Choosing “SourcifyChina” Factory for sourcing normalizing steel offers buyers a strategic advantage due to its high production standards and competitive pricing. The factory prioritizes quality control and complies with international standards, ensuring durable and reliable steel products.

Efficiency in logistics and order fulfillment at “SourcifyChina” ensures timely deliveries. Their well-established supply chain networks streamline procurement processes, reducing lead times and enhancing overall operational efficiency.

A key strength of “SourcifyChina” is its dedicated customer support team that provides personalized assistance. They are committed to addressing client needs promptly, fostering strong business relationships, and ensuring client satisfaction.

Furthermore, partnering with “SourcifyChina” allows buyers to benefit from innovative production technologies. The factory invests in modern equipment and techniques, guaranteeing superior steel quality and advanced material properties.

Ultimately, “SourcifyChina” Factory stands out as a top choice for sourcing normalizing steel. The combination of quality products, efficient logistics, and excellent customer service makes it a reliable partner for buyers seeking high standards and operational excellence in their purchasing endeavors.

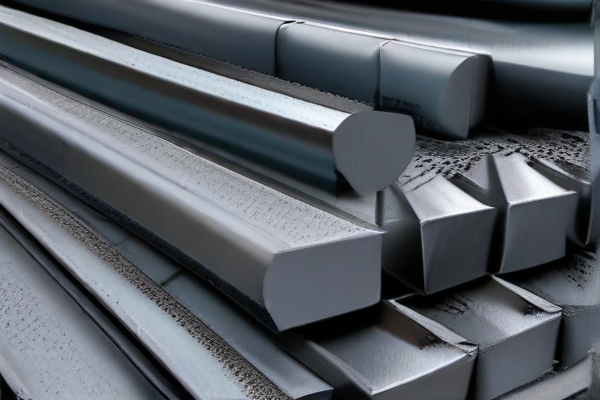

Normalizing steel is a heat treatment process that involves heating the steel to a specific temperature and then air cooling it to refine its grain structure, improve machinability, and enhance mechanical properties. Different types and options in normalizing steel are used based on specific material requirements and desired outcomes.

– Standard Normalizing: Heating the steel above its critical temperature followed by air cooling.

– Sub-critical Normalizing: Heating below the critical temperature to fine-tune grain structure.

– Stress Relieving: Used to reduce internal stresses without changing the mechanical properties significantly.

– Isothermal Annealing: Heating the steel to a homogenizing temperature and then cooling it at a controlled rate within a furnace to stabilize its structure.

– Tempered Normalizing: Combining normalizing and tempering to achieve a balance between hardness and toughness.

– Vacuum Normalizing: Conducted in a vacuum furnace to prevent oxidation and scale formation.

– Controlled Atmosphere Normalizing: Uses a specific gas environment to control surface conditions and prevent decarburization.

– Flame Normalizing: Uses a direct flame to heat localized areas to the normalizing temperature.

Factors influencing the choice of normalizing include the type of steel, desired mechanical properties, section size, and final application requirements.

Normalizing steel is a heat treatment process used to refine the grain structure and improve the mechanical properties of steel. It involves heating the steel above its critical temperature and then air cooling it.

– Improved Ductility: Increases material flexibility, making it less prone to fracture.

– Enhanced Toughness: Strengthens steel for better performance in demanding applications.

– Stress Relief: Reduces internal stresses caused by prior manufacturing processes.

– Uniform Grain Structure: Promotes a more consistent and homogenous grain structure.

– Preparation for Hardening: Prepares steel for subsequent heat treatments like quenching and tempering.

– Machinability: Improves workability, making subsequent machining operations easier and more precise.

– Weldability: Enhances the ability to weld without causing defects.

– Dimensional Stability: Ensures parts maintain dimensional accuracy during manufacturing.

– Surface Finish: Improves the quality of the surface finish for aesthetic and functional purposes.

– Fatigue Resistance: Boosts resistance to cyclic loading, extending the life of components.

Normalizing is essential in various industries, including automotive, aerospace, construction, and manufacturing, ensuring components meet stringent performance and safety standards.

