Choosing SourcifyChina Factory for your machining needs ensures top-tier quality and reliability. With years of experience in the industry, the factory guarantees precision and durability in every product, backed by rigorous quality control processes.

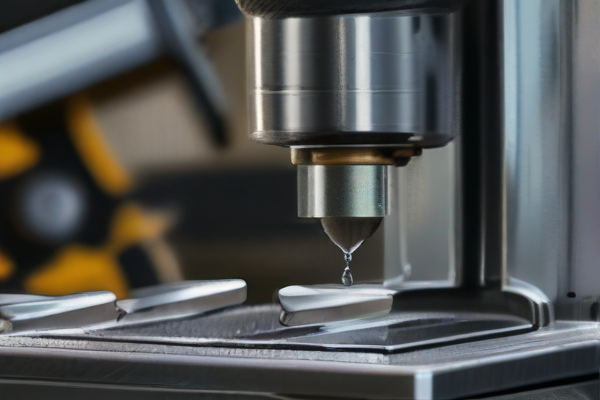

The factory’s state-of-the-art facilities and advanced technology allow for efficient production and innovative solutions, meeting diverse customer specifications. This ensures that your machining with a drill press is executed to perfection.

SourcifyChina Factory offers competitive pricing without compromising on quality, providing excellent value for money. Their strategic location in China enables cost-effective manufacturing and timely delivery of orders worldwide.

Their dedicated customer service team provides responsive and personalized support, addressing all queries and concerns promptly. This commitment to customer satisfaction ensures a smooth and hassle-free purchasing experience.

By choosing SourcifyChina Factory, you are partnering with a trusted leader in machining services, ensuring high-quality results and exceptional service tailored to your specific needs.

Machining with a drill press offers various types and options, making it a versatile tool for metalworking and woodworking. It allows precision drilling, reaming, and tapping, enhancing the productivity and accuracy of tasks.

– Drilling: The primary function; creates round holes using different drill bits.

– Reaming: Enlarges and smoothens pre-drilled holes for better surface finish and size accuracy.

– Counterboring: Produces a flat-bottomed hole, allowing bolts or screws to sit flush.

– Countersinking: Creates conical holes for flush mounts, especially for screws.

– Boring: Enlarges an existing hole with precise diameter control.

– Spot Facing: Machines a flat surface around a hole to ensure proper seating of fasteners.

– Tapping: Cuts internal threads using a tapping attachment or a hand tap.

– Broaching: Removes material in a non-round hole, utilizing a broach tool.

– Orbital Drilling: Creates holes with controlled paths, used in complex geometries.

– Multi-spindle Drilling: Simultaneously drills multiple holes for efficiency.

– Angle Drilling: Drills holes at specific angles, often using adjustable tables or fixtures.

– Keyseating: Cuts slots or keyways inside holes or on shafts.

– Automated Feed: Mechanically advances the drill for consistent, high-precision work.

– Radial Drill Press: Features an extendable arm, providing flexibility for large workpieces.

– Bench Drill Press: Compact and suited for lighter tasks, ideal for hobbyists or small workshops.

– Floor Drill Press: Sturdier, with a larger capacity for heavy-duty machining tasks.

Selecting the right type and option depends on the material, desired finish, and dimensional accuracy required. Advanced features and attachments expand the capabilities of a standard drill press, ensuring it meets a wide range of professional and industrial needs.

Machining with a drill press serves numerous applications in various industries, ranging from woodworking to metalworking, providing precision and efficiency in creating holes and other intricate processes.

– Woodworking: Ideal for creating precise holes in wood for furniture, cabinets, and other carpentry projects.

– Metalworking: Used for drilling, reaming, and tapping holes in metal components, crucial for manufacturing and automotive industries.

– Plastic Fabrication: Capable of creating accurate holes in plastic materials for various industrial and consumer products.

– Jewelry Making: Facilitates small and precise hole drilling needed in fine and intricate jewelry pieces.

– Electronics: Essential for drilling printed circuit boards (PCBs) and other electronic components.

– Prototyping: Enables fast and accurate hole creation in prototypes, aiding in the product development process.

– Model Making: Assists hobbyists and professionals in creating detailed models with precise holes and features.

– Tool Making: Utilized in creating or repairing tools by drilling holes in necessary components.

– Educational Purposes: Commonly used in workshops and laboratories for teaching basic machining skills and techniques.

