High-Quality Manufacturing

SourcifyChina Factory specializes in producing high-quality laser cutters for metal, ensuring durability and precision. Their robust QA processes guarantee that each machine meets international standards, offering reliability to buyers.

Competitive Pricing

One of the main reasons to choose SourcifyChina Factory is their competitive pricing. They leverage economies of scale and efficient manufacturing processes to offer affordable pricing without compromising quality.

Advanced Technology

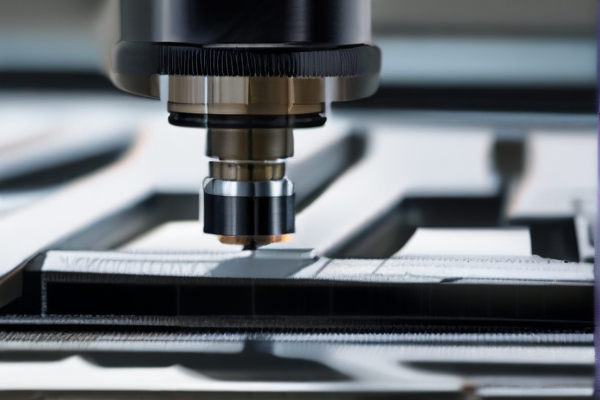

The factory incorporates state-of-the-art technology in its machinery, making it a go-to choice for buyers seeking advanced laser cutting solutions. Their equipment is designed to handle complex cutting needs efficiently.

Customization Options

SourcifyChina Factory provides various customization options to meet specific buyer requirements. Whether it’s altering dimensions or adding additional features, they accommodate unique needs to ensure total buyer satisfaction.

Strong After-Sales Support

Their robust after-sales support ensures that clients receive the help they need long after the purchase. From training to maintenance, their comprehensive support guarantees that your laser cutting operations run smoothly.

Strong Logistics Network

SourcifyChina Factory boasts a well-established logistics network that ensures timely delivery of products. Buyers can trust them for a reliable and efficient shipping process, reducing lead times and improving overall productivity.

In conclusion, choosing SourcifyChina Factory for purchasing laser cutters for metal offers several advantages. Their commitment to quality, affordability, advanced technology, and strong after-sales support make them a reliable partner. Additionally, their extensive customization options and efficient logistics network ensure that buyers receive products tailored to their needs, delivered on time.

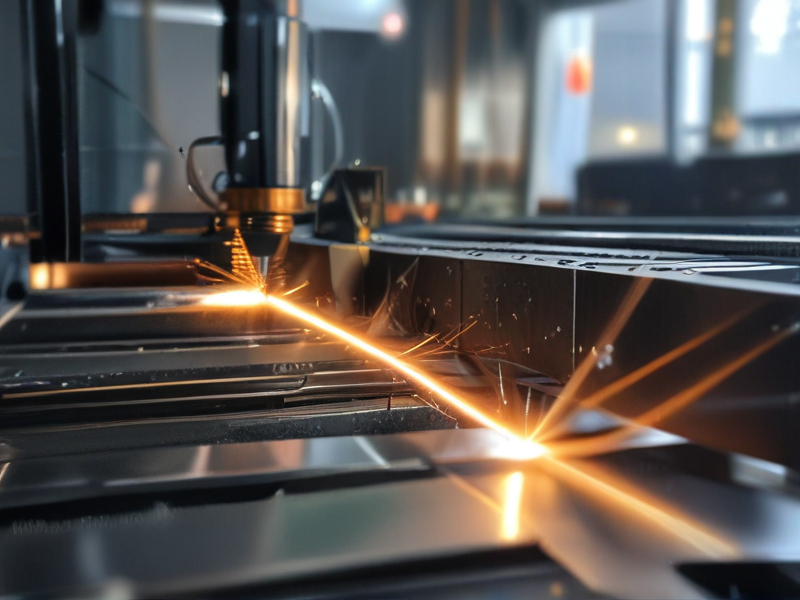

Laser cutter machines for metal processing come in various types, such as CO2 lasers, fiber lasers, and Nd:YAG lasers. Each offers different capabilities in terms of power, precision, and material compatibility, catering to diverse industrial needs.

– CO2 Lasers

– Ideal for cutting, engraving, and marking

– Works well on non-metal and thin metal sheets

– Typically offers lower operational costs

– Fiber Lasers

– Highly efficient and powerful

– Excellent for cutting thick and reflective metals

– Lower maintenance requirements compared to CO2 lasers

– Nd:YAG Lasers

– Suitable for high-precision applications

– Effective on both metallic and non-metallic materials

– Generally used in micro-machining and medical device manufacturing

– Hybrid Lasers

– Combines the features of multiple laser technologies

– Provides versatility for various cutting tasks

– Balances efficiency and operational cost

– Key Factors to Consider

– Material Type: Ensure the laser is compatible with the metal you intend to cut.

