Understanding CNC Machining: How SourcifyChina Factory Ensures Precision and Reliability

Choosing SourcifyChina Factory ensures high-quality CNC machining services for buyers. With advanced technology and skilled professionals, they offer precision, reliability, and efficiency, meeting diverse industrial needs. Their commitment to quality and customer satisfaction makes them a top choice for sourcing from China.

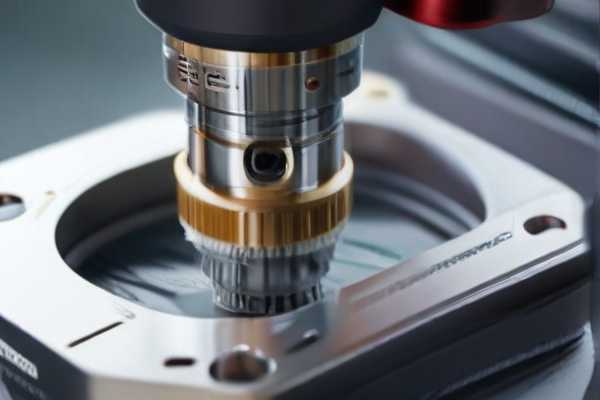

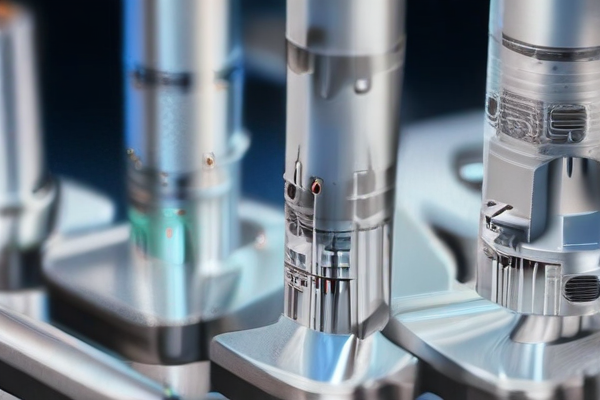

CNC machining at SourcifyChina involves computer-controlled tools that precisely cut, shape, and finish materials. The process starts with a digital design, which is translated into machine instructions. These machines execute the design with high accuracy, ensuring consistent and high-quality production, crucial for complex and detailed components.

The advantages of using SourcifyChina include competitive pricing, quick turnaround times, and adherence to international standards. Their extensive experience in the industry means they understand the intricacies of manufacturing, ensuring that each product meets exact specifications. This combination of factors makes them a reliable partner for buyers globally.

In conclusion, SourcifyChina Factory offers a seamless experience for buyers looking for CNC machining services in China. Their advanced technology, skilled workforce, and commitment to quality ensure that every product meets the highest standards. Partnering with SourcifyChina guarantees precision, efficiency, and satisfaction in every purchase.

CNC machining, or Computer Numerical Control machining, involves using computers to control machine tools. This process enhances precision and efficiency in manufacturing.

Types and options for CNC machining include:

– Milling: Rotating cutters to remove material.

– Turning: Rotating the workpiece while a cutting tool shapes it.

– Drilling: Creating holes using rotating drill bits.

– Grinding: Using abrasive wheels for finishing.

– EDM (Electrical Discharge Machining): Using electrical discharges to shape materials.

– Laser Cutting: Employing laser beams to cut materials.

– Water Jet Cutting: Utilizing high-pressure water jets for cutting.

– Plasma Cutting: Using a high-velocity jet of ionized gas.

Options for CNC machining also involve:

– 3-Axis, 4-Axis, and 5-Axis Machines: Indicating the number of directions the tool or workpiece can move.

– CAD/CAM Software Integration: Facilitating design and manufacturing processes.

– Material Choices: Metals, plastics, composites, and more.

– Custom Tooling: Designing specific tools for unique projects.

– Automation and Robotics: Enhancing efficiency and precision.

– Quality Control: Implementing inspection systems to ensure accuracy.

These options allow for versatile and precise manufacturing solutions across various industries.

