Choosing SourcifyChina Factory for purchasing marking metal from China ensures high-quality products and competitive prices. The factory’s advanced technology and stringent quality control guarantee durable and precise marking metal that meets international standards.

Additionally, SourcifyChina Factory provides exceptional customer service, ensuring a smooth and efficient purchasing process. The experienced team offers personalized support to address any inquiries and facilitate seamless transactions.

Moreover, the factory’s strategic location in China enables efficient logistics and reduced shipping times. This advantage ensures timely delivery of orders, helping buyers meet their project deadlines without hassle.

In summary, SourcifyChina Factory stands out with its unparalleled product quality, excellent customer support, and strategic logistics. By choosing this factory, buyers can confidently acquire premium marking metal from China with utmost satisfaction.

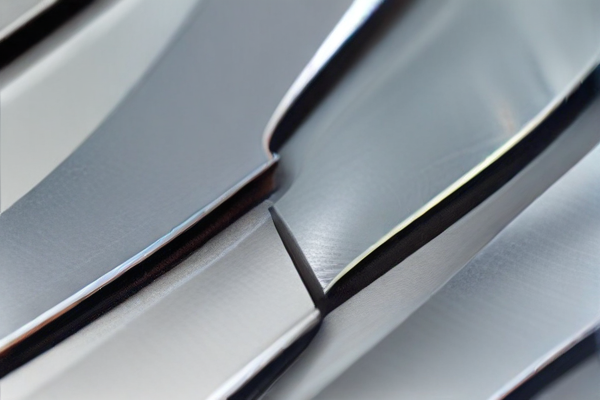

Marking metal involves various methods to label, decorate, or provide information on metal surfaces. Techniques range from traditional to advanced, each suited for specific applications and material types.

– Engraving: Mechanical process that removes metal to create designs or text.

– Stamping: Uses dies to imprint shapes or letters onto metal.

– Laser Marking: Employs lasers to etch or engrave without contact, offering high precision.

– Electrochemical Etching: Uses electrical current and a chemical solution to create permanent marks.

– Inkjet Printing: Applies ink to metal surfaces, suitable for non-permanent marks.

– Dot Peen Marking: Creates dots on the surface using a carbide or diamond tip for durable marks.

– CNC Milling: Uses computer-controlled mills to engrave intricate patterns or text.

– Chemical Etching: Involves using acids or other chemicals to etch designs onto metal.

– Annealing: Alters the metal surface at a molecular level using lasers, creating dark, high-contrast marks without material removal.

– Hand Engraving: A manual technique where artisans use tools to carve designs by hand.

Each method varies in terms of durability, precision, cost, and suitability for different metals and applications, making it important to choose the right technique for specific marking needs.

Marking metal is essential in various industries for identification, traceability, and quality control. It ensures parts are correctly identified throughout their lifecycle, enhancing efficiency and compliance.

– Industrial Manufacturing: Tracking components, tools, and machinery.

– Aerospace: Marking parts for maintenance and safety compliance.

– Automotive: Identifying parts for assembly and recalls.

– Electronics: Labeling circuit boards and components.

– Medical Devices: Ensuring traceability and compliance with regulations.

– Jewelry: Engraving for customization and branding.

– Defense: Marking for identification and inventory control.

– Construction: Labeling tools and structural components.

– Art and Crafts: Creating detailed engravings for decorative purposes.

– Inventory Management: Ensuring accurate stock control and asset tracking.

– Legal Compliance: Meeting regulatory standards for traceability and documentation.

– Security: Anti-counterfeiting measures and asset protection.

– Fabrication: Identifying materials and components during the production process.

– Maintenance: Tracking parts for repair and service schedules.

– Custom Branding: Adding logos and branding on products.

SourcifyChina specializes in marking metal materials known for their high durability and precision. These metals are essential in various industries for creating detailed and long-lasting engravings and marks.

The metal used by SourcifyChina boasts excellent resistance to corrosion and wear, ensuring that markings remain clear and intact over time. This feature is crucial for applications that require longevity and reliability.

Their marking metal also offers superior workability, allowing for intricate designs and precise details. This makes it ideal for high-quality product branding and identification.

Furthermore, SourcifyChina’s metal materials are versatile, suitable for use with different marking technologies, including laser engraving and stamping. This versatility meets diverse client needs across various sectors.