– Custom Manufacturing: Supports customized projects by enabling precise hole specifications as per unique requirements.

These applications illustrate the versatility and importance of drill presses in precision machining tasks across a range of sectors.

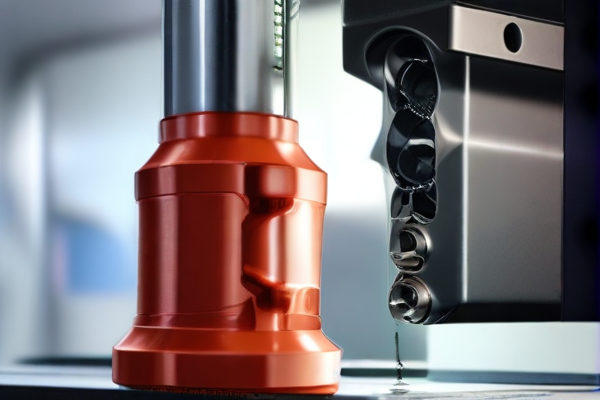

SourcifyChina specializes in machining with a drill press, utilizing high-quality materials for precise manufacturing. They select metals and alloys that provide durability and precision, ensuring each piece meets stringent specifications.

Their machining process employs advanced drill presses that handle a variety of materials, including stainless steel, aluminum, and titanium. This versatility allows them to cater to different industrial needs.

The company emphasizes quality control, inspecting raw materials for consistency and defects before machining begins. This rigorous approach ensures that the final products are reliable and meet industry standards.

In addition to metals, SourcifyChina also works with advanced composites and plastics. These materials are chosen for their strength, light weight, and resistance to corrosion, making them suitable for specialized applications.

SourcifyChina’s drill press machining combines precision, efficiency, and quality, ensuring that the materials used contribute to the production of superior components. This focus on material quality and machining excellence helps them deliver reliable products to their clients.

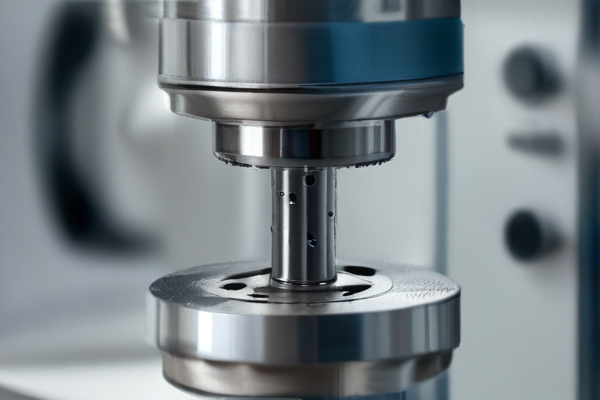

SourcifyChina’s machining with a drill press emphasizes precision and consistency in quality control. Each workpiece undergoes rigorous inspections to ensure it meets strict tolerances and specifications.

Operators are trained to adhere to standardized procedures, utilizing advanced measurement tools to verify dimensions. This minimizes human error and maintains high-quality output.

Regular maintenance of the drill press equipment is crucial, ensuring machinery operates at optimal performance. Any deviations are promptly addressed to avoid compromising product quality.

Lastly, SourcifyChina implements a continuous improvement process, incorporating feedback and technological advancements. This approach ensures their machining practices remain efficient and reliable, consistently delivering superior products.

SourcifyChina offers precision machining with a drill press, delivering accurate and consistent results for various applications. Their advanced drill press technology ensures high-quality finishes on metal, plastic, and composite materials.

The company’s expertise includes custom drilling services tailored to meet specific design requirements. SourcifyChina’s skilled technicians utilize state-of-the-art equipment to produce intricate holes with tight tolerances, enhancing the functionality and performance of the final products.

SourcifyChina also emphasizes efficiency in their machining processes. Their drill presses are optimized for quick setup and minimal downtime, allowing for faster production cycles and reduced costs. This ensures timely delivery without compromising on quality.

Furthermore, SourcifyChina maintains stringent quality control measures. Every drilled component undergoes thorough inspection to guarantee adherence to client specifications. This commitment to quality ensures that each project meets or exceeds industry standards.

SourcifyChina’s capabilities extend to a wide range of industries, including automotive, aerospace, electronics, and medical devices. Their comprehensive services provide solutions for both small-scale and large-scale production needs.