CNC machining, or Computer Numerical Control machining, involves automated control of machining tools using a computer. This precise and efficient process is widely used in various industries for producing complex parts and components.

Applications of CNC machining include:

– Automotive Industry: Manufacturing engine components, gears, and prototypes.

– Aerospace Industry: Producing aircraft parts, turbine blades, and structural components.

– Medical Industry: Creating surgical instruments, implants, and custom prosthetics.

– Electronics Industry: Fabricating circuit boards, enclosures, and connectors.

– Defense Industry: Crafting weapon parts, surveillance equipment, and military hardware.

– Oil and Gas Industry: Making valves, pumps, and drilling equipment.

– Furniture Industry: Designing intricate patterns and joints for wooden furniture.

– Jewelry Industry: Crafting detailed designs and customized pieces.

– Consumer Goods: Producing household items, sports equipment, and toys.

– Prototyping: Rapidly creating accurate prototypes for testing and development.

Overall, CNC machining offers versatility, precision, and efficiency, making it essential for modern manufacturing and engineering applications.

SourcifyChina provides a comprehensive guide on CNC machining, highlighting its precision and efficiency. CNC, or Computer Numerical Control, uses computer programs to control machine tools, producing highly accurate parts. This technology is essential in various industries, including automotive and aerospace.

The process begins with designing a part using CAD software. The CAD model is then converted into a CNC program, which guides the machine’s movements. This program is loaded into the CNC machine, which can be a mill, lathe, or router, among others.

During operation, the CNC machine removes material from a workpiece to create the desired shape. The machine’s movements are precisely controlled by the CNC program, ensuring high accuracy and repeatability. Tools are automatically changed as needed to perform different operations, such as drilling, milling, and turning.

Quality control is an integral part of CNC machining. SourcifyChina emphasizes the importance of monitoring each step to ensure the final product meets specifications. Advanced sensors and measuring devices are often used to check dimensions and surface quality.

CNC machining’s efficiency and precision make it a preferred choice for manufacturing complex parts. SourcifyChina’s expertise in this field ensures that clients receive high-quality, reliable components tailored to their needs. Whether for prototypes or large production runs, CNC machining offers versatility and consistency.

SourcifyChina employs CNC machining to produce precision parts by controlling machine tools via computer programming. The process begins with a CAD design, which is then translated into a G-code program guiding the machine’s movements.

High-quality raw materials are selected to ensure durability and performance. The CNC machines operate with minimal human intervention, reducing the risk of errors and ensuring consistency across production batches.

Quality control is integral to SourcifyChina’s manufacturing process. Inspections occur at multiple stages: raw material verification, in-process checks, and final product evaluation. Advanced measuring instruments and techniques are used to verify dimensions and tolerances.

SourcifyChina adheres to stringent quality standards, including ISO certifications, ensuring products meet or exceed customer expectations. Continuous improvement processes are in place to enhance efficiency and product quality over time.

With a focus on precision and quality control, SourcifyChina’s CNC machining capabilities are robust, delivering high-quality components suited for various industries, from automotive to aerospace. Regular maintenance and calibration of machinery ensure optimal performance and longevity.

In summary, SourcifyChina combines advanced CNC machining with rigorous quality control to produce reliable, high-precision parts. The entire process, from material selection to final inspection, is designed to maintain the highest standards, ensuring customer satisfaction and industry compliance.

SourcifyChina offers an extensive array of CNC machining capabilities, utilizing state-of-the-art equipment to provide high-precision components. Their services cater to various industries including automotive, aerospace, and electronics.

The CNC machining process involves programming computers to control machine tools. This automation ensures high accuracy, efficiency, and consistency, crucial for complex designs and tight tolerances.

Materials such as aluminum, stainless steel, and plastics are precisely machined to meet client specifications. SourcifyChina’s advanced CNC equipment can perform milling, turning, drilling, and more, producing intricate parts with excellent surface finishes.

Their skilled technicians and engineers work collaboratively to optimize manufacturing processes, reduce lead times, and ensure stringent quality control. SourcifyChina prioritizes customer satisfaction through rigorous testing and on-time delivery.