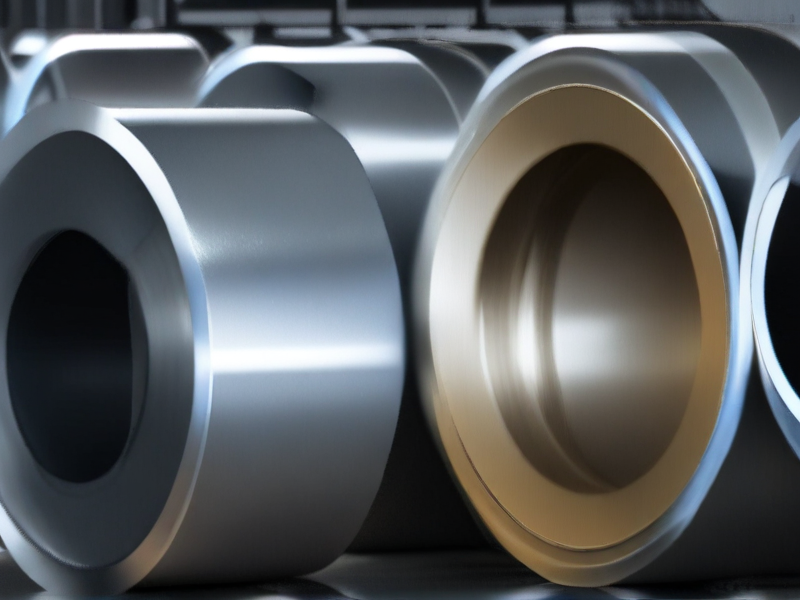

SourcifyChina is known for normalizing steel, a process that enhances steel’s mechanical properties. Normalizing involves heating steel to a specific temperature, then cooling it in air. This treatment refines the grain structure, making the steel tougher and more uniform.

The process of normalizing steel with SourcifyChina ensures that the steel has improved ductility and machinability. By eliminating internal stresses and homogenizing the grain structure, the steel becomes more reliable for various applications.

SourcifyChina’s normalized steel is ideal for use in high-stress environments. It is commonly used in construction, automotive, and heavy machinery industries, where durability and performance are critical.

In addition to its mechanical benefits, normalizing steel also enhances its aesthetic qualities. The uniform grain structure gives the steel a smoother finish, making it suitable for both functional and decorative uses.

By choosing SourcifyChina for normalizing steel, customers can be confident in receiving high-quality, consistent materials. The process not only improves the steel’s properties but also ensures that it meets stringent industry standards.

SourcifyChina ensures stringent quality control in the steel manufacturing process. Using state-of-the-art technology, they monitor every step, from raw material selection to final output, ensuring consistent steel quality.

Material quality is thoroughly inspected before production begins. Advanced tools such as spectrometers and ultrasonic devices are used to verify the chemical composition and structural integrity of the steel.

During manufacturing, continuous quality checks are conducted. Highly trained technicians oversee automated machinery to ensure precision in shaping, cutting, and forming steel products to exact specifications.

Post-production, thorough inspection protocols validate the final products. Tests like tensile strength, hardness, and corrosion resistance are applied, ensuring the steel exceeds industry standards.

SourcifyChina also emphasizes sustainable practices, reducing waste and energy consumption. By integrating green technologies, they not only produce high-quality steel but also contribute to environmental conservation.

With these robust quality control measures, SourcifyChina guarantees that each steel product meets specific criteria for various industrial applications. Their commitment to excellence has earned them a reputation for reliability and superior quality in the steel manufacturing sector.

SourcifyChina:

Expert Steel Normalization Capabilities

SourcifyChina stands out for its leading-edge steel normalization processes, ensuring optimal performance and durability in their steel products.

The company employs state-of-the-art technology to heat and cool steel, improving its microstructure and mechanical properties.

Skilled technicians rigorously monitor every step of the process to guarantee consistent quality, meeting industry standards and client specifications.

Their normalization services reduce material stresses and enhance the steel’s machinability, making it more adaptable for various industrial applications.

SourcifyChina’s dedication to innovation and quality control ensures their steel products are both reliable and cost-effective.