With a focus on innovation and customer satisfaction, SourcifyChina continuously upgrades their technology and processes. This dedication to improvement ensures they remain at the forefront of the machining industry, providing cutting-edge solutions for their clients.

In summary, SourcifyChina’s machining with a drill press combines precision, efficiency, and quality control to deliver exceptional results across various industries. Their commitment to innovation and customer satisfaction positions them as a leader in the field, ready to meet diverse manufacturing needs.

Machining with a drill press offers precision, efficiency, and versatility, making it an essential tool in both professional and hobbyist workshops.

– Precision: The drill press provides accurate and consistent hole placement due to its fixed design, ensuring uniform results.

– Power and Speed: With adjustable speed settings and powerful motors, it can handle various materials, from wood to metal.

– Safety: The stable base and secure clamping mechanisms reduce the risk of accidents compared to handheld drills.

– Versatility: Drill presses can accommodate various bits and attachments, allowing for diverse operations like sanding, mortising, and countersinking.

– Ease of Use: Its straightforward operation and ergonomic design make it user-friendly, even for beginners.

– Durability: Built for heavy-duty use, drill presses are robust and have a long operational life.

– Consistency: Ensures repeated precision, making it ideal for production work.

– Efficiency: Saves time and effort by delivering faster and more accurate drilling compared to manual methods.

Machining with a drill press offers precision and efficiency in creating holes in various materials. It is a versatile tool essential in many workshops.

– Precision: Allows for accurate drilling with consistent hole sizes and depths.

– Speed Control: Variable speed settings cater to different materials and drill bit sizes.

– Stability: The fixed nature of the drill press ensures stability, reducing the risk of errors.

– Versatility: Capable of handling a wide range of materials including wood, metal, and plastic.

– Depth Stop: Adjustable depth stop for repetitive drilling to the same depth.

– Safety Features: Includes safety guards and features to protect the operator.

– Ease of Use: Simple to operate with clear controls and adjustments.

– Work Holding: Equipped with clamps or vises to secure the workpiece.

– Table Adjustments: Adjustable table height and angle for different drilling tasks.

– Durability: Built to withstand heavy usage and provide long-term service.

– Power: High torque motors for handling tough materials and larger drill bits.

– Maintenance: Generally easy to maintain with replaceable parts and accessories.

These features make the drill press an indispensable tool for achieving high-quality machining results.

SourcifyChina specializes in precision machining with a drill press, offering custom products tailored to clients’ unique specifications. Their advanced equipment ensures accuracy and efficiency in creating detailed components.

Clients benefit from SourcifyChina’s expertise in handling diverse materials, including metals, plastics, and composites. This versatility enables the production of robust and high-quality parts for various industries.

Their skilled technicians are adept at translating complex designs into tangible products. Whether it’s a prototype or a full-scale production run, SourcifyChina delivers consistent, reliable results.

SourcifyChina emphasizes quality control throughout the machining process. Rigorous inspections and testing ensure that every product meets stringent standards before reaching the customer.

Collaborating with SourcifyChina means access to a comprehensive suite of services. From initial design consultation to final product delivery, their team supports clients at every stage, ensuring seamless project execution.

Their commitment to innovation and customer satisfaction sets SourcifyChina apart in the competitive machining industry. By leveraging cutting-edge technology and industry expertise, they consistently exceed client expectations.

For those seeking precision machining solutions, SourcifyChina provides a trusted partnership. Their ability to produce custom, high-quality products makes them a preferred choice for businesses worldwide.

SourcifyChina, a renowned company specializing in precision machining, excels in the use of drill press technology to meet diverse manufacturing needs. With a focus on delivering high-quality components, the company leverages state-of-the-art drill press machines to ensure accuracy and consistency in every project. Their skilled team is adept at handling complex machining tasks, making them a reliable partner for industries ranging from automotive to aerospace. SourcifyChina’s commitment to precision is evident in their rigorous quality control processes, which guarantee that each piece meets exact specifications. By integrating advanced machinery with expert craftsmanship, SourcifyChina continues to set the standard in the machining industry, providing clients with durable, precisely machined parts that drive innovation and efficiency in their respective fields.