Ultimately, SourcifyChina’s CNC machining solutions provide reliable, high-quality parts tailored to specific client needs. This positions them as a trusted partner for businesses seeking excellence in manufacturing.

How CNC Machining Works:

CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery.

Benefits of CNC Machining:

– Precision and Accuracy: Consistently produces parts with tight tolerances, reducing errors and enhancing quality.

– Efficiency: Automated process allows for faster production rates and reduces manual labor.

– Versatility: Capable of working with various materials like metals, plastics, and composites.

– Repeatability: Ensures uniformity across multiple production runs, essential for mass production.

– Complex Designs: Enables the creation of intricate and detailed parts that are difficult to achieve with traditional machining.

– Reduced Waste: Optimized tool paths and efficient material usage minimize waste and lower production costs.

– Flexibility: Easy to switch between different product designs by updating the software program, reducing downtime.

– Safety: Reduces the need for direct human interaction with machinery, minimizing the risk of accidents.

– Scalability: Suitable for both small batch and large-scale production, adapting to varying production needs.

– Cost-Effectiveness: Initial setup costs are offset by long-term savings in labor, material efficiency, and reduced error rates.

CNC (Computer Numerical Control) machining is a manufacturing process that uses computer-controlled machine tools to remove material from a workpiece to create precise parts. This automated method enhances accuracy, consistency, and efficiency.

Key features of how CNC machining works include:

– Computer-Aided Design (CAD): The process begins with creating a digital design using CAD software.

– CAM Software: Computer-Aided Manufacturing (CAM) software converts the CAD model into CNC machine instructions.

– G-Code: The CNC machine interprets these instructions, typically in G-code, which dictates the toolpath.

– Machine Setup: The workpiece is secured, and the appropriate cutting tools are installed.

– Automated Operation: The CNC machine follows the programmed instructions to perform cutting, drilling, milling, or turning operations.

– Precision and Repeatability: CNC machines can produce complex and intricate parts with high precision and repeatability.

– Multi-Axis Control: Advanced CNC machines operate on multiple axes, allowing for more complex geometries.

– Material Versatility: CNC machining can work with various materials, including metals, plastics, and composites.

– Real-Time Monitoring: Many CNC systems feature real-time monitoring and adjustments to ensure quality and accuracy.

– Post-Processing: Finished parts may undergo additional processes such as deburring or surface finishing.

CNC machining revolutionizes manufacturing by combining automation with precision, making it ideal for both prototyping and production runs.

SourcifyChina specializes in custom CNC machining, transforming raw materials into precise parts and products. This process involves automated control of machining tools via computer programs.

CNC machining begins with a digital design, often created in CAD software. This design is then translated into a set of instructions that guide the machinery.

The CNC machines follow these instructions with high precision, cutting and shaping materials such as metal, plastic, and wood into the desired forms.

SourcifyChina uses advanced CNC technology to ensure each product meets exact specifications, ensuring consistency and quality across all projects.

From prototyping to mass production, CNC machining at SourcifyChina offers flexibility and efficiency. This allows for quick adjustments and scalability for various project needs.

Their services cover a wide range of industries, including automotive, aerospace, and consumer electronics, showcasing their versatility and expertise in custom manufacturing solutions.

SourcifyChina specializes in providing high-quality CNC machining services, leveraging advanced technology to produce precise and intricate components for various industries. CNC machining, or Computer Numerical Control machining, involves the use of computers to control machine tools, which can include lathes, mills, routers, and grinders. At SourcifyChina, this process starts with a CAD (Computer-Aided Design) model of the part, which is then converted into a set of digital instructions using CAM (Computer-Aided Manufacturing) software. These instructions guide the CNC machines in executing precise movements to shape the material, typically metal or plastic, into the desired form. The company emphasizes precision, efficiency, and repeatability, ensuring that each part meets strict specifications and quality standards. By utilizing state-of-the-art machinery and skilled technicians, SourcifyChina delivers reliable and cost-effective solutions tailored to the unique needs of its clients, making it a leader in the CNC machining industry.

