Comprehensive Guide on Stainless Steel Heat Treatment: SourcifyChina Factory Insights and Reliable Methods

Explore SourcifyChina’s trusted expertise in stainless steel heat treatment processes. This guide provides in-depth insights into industry-best practices and reliable methods, ensuring top-quality and durable stainless steel products from SourcifyChina’s advanced manufacturing facilities.

SourcifyChina offers unparalleled expertise in heat treatment of stainless steel. Their advanced facilities ensure precise, high-quality results, meeting international standards. With a strong focus on innovation, they provide customized solutions to fit diverse needs.

SourcifyChina’s team of skilled professionals ensures consistent quality and efficiency in every project. Their rigorous quality control processes and adherence to global standards guarantee reliable, durable products.

Competitive pricing at SourcifyChina does not compromise on quality. By leveraging local resources and advanced technologies, they offer cost-effective solutions, making them an attractive choice for buyers seeking value for money.

Their excellent customer service sets SourcifyChina apart. With dedicated support throughout the purchasing process, they ensure clear communication, timely delivery, and complete satisfaction. Choosing SourcifyChina means partnering with a reliable and innovative leader in the industry.

Heat treatment of stainless steel is essential for enhancing its properties. Common methods include annealing, hardening, stress relieving, and solution treating, each tailored for specific performance characteristics.

– Annealing: Softens the steel, improves ductility and corrosion resistance.

– Hardening: Increases strength and wear resistance.

– Stress Relieving: Reduces internal stresses caused by welding or machining.

– Solution Treating: Homogenizes the structure and dissolves precipitates.

– Tempering: Adjusts the hardness and toughness post-hardening.

– Aging: Enhances the properties of precipitation-hardening stainless steels.

Options

for Heat Treatment:

1. Full Annealing: Heating to 1040-1120°C, then cooling slowly to ensure a soft, ductile microstructure.

2. Stress Relief Annealing: Heating to 200-500°C, holding for a specified time, then cooling in air to reduce residual stresses.

3. Solution Annealing: Heating to 1040-1150°C, followed by rapid cooling, typically in water or air, to achieve a uniform microstructure.

4. Quenching and Tempering: Heating to a high temperature, then rapidly cooling (quenching) in water or oil, followed by tempering at a lower temperature to balance hardness and toughness.

5. Sub-Critical Annealing: Heating to below the critical temperature, typically 700-800°C, to enhance machinability without altering the overall microstructure.

6. Precipitation Hardening: Involves solution treating and aging at lower temperatures (e.g., 480-620°C) to form fine precipitates that strengthen the steel.

7. Cryogenic Treatment: Cooling to extremely low temperatures, typically below -185°C, to transform retained austenite into martensite, enhancing wear resistance and dimensional stability.

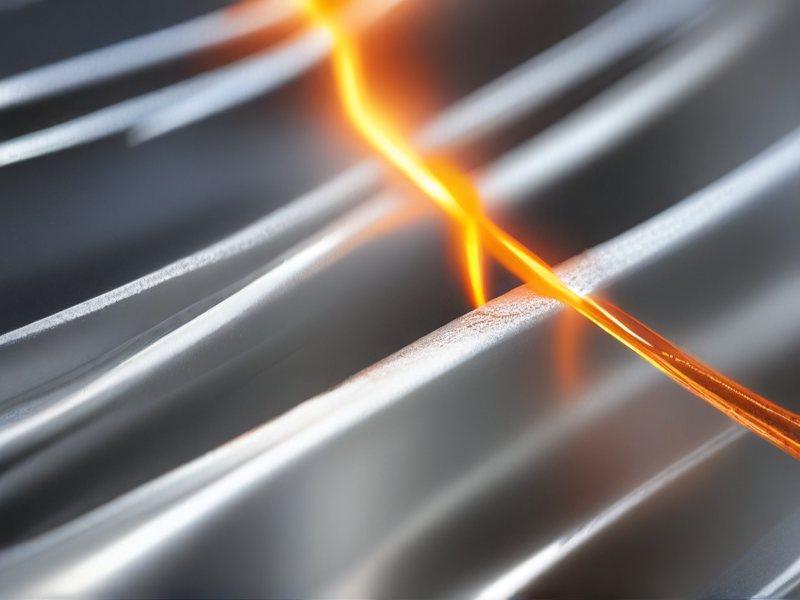

Heat treatment of stainless steel improves its mechanical properties, corrosion resistance, and workability. This process involves heating, holding, and cooling the steel in a controlled environment.