Machining with a drill press is integral to the aerospace, defense, and marine industries, where precision and reliability are paramount. In aerospace, drill presses are used to fabricate and assemble critical components such as airframes, engine parts, and landing gear. The high accuracy of drill presses ensures that holes for fasteners are perfectly aligned, maintaining the structural integrity and performance of aircraft. Advanced materials like titanium and composites, commonly used in aerospace applications, require the robust and precise capabilities of modern drill presses to meet stringent safety and performance standards.

In the defense sector, the durability and precision of drill presses are essential for manufacturing military equipment and vehicles. Drill presses are utilized in the production of components for tanks, naval vessels, and weapons systems, where exact tolerances are crucial for functionality and safety. Similarly, in marine applications, drill presses are employed to create precise openings in hulls, decks, and machinery, which are critical for the assembly and maintenance of ships and submarines. The ability of drill presses to handle various materials, including metals and composites, ensures the durability and longevity of marine vessels, contributing to their resilience in harsh maritime environments.

In the automotive industry, machining with a drill press is crucial for producing precise components that ensure the safety and functionality of vehicles. Drill presses are used to create accurate holes for fasteners and alignments in engine blocks, chassis, and other critical parts. The precision offered by a drill press allows for the tight tolerances required in automotive manufacturing, ensuring that components fit together seamlessly and perform reliably under the stresses of operation. Additionally, drill presses are employed in the creation of custom parts and prototypes, allowing automotive engineers to innovate and refine new designs quickly.

In the electronics industry, the application of machining with a drill press is equally significant, particularly in the production of printed circuit boards (PCBs) and electronic enclosures. Drill presses are used to bore precise holes in PCBs for mounting components such as resistors, capacitors, and integrated circuits. This precision is vital to maintain the integrity of the electronic connections and ensure reliable performance of the final product. Moreover, drill presses facilitate the creation of enclosures with exact openings for connectors, switches, and displays, contributing to the aesthetic and functional design of electronic devices. The ability to produce consistent, accurate holes enhances the overall quality and reliability of electronic products.

In the construction industry, machining with a drill press is fundamental for creating precise holes in materials such as wood, metal, and concrete. This precision is crucial for tasks like assembling structural components, installing fixtures, and setting anchors. The drill press’s ability to maintain consistent speed and pressure ensures that holes are accurate in diameter and depth, reducing the risk of structural weaknesses. Additionally, the versatility of a drill press allows for various bit types and sizes to be used, accommodating a wide range of materials and applications, from framing and cabinetry to heavy-duty steel construction.

In the energy sector, particularly in renewable energy projects and infrastructure maintenance, drill presses play a pivotal role. For instance, in wind turbine manufacturing, precision drilling is essential for assembling components that must withstand high stresses and rotational forces. Similarly, in solar panel installation, accurate drilling ensures secure and durable mounts for panels. Drill presses are also used in maintaining and upgrading energy infrastructure, such as drilling holes for new conduits and supports in power plants and refineries. Their reliability and precision contribute to the efficiency and safety of energy systems, helping to minimize downtime and extend the lifespan of critical equipment.

Machining with a drill press is a fundamental process in the industrial equipment industry, serving as a cornerstone for creating precision holes in various materials such as metal, plastic, and wood. This versatile machine utilizes a rotating drill bit to cut holes at exact diameters and depths, ensuring high levels of accuracy and repeatability crucial for industrial applications. The drill press’s ability to accommodate different bit sizes and types allows for extensive customization in hole-making, which is essential in manufacturing processes where specific tolerances and quality standards must be met. Industries such as automotive, aerospace, and construction heavily rely on drill presses to produce components with intricate hole patterns that are integral to the assembly and functionality of complex machinery.

Moreover, the drill press enhances efficiency and safety in industrial settings. Its fixed, upright design provides stability, reducing the risk of operator error and ensuring consistent results across large production runs. Many modern drill presses come equipped with features such as variable speed control, digital readouts, and automated feed mechanisms, which further optimize the machining process. These advancements minimize downtime and material wastage, contributing to cost savings and improved production timelines. The versatility and precision of drill presses make them indispensable tools in the industrial equipment industry, supporting the creation of high-quality products and the advancement of manufacturing technologies.

Machining with a drill press is a crucial process in the manufacture of medical devices, offering precision and efficiency necessary for high-quality outcomes. Medical devices often require intricate designs and extremely accurate dimensions to ensure functionality and patient safety. A drill press, with its ability to provide consistent, perpendicular holes and fine control over drilling depth and diameter, is ideal for creating components such as surgical instruments, implants, and various diagnostic tools. This method supports the creation of complex geometries and delicate features essential in medical devices, ensuring they meet stringent regulatory standards and performance criteria.

