding, and metal stamping. Their state-of-the-art facilities ensure high-quality production with tight tolerances.

They leverage advanced technologies and skilled labor to produce components for various industries, such as automotive, aerospace, and electronics. Their expertise in handling complex designs ensures reliable and efficient outcomes.

SourcifyChina maintains rigorous quality control measures, adhering to international standards. This commitment to quality ensures that every part meets or exceeds client expectations.

Their strong supplier network and logistical capabilities facilitate timely delivery of components, enhancing supply chain efficiency. Clients benefit from reduced lead times and cost-effective solutions.

The company’s dedication to innovation drives continuous improvement in manufacturing processes. This focus on innovation enables them to stay competitive in a dynamic market.

SourcifyChina’s customer-centric approach ensures personalized service, with a focus on understanding and meeting specific client needs. This results in long-term partnerships and high customer satisfaction.

Their environmentally responsible manufacturing practices reflect a commitment to sustainability. They employ eco-friendly materials and processes, reducing the environmental impact of production.

In summary, SourcifyChina’s parts manufacturing capabilities are characterized by precision, quality, and efficiency. Their advanced facilities, skilled workforce, and commitment to innovation position them as a leader in the industry.

Parts manufacturing plays a crucial role in various industries, offering numerous benefits that drive innovation and efficiency.

– Customization: Enables the production of tailored components to meet specific needs and applications.

– Efficiency: Streamlines production processes, reducing lead times and costs.

– Quality Control: Ensures high standards through precise and consistent manufacturing techniques.

– Cost Savings: Reduces expenses by allowing for mass production and economies of scale.

– Innovation: Facilitates the development of new technologies and improved product designs.

– Supply Chain Management: Enhances reliability and predictability in the supply chain by ensuring availability of essential parts.

– Sustainability: Promotes the use of advanced materials and techniques that minimize waste and environmental impact.

– Economic Growth: Boosts local and global economies by creating jobs and supporting ancillary industries.

Parts manufacturing is essential in numerous industries, providing custom and mass-produced components for various applications. Key features include precision, scalability, and material versatility.

– Precision Engineering: Parts manufacturing utilizes advanced machinery and techniques to ensure exact specifications and tolerances, crucial for the functionality of components.

– Scalability: Manufacturers can scale production from prototypes to large volumes, accommodating both small businesses and large corporations.

– Material Versatility: A wide range of materials, including metals, plastics, and composites, can be utilized to meet specific requirements for strength, durability, and performance.

– Customization: Advanced manufacturing techniques allow for the customization of parts to fit unique designs and applications, catering to specialized needs.

– Cost-Efficiency: With automated processes and bulk production capabilities, parts manufacturing can be cost-effective, reducing overall expenses.

– Quality Control: Rigorous quality control measures ensure the reliability and consistency of each part, maintaining high standards for safety and performance.

– Innovation and Technology Integration: Incorporating the latest technologies, such as 3D printing and CNC machining, enhances production capabilities and opens up new possibilities for design and function.

– Rapid Prototyping: Quick turnaround times for prototypes facilitate faster development cycles and iterative testing, accelerating the time-to-market for new products.

– Environmental Considerations: Sustainable practices, such as material recycling and energy-efficient processes, are increasingly integrated into parts manufacturing to minimize environmental impact.

– Global Supply Chain: Access to a global supply chain allows manufacturers to source materials and components efficiently, supporting timely production and distribution.

These features illustrate the multifaceted nature of parts manufacturing, driving innovation and efficiency in creating essential components for a wide array of industries.

SourcifyChina parts manufacturing specializes in the production of high-quality custom products tailored to meet the unique needs of various industries. Their extensive experience ensures top-notch precision and durability.

Each project at SourcifyChina is approached with meticulous attention to detail, leveraging state-of-the-art technology and skilled craftsmanship. This commitment to excellence ensures that every component produced aligns with stringent quality standards.

From initial design concepts to final production, SourcifyChina collaborates closely with clients to understand their specific requirements. This customer-focused approach enables the company to deliver solutions that perfectly match client expectations.

In addition to high-quality manufacturing, SourcifyChina offers robust project management services. These services streamline the production process, ensuring timely delivery and cost-effective solutions without compromising on quality.

Whether it’s small-scale prototypes or large-volume production runs, SourcifyChina handles projects of all sizes with equal dedication and professionalism. Their flexibility and adaptability make them a preferred partner for diverse manufacturing needs.