– Hardening: Enhancing wear resistance for cutting tools and industrial equipment.

– Tempering: Reducing brittleness for springs and fasteners in automotive applications.

– Annealing: Softening the material for improved machinability and forming processes in the aerospace industry.

– Stress Relieving: Minimizing residual stresses for welded components in construction and structural applications.

– Solution Treatment: Homogenizing the microstructure for medical devices and surgical instruments.

– Precipitation Hardening: Increasing hardness and strength for high-performance aerospace components.

– Normalization: Refining the grain structure for improved toughness in heavy machinery parts.

– Cryogenic Treatment: Enhancing wear resistance and dimensional stability for cryogenic storage tanks and pipelines.

– Surface Hardening: Increasing surface hardness and wear resistance for gears and camshafts.

– Grain Refinement: Producing superior surface finish and mechanical properties for kitchenware and cutlery.

– Decarburization: Removing carbon to improve corrosion resistance in maritime and chemical processing equipment.

– Isothermal Annealing: Improving magnetic properties for electronic components and sensors.

– Martempering: Achieving high hardness with reduced risk of cracking for military and defense applications.

– Sub-Zero Treatment: Enhancing toughness and fatigue resistance for bearings and turbine blades.

Each type of heat treatment enhances the specific characteristics required for various industrial, medical, and commercial applications, ensuring reliability and performance of the stainless steel components.

SourcifyChina offers specialized heat treatment services for stainless steel to enhance its mechanical properties and performance. Their process includes annealing, hardening, and stress relieving, tailored to meet specific industrial requirements.

The annealing process softens stainless steel, improving its ductility and machinability. This is crucial for applications that require extensive forming and shaping of the material.

Hardening increases the steel’s strength and wear resistance, making it suitable for demanding environments. This treatment is ideal for parts exposed to high stress and wear conditions.

Stress relieving reduces internal stresses induced by welding or machining. This step is essential to prevent deformation and ensure dimensional stability.

SourcifyChina’s expertise in stainless steel heat treatment guarantees high-quality results, optimizing the material’s properties for diverse industrial applications. Their precise control over treatment parameters ensures reliable and consistent performance.

SourcifyChina’s heat treatment of stainless steel involves precise control of temperature and atmosphere. This ensures optimal mechanical properties, like hardness and strength, meeting stringent industry standards.

The process begins with thorough material inspection to identify defects. This initial quality control step guarantees only high-quality stainless steel enters the heat treatment phase.

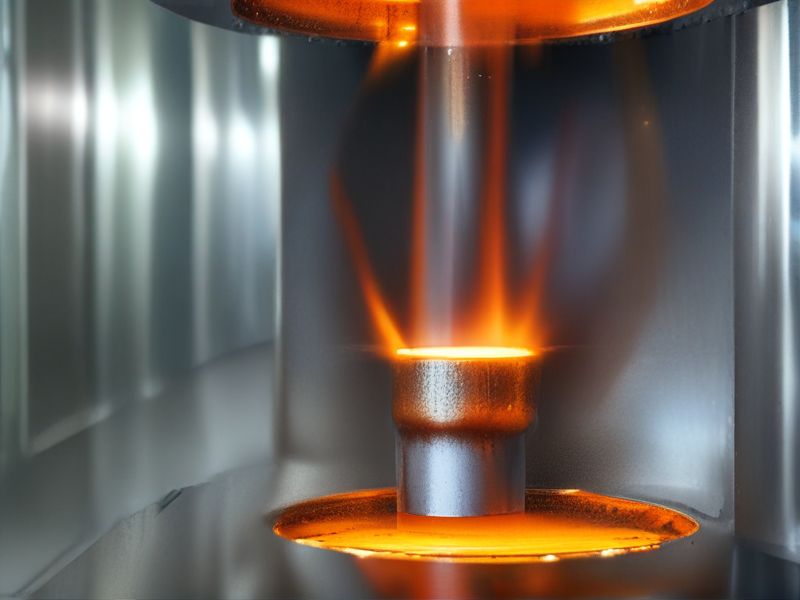

During heat treatment, advanced furnaces and real-time monitoring systems are employed. These tools ensure uniform heating and cooling, crucial for achieving consistent and reliable results.