– Thickness: Different lasers have varying capabilities for cutting through material thickness.

– Precision: Choose a laser that meets the precision requirements of your application.

– Speed: Evaluate the cutting speed to meet production rate needs.

– Cost: Assess the total cost, including initial investment, maintenance, and operational expenses.

– Cooling System: Proper cooling mechanisms are crucial to prevent overheating and maintain efficiency.

By understanding the types and features of laser cutters for metal, you can make an informed choice that best suits your specific industrial needs.

Laser cutters for metal are versatile tools used in various industries for precise and efficient cutting, engraving, and shaping of metal components. They offer high accuracy and speed, making them essential for manufacturing, construction, and creative projects.

– Manufacturing: Used for creating intricate parts with high precision.

– Automotive: Produces car components and custom parts.

– Aerospace: Cuts materials for aircraft and spacecraft construction.

– Medical Devices: Fabricates surgical tools and medical equipment.

– Jewelry Making: Engraves and shapes metal for custom designs.

– Construction: Cuts structural components and decorative elements.

– Prototyping: Helps in rapid creation of prototypes with exact specifications.

– Signage: Creates detailed metal signs and logos.

– Art and Sculpture: Enables detailed metal artwork and sculptures.

– Electronics: Cuts metal parts for electronic devices and enclosures.

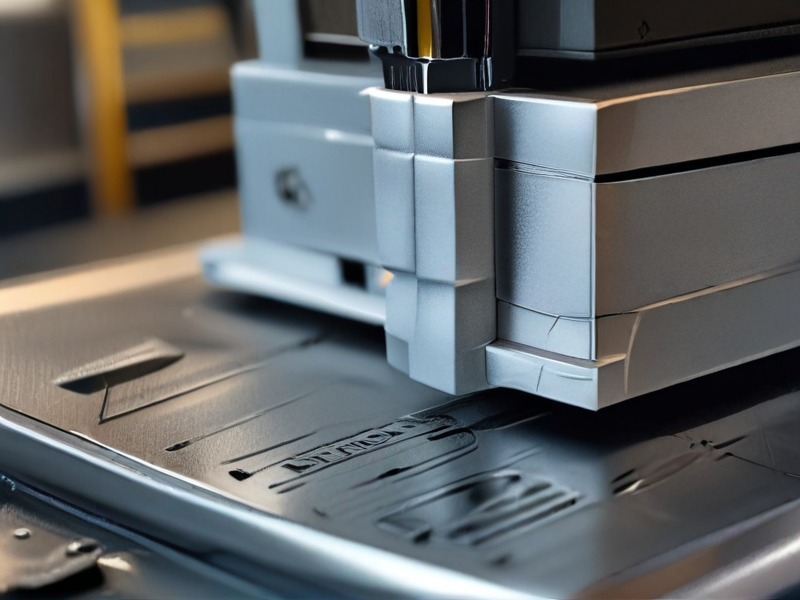

The SourcifyChina laser cutter metal is crafted from high-quality stainless steel, ensuring durability and longevity. This robust material is resistant to rust and corrosion, making it ideal for various cutting applications.

Additionally, the stainless steel construction provides the laser cutter with excellent structural integrity, allowing for precise and consistent cutting performance. Its strength ensures that it can handle a wide range of metals with ease.

The cutter’s body is designed to minimize vibrations and enhance stability during operation. This results in smoother cuts and a more reliable overall performance, which is crucial for intricate designs and detailed work.

Overall, the use of stainless steel in the SourcifyChina laser cutter metal ensures a reliable, efficient, and durable tool that meets the needs of professionals and hobbyists alike. This combination of strength and precision makes it a valuable addition to any workshop.

SourcifyChina employs rigorous quality control in the manufacturing of their laser cutter metal products. Each stage of production is meticulously monitored to ensure precision and consistency.

Raw materials are sourced from certified suppliers, guaranteeing high-grade metals. These materials undergo initial inspection to verify their compliance with stringent quality standards.

Advanced machinery and skilled technicians handle the cutting process, ensuring accuracy and minimal waste. Each cutter is tested under real-world conditions to confirm performance reliability.

Post-production, products are subjected to comprehensive inspections, including dimensional checks and surface finish assessments. Final products meet both customer specifications and international standards.

This thorough quality control process ensures that SourcifyChina’s laser cutter metal products are reliable, durable, and high-performing, ultimately leading to high customer satisfaction and trust in their products.