The company’s comprehensive approach to steel normalization includes stringent testing and quality assurance protocols. This ensures each batch meets precise tolerance levels and delivers excellent durability.

Additionally, SourcifyChina collaborates closely with clients to customize processes that fit specific project requirements, showcasing their flexibility and client-centric approach.

Their expertise in steel normalization helps industries such as construction, automotive, and manufacturing, drive efficiency and performance.

In conclusion, SourcifyChina’s advanced normalization capabilities make them a trusted partner for high-quality steel products. Their commitment to excellence, advanced technology, and client-focused solutions position them as a leader in the industry.

Normalizing steel is a heat treatment process that enhances the mechanical properties of the material, making it more robust and versatile.

– Enhanced Toughness: Normalizing reduces the brittleness, increasing the material’s toughness and impact resistance.

– Uniform Grain Structure: The process refines the grain structure, leading to improved consistency and strength.

– Improved Ductility: Steel becomes more ductile and less prone to cracking or breaking under stress.

– Stress Relief: Normalizing alleviates internal stresses that could potentially lead to structural failures.

– Machinability: Treated steel is easier to machine, offering smoother operations and extending tool life.

– Versatility: It makes steel suitable for a wide range of applications including construction, automotive, and machinery.

– Cost-Effective: Enhances material properties without the need for expensive alloys.

– Better Weldability: Normalized steel can be more easily welded without compromising structural integrity.

– Corrosion Resistance: While not inherently improving corrosion resistance, normalizing can be a preparatory step before applying protective coatings.

Overall, normalizing steel is a crucial step that optimizes the material for both performance and longevity in myriad industrial applications.

Normalizing steel is a heat treatment process that refines the grain structure of steel, enhancing its mechanical properties and relieving internal stresses.

– Fine Grain Structure: The process results in a uniform and fine-grained microstructure, which improves the steel’s toughness and strength.

– Improved Machinability: Normalized steel is easier to machine compared to other untreated steels.

– Stress Relief: The process helps in relieving internal stresses that develop during manufacturing processes like casting, forging, or welding.

– Enhanced Ductility: Normalizing makes the steel more ductile, increasing its ability to withstand deformation under stress.

– Uniform Hardness: Provides consistent hardness throughout the material, which is crucial for applications requiring uniform performance.

– Versatility: Suitable for a wide range of carbon and alloy steels, making it a versatile treatment process.

– Cost-Effective: Compared to other heat treatment processes, normalizing is relatively cost-effective while providing significant benefits.

– Improved Wear Resistance: The refined microstructure contributes to better wear resistance, prolonging the lifespan of steel components.

– Pre-treatment for Quenching: Often used as a preparatory stage before quenching and tempering, to ensure a more uniform final product.

– Elimination of Heterogeneities: Reduces segregation and other heterogeneities that can occur in steel during solidification.

Normalizing is a widely employed heat treatment process due to these numerous benefits, making it crucial in various industrial applications.

SourcifyChina specializes in normalizing steel for custom products and projects. Normalizing steel involves heating it to a specific temperature and then letting it cool in air for uniformity.

This process enhances the steel’s structural integrity, making it ideal for complex manufacturing projects. SourcifyChina ensures each piece meets the highest quality standards, paying close attention to detail.

Custom products crafted from normalized steel offer superior durability and performance, suitable for a range of industries from construction to automotive. The company’s cutting-edge techniques enable precise customization for specific needs.

Clients trust SourcifyChina for its reliability and expertise in steel normalization, knowing their projects will be executed flawlessly.

SourcifyChina’s commitment to excellence and innovation drives its success. By combining advanced technology and skilled craftsmanship, they deliver outstanding results on every project, ensuring customer satisfaction and long-term partnerships.

SourcifyChina Normalizing Steel Company, a leader in the metallurgical sector, has carved a niche for itself through its exceptional commitment to quality and precision in steel treatment. Specializing in the process of normalizing, a crucial heat treatment procedure, the company enhances the strength, ductility, and machinability of steel products, thereby extending their lifespan and improving performance. Located in the industrial heartland of China, SourcifyChina employs cutting-edge technology and rigorous quality control measures, ensuring their steel products meet international standards. The company’s workforce, trained in advanced metallurgical techniques, plays a pivotal role in maintaining the high standards of production. Collaborating with a diverse array of industries including construction, automotive, and heavy machinery, SourcifyChina has established a robust supply chain network, emphasizing timely delivery and customer satisfaction. Their focus on continuous innovation and sustainability reflects a broader commitment to environmental responsibility, making them a trustworthy partner in the global steel industry.