Post-treatment, the stainless steel undergoes rigorous testing, including hardness and tensile strength assessments. These tests verify that the heat treatment has successfully enhanced the material properties as intended.

Finally, comprehensive documentation and traceability are maintained throughout the process. This ensures full accountability and allows for continuous improvement in the heat treatment quality control process.

SourcifyChina specializes in the heat treatment of stainless steel, ensuring enhanced durability and performance. Through carefully calibrated processes, they improve the material’s hardness, strength, and resistance to wear and corrosion, catering to diverse industrial requirements.

Their state-of-the-art machinery allows for precise temperature control and uniform heating, resulting in consistently high-quality stainless steel products. SourcifyChina employs skilled technicians who follow rigorous quality control procedures, guaranteeing reliable and repeatable results that meet international standards.

With a range of heat treatment services including annealing, quenching, and tempering, SourcifyChina is capable of customizing solutions to suit specific client needs. Their flexibility and comprehensive expertise ensure that each project’s unique requirements are met with precision.

Clients benefit from SourcifyChina’s commitment to timely delivery and competitive pricing. Their streamlined processes and efficient operations minimize lead times without compromising the quality of heat-treated stainless steel, making them a trusted partner in the industry.

In summary, SourcifyChina’s capabilities in the heat treatment of stainless steel encompass advanced technology, expert technicians, and a dedication to quality and customer satisfaction. Their tailored services and commitment to excellence make them a leading choice for heat-treated stainless steel solutions, ensuring long-lasting performance for various applications.

Heat treatment of stainless steel offers significant benefits by enhancing its mechanical properties, corrosion resistance, and machinability. This process involves controlled heating and cooling to achieve desired material characteristics.

– Improved Hardness and Strength: Heat treatment increases the hardness and tensile strength of stainless steel, making it more durable and wear-resistant.

– Enhanced Corrosion Resistance: By altering the microstructure, heat treatment can improve the alloy’s resistance to oxidation and corrosion.

– Better Machinability: The process can reduce internal stresses and refine grain structure, making stainless steel easier to machine and shape.

– Increased Ductility and Toughness: Heat-treated stainless steel often exhibits better ductility and toughness, allowing for more versatile applications.

– Stress Relief: Heat treatment helps in relieving residual stresses induced during manufacturing processes, reducing the risk of distortion and cracking.

– Tailored Properties: Different heat treatment methods, such as annealing, quenching, and tempering, allow for customization of the steel’s properties to suit specific industrial needs.

– Enhanced Surface Finish: Improved surface properties can be achieved, resulting in better appearance and reduced friction.

– Extended Service Life: The overall durability and performance of stainless steel components are increased, leading to longer service life and reduced maintenance costs.

In conclusion, heat treatment of stainless steel is crucial in optimizing its performance for various industrial applications, ensuring reliability and longevity.

Heat treatment of stainless steel involves various processes to enhance its mechanical and physical properties, making it suitable for diverse industrial applications.

– Annealing: Softens the material, improves ductility, and reduces hardness and internal stresses by heating and slow cooling.

– Quenching: Rapid cooling to form martensite or other hard microstructures, increasing hardness but potentially causing brittleness.

– Tempering: Conducted after quenching, involves reheating to reduce brittleness while maintaining hardness and enhancing toughness.

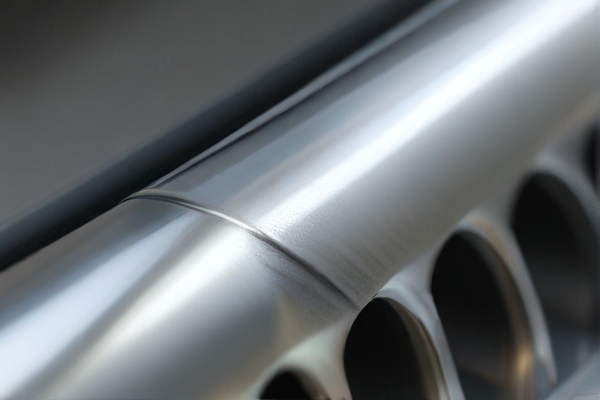

– Solution Annealing: Heating to high temperatures and then rapidly cooling to dissolve carbides and achieve a homogenous structure, improving corrosion resistance.