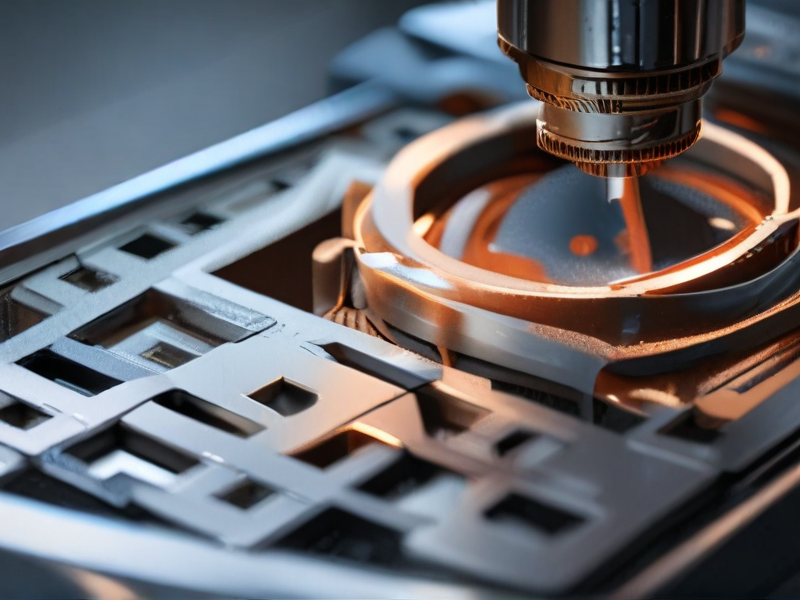

SourcifyChina’s laser cutter for metal showcases impressive precision and efficiency, making it ideal for intricate designs and complex cuts. Its high-powered laser beam ensures clean, smooth edges on a variety of metals.

This machine is versatile, capable of cutting through steel, aluminum, brass, and other metals with ease. The adjustable settings allow for customization based on material thickness and hardness, ensuring optimal results.

Safety features are paramount, with automated shut-off mechanisms and enclosed cutting areas to protect operators from laser exposure and flying debris, enhancing workplace safety.

The user-friendly interface and software integration streamline the cutting process, allowing for quick setup and seamless execution. Its compatibility with various design software simplifies importing and editing files, making it accessible for both novice and experienced users.

Overall, the SourcifyChina laser cutter is a reliable, high-performance tool suitable for industrial applications, small businesses, and hobbyists, offering precision, versatility, and safety.

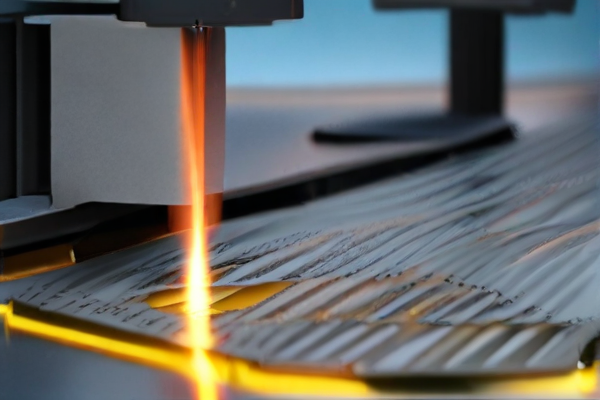

Laser cutting metal offers precision, efficiency, and versatility, making it an essential tool in modern manufacturing. Here are some key benefits:

– Precision: Laser cutting provides extremely accurate cuts with high tolerances, making it ideal for complex designs.

– Speed: Laser cutters operate much faster than traditional cutting methods, significantly speeding up production times.

– Versatility: They can cut a wide range of metals including steel, aluminum, and titanium.

– Quality: Laser cutting results in clean edges with minimal burrs, reducing the need for additional finishing.

– Cost-Effectiveness: Reduces material waste and labor costs, enhancing overall cost-efficiency.

– Automation: Easily integrates into automated production lines, supporting high-volume manufacturing.

– Reproducibility: Ensures consistent quality across multiple pieces, crucial for mass production.

– Efficiency: Optimizes material usage by nesting multiple pieces on a single sheet, minimizing waste.

– Non-Contact Process: Avoids physical contact with the material, reducing the risk of contamination and damage.

– Complex Geometries: Capable of producing intricate shapes that are difficult or impossible with other cutting methods.

– Reduced Thermal Distortion: Focused laser beams minimize heat-affected zones, preserving material integrity.

– Low Maintenance: Laser cutters typically require less maintenance compared to mechanical cutting tools.

– Safety: Advanced laser systems come with safety features that protect operators from harmful laser exposure.

– Eco-Friendly: Produces fewer pollutants and noise compared to traditional cutting methods.

– Flexibility: Easily adaptable to different thicknesses and metal types without changing tools.

These benefits collectively make laser cutting a highly advantageous choice for various industrial applications.