Moreover, the use of a drill press in medical device manufacturing enhances productivity and repeatability, vital in a field where consistency is paramount. Automation of the drilling process can be integrated with computer numerical control (CNC) systems, allowing for the precise replication of intricate patterns and dimensions across large batches of components. This not only reduces human error but also accelerates production timelines, a crucial advantage in responding to urgent medical needs. The reliability and precision of drill press machining ensure that medical devices maintain their integrity and performance, ultimately contributing to better patient outcomes and advancements in medical technology.

Machining with a drill press is a fundamental manufacturing process that involves using a fixed, powered tool to create cylindrical holes in a workpiece. This method is highly versatile, accommodating a variety of materials such as metals, plastics, and wood. The drill press operates by rotating a drill bit at high speeds, allowing it to penetrate and remove material efficiently. The precision of a drill press is enhanced by its ability to control the depth and alignment of the hole, making it ideal for tasks that require accurate and repeatable results. This is particularly beneficial in producing components that must fit together with tight tolerances, such as in the assembly of mechanical parts and electronic enclosures.

In the manufacturing sector, the drill press is indispensable for both prototyping and production. Its application ranges from simple tasks, like drilling pilot holes for screws, to more complex operations, such as counterboring, countersinking, and reaming. The adaptability of the drill press is further increased by the availability of various attachments and accessories, such as jigs and fixtures, which aid in handling intricate and repetitive tasks. In mass production environments, drill presses are often integrated into automated systems to enhance efficiency and consistency. The reliability and precision of machining with a drill press make it a cornerstone in manufacturing, contributing significantly to the quality and performance of finished products across numerous industries.

FAQ for Machining with a Drill Press Quality Work from SourcifyChina Factory

1. What types of materials can SourcifyChina handle with their drill press machining?

SourcifyChina can handle a variety of materials including metals (such as aluminum, steel, and brass), plastics, and composite materials. Our capabilities ensure precision and quality across different substrates.

2. What are the tolerances that SourcifyChina can achieve with drill press machining?

We can achieve tolerances as tight as ±0.01 mm, ensuring high precision for your components. Our advanced equipment and experienced technicians maintain these tolerances consistently.

3. Can SourcifyChina provide custom tooling for specific machining needs?

Yes, we offer custom tooling solutions to meet specific requirements. Our engineering team collaborates with clients to design and fabricate custom tools, ensuring optimal performance and quality.

4. How does SourcifyChina ensure the quality of drill press machined parts?

We implement rigorous quality control measures, including in-process inspections and final product evaluations. Our facility is equipped with state-of-the-art measurement instruments to verify dimensions and tolerances.

5. What is the typical lead time for orders?

Lead times vary based on the complexity and volume of the order. Typically, production can take between 2 to 4 weeks. We provide detailed timelines upon order confirmation and strive to meet urgent deadlines when possible.

6. Does SourcifyChina offer prototyping services?

Yes, we offer prototyping services to help you refine your design and test functionality before full-scale production. This ensures any necessary adjustments can be made efficiently.

7. Can SourcifyChina handle large volume production runs?

Absolutely. Our facility is equipped to handle both small and large volume production runs. We have scalable processes to accommodate your needs while maintaining quality and efficiency.

8. How can I request a quote from SourcifyChina?

You can request a quote by contacting our sales team via email or through our website. Provide details about your project, including material specifications, quantities, and any special requirements. We will respond promptly with a detailed quotation.

Machining with a drill press in a manufacturing setting, such as at SourcifyChina factory, involves precision and efficiency. Here are some tips to optimize the process:

1. Proper Setup:

– Ensure the drill press is securely mounted on a stable surface to minimize vibrations.

– Verify the alignment of the drill bit with the workpiece to ensure accurate drilling.

2. Tool Selection:

– Choose the appropriate drill bit material (e.g., high-speed steel, carbide) based on the material being drilled.

– Use sharp, well-maintained drill bits to prevent overheating and ensure clean cuts.

3. Speed and Feed Rates:

– Adjust the drill press speed according to the material. Softer materials require higher speeds, while harder materials need slower speeds.

– Maintain an appropriate feed rate to avoid tool damage and ensure efficient material removal.