– Stress Relieving: Heating to moderate temperatures to reduce residual stresses without significantly affecting hardness or mechanical properties.

– Precipitation Hardening: Aged to form fine precipitates that enhance hardness and strength, typically used for certain stainless steel grades.

– Passivation: Surface treatment that removes free iron and enhances the natural protective oxide layer, improving corrosion resistance.

These techniques are tailored based on the specific type of stainless steel and desired properties, ensuring optimal performance in various conditions.

SourcifyChina specializes in custom heat treatment of stainless steel, offering tailored solutions for diverse industries. Their expertise ensures optimal performance and durability of stainless steel components.

With advanced technology, SourcifyChina provides precise heat treatment services, enhancing the mechanical properties of stainless steel. This process improves hardness, strength, and resistance to wear and corrosion.

Custom projects by SourcifyChina cater to specific client needs, ensuring high-quality results. Their team collaborates closely with customers to develop customized solutions that meet stringent industry standards.

In addition to custom products, SourcifyChina’s heat treatment services support various applications, from automotive to medical devices. Their commitment to excellence ensures reliable and efficient solutions.

By leveraging their extensive experience and state-of-the-art equipment, SourcifyChina delivers superior heat-treated stainless steel products. Their focus on quality and customer satisfaction makes them a trusted partner in the industry.

SourcifyChina is a leading company specializing in the heat treatment of stainless steel, providing top-notch metallurgical solutions tailored to meet the rigorous demands of various industries. Their advanced heat treatment processes, including annealing, quenching, tempering, and stress relieving, are designed to enhance the mechanical properties, corrosion resistance, and durability of stainless steel components. With state-of-the-art facilities and a team of experienced metallurgists, SourcifyChina ensures precise temperature control and uniform heating to achieve optimal results. The company is dedicated to delivering high-quality, reliable, and cost-effective services, making them a trusted partner for clients seeking superior performance in stainless steel applications across sectors such as aerospace, automotive, medical, and industrial manufacturing.

Heat treatment of stainless steel plays a critical role in the aerospace, defense, and marine industries, where material performance under extreme conditions is paramount. In aerospace applications, heat treatment enhances the mechanical properties of stainless steel, such as strength, toughness, and resistance to fatigue and stress-corrosion cracking. Components like turbine blades, structural elements, and fasteners undergo precise heat treatment processes to ensure they can withstand the high-stress environments of flight, rapid temperature changes, and exposure to aggressive chemicals. The controlled application of heat improves grain structure and refines the material’s overall integrity, ensuring reliability and safety in critical aerospace functions.

In the defense sector, heat-treated stainless steel is integral to the manufacture of armor plating, ballistic-resistant components, and various weapon systems. The enhanced hardness and durability provided by heat treatment enable these materials to endure harsh combat conditions, resist wear and deformation, and maintain their structural integrity. Similarly, the marine industry relies heavily on heat-treated stainless steel for constructing corrosion-resistant components for ships, submarines, and offshore structures. The heat treatment process ensures that stainless steel can resist saltwater corrosion, biofouling, and the mechanical stresses encountered in marine environments. This application is essential for the long-term durability and maintenance of marine vessels and installations. Through meticulous heat treatment processes, stainless steel achieves the performance levels required for these demanding applications.

Heat treatment of stainless steel plays a crucial role in the automotive industry by enhancing the performance and longevity of critical components. Through processes such as annealing, quenching, and tempering, the mechanical properties of stainless steel, including hardness, ductility, and tensile strength, can be optimized. For instance, exhaust systems, fuel injectors, and various engine parts are subjected to specific heat treatments to improve their resistance to high temperatures and corrosive environments. This not only extends the lifespan of these components but also contributes to the overall efficiency and reliability of vehicles, ensuring they meet stringent performance and safety standards.

In the electronics industry, heat treatment of stainless steel is essential for producing components that demand high precision and durability. Stainless steel used in electronic housings, connectors, and heat sinks undergoes heat treatments to achieve the desired microstructure and surface properties. This enhances their corrosion resistance, electrical conductivity, and thermal stability, which are critical for the proper functioning of electronic devices. Heat-treated stainless steel ensures that components can withstand the stresses of thermal cycling and maintain their integrity in various environmental conditions, thereby improving the performance and reliability of consumer electronics, industrial equipment, and advanced technological devices.