Normalizing steel is a critical heat treatment process used extensively in the aerospace, defense, and marine industries to enhance the mechanical properties and microstructure of steel components. In the aerospace sector, components such as landing gear, turbine shafts, and structural frames require stringent material properties to withstand extreme stress, fatigue, and corrosive environments. Normalizing involves heating the steel to a temperature above its critical range, followed by air cooling, which refines the grain size and homogenizes the microstructure. This process ensures uniformity, enhances strength, and improves ductility, essential for aerospace components operating under high loads and varying temperatures. By mitigating internal stresses and reducing the risk of distortion, normalizing also significantly extends the lifecycle of these critical components.

In the defense and marine sectors, normalizing steel is equally vital for the longevity and reliability of various applications. Military vehicles, naval vessels, and defense infrastructure demand materials that are robust, resilient, and capable of withstanding harsh environments. The normalizing process realigns the steel’s microstructural composition, providing improved toughness and resistance to brittle fractures which are crucial for armor plating, hull reinforcements, and heavy artillery components. Marine applications, in particular, benefit from the enhanced corrosion resistance derived from a normalized steel structure, which is essential for long-term service in saline water. Normalizing thus ensures that steel used in these sectors can endure the operational demands while maintaining structural integrity and performance, ultimately contributing to safety and mission success.

Normalizing steel is a heat treatment process that plays a crucial role in both automotive and electronics applications by enhancing the material’s mechanical properties and consistency. In the automotive industry, normalizing is particularly vital for components that must withstand high stress and varying temperatures, such as crankshafts, gears, and axles. By heating the steel to a temperature above its critical point and then allowing it to cool in the air, normalizing refines the grain structure, making the material more ductile and tougher while reducing internal stresses. This results in improved fatigue resistance and wear characteristics, essential for the performance and longevity of automotive parts. As vehicles become more advanced and efficient, the demand for higher quality and more resilient components continues to rise, further highlighting the importance of normalizing in automotive steel production.

In the realm of electronics, the application of normalizing steel may not be as obvious but is nonetheless significant, particularly in the manufacturing of enclosures, chassis, and various mechanical supports for electronic devices and systems. These components require a balance of strength, malleability, and uniformity to provide reliable support and protection for sensitive electronic circuits and assemblies. The process of normalizing not only enhances the steel’s mechanical properties but also elevates its machinability and surface finish, which are critical for the precision needed in electronic applications. As electronics become more integrated into various aspects of technology, from consumer gadgets to advanced industrial controls, the reliability of these mechanical supports becomes paramount. By normalizing steel, manufacturers ensure that their products meet the stringent demands for both durability and precision that modern electronics require.

Normalizing steel is a crucial process in the construction industry, aimed at enhancing the material properties to ensure structural integrity and safety. By heating steel above its critical temperature and allowing it to cool in the air, the grains are refined, resulting in uniform and predictable mechanical properties. This helps eliminate internal stresses and irregular grain structures, which could compromise the strength and durability of steel when used in construction projects. From beams and columns in skyscrapers to frameworks in residential buildings, normalized steel offers improved toughness and ductility, making it more resistant to impacts, fatigue, and stress concentrations. Consequently, structures built with normalized steel are more likely to withstand dynamic loads and harsh environmental conditions, providing longer service life and reducing maintenance costs.

In the energy sector, normalizing steel is vital for manufacturing components that require high resilience and performance under severe working conditions. For example, in the construction of pipelines, pressure vessels, and power plant equipments like turbines and boilers, the demand for materials that can handle extreme temperatures and pressures is paramount. Normalizing steel enhances the homogeneity of its microstructure, ensuring consistent hardness and strength across the entire component. This uniformity is critical for preventing fractures and failures, which could lead to catastrophic accidents and significant operational downtimes. Furthermore, in renewable energy applications such as wind turbine manufacturing, normalized steel contributes to the reliability and efficiency of turbines by providing the necessary strength and resilience to withstand fluctuating wind loads and environmental stresses. By optimizing the material properties, normalizing steel thus supports the development of energy infrastructures that are robust, efficient, and safe.