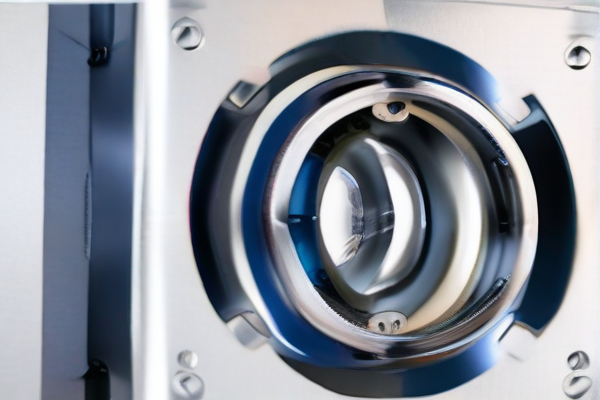

CNC (Computer Numerical Control) machining is pivotal in the aerospace, defense, and marine industries due to its precision and ability to produce complex components. In aerospace, CNC machining is used to manufacture critical parts such as turbine blades, engine components, and structural elements, which require high tolerance and impeccable accuracy. The process involves programming a computer to control the movement of machine tools, enabling the creation of intricate designs from materials like titanium, aluminum, and composites. This ensures that components meet strict safety and performance standards, essential for aircraft reliability and efficiency.

In the defense and marine sectors, CNC machining is equally vital for producing durable and precise parts. For defense applications, CNC machines fabricate weapon components, communication devices, and armored vehicle parts, where precision and robustness are paramount. Similarly, in the marine industry, CNC machining is used to produce parts for propulsion systems, hull components, and navigational instruments, ensuring that vessels operate efficiently and withstand harsh maritime environments. The automated nature of CNC machining not only enhances production speed and consistency but also allows for rapid prototyping and customization, which is crucial for meeting the specific demands of these high-stakes industries.

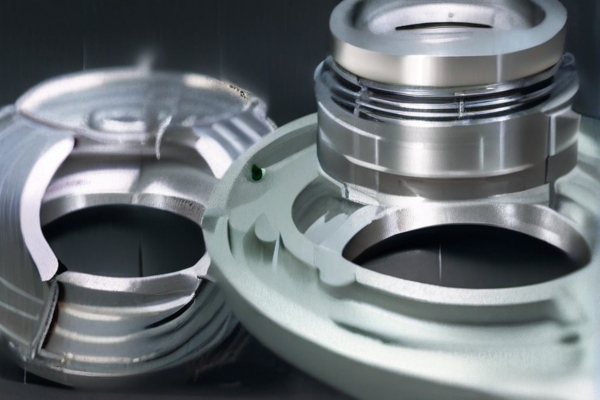

CNC (Computer Numerical Control) machining has revolutionized the automotive industry by streamlining the production of complex and precise components. In automobiles, parts such as engine blocks, cylinder heads, and transmission components require intricate designs and tight tolerances to function efficiently. CNC machining ensures that each of these parts is manufactured with consistent accuracy, enhancing the overall performance and reliability of the vehicles. By utilizing computer-aided design (CAD) software, engineers can create detailed 3D models of the parts, which are then translated into precise instructions for the CNC machine. This automation not only reduces human error but also increases production speed and scalability, meeting the high demands of automotive manufacturing.

In the electronics industry, CNC machining plays a crucial role in producing the delicate and intricately designed components that modern electronic devices rely on. From circuit boards to housing enclosures, CNC tools can fabricate parts with micron-level precision, essential for the miniaturization of electronic devices. CNC machining is particularly useful in prototyping and manufacturing small batches of electronic components, where high precision and consistency are paramount. Moreover, materials such as aluminum, plastic, and even advanced composites can be meticulously shaped to meet the stringent standards of the electronics industry. The integration of CNC machining allows electronics manufacturers to innovate rapidly while maintaining the highest quality standards, thus supporting the continuous advancement and miniaturization of technology.