Construction Application of Heat Treatment of Stainless Steel:

In the construction industry, the heat treatment of stainless steel is essential for enhancing the material’s mechanical properties and corrosion resistance, making it suitable for demanding structural applications. Processes such as annealing, quenching, and tempering are employed to adjust the hardness, ductility, and tensile strength of stainless steel. Annealing, for instance, involves heating the steel to a high temperature and then cooling it slowly to relieve internal stresses, which enhances its formability and weldability. This process is crucial for creating components that must withstand heavy loads and harsh environmental conditions, such as bridges, building frameworks, and reinforced concrete structures. Heat-treated stainless steel also exhibits improved resistance to oxidation and rust, ensuring long-term durability and reduced maintenance costs in construction projects.

Energy Application of Heat Treatment of Stainless Steel:

In the energy sector, the heat treatment of stainless steel plays a pivotal role in manufacturing components that operate under high temperatures and corrosive environments, such as those found in power plants, oil refineries, and renewable energy systems. Processes like solution treatment and precipitation hardening are used to enhance the high-temperature performance and fatigue resistance of stainless steel. Solution treatment involves heating the steel to a temperature where alloying elements form a solid solution, followed by rapid cooling to retain the solution structure, thus improving the steel’s strength and corrosion resistance. This is particularly important for components like turbines, heat exchangers, and pipelines, which must maintain structural integrity and efficiency over prolonged periods. Additionally, heat-treated stainless steel’s improved mechanical properties enable the design of thinner, lighter components, contributing to energy efficiency and cost savings in energy production and distribution.

The industrial equipment industry relies heavily on the heat treatment of stainless steel to enhance the material properties critical for demanding applications. Heat treatment processes, particularly annealing, quenching, and tempering, are employed to modify the microstructure of stainless steel, thereby improving its mechanical properties such as hardness, ductility, and tensile strength. For instance, annealing involves heating stainless steel to a high temperature and then slowly cooling it, which relieves internal stresses and enhances corrosion resistance. This is especially vital in industries like oil and gas, where components are subject to extreme environmental conditions. Quenching and tempering, on the other hand, are used to increase hardness and wear resistance, crucial for parts used in heavy machinery and high-stress environments.

Furthermore, the control of thermal cycles during the heat treatment process ensures that stainless steel components meet exacting standards required in the industrial sector. This precision is crucial for the durability and reliability of equipment used in sectors such as aerospace, automotive, and manufacturing. For example, aerospace components like fasteners and structural elements undergo specific heat treatments to ensure they maintain their integrity under high-stress, high-temperature conditions. In the automotive industry, heat-treated stainless steel improves the performance and longevity of engine parts, exhaust systems, and transmission components. By employing advanced heat treatment techniques, manufacturers can optimize the properties of stainless steel to extend the life span and enhance the performance of industrial equipment, ultimately leading to increased safety and efficiency in critical applications.

Heat treatment of stainless steel is a critical process in the manufacturing of medical devices, ensuring both the material’s durability and biocompatibility. Stainless steel, particularly types like 316L, undergoes processes such as annealing, quenching, and tempering to enhance its mechanical properties and corrosion resistance. Annealing involves heating the steel to a specific temperature and then cooling it slowly, which helps to reduce internal stresses and improve ductility, making the material easier to form into intricate shapes required for medical instruments. Quenching, followed by tempering, further refines the material’s hardness and strength, ensuring that medical devices can withstand the rigorous demands of surgical and diagnostic procedures.

The precise control of heat treatment parameters is crucial in the medical field to maintain the steel’s passivation layer, which prevents corrosion and ensures biocompatibility, a critical factor for implants and tools that come into direct contact with bodily tissues. For instance, surgical tools, orthopedic implants, and dental instruments must maintain their structural integrity and avoid any adverse reactions within the body. Properly heat-treated stainless steel exhibits excellent surface finish and mechanical properties, essential for ensuring the safety, reliability, and longevity of medical devices. The heat treatment process not only enhances the physical characteristics of stainless steel but also extends the lifespan of medical devices, ensuring they meet stringent regulatory standards and perform effectively in clinical settings.