In summary, SourcifyChina’s marking metals provide a combination of durability, precision, and versatility. These qualities make them an excellent choice for industries requiring permanent and precise markings on metal surfaces.

SourcifyChina’s metal marking quality control process ensures high standards and precision. It begins with rigorous selection of raw materials, ensuring they meet specified criteria. Each batch undergoes thorough inspection for defects and consistency.

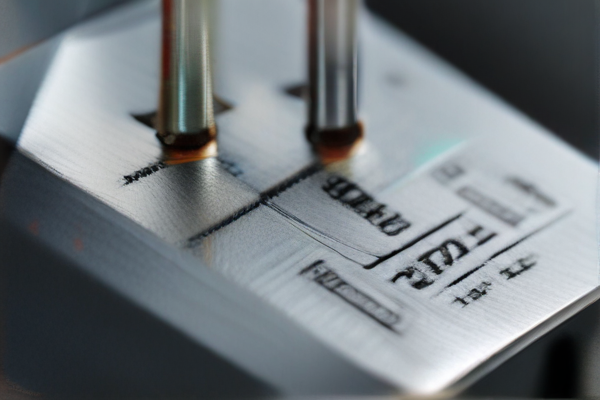

The next step involves advanced machinery and technology for metal marking, which guarantees accuracy and durability. State-of-the-art laser marking systems are employed to achieve precise and permanent marks on various metal surfaces.

During production, continuous monitoring and testing are conducted to maintain quality. Skilled technicians oversee the process, ensuring adherence to design specifications and identifying any discrepancies early on.

Final inspection is crucial, where each marked piece is carefully examined. This stage involves both automated and manual checks to ensure the markings are clear, precise, and meet client requirements.

Additionally, SourcifyChina places great emphasis on feedback and improvement. Post-production evaluations and client feedback are integral to refining the process, ensuring that quality consistently meets or exceeds expectations.

SourcifyChina excels in metal marking, offering advanced laser marking technology. This ensures high precision and clarity, which is ideal for intricate designs and detailed information. The company caters to various industries, including automotive, electronics, and medical devices, providing customized solutions that meet specific requirements.

Their metal marking capabilities cover a wide range of metals such as stainless steel, aluminum, brass, and titanium. The versatility in materials allows clients to choose the best fit for their products. SourcifyChina’s technology ensures durability, making the marks resistant to wear, heat, and corrosion.

SourcifyChina employs state-of-the-art equipment that supports both large-scale production and small-batch projects. This flexibility is beneficial for businesses of all sizes, ensuring that each project receives the appropriate level of attention and resources. Their process is efficient, reducing turnaround times and maintaining high quality.

In addition to traditional laser marking, SourcifyChina offers services such as engraving, etching, and deep marking. This variety allows them to cater to different aesthetic and functional needs. Whether it’s branding, traceability, or compliance marks, SourcifyChina ensures that each mark is permanent and legible.

Their team of skilled technicians provides expert guidance from design to execution. This collaborative approach ensures that clients achieve optimal results. SourcifyChina’s commitment to quality and customer satisfaction is evident in their meticulous attention to detail and use of the latest technology.

Overall, SourcifyChina’s metal marking capabilities are comprehensive and adaptable, making them a reliable partner for businesses seeking high-quality marking solutions. With a focus on innovation and precision, they continue to set industry standards in metal marking services.

Marking metal offers numerous benefits across various industries, enhancing both functionality and traceability of metal components. Here are the key advantages:

– Traceability: Ensures every component can be tracked through its lifecycle, aiding in quality control and recall management.

– Branding: Allows manufacturers to mark their logo or brand, helping in product identification and promoting brand recognition.

– Compliance: Meets regulatory requirements by providing essential information such as serial numbers, batch numbers, and manufacturing details.

– Anti-Counterfeiting: Deters counterfeiters by making it difficult to replicate marked components.

– Maintenance: Facilitates easier maintenance and repairs by providing clear identification of parts and specifications.

– Inventory Management: Simplifies inventory tracking and management by providing detailed information about each component.

– Durability: Creates permanent marks that withstand harsh environments and wear, ensuring long-term legibility.

– Customization: Enables personalization of products, offering customers tailored solutions and enhancing customer satisfaction.