CNC (Computer Numerical Control) machining is revolutionizing the construction industry by offering precision, efficiency, and scalability. In construction, components such as metal beams, custom fixtures, and architectural elements require exact dimensions and finishes to ensure structural integrity and aesthetic appeal. CNC machines, guided by precise CAD (Computer-Aided Design) models, automate the cutting, drilling, and milling processes, which significantly reduces human error and material wastage. Complex shapes and intricate designs, which would otherwise be time-consuming and labor-intensive, can be produced with high accuracy and repeatability. Furthermore, the capability to work with a variety of materials, from metals to composites, makes CNC machining an invaluable tool in constructing robust and adaptable buildings and infrastructure.

In the energy sector, CNC machining plays a critical role in the fabrication of high-precision components used in power generation and distribution. For instance, turbine blades, engine parts, and other critical components of wind, gas, and hydroelectric power systems must withstand extreme conditions and operate efficiently. CNC machining enables the production of these parts with tight tolerances and superior surface finishes, ensuring optimal performance and longevity. Additionally, CNC technology facilitates the creation of complex geometries required for innovations in renewable energy, such as intricate solar panel components and high-efficiency battery parts. By enhancing the precision and quality of energy components, CNC machining helps improve the reliability and efficacy of energy production systems, ultimately contributing to a more sustainable energy future.

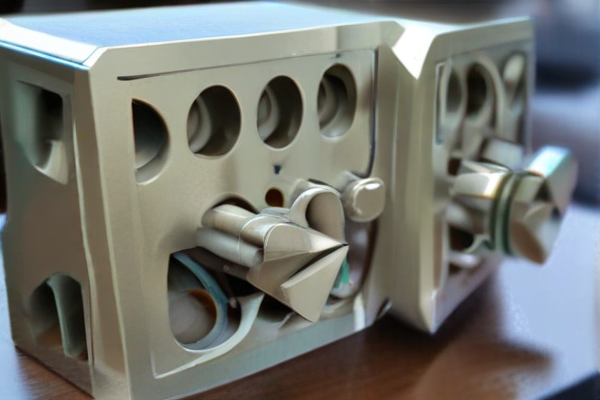

CNC (Computer Numerical Control) machining plays a crucial role in the industrial equipment industry by enabling the precise and efficient manufacturing of complex parts and components. CNC machines operate based on pre-programmed computer software that dictates the movement of tools and machinery. This technology is utilized to cut, drill, grind, and shape raw materials into finished products with high accuracy. The process begins with the creation of a CAD (Computer-Aided Design) model, which is then converted into a CNC program using CAM (Computer-Aided Manufacturing) software. This program directs the machine’s movements, ensuring consistent production quality and reducing human error.

In the industrial equipment sector, CNC machining is essential for producing high-quality, custom-made parts that meet specific industry standards and requirements. It is particularly valuable in the manufacturing of heavy machinery, automotive components, and aerospace parts, where precision and durability are paramount. CNC machines can handle a variety of materials, including metals, plastics, and composites, making them versatile for different industrial applications. Moreover, the automation capabilities of CNC machining streamline production processes, enhance productivity, and reduce lead times, ultimately leading to cost savings and improved efficiency for manufacturers. This technology also supports the rapid prototyping and iterative testing essential for innovation and development in the industrial equipment industry.

CNC (Computer Numerical Control) machining plays a critical role in the medical devices industry by enabling the precise and efficient manufacturing of complex components. This technology involves the use of computer-controlled machines to perform a variety of tasks such as cutting, milling, and drilling. CNC machines follow programmed instructions to shape raw materials into finished products with high accuracy and consistency. This precision is crucial in the medical field, where components often require exact dimensions and tolerances to function properly within medical devices like implants, prosthetics, and surgical instruments. The ability to produce intricate and detailed parts repeatedly without deviation ensures the reliability and safety of these medical devices.

In the context of medical devices, CNC machining supports the production of parts made from a wide range of materials, including metals like titanium and stainless steel, and high-grade plastics. The process starts with a digital design, usually created using CAD (Computer-Aided Design) software. This design is then converted into a set of coded instructions, which the CNC machine interprets to execute precise movements and operations on the material. Advanced CNC machines can perform multiple operations in a single setup, reducing the need for multiple machines and manual intervention. This not only enhances efficiency but also minimizes the risk of contamination, which is vital in maintaining the sterility of medical components. As a result, CNC machining contributes significantly to the development and production of high-quality, reliable medical devices that meet stringent regulatory standards.