Heat treatment of stainless steel plays a crucial role in machining and manufacturing by enhancing its mechanical properties and ensuring optimal performance in various applications. This process involves controlled heating and cooling to alter the physical and sometimes chemical properties of the material. Key treatments include annealing, quenching, and tempering, which help improve hardness, strength, and resistance to wear and corrosion. For instance, annealing is used to soften stainless steel, making it more ductile and easier to machine. Quenching followed by tempering can significantly increase hardness and tensile strength, which is essential for components subjected to high stress and demanding environments.

In manufacturing, heat-treated stainless steel is preferred for critical parts in industries such as aerospace, automotive, and medical devices due to its enhanced durability and reliability. The improved machinability of heat-treated stainless steel allows for more precise and efficient cutting, drilling, and shaping, reducing tool wear and production time. Additionally, the corrosion-resistant properties gained from heat treatment ensure longevity and maintain the integrity of components exposed to harsh conditions, such as marine or chemical processing environments. Overall, the heat treatment of stainless steel is integral to achieving the desired balance of toughness, strength, and resistance to various forms of degradation, making it indispensable in high-performance manufacturing applications.

Sure! Below are some frequently asked questions (FAQs) about manufacturing “heat treatment of stainless steel quality work from SourcifyChina factory”:

Q1: What types of stainless steel can be heat treated at SourcifyChina?

A1: SourcifyChina factory can handle various types of stainless steel, including austenitic, martensitic, and duplex stainless steels, providing tailored heat treatment processes for each type.

Q2: What specific heat treatment processes are available?

A2: SourcifyChina offers processes such as annealing, quenching, tempering, stress relieving, and solution treatment to enhance the properties of stainless steel workpieces.

Q3: What temperatures are used for heat treating stainless steel?

A3: The temperature range depends on the specific type of stainless steel and the desired outcome. Typically, it ranges from 1000°F to 2100°F (538°C to 1150°C).

Q4: How does heat treatment affect the properties of stainless steel?

A4: Heat treatment can improve the mechanical properties, such as hardness, strength, and toughness. It also helps in relieving internal stresses and increasing corrosion resistance.

Q5: Can SourcifyChina customize heat treatment services for specific applications?

A5: Yes, SourcifyChina offers customizable heat treatment solutions tailored to meet the specific requirements of various applications and industry standards.

Q6: What quality standards does SourcifyChina follow?

A6: SourcifyChina adheres to international quality standards like ASTM, ISO, and DIN, ensuring high-quality and consistent heat treatment processes.

Q7: Are there any certifications available for the heat-treated stainless steel?

A7: Yes, SourcifyChina provides certifications and detailed quality reports for heat-treated stainless steel, ensuring traceability and compliance with industry requirements.

Q8: How long does the heat treatment process take?

A8: The duration of the heat treatment process varies based on the type and thickness of the stainless steel, as well as the specific treatment being applied. Turnaround times are provided upon request.

Q9: Is sample testing available before full-scale production?

A9: Yes, SourcifyChina offers sample testing to validate the heat treatment process and ensure that the final product meets the required specifications before moving to full-scale production.

Q10: How can I request a quote or additional information?

Heat treatment of stainless steel is crucial for enhancing its mechanical properties, corrosion resistance, and durability. Here are some key tips, specifically from SourcifyChina factory’s practices:

1. Types of Heat Treatment:

– Annealing: Involves heating the steel to a high temperature and then cooling it slowly to relieve stresses and enhance ductility. Commonly performed at 1040-1120°C.

– Quenching: Rapid cooling from high temperatures to achieve desired hardness and strength. Often used with martensitic stainless steels.

– Tempering: Post-quenching process where steel is reheated to a lower temperature and then cooled to achieve a balance between hardness and toughness.

– Solution Treatment: Heating austenitic stainless steels to 1000-1150°C and then rapid cooling to dissolve precipitates and retain a solid solution.

2. Temperature Control:

– Precise temperature control is vital. Use calibrated thermocouples and controlled atmosphere furnaces to ensure uniform heating and cooling.

3. Atmosphere:

– Maintain a protective atmosphere (e.g., argon, hydrogen) to prevent oxidation and decarburization during heat treatment.

4. Cooling Rate:

– Control the cooling rate to avoid thermal stresses and distortion. Water, oil, or air quenching methods are selected based on steel grade and desired properties.

5. Equipment Maintenance:

– Regularly inspect and maintain heat treatment equipment to ensure consistent quality. Check furnace integrity, calibration, and atmosphere controls.