Marking metal involves techniques and tools to inscribe, etch, or engrave information on metal surfaces for identification, decoration, or functionality.

Key Features of Marking Metal:

– Permanence: Marks are long-lasting and resistant to wear and tear.

– Precision: Allows for detailed and accurate markings, even on small surfaces.

– Versatility: Can be applied to various types of metals and surfaces.

– Customization: Enables unique designs, logos, and information to be inscribed.

– Traceability: Useful for tracking and inventory management.

– Durability: Markings withstand harsh environments, including extreme temperatures and chemicals.

– Aesthetic Appeal: Enhances the visual appearance of products.

– Anti-Counterfeiting: Helps prevent forgery and ensure authenticity.

– Ease of Application: Can be done using various methods such as laser engraving, stamping, or chemical etching.

– Compliance: Meets industry standards and regulations for product identification and safety.

SourcifyChina specializes in custom metal marking products and projects, providing tailored solutions for diverse industrial needs. Their expertise covers a wide range of metal types and marking techniques, ensuring high precision and durability.

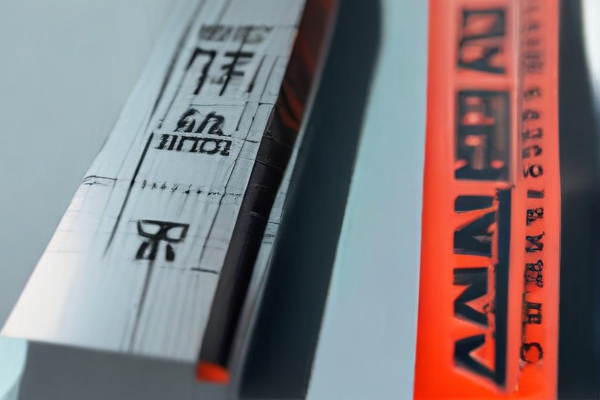

Their product lineup includes engraved nameplates, metal tags, and custom plaques, designed to withstand harsh environments. These products are ideal for applications in manufacturing, construction, and other industries requiring durable identification.

SourcifyChina also offers bespoke project solutions, collaborating closely with clients to meet specific requirements. Their advanced technology and skilled craftsmanship guarantee top-quality results, enhancing both functionality and aesthetic appeal.

Customer satisfaction is a priority for SourcifyChina. They provide comprehensive support, from initial consultation to final delivery, ensuring each project meets the highest standards. This dedication to quality and service makes them a trusted partner for custom metal marking needs.

SourcifyChina Marking Metal is a prominent company specializing in the provision of high-quality metal marking solutions tailored for diverse industrial applications. With a strong foothold in the manufacturing sector, SourcifyChina offers a wide array of marking technologies, including laser marking, dot peen marking, and engraving, ensuring precision and durability. Their services cater to various industries such as automotive, aerospace, electronics, and heavy machinery, meeting the stringent requirements for traceability, part identification, and branding. The company prides itself on its advanced technology and commitment to innovation, which enables them to deliver customized solutions that enhance efficiency and product integrity. Additionally, SourcifyChina places a significant emphasis on customer service, providing comprehensive support from consultation to implementation, thereby fostering long-term partnerships with clients worldwide. This dedication to excellence and adaptability positions SourcifyChina Marking Metal as a leader in the metal marking industry, continually driving progress through cutting-edge technology and exceptional service standards.

Marking metal plays a pivotal role in the aerospace, defense, and marine sectors, where precision, durability, and traceability are of utmost importance. In aerospace applications, every component, from engine parts to structural elements, must be marked with critical information such as part numbers, serial numbers, and manufacturing dates. Laser marking is often employed due to its ability to produce clear, permanent marks that can withstand extreme conditions such as high temperatures and corrosion. This ensures that parts can be reliably traced throughout their lifecycle, aiding in maintenance and quality control. Moreover, the aerospace industry demands compliance with stringent regulations and standards, and accurate marking is crucial for certification and safety audits.

In the defense and marine sectors, robust and legible markings on metal components are essential for both operational efficiency and logistical management. Metal marking techniques, such as dot peen or deep engraving, are commonly used to identify weaponry, machinery, and structural parts with unique identifiers and barcodes. These marks must endure harsh environments, including saltwater exposure and extreme weather conditions, ensuring that equipment and vehicles can be accurately identified and maintained. For example, in naval operations, the ability to trace the origin and service history of parts is key to preventing equipment failure and maintaining fleet readiness. Both sectors also use marking to enhance security by embedding anti-counterfeiting features and ensuring the traceability of sensitive and high-value items.