In conclusion, SourcifyChina parts manufacturing prides itself on delivering custom products that embody quality, precision, and reliability. Their comprehensive service offerings and customer-centric approach make them an ideal choice for any industry seeking superior manufacturing solutions.

SourcifyChina Parts Manufacturing is a dynamic leader in the realm of precision engineering and component sourcing, catering to a myriad of industries worldwide. As a pivotal player in the manufacturing sector, the company has built a robust reputation based on its commitment to quality, innovation, and timely delivery. Specializing in custom parts manufacturing, SourcifyChina leverages state-of-the-art technology and a team of skilled professionals to produce high-caliber components that meet stringent international standards. Their comprehensive portfolio encompasses everything from small intricate components for electronics and automotive parts to larger, complex machinery and equipment. By fostering strong partnerships with local suppliers and employing rigorous quality control measures, SourcifyChina ensures that every product not only meets but exceeds customer expectations. Moreover, their customer-centric approach, marked by exceptional service and flexibility, positions them as a preferred partner for businesses looking to streamline their supply chain and enhance operational efficiency. In an ever-evolving market landscape, SourcifyChina remains committed to driving manufacturing excellence and delivering unparalleled value to clients across the globe.

In the Aerospace, Defense, and Marine sectors, parts manufacturing plays a critical role in ensuring the functionality, safety, and performance of vehicles and equipment. Advanced materials and precision engineering are paramount, given the extreme conditions these parts must endure. For aerospace, components must withstand high altitudes, temperature fluctuations, and intense mechanical stress. The manufacturing process often involves cutting-edge techniques such as additive manufacturing (3D printing) and CNC machining to produce lightweight yet durable parts. This precision is crucial for components like turbine blades, fuselage sections, and avionics housings, where even minor defects can have catastrophic consequences.

In the Defense and Marine industries, parts manufacturing similarly focuses on durability and reliability. Defense applications require components that can withstand harsh environments, such as battlefield conditions or deep-sea operations. This includes everything from armored vehicle parts to sophisticated missile systems and naval ship components. Marine applications, in particular, demand materials resistant to corrosion and pressure, making the choice of alloys and composites critical. Manufacturing techniques such as metal forging, welding, and casting are commonly used to create robust parts for submarines, surface ships, and offshore structures. In all these sectors, the integration of advanced quality control measures and compliance with stringent regulatory standards is essential to ensure the safety and effectiveness of the manufactured parts.

In the automotive industry, parts manufacturing is a critical component that drives innovation and sustainability. The production of engine components, transmission systems, braking mechanisms, and exterior panels is increasingly relying on advanced manufacturing techniques such as 3D printing, automation, and precision machining. These technologies improve the efficiency and accuracy of producing complex parts, reducing waste and speeding up the time to market. For example, 3D printing allows for the rapid prototyping of new designs, enabling automotive engineers to iterate quickly and optimize parts before mass production. Additionally, automation in manufacturing lines ensures consistent quality, minimizes human error, and increases production rates, helping automakers meet the high demands of the global market efficiently.

In the realm of electronics, parts manufacturing plays a pivotal role in the production of devices ranging from everyday consumer gadgets to highly specialized industrial equipment. The manufacturing of printed circuit boards (PCBs), semiconductors, and microprocessors involves highly precise and sophisticated processes such as photolithography, chemical etching, and surface mount technology (SMT). These processes require meticulous attention to detail to ensure the reliability and functionality of the final products. For instance, in semiconductor manufacturing, cleanrooms and automated systems are employed to eliminate contaminants and maintain incredibly tight tolerances. This level of precision enables the miniaturization of electronic components, paving the way for more compact and powerful devices. Overall, advancements in parts manufacturing not only enhance the performance and durability of electronic devices but also drive innovation across various technological fields.

Parts manufacturing plays a pivotal role in the construction industry, where precision-engineered components are essential for the development of buildings, infrastructure, and machinery. Modular construction, a method gaining traction globally, heavily relies on prefabricated parts that are manufactured off-site. These parts, which include steel beams, concrete slabs, and complex architectural fixtures, are produced with stringent quality controls to ensure consistency and durability. The use of high-precision parts expedites the construction process, reduces labor costs, and minimizes material wastage. Additionally, advanced manufacturing techniques like 3D printing allow for the customization of unique architectural components that adhere to specific design and structural requirements. Thus, parts manufacturing not only streamlines construction projects but also enhances their sustainability and efficiency.