6. Quality Control:

– Perform hardness testing, microstructure analysis, and corrosion testing post-treatment to ensure the steel meets required specifications.

7. Documentation:

– Maintain detailed records of heat treatment cycles, temperatures, and cooling rates for traceability and process optimization.

By adhering to these practices, SourcifyChina ensures the production of high-quality stainless steel with enhanced performance characteristics.

FAQ:

Heat Treatment of Stainless Steel from SourcifyChina Factory

Q: What types of stainless steel can SourcifyChina factory heat treat?

A: SourcifyChina factory is capable of heat treating a variety of stainless steel grades, including austenitic, martensitic, ferritic, and duplex stainless steels.

Q: What heat treatment processes does SourcifyChina factory offer?

A: The factory offers processes such as annealing, quenching, tempering, stress relieving, and solution treatment.

Q: Why is heat treatment important for stainless steel?

A: Heat treatment enhances mechanical properties, improves corrosion resistance, and tailors the material for specific applications.

Q: How does SourcifyChina ensure quality during the heat treatment process?

A: Quality is ensured through rigorous process control, advanced equipment, and adherence to international standards such as ASTM and ISO.

Q: What is annealing, and when is it used?

A: Annealing involves heating stainless steel to a specific temperature and then cooling it slowly to relieve internal stresses, improve ductility, and refine the microstructure. It is used to soften the material for further processing.

Q: Can SourcifyChina customize heat treatment processes for specific applications?

A: Yes, SourcifyChina can tailor heat treatment processes to meet specific customer requirements, ensuring optimal performance for the intended application.

Q: What is solution treatment, and which stainless steel grades benefit from it?

A: Solution treatment involves heating the steel to a high temperature to dissolve alloying elements into a solid solution, followed by rapid cooling. This process is particularly beneficial for austenitic and duplex stainless steels to enhance their corrosion resistance and mechanical properties.

Q: How long does the heat treatment process take at SourcifyChina factory?

A: The duration of heat treatment varies depending on the specific process and material thickness but typically ranges from a few hours to several days.

Q: Does SourcifyChina provide certification and documentation for heat-treated stainless steel?

A: Yes, the factory provides detailed certification and documentation, including test reports and compliance certificates, to verify the quality and conformity of the heat-treated materials.

Q: How can I get a quote or place an order for heat treatment services?

A: To get a quote or place an order, you can contact SourcifyChina directly through their website or customer service hotline, providing details about your requirements and specifications.

Sourcing heat treatment services for stainless steel from SourcifyChina factory requires a systematic approach to ensure quality and reliability. Here are some tips to guide you through the process:

1. Understand Your Requirements: Clearly define the type of heat treatment required (e.g., annealing, quenching, tempering) and the specific stainless steel grade. This ensures the factory can meet your technical needs.

2. Research the Factory: Look into SourcifyChina’s background, including their experience with heat treatment processes. Check for certifications such as ISO 9001, which indicates adherence to quality management standards.

3. Verify Capabilities: Confirm that SourcifyChina has the necessary equipment and technology to perform the heat treatment processes you need. Advanced furnaces and precision temperature controls are critical for consistent results.

4. Request Samples: Before committing to large orders, ask for samples of heat-treated stainless steel to evaluate the quality of their work. Examine factors like hardness, microstructure, and surface finish.

5. Quality Assurance Processes: Inquire about their quality control measures. This includes inspection methods, testing facilities (e.g., hardness testing, metallography), and adherence to international standards.

6. Lead Times and Capacity: Discuss production lead times and their capacity to handle your order volume. Ensure their schedule aligns with your project timelines to avoid delays.

7. Communication and Support: Ensure clear communication channels. A responsive supplier who can address your queries promptly is crucial for a smooth partnership.

8. Logistics and Shipping: Understand the logistics involved, including packaging, shipping methods, and delivery timelines. Factor in potential delays and customs procedures if importing.

9. Cost and Payment Terms: Compare costs with other suppliers to ensure competitiveness. Clarify payment terms, including any upfront costs, milestones, and final payment upon delivery.

10. References and Reviews: Seek testimonials or reviews from other clients who have used SourcifyChina for heat treatment services. Positive feedback can provide confidence in their reliability and quality.

By following these tips, you can effectively source high-quality heat treatment services for stainless steel from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.