In the automotive industry, marking metal is a critical process for ensuring the traceability and identification of various components. Laser marking, in particular, is widely used to engrave serial numbers, barcodes, and other identifying information directly onto metal parts. This practice enhances quality control and compliance with industry regulations, as it allows for the precise tracking of parts throughout the manufacturing process and the entire lifecycle of the vehicle. Additionally, marking metal helps prevent counterfeiting and ensures that any defective components can be quickly identified and replaced, thereby maintaining the integrity and safety of the vehicles produced.

In the electronics sector, marking metal plays a pivotal role in the identification and classification of components, especially on printed circuit boards (PCBs) and electronic enclosures. Laser marking is preferred due to its ability to produce high-resolution, durable markings without damaging sensitive electronic parts. This process ensures that important information, such as product codes, batch numbers, and compliance logos, remains legible even in harsh environments. Marking metal also facilitates efficient inventory management and quality assurance by enabling manufacturers to trace the origin and history of each component, thereby improving the reliability and performance of electronic devices.

In the construction industry, marking metal is an essential process that ensures precision and accuracy in cutting, welding, and assembly. By clearly marking the dimensions and specifications on metal beams, plates, and other components, workers can avoid costly errors and rework. This practice is crucial in the fabrication of structural frameworks, where precise measurements are vital for the stability and integrity of buildings and infrastructure. Moreover, the use of advanced marking technologies, such as laser marking and CNC machines, has enhanced the speed and accuracy of the construction process, allowing for the efficient production of complex metal parts that meet stringent safety and quality standards.

In the energy sector, marking metal plays a significant role in the maintenance and operation of various systems, including pipelines, power plants, and renewable energy installations. Properly marked metal components facilitate easy identification and tracking, which is critical for ensuring the reliability and safety of energy infrastructure. For example, in the case of pipelines, marking can indicate the type of material, thickness, and other specifications, aiding in inspection and maintenance activities. Similarly, in power plants, marked metal parts help in the quick identification of components during repairs, reducing downtime and enhancing operational efficiency. In renewable energy projects, such as wind turbines and solar farms, precise marking ensures the correct assembly and alignment of metal structures, contributing to the overall performance and longevity of the installations.

In the industrial equipment industry, marking metal plays a crucial role in ensuring traceability, quality control, and brand recognition. This process involves the use of various techniques such as laser engraving, dot peen marking, and inkjet printing to imprint permanent identifiers, such as serial numbers, barcodes, and logos, on metal surfaces. Laser marking, in particular, is favored for its precision and ability to produce high-contrast, durable marks without compromising the integrity of the material. These identifiers are essential for tracking parts through the manufacturing process, verifying authenticity, and facilitating maintenance by providing clear, readable information even in harsh environments.

Additionally, marking metal is instrumental in meeting regulatory requirements and industry standards. Sectors such as aerospace, automotive, and medical devices rely heavily on marked components to adhere to stringent safety and compliance guidelines. For instance, the automotive industry uses VIN (Vehicle Identification Number) marking to ensure each vehicle part is traceable back to its origin, which is critical for recalls and quality assurance. In the medical field, marked surgical instruments and implants help prevent mix-ups and ensure patient safety. Overall, the application of marking metal in the industrial equipment industry enhances operational efficiency, improves product lifecycle management, and supports robust quality assurance protocols.

Medical Devices Application of Marking Metal

Marking metal in medical devices is crucial for ensuring traceability, compliance, and identification. This process involves permanently engraving or etching information such as serial numbers, barcodes, and manufacturer details onto the metal parts of devices like surgical instruments, implants, and diagnostic equipment. The permanence and precision of metal marking, achieved through techniques like laser marking or electrochemical etching, allow for the accurate tracking of devices through their lifecycle. This traceability is vital for regulatory compliance, especially under frameworks like the FDA’s Unique Device Identification (UDI) system, which mandates that each medical device must have a distinct identifier to enhance patient safety and facilitate efficient recalls if necessary.