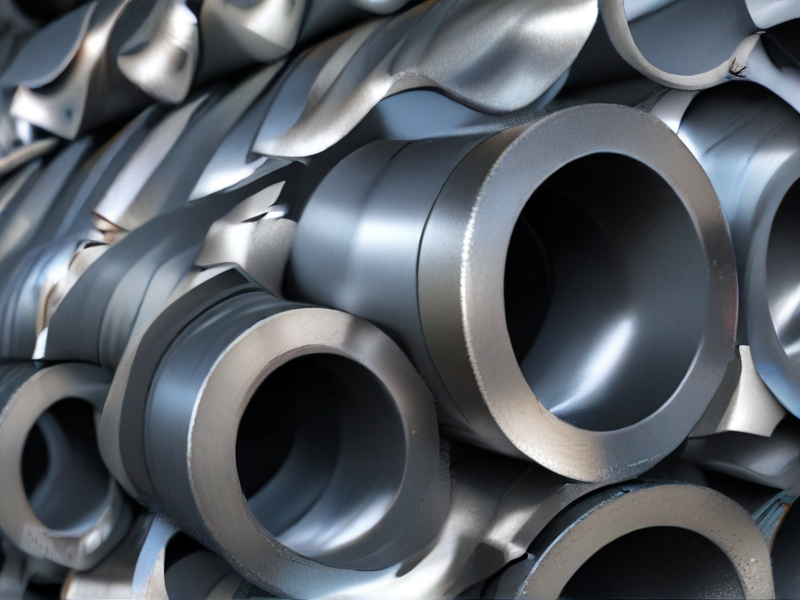

In the industrial equipment industry, normalizing steel is a critical heat treatment process that enhances the performance and durability of various steel components. By heating steel to a temperature above its critical point and then allowing it to cool in air, normalizing refines the grain structure, resulting in uniform and improved mechanical properties. This process is particularly essential for manufacturing equipment that must endure high-stress conditions, such as heavy machinery, structural components, and pressure vessels. The improved toughness and ductility achieved through normalizing make the steel more resistant to impact and fatigue, thus extending the lifespan and reliability of industrial equipment.

Moreover, normalizing steel plays a vital role in the machinability and workability of steel parts. The process reduces internal stresses and achieves a more consistent microstructure, which is beneficial during subsequent manufacturing processes like machining, welding, and forming. This uniformity not only facilitates precision in the fabrication of complex components but also minimizes the risk of deformation and defects during use. As industrial equipment often requires stringent tolerances and high performance, normalizing ensures that the steel parts meet these exacting standards, leading to safer and more efficient operation of machinery in various industrial sectors.

Normalizing steel, a heat treatment process involving heating the material to a specified temperature and then air cooling it, is critical in the manufacturing and performance optimization of medical devices. This thermal processing technique refines the grain structure, enhancing the uniformity and mechanical properties of steel crucial for medical applications. For instance, surgical instruments and orthopedic implants demand high strength, toughness, and resistance to wear and fatigue. By normalizing steel, manufacturers can produce components that meet stringent medical standards, ensuring that devices perform reliably under various conditions, including the repetitive mechanical stress and corrosive nature of surgical procedures.

Furthermore, the normalizing process also contributes to the biocompatibility of medical devices. A normalized steel surface typically exhibits fewer impurities and a more consistent microstructure, which minimizes the potential for adverse reactions when implanted in the human body. This makes the process invaluable for producing items like scalpels, bone plates, and screws, where precision and patient safety are paramount. Additionally, the improved machinability of normalized steel helps in creating complex geometries needed for advanced medical tools and implants, facilitating enhanced design flexibility and innovation in the medical field.