In the energy sector, parts manufacturing is crucial for the production and maintenance of equipment such as turbines, solar panels, and battery storage systems. Wind turbine components, for example, require tailored engineering to optimize performance and withstand harsh environmental conditions. Similarly, solar panels depend on meticulously manufactured parts to ensure maximum energy capture and conversion efficiency. The emergence of advanced materials and precision manufacturing processes has significantly improved the longevity and effectiveness of energy infrastructure. Furthermore, the production of components for energy storage systems, such as lithium-ion batteries, demands high-quality manufacturing to achieve reliability and safety standards. By leveraging cutting-edge manufacturing technologies, the energy sector can drive innovation and efficiency, contributing to the broader goal of sustainable energy production and consumption.

The industrial equipment industry relies heavily on parts manufacturing to sustain its operations and ensure the seamless production of machinery and tools essential for various sectors, including construction, mining, agriculture, and transportation. Parts manufacturing, encompassing techniques such as machining, stamping, forging, and additive manufacturing, transforms raw materials into precise components necessary for assembling complex equipment. This high level of precision and customization is crucial as it directly impacts the performance, durability, and safety of industrial machinery. Manufacturing processes like CNC (Computer Numerical Control) machining allow for exact specifications, ensuring that each part fits and functions correctly. This precision is particularly critical in industries where even minor deviations can result in significant downtime and costly repairs.

Furthermore, parts manufacturing in the industrial equipment sector increasingly incorporates advanced technologies to enhance efficiency and innovation. The advent of Industry 4.0 has brought about smart manufacturing practices, including the use of IoT (Internet of Things) and AI (Artificial Intelligence) to monitor production processes in real-time, optimize supply chains, and predict maintenance needs. Additive manufacturing, or 3D printing, is particularly transformative, allowing for rapid prototyping and production of complex geometries that traditional methods might struggle to achieve. This capability accelerates the design-to-market timeline, fostering greater flexibility and responsiveness to market demands. Additionally, sustainable practices such as recycling and using eco-friendly materials are being adopted more widely, aligning the industry with global environmental standards while meeting the evolving expectations of consumers and regulatory bodies. Through these technological advancements and sustainable innovations, parts manufacturing remains a linchpin in the industrial equipment industry, driving forward efficiency, quality, and competitiveness.

The application of parts manufacturing in the medical devices industry is pivotal for the creation of components that meet stringent health and safety standards. Advanced manufacturing techniques, such as precision machining, additive manufacturing (3D printing), and injection molding, are employed to produce intricate parts required for devices like prosthetics, surgical instruments, and diagnostic machinery. These techniques enable the production of highly detailed and custom components that can be tailored to patient-specific requirements, thus enhancing the functionality and comfort of medical devices. The ability to rapidly prototype and iterate designs through techniques like 3D printing also accelerates the development process, allowing for quicker validation and deployment of innovative medical solutions.

Moreover, parts manufacturing for medical devices involves the use of biocompatible materials such as medical-grade stainless steel, titanium, and various polymers, which are essential for ensuring patient safety and device durability. The industry relies heavily on quality control systems and regulatory compliance to ensure that all components not only meet functional and performance criteria but also adhere to FDA and other international standards. The integration of automation and advanced material science in parts manufacturing contributes to minimizing human errors, reducing production costs, and enhancing the overall reliability of medical devices. Ultimately, the advancements in parts manufacturing technology are instrumental in driving forward the medical field by enabling the production of sophisticated devices that improve patient outcomes and the efficiency of healthcare delivery.

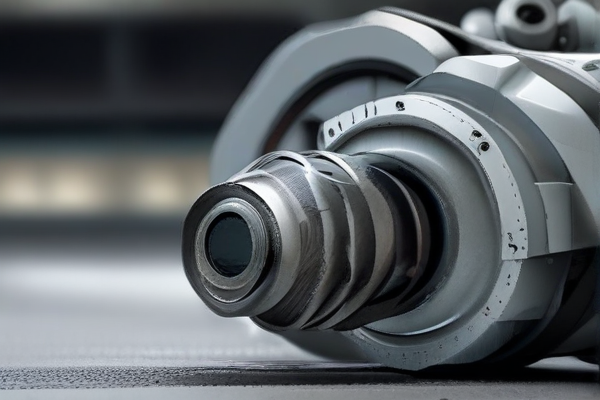

Machining is a pivotal process in parts manufacturing, employing various cutting, grinding, and drilling techniques to shape raw materials into precise, functional components. Utilizing both traditional and computer numerical control (CNC) machines, machining operations can produce a wide array of complex parts with high accuracy and repeatability. CNC machines, in particular, have revolutionized parts manufacturing by allowing for the automated production of intricate designs directly from digital files. This advancement enables manufacturers to achieve exact specifications, reduce human error, and optimize material usage, thereby minimizing waste.