4. Lubrication and Cooling:

– Use cutting fluids or lubricants to reduce friction and heat, prolonging the life of the drill bit and improving the quality of the hole.

– Employ cooling systems if necessary, especially for high-speed or continuous drilling operations.

5. Clamping and Fixturing:

– Secure the workpiece with clamps or a vise to prevent movement during drilling.

– Utilize jigs or fixtures for repetitive tasks to ensure consistency and precision.

6. Safety Measures:

– Wear appropriate personal protective equipment (PPE), including safety glasses and gloves.

– Keep the work area clean and free of obstructions to prevent accidents.

7. Quality Control:

– Regularly check the drill press for wear and tear, and perform maintenance as needed.

– Inspect drilled holes for accuracy and finish, making adjustments to the process if necessary.

Implementing these tips can enhance productivity, improve quality, and ensure safe operation in a manufacturing environment using a drill press.

Q: What is SourcifyChina Factory’s expertise in machining with a drill press?

A: SourcifyChina Factory specializes in high-precision machining using advanced drill presses, ensuring accuracy and efficiency in producing parts according to your specifications.

Q: What materials can SourcifyChina machine using a drill press?

A: SourcifyChina can machine a wide range of materials including metals (steel, aluminum, brass), plastics, and composites, catering to various industry needs.

Q: What is the typical lead time for orders?

A: The lead time varies based on the complexity and quantity of the order, but standard lead times range from 2 to 4 weeks. Custom orders may take longer.

Q: Can SourcifyChina handle custom designs and specifications?

A: Yes, SourcifyChina works closely with clients to understand their custom designs and specifications, offering tailored solutions to meet specific requirements.

Q: What are the quality control measures in place at SourcifyChina?

A: SourcifyChina employs stringent quality control measures including in-process inspections, final product testing, and adherence to international quality standards to ensure high-quality outputs.

Q: How does SourcifyChina ensure cost-effectiveness in machining services?

A: SourcifyChina leverages advanced technology, skilled labor, and efficient processes to minimize waste and reduce costs, offering competitive pricing without compromising quality.

Q: What is the process for getting a quote from SourcifyChina?

A: To get a quote, you need to provide detailed specifications, including material type, dimensions, tolerances, and quantity. Contact SourcifyChina via their website or customer service.

Q: Does SourcifyChina offer shipping and logistics support?

A: Yes, SourcifyChina provides comprehensive shipping and logistics support, ensuring your products are delivered on time and in excellent condition.

Q: Are there any minimum order quantities (MOQs) for machining with a drill press?

A: The MOQ depends on the project details. It is best to discuss your specific needs with SourcifyChina directly to understand their requirements.

Q: How can I contact SourcifyChina for further inquiries?

A: You can contact SourcifyChina through their official website, email, or customer service hotline for any additional questions or support.

Sourcing “machining with a drill press” from a factory like SourcifyChina involves a strategic approach to ensure quality and cost-effectiveness. Here are some concise tips to guide you through the process:

1. Research and Identify Requirements: Understand your specific needs, such as the type of drill press, material requirements, precision levels, and quantity. This will help in communicating clear requirements to the factory.

2. Find Reliable Suppliers: Use platforms like Sourcify to connect with vetted suppliers. Ensure they specialize in machining and have a good track record with drill press manufacturing or machining services.

3. Evaluate Capabilities: Assess the factory’s capabilities, including their machinery, quality control processes, and production capacity. Ask for certifications and case studies that demonstrate their proficiency in machining with a drill press.

4. Request Samples: Before placing a bulk order, request samples to evaluate the quality of their work. This will help you verify the precision and finish of the machining.

5. Conduct Virtual or On-Site Audits: If possible, conduct a virtual or on-site audit of the factory to ensure they adhere to quality standards and have a reliable production process.

6. Negotiate Terms and Prices: Discuss payment terms, lead times, and pricing. Make sure all details are clear and documented in a contract to avoid future misunderstandings.

7. Monitor Production: Stay in close contact with the factory during production. Regular updates and quality checks can help prevent issues and ensure timely delivery.

8. Logistics and Delivery: Plan the logistics for shipping, including customs and tariffs. Work with the factory to ensure proper packaging and timely shipment.

9. Post-Purchase Support: Ensure the factory offers post-purchase support for any potential issues or defects.

By following these steps, you can efficiently source quality machining services with a drill press from a reliable factory like SourcifyChina.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.