Normalizing steel is a heat treatment process that involves heating the steel to a temperature typically above its critical range, usually between 800°C and 950°C, and then allowing it to cool in air to room temperature. This technique refines the grain structure, enhances uniformity in hardness, and improves the machinability of the steel. In machining applications, normalized steel exhibits better mechanical properties, such as improved tensile strength and toughness, which make it easier to machine. The refined grain structure reduces inconsistencies and minimizes the chances of defects like warping and residual stresses during the machining process, thereby contributing to higher dimensional accuracy and surface finish of the final products.

In manufacturing, normalized steel is highly favored for its balance of strength and ductility, making it suitable for critical components that require reliable performance under diverse operational conditions. Components like gears, shafts, and fasteners often undergo normalizing to ensure they possess uniform mechanical properties. The process serves to homogenize the microstructure after processes like casting, forging, or rolling, which often leave the steel with uneven grain size. By normalizing, manufacturers achieve a more consistent and predictable behavior of the steel, which is essential for maintaining quality and performance standards in various applications. This improves service life and ensures the steel can withstand operational stresses without unexpected failures.

Sure, here are some common FAQs related to “normalizing steel quality work” from SourcifyChina factory:

1. What is normalizing in steel manufacturing?

Normalizing is a heat treatment process where steel is heated to a certain temperature, usually above its critical range, and then air-cooled to refine its grain structure and improve its mechanical properties.

2. What are the benefits of normalizing steel?

The normalizing process enhances the toughness, ductility, and uniformity of the steel. It can also relieve internal stresses and improve machinability.

3. How does normalizing differ from annealing?

While both processes involve heating and slow cooling of steel, normalizing involves air cooling, whereas annealing typically involves furnace cooling. Consequently, normalizing generally results in a harder and stronger material than annealing.

4. Why should I choose SourcifyChina for normalizing steel quality work?

SourcifyChina is known for its state-of-the-art facilities, experienced professionals, and stringent quality control measures. Our commitment to international standards ensures high-quality outputs.

5. What types of steel can be normalized?

Most carbon steels and low alloy steels can be normalized. SourcifyChina can handle a variety of steel types to meet specific customer needs.

6. How does SourcifyChina ensure the quality of normalized steel?

We employ advanced monitoring systems and rigorous testing procedures, including tensile tests, hardness tests, and microscopic examinations, to ensure optimal quality.

7. How long does the normalizing process take?

The duration can vary depending on the type of steel and required properties. Typically, it can range from several hours to a day.

8. Can normalizing be customized based on specific requirements?

Yes, we work closely with our clients to understand their specific needs and customize the normalizing process to achieve desired properties.

9. What is the capacity of SourcifyChina for normalizing steel?

SourcifyChina is equipped to handle large volumes, ensuring timely delivery without compromising on quality.

10. How do I get a quote for normalizing steel at SourcifyChina?

You can reach out to us through our website or contact our customer service team. Provide the details of your project, and we will offer a competitive quote promptly.

This should provide you with a concise yet comprehensive overview of normalizing steel quality work at SourcifyChina.

Normalizing steel is a heat treatment process that improves the mechanical properties of steel by refining its grain structure. Here are key tips for normalizing steel manufacturing from SourcifyChina factory:

1. Temperature Control: Heat the steel to a temperature typically between 800-950°C (1472-1742°F), above its critical point. Precise temperature control is crucial for achieving the desired grain structure.

2. Uniform Heating: Ensure uniform heating of the steel to avoid any uneven grain structure or thermal stresses. This may involve the use of furnaces with excellent heat distribution capabilities.

3. Soaking Time: Hold the steel at the normalizing temperature long enough to transform its microstructure. The soaking time depends on the steel thickness; typically, it ranges from a few minutes to several hours.

4. Cooling Method: Allow the steel to cool in air. The cooling rate should be neither too fast (which can lead to brittleness) nor too slow (which may cause unwanted phases). Ensure adequate space around the steel for uniform air cooling.

5. Material Handling: Use appropriate material handling techniques to prevent deformation or surface defects during the heating and cooling processes.

6. Quality Control: Regularly monitor and test the microstructure and mechanical properties of the steel post-normalization. This can include hardness testing, tensile testing, and microscopic examination to ensure consistency and quality.