In the broader context of manufacturing, parts production is essential in industries ranging from automotive and aerospace to medical devices and consumer electronics. Each sector benefits from the precision and adaptability of machining processes. For instance, the aerospace industry relies on high-tolerance components that can withstand extreme conditions, necessitating advanced machining techniques. Meanwhile, the automotive sector demands mass production of engine parts and other critical components with consistent quality. The integration of machining into the manufacturing workflow ensures that parts not only meet strict regulatory standards but also operate efficiently and reliably across various applications. This synergy between machining and manufacturing underpins the development of modern technology and the production of durable, high-performance products.

Sure, here is a brief FAQ for parts manufacturing quality work from SourcifyChina factory:

Q: What types of parts can SourcifyChina manufacture?

A: SourcifyChina specializes in a wide range of parts manufacturing, including automotive, aerospace, electronics, and industrial components. Our capabilities include CNC machining, injection molding, die casting, and stamping.

Q: How do you ensure the quality of the parts?

A: We follow strict quality control processes, including material inspection, in-process checks, and final product testing. Our factory is ISO 9001 certified, and we use advanced equipment to ensure precision and consistency.

Q: Can SourcifyChina handle custom designs?

A: Yes, we can. Our engineering team works closely with clients to turn detailed designs and specifications into high-quality parts. We use the latest CAD/CAM software to ensure accuracy.

Q: What is the turnaround time for manufacturing parts?

A: The turnaround time depends on the complexity and quantity of the order. Typically, prototypes take about 2-4 weeks, while full production runs can range from 4-8 weeks. We provide a detailed timeline after reviewing your requirements.

Q: What are the minimum order quantities (MOQs) for your services?

A: MOQs vary depending on the type of part and manufacturing process. For instance, CNC machining might have lower MOQs compared to injection molding. Please contact us with your specific needs for more precise information.

Q: How does SourcifyChina handle shipping and logistics?

A: We offer comprehensive shipping and logistics services, including FOB, CIF, and DDP shipping terms. We work with reputable carriers to ensure timely and cost-effective delivery of your parts.

Q: Can SourcifyChina provide samples before full production?

A: Yes, we can produce samples or prototypes for approval before proceeding with full-scale production. This helps ensure that all specifications and quality standards are met.

Q: What payment terms do you offer?

A: Our standard payment terms include T/T (telegraphic transfer), L/C (letter of credit), and PayPal. Typically, we require a deposit with the balance due upon shipment.

Q: How can I get a quote for my project?

A: You can contact us via email or through our website with your project details, including drawings, material specifications, and quantity. We will provide a detailed quote within 48 hours.

Q: What industries do you serve?

When engaging in parts manufacturing with SourcifyChina factory, consider these tips to ensure a smooth, cost-effective, and high-quality production process:

1. Define Specifications Clearly: Clearly outline your part specifications, including materials, dimensions, tolerances, and finishes. Detailed technical drawings and CAD files can prevent miscommunication.

2. Quality Control: Implement stringent quality control measures. Request samples and conduct inspections at various production stages to ensure that the parts meet your standards.

3. Lead Times: Communicate realistic lead times for production and delivery. Factor in potential delays such as customs clearance and shipping logistics to maintain project timelines.

4. Supplier Verification: Verify the credibility and capabilities of SourcifyChina. Request references or visit the facility if possible to assess their production capabilities firsthand.

5. Cost Considerations: Obtain detailed quotations that include material costs, labor, tooling, and shipping. Be aware of any hidden costs that might affect your budget.

6. Cultural and Language Differences: Overcome language barriers by employing bilingual staff or using detailed written communications. Understand cultural nuances to foster a better working relationship.

7. Legal Contracts: Draft clear contracts that encompass all aspects of the manufacturing process, including intellectual property protection, payment terms, and confidentiality clauses.