Moreover, marking metal contributes significantly to the integrity and performance of medical devices. Precise marking ensures that essential information is easily readable and remains intact even after sterilization processes or exposure to bodily fluids. This durability is critical in high-stress medical environments where device integrity can impact patient outcomes. For instance, implants and prosthetics often bear markings that include material composition or manufacturer identifiers, aiding in compatibility checks and post-implantation assessments. As medical devices become increasingly sophisticated, the need for reliable and enduring metal marking grows, underscoring its role in the evolving landscape of medical technology.

Marking metal in machining and manufacturing is a critical process that ensures traceability, quality control, and proper assembly of components. This practice involves inscribing or etching identifiers such as serial numbers, batch numbers, or barcodes onto metal surfaces. These marks enable manufacturers to track each part through the production process, ensuring that any defects can be traced back to their source, thus improving overall product quality. Techniques like laser marking, dot peen marking, and inkjet printing are commonly used, with laser marking offering high precision and durability without compromising the metal’s integrity. This capability is essential in industries like aerospace, automotive, and medical devices, where stringent quality standards are mandatory.

In addition to traceability, marking metal also facilitates assembly and maintenance operations. Parts marked with clear identifiers can be easily matched and assembled, reducing errors and improving efficiency. For instance, during complex assembly processes in automotive manufacturing, components must be correctly matched and fitted, and marked identifiers simplify this task. Furthermore, in maintenance and repair operations, marked components enable technicians to quickly identify and replace faulty parts, minimizing downtime. This process is also integral in ensuring compliance with industry regulations and standards, as traceable and marked components are often a legal requirement. Overall, the marking of metal is a vital practice that supports the seamless and efficient operation of modern manufacturing and machining processes.

Q1: What types of metal marking services does SourcifyChina offer?

A1: SourcifyChina provides laser marking, engraving, and etching services for a variety of metals, ensuring precise and high-quality results suitable for industrial and consumer products.

Q2: Can you handle large volume orders?

A2: Yes, SourcifyChina is equipped to manage both small and large volume orders, ensuring timely delivery without compromising on quality.

Q3: What metals can be marked at SourcifyChina?

A3: We can mark a wide range of metals, including stainless steel, aluminum, brass, copper, and titanium, among others.

Q4: How precise is the metal marking process?

A4: Our advanced laser marking technology ensures high precision, with accuracy up to microns, making it ideal for detailed designs and fine text.

Q5: Is there a minimum order quantity (MOQ) for metal marking services?

A5: While there is no strict MOQ, we recommend discussing your project with our team to ensure we can meet your specific requirements efficiently.

Q6: How does SourcifyChina ensure the quality of marked products?

A6: Quality is ensured through rigorous inspection processes at every stage of production, coupled with advanced machinery and experienced technicians.

Q7: What is the turnaround time for orders?

A7: Turnaround time depends on the order size and complexity. Typically, we aim to complete orders within 1-2 weeks, but exact timelines will be confirmed upon order placement.

Q8: Can you provide custom designs for metal marking?

A8: Yes, we offer customization services to meet your specific design requirements. Our team can work with you to create custom logos, text, and patterns.

Q9: How do I get a quote for my project?

A9: To get a quote, please contact us with details of your project, including the type of metal, design specifications, and order volume. We will respond promptly with a detailed quote.

Q10: What industries do you serve?

A10: SourcifyChina serves a variety of industries including automotive, aerospace, medical, electronics, and consumer goods, providing tailored solutions to meet industry-specific needs.

Marking metal manufacturing involves creating permanent marks or designs on metal surfaces, which can include logos, serial numbers, or barcodes. SourcifyChina, a prominent factory in this field, offers several tips to ensure high-quality results:

1. Material Selection: Choose the right metal for your project. Different metals, such as stainless steel, aluminum, and brass, respond differently to marking techniques. Understanding the properties of each metal can help in achieving the desired outcome.

2. Technique Choice: Various marking techniques are available, including laser marking, engraving, etching, and stamping. Laser marking is precise and suitable for detailed designs, while engraving offers depth and texture. Etching provides a durable mark, and stamping is ideal for mass production.

3. Surface Preparation: Ensure the metal surface is clean and free from contaminants. Oils, dust, and rust can affect the quality of the mark. Proper cleaning and preparation can lead to clearer and more durable markings.

4. Design Considerations: Optimize your design for the chosen marking technique. Fine details might not be suitable for all methods, so adjust the design to ensure legibility and durability.