CNC (Computer Numerical Control) machining is a sophisticated manufacturing process that leverages computer technology to control machine tools with high precision. The process begins with a CAD (Computer-Aided Design) model, which is then converted into a series of commands that the CNC machine can interpret. These commands are fed into the CNC machine through a specialized software known as the CAM (Computer-Aided Manufacturing) program. The CNC machine interprets these commands to operate various machine tools such as lathes, mills, and routers, performing operations like cutting, drilling, and milling to shape the material into the desired form. The primary advantage of CNC machining is its ability to produce complex parts with tight tolerances and high repeatability, making it ideal for applications in aerospace, automotive, medical, and electronics industries.

In manufacturing, CNC machining offers significant improvements over traditional manual machining techniques. It significantly reduces human error, enhances production speed, and ensures consistency across large volumes of parts. Automation also allows for 24/7 operation, maximizing output and efficiency. Advanced CNC machines are even capable of multi-axis machining, which allows for the creation of intricate geometries that would be impossible or highly time-consuming to achieve manually. CNC machining also supports a wide range of materials, including metals, plastics, and composites, further widening its application scope. By transforming digital designs into physical components with remarkable precision, CNC machining plays a crucial role in modern manufacturing, pushing the boundaries of what’s possible in design and production.

1. What is CNC machining?

CNC (Computer Numerical Control) machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. It can control a range of complex machinery, from grinders and lathes to mills and routers. CNC machining is used to produce precision parts and components.

2. How does CNC machining work?

CNC machining works by following a programmed sequence of operations based on CAD (Computer-Aided Design) models. The CNC machine interprets the design as a set of instructions, guiding the cutting tools to shape the material (such as metal, plastic, or wood) into the desired form with high precision and repeatability.

3. What materials can be used in CNC machining?

CNC machining can work with a variety of materials, including metals (aluminum, steel, brass), plastics (ABS, polycarbonate, nylon), composites, and wood. The choice of material depends on the specific requirements of the part being produced.

4. How does SourcifyChina ensure the quality of CNC machined parts?

SourcifyChina ensures quality through rigorous quality control processes, including:

– Detailed inspections using precision measurement tools.

– Adherence to ISO standards.

– Regular maintenance and calibration of CNC machines.

– Skilled operators and engineers oversee the entire process.

5. What are the advantages of using SourcifyChina for CNC machining?

SourcifyChina offers several advantages, including:

– High precision and consistency in part production.

– Fast turnaround times due to advanced machinery and efficient processes.

– Cost-effective solutions through optimized production techniques.

– Comprehensive quality control to ensure each part meets specifications.

6. Can SourcifyChina handle large volume orders?

Yes, SourcifyChina is equipped to handle both small and large volume orders. Their scalable processes and robust supply chain ensure timely delivery of high-quality parts, regardless of order size.

7. How can I get a quote for CNC machining services from SourcifyChina?

To get a quote, you can contact SourcifyChina directly through their website, providing details about your project, including CAD files, material specifications, and quantity. They will review your requirements and provide a detailed quotation.

CNC (Computer Numerical Control) machining is a manufacturing process in which pre-programmed software controls the movement of machinery and tools. Here’s a concise overview of how CNC machining works, particularly as practiced by factories like SourcifyChina:

1. Design and Programming: The process begins with designing a part using CAD (Computer-Aided Design) software. The design is then converted into a CNC program using CAM (Computer-Aided Manufacturing) software. This program contains precise instructions for machine operations.

2. Setup: The CNC machine setup includes securing the workpiece and installing the required cutting tools. Proper alignment and calibration ensure accuracy during machining.

3. Machining: The CNC machine executes the programmed instructions, guiding the cutting tools along specified paths to shape the material. This can involve various operations such as drilling, milling, turning, and grinding.

4. Tool Changes: Advanced CNC machines can automatically switch between multiple tools to perform different operations in a single setup, enhancing efficiency and precision.