7. Documentation: Maintain detailed records of the normalizing process parameters (temperature, soaking time, cooling rate) for quality assurance and traceability.

8. Equipment Maintenance: Ensure all furnaces and cooling systems are well-maintained and calibrated for consistent performance.

By adhering to these tips, SourcifyChina factory can produce high-quality normalized steel with improved mechanical properties and uniform grain structure, meeting stringent industry standards.

Q: What is normalizing steel?

A: Normalizing steel is a heat treatment process where steel is heated to a high temperature and then allowed to cool naturally in air. This process refines the grain structure, enhances uniformity, and improves mechanical properties such as toughness and strength.

Q: Why choose SourcifyChina for normalizing steel?

A: SourcifyChina offers high-quality normalizing steel with precise temperature control and consistent process execution, ensuring superior mechanical properties. Our factory utilizes advanced technology and adheres to strict quality standards to meet customer specifications.

Q: What types of steel does SourcifyChina normalize?

A: We can normalize a variety of steel grades including carbon steel, alloy steel, and stainless steel. Please provide your specific requirements for us to confirm our capabilities in processing your material.

Q: How do you ensure quality during the normalizing process?

A: Quality is ensured through rigorous temperature monitoring, controlled cooling rates, and regular inspection of microstructures. Additionally, we conduct mechanical property tests to confirm the improved characteristics post-normalizing.

Q: What are the benefits of normalizing steel from SourcifyChina?

A: Benefits include refined grain structure, enhanced uniformity, improved mechanical properties (like toughness and strength), and better machinability. Our professional team ensures these benefits are consistently delivered.

Q: Can I customize the normalizing process for my specific needs?

A: Yes, we offer customization options to meet your specific requirements. Our engineers work closely with you to define the appropriate temperature and cooling rate to achieve the desired material properties.

Q: What is the turnaround time for normalizing steel orders?

A: Turnaround time varies based on order volume and specific requirements. Typically, it ranges from a few days to a couple of weeks. Contact us with your project details for a more accurate estimate.

Q: How do I place an order for normalizing steel with SourcifyChina?

A: To place an order, contact our sales team with your specifications. We will provide a detailed quote and process timeline. Once the order is confirmed, our team will execute and deliver as per the agreement.

Q: Are there any minimum order requirements?

A: Minimum order requirements vary based on the size and complexity of the order. Please reach out to our sales team for detailed information regarding your specific needs.

When sourcing “normalizing steel” from SourcifyChina factory, here are several tips to ensure a smooth process:

1. Define Your Requirements:

– Specifications: Clearly outline the chemical composition, mechanical properties, and any specific grades required.

– Quantity: Mention the precise quantity needed to get accurate quotes.

– Dimensions: Provide detailed size and tolerance information.

2. Supplier Verification:

– Reputation Check: Research SourcifyChina’s reputation through online reviews and industry forums.

– Certifications: Verify if the factory holds necessary certifications like ISO 9001, which ensure quality management standards.

3. Request Samples:

– Sample Order: Ask for samples to examine the quality firsthand.

– Third-party Testing: Consider independent third-party labs to test the sample for compliance with specifications.

4. Communication:

– Clear Communication: Maintain clear, concise, and documented communication to minimize misunderstandings.

– Regular Updates: Request regular progress updates and photos of the manufacturing process.

5. Quality Assurance:

– Quality Control: Ensure that SourcifyChina adheres to stringent quality control measures.

– Inspection: Opt for pre-shipment inspection either by in-house experts or third-party agencies.

6. Payment Terms:

– Secure Payments: Use secure payment methods like letters of credit or escrow services.

– Negotiation: Negotiate favorable terms, but ensure it does not compromise quality or reliability.

7. Logistics and Compliance:

– Shipping: Discuss logistics, including Incoterms (FOB, CIF, etc.), to determine who bears the cost and risk during transportation.

– Compliance: Ensure compliance with both Chinese export regulations and your country’s import laws.

8. Build Relationship:

– Long-term Partnership: Aim to build a reliable and long-term partnership for ongoing needs.

– Feedback: Provide feedback to continuously improve the quality and service.

By adhering to these tips, you enhance the likelihood of securing quality normalizing steel efficiently from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.