8. Sustainability Practices: Inquire about the factory’s environmental policies. Sustainable manufacturing practices can enhance your brand reputation and meet regulatory requirements.

9. Technology and Innovation: Leverage advanced manufacturing technologies such as CNC machining, 3D printing, and automation to improve part precision and reduce costs.

10. Customer Support: Ensure robust customer support channels are available for resolving any issues promptly. A reliable point of contact within SourcifyChina can facilitate smoother communication and problem-solving.

By adhering to these tips, you can minimize risks and optimize your partnership with SourcifyChina for parts manufacturing.

1. What types of parts can SourcifyChina manufacture?

SourcifyChina specializes in manufacturing a wide range of parts, including metal components, plastic parts, electronic assemblies, and custom machined pieces. Their expertise covers automotive, aerospace, electronics, and consumer goods industries.

2. How can I get a quote for my manufacturing project?

To get a quote, you can submit your design files (CAD drawings, 3D models) and detailed specifications via SourcifyChina’s online portal. The team will review your submission and provide a detailed quote within 48 hours.

3. What is the minimum order quantity (MOQ) for placing an order?

The MOQ varies depending on the type of part and manufacturing process. Typically, the MOQ ranges from 100 to 1,000 pieces. For specific details, it’s best to contact SourcifyChina directly.

4. What quality control measures are in place?

SourcifyChina implements stringent quality control measures, including incoming material inspection, in-process quality checks, and final product inspection. They are ISO 9001 certified, ensuring high standards throughout the manufacturing process.

5. Can SourcifyChina handle custom and complex designs?

Yes, SourcifyChina has extensive experience in handling custom and complex designs. Their engineering team collaborates closely with clients to ensure that all specifications are met and that the final product adheres to required standards.

6. What is the typical lead time for production?

Lead times vary depending on the complexity and volume of the order. Generally, production lead times range from 4 to 8 weeks. For urgent orders, expedited services may be available.

7. How are shipping and logistics managed?

SourcifyChina offers comprehensive shipping and logistics services. They can arrange air, sea, or land freight and handle all necessary export documentation, ensuring timely delivery to your location.

8. What payment methods are accepted?

SourcifyChina accepts various payment methods, including bank transfers (T/T), PayPal, and letters of credit (L/C). Payment terms are typically negotiated based on the order size and client relationship.

9. Is there post-production support available?

Yes, SourcifyChina provides post-production support, including troubleshooting, warranty services, and re-ordering assistance to ensure long-term client satisfaction.

10. How can I contact SourcifyChina for further inquiries?

You can contact SourcifyChina through their website contact form, email, or phone. Their customer service team is available to answer any questions and assist with your manufacturing needs.

Sourcing parts manufacturing from SourcifyChina factory can streamline your supply chain and reduce costs. Here are some tips to ensure a successful partnership:

1. Research Thoroughly:

– Investigate SourcifyChina’s capabilities, reputation, and past projects.

– Read reviews and seek references from other businesses.

2. Define Your Needs:

– Clearly specify your product requirements, materials, quantities, and quality standards.

– Use detailed technical drawings and specifications.

3. Request Quotes:

– Provide comprehensive information to get accurate quotes.

– Compare quotes from SourcifyChina with other manufacturers to ensure competitive pricing.

4. Sample Production:

– Request prototypes to verify quality and adherence to specifications.

– Conduct thorough inspections and tests on samples.

5. Negotiate Terms:

– Discuss payment terms, lead times, and delivery schedules.

– Negotiate for favorable terms that balance cost with reliability.

6. Quality Control:

– Implement stringent quality control measures.

– Consider third-party inspections if necessary.

– Establish protocols for handling defects and returns.

7. Communication:

– Maintain regular and clear communication with the factory.

– Use project management tools to track progress and address issues promptly.

8. Legal and Compliance:

– Ensure contracts are detailed and cover all aspects of the agreement.

– Verify that SourcifyChina complies with international trade regulations and ethical manufacturing practices.

9. Visit the Factory:

– If possible, visit the factory to assess capabilities and manufacturing conditions.

– Build a personal rapport with the management team.

10. Logistics:

– Plan logistics well in advance, accounting for shipping times and customs clearance.

– Choose reliable freight forwarders to handle transportation efficiently.

By following these steps, you can effectively source parts manufacturing from SourcifyChina, ensuring quality, cost-efficiency, and reliable delivery.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.