5. Quality Control: Continuous monitoring and quality checks are essential. Factories like SourcifyChina use precision measurement tools and inspection techniques to ensure parts meet exact specifications.

6. Post-Processing: After machining, parts may undergo additional processes such as deburring, polishing, and surface treatment to achieve the desired finish and functionality.

7. Automation and Efficiency: CNC machining at factories like SourcifyChina leverages automation to produce high-quality parts consistently and efficiently, reducing human error and increasing production speed.

In summary, CNC machining at SourcifyChina involves a meticulous process from design to finished product, utilizing advanced technology and precise control to manufacture complex parts with high accuracy.

FAQ:

How Does CNC Machining Work at SourcifyChina Factory?

What is CNC machining?

CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. It is used to control a range of complex machinery, from grinders and lathes to mills and routers.

How does SourcifyChina ensure precision in CNC machining?

SourcifyChina utilizes advanced CNC machines that are programmed with high accuracy. Our skilled technicians oversee the process to ensure that each component meets the specified tolerances and quality standards.

What materials can be machined at SourcifyChina?

We work with a wide variety of materials, including metals (such as aluminum, steel, and titanium), plastics, and composites. Our equipment and expertise allow us to handle both common and specialized materials.

What are the steps involved in the CNC machining process at SourcifyChina?

1. Design: We start with a CAD (Computer-Aided Design) model provided by the client.

2. Programming: The CAD model is converted into a CNC program using CAM (Computer-Aided Manufacturing) software.

3. Setup: The material is secured in the CNC machine.

4. Machining: The CNC machine follows the programmed instructions to create the part.

5. Quality Control: Each part is inspected for precision and accuracy before delivery.

How does SourcifyChina handle custom CNC machining requests?

Clients can submit their designs, and our engineering team will review them for feasibility. We then provide a quote and timeline. Custom orders are managed closely to ensure specifications are met.

What are the typical turnaround times for CNC machining orders?

Turnaround times vary depending on the complexity and quantity of the parts. Generally, orders can be completed within a few days to a couple of weeks. We strive to meet all deadlines and can expedite orders if necessary.

Why choose SourcifyChina for CNC machining?

We offer high precision, competitive pricing, and a commitment to quality. Our state-of-the-art facilities and experienced team ensure that we can meet a wide range of machining needs efficiently.

Certainly! Here’s a brief explanation of how CNC machining works, specifically sourced from SourcifyChina Factory:

—

How CNC Machining Works: Insights from SourcifyChina Factory

CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed software dictates the movement of factory tools and machinery. SourcifyChina Factory, a leading provider of CNC machining services, follows a precise workflow to ensure high-quality production.

1. Design and Programming:

– CAD Design: The process starts with a detailed CAD (Computer-Aided Design) model of the part.

– CAM Software: This design is then imported into CAM (Computer-Aided Manufacturing) software to generate a G-code, which acts as instructions for the CNC machine.

2. Machine Setup:

– The machine is set up with the appropriate tools (e.g., drills, lathes, mills).

– The raw material is secured onto the machine’s work surface.

3. Execution:

– The CNC machine reads the G-code and executes the commands, guiding the tools to shape and cut the material with high precision.

– Various operations such as drilling, milling, turning, and grinding are performed automatically, ensuring consistent and accurate results.

4. Quality Control:

– SourcifyChina Factory employs rigorous quality checks at each stage of the process.

– Finished parts are measured against design specifications to ensure they meet the required tolerances.

5. Advantages:

– Precision: CNC machining offers high accuracy and repeatability.

– Efficiency: It reduces human error and increases production speed.

– Versatility: Suitable for a wide range of materials, including metals, plastics, and composites.

SourcifyChina Factory leverages state-of-the-art CNC machinery and expert technicians to deliver parts that meet exacting standards. This process ensures that each component is manufactured with superior precision and quality.

For more detailed insights, visiting SourcifyChina’s website or directly contacting their support team can provide additional information tailored to specific needs.

—

This summary captures the essence of CNC machining as practiced by SourcifyChina Factory within 300 words.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.