5. Quality Control: Implement a robust quality control process to check the consistency and clarity of the markings. This can include visual inspections, adhesion tests, and durability assessments.

6. Equipment Maintenance: Regular maintenance of marking equipment ensures consistent performance and prolongs the lifespan of the machinery. Follow manufacturer guidelines for cleaning and servicing.

7. Customization and Flexibility: SourcifyChina offers customization options to meet specific needs. Whether it’s for small batches or large-scale production, tailor the marking process to your requirements.

By following these tips, you can achieve high-quality, durable markings that meet your manufacturing standards and customer expectations.

Sure, here are some frequently asked questions (FAQ) along with answers regarding sourcing “marking metal from SourcifyChina factory”:

Q: What types of metal marking products does SourcifyChina offer?

A: SourcifyChina provides a wide range of metal marking products, including laser-marked metals, engraved plates, etched tags, and custom-marked metal components suitable for various industries.

Q: Can SourcifyChina handle custom designs for metal marking?

A: Yes, SourcifyChina specializes in custom designs. You can provide your own designs or work with their team to create unique markings tailored to your specifications.

Q: What materials are available for metal marking at SourcifyChina?

A: SourcifyChina works with various metals, including stainless steel, aluminum, brass, copper, and more, to meet diverse application needs.

Q: What is the lead time for orders from SourcifyChina?

A: The lead time varies depending on the order size and complexity. Typically, it ranges from 2 to 4 weeks. For specific lead times, it’s best to contact SourcifyChina directly.

Q: How does SourcifyChina ensure the quality of its metal marking products?

A: SourcifyChina implements strict quality control measures, including rigorous inspections and testing, to ensure that all products meet high standards of durability and precision.

Q: Are there minimum order quantities (MOQs) for metal marking products?

A: Yes, MOQs apply and can vary based on the product type and customization level. Contact SourcifyChina for detailed MOQ information.

Q: What are the pricing terms for metal marking services at SourcifyChina?

A: Pricing depends on factors such as material type, marking method, order quantity, and customization requirements. For a precise quote, provide your project details to SourcifyChina.

Q: Does SourcifyChina offer international shipping?

A: Yes, SourcifyChina ships products internationally. They work with reliable logistics partners to ensure timely and safe delivery.

Q: What payment methods are accepted by SourcifyChina?

A: SourcifyChina accepts various payment methods, including wire transfers, credit cards, and PayPal. Contact their sales team for more details on payment options.

Q: How can I get a quote for my metal marking project from SourcifyChina?

A: To get a quote, you can visit SourcifyChina’s website and fill out the request form with your project details, or contact their sales team directly via email or phone.

When sourcing metal marking services from SourcifyChina factory, consider the following tips to ensure quality and reliability:

1. Research the Factory:

– Verify the factory’s reputation and history. Look for reviews, ratings, and any complaints.

– Check if they have experience with metal marking and if they have worked with international clients.

2. Define Requirements Clearly:

– Specify the type of metal, dimensions, marking technique (laser, etching, engraving), and any design details.

– Provide clear and detailed specifications to avoid misunderstandings.

3. Request Samples:

– Ask for samples of previous work or a prototype of your design to assess the quality.

– Evaluate the precision, durability, and appearance of the markings on the samples.

4. Quality Control:

– Inquire about the factory’s quality control processes. Ensure they have stringent checks at every production stage.

– Consider hiring a third-party inspection service to verify the quality before shipment.

5. Communication:

– Maintain clear and frequent communication with the factory. Ensure they understand your requirements and deadlines.

– Use visual aids like sketches or CAD files to convey your design specifications accurately.

6. Cost and Lead Time:

– Get detailed quotes including all costs (materials, labor, shipping, taxes).

– Clarify lead times and ensure they align with your project timelines.

7. Intellectual Property Protection:

– Ensure there are agreements in place to protect your designs and intellectual property.

– Use non-disclosure agreements (NDAs) if necessary.

8. Payment Terms:

– Discuss payment terms upfront. Be wary of factories that demand full payment before production.

– Opt for a balanced payment schedule, such as a deposit with the order and the balance upon completion or delivery.

By following these steps, you can effectively source metal marking services from SourcifyChina factory, ensuring high quality and meeting your specific needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.