Laser cutters for metal are advanced tools used in manufacturing and crafting. They offer precision and efficiency in cutting various metals. Key features include:

– Precision Cutting: Achieves high accuracy and fine detail.

– Versatility: Cuts a wide range of metals including steel, aluminum, and titanium.

– Speed: High-speed cutting for increased productivity.

– Minimal Waste: Efficient use of material reduces waste.

– Automated Control: Computer numerical control (CNC) systems for automated operation.

– Clean Cuts: Produces smooth edges with minimal burring.

– Customization: Easily programmable for custom designs and intricate patterns.

– Energy Efficiency: Modern systems are energy efficient.

– Safety Features: Equipped with safety mechanisms to protect operators.

– Maintenance: Requires regular maintenance but offers long-term reliability.

SourcifyChina offers advanced laser cutter metal solutions, providing high-precision custom products. Their state-of-the-art laser technology ensures accuracy and efficiency in every cut. This precision is essential for producing intricate designs and detailed projects.

They cater to various industries, including automotive, aerospace, and manufacturing, ensuring that each sector benefits from their high-quality metal cutting services. SourcifyChina’s ability to handle both small and large-scale projects makes them a versatile choice for businesses.

Their custom products range from simple components to complex assemblies. Each piece is crafted to meet the client’s exact specifications, ensuring satisfaction and optimal performance in application.

SourcifyChina also offers design support, assisting clients in turning their concepts into reality. Their team of experts collaborates closely with customers to refine designs and achieve the best possible outcomes.

The company prides itself on its fast turnaround times and competitive pricing. By leveraging advanced technology and skilled professionals, SourcifyChina delivers exceptional value without compromising on quality.

Sustainability is also a focus for SourcifyChina. They implement eco-friendly practices in their production processes, reducing waste and promoting environmental responsibility.

In summary, SourcifyChina’s laser cutter metal services stand out due to their precision, versatility, and commitment to customer satisfaction. They provide tailored solutions across various industries, combining cutting-edge technology with expert craftsmanship. Their dedication to quality, efficiency, and sustainability makes them a reliable partner for any metal cutting needs.

SourcifyChina is a prominent company specializing in laser cutting technology for metal, renowned for its precision and efficiency. Catering to a diverse clientele across various industries, the company employs state-of-the-art laser cutters capable of handling a wide range of metals, including steel, aluminum, and titanium. SourcifyChina emphasizes high-quality output, ensuring that each cut is clean and precise, which is critical for manufacturing components with strict tolerances. Their advanced machinery is designed to maximize productivity while minimizing waste, making their services both cost-effective and environmentally friendly. Additionally, SourcifyChina is committed to continuous innovation, regularly updating their technology and processes to stay at the forefront of the industry. This dedication to excellence has cemented their reputation as a reliable partner for businesses needing superior metal cutting solutions.

The aerospace industry has greatly benefited from the integration of laser cutter metal technology, which allows for unparalleled precision in the manufacturing of complex components and structures. Laser cutters can handle the intricate geometries required for modern aircraft’s lightweight and durable parts, such as fuselage sections, turbine blades, and interior cabin components. The ability to cut through high-strength alloys with exceptional accuracy reduces material wastage and shortens production timelines. This efficiency is crucial in adhering to the stringent safety and performance standards that aerospace demands. Consequently, the use of laser cutters has become an integral part of the processes for both commercial aviation and space exploration, ensuring that parts are consistently produced to exact specifications, thus enhancing overall reliability.

In the defense and marine sectors, laser cutter metal technology similarly revolutionizes the manufacturing and maintenance of critical components. In defense, the precision cutting capabilities are essential for producing parts for vehicles, weaponry, and communication systems, where reliability and robustness are non-negotiable. For naval applications, the ability to swiftly cut and shape steel and other metals contributes significantly to the construction and repair of ships and submarines. This technology not only supports the development of stealth features and high-performance armaments but also enhances the efficiency of retrofitting and refurbishment operations. The adoption of laser cutters thus ensures that both defense and marine equipment meet rigorous performance standards while maintaining cost-efficiency and accelerating project timelines, ultimately fortifying operational readiness and effectiveness.

In the automotive industry, laser cutter metal technology has revolutionized manufacturing processes by enabling precise and efficient cutting of various metal components. This technology allows for the creation of intricate and complex parts, which are essential for modern vehicle designs that prioritize both performance and aesthetics. The high precision of laser cutters ensures minimal waste and optimal material usage, significantly reducing production costs. Additionally, the speed and accuracy of laser cutting improve the overall efficiency of manufacturing lines, leading to faster production times and the ability to quickly adapt to new designs or modifications. This versatility is crucial in an industry where innovation and adaptability are key to staying competitive.

In the electronics sector, laser cutter metal technology is indispensable for producing the delicate and intricate components required for electronic devices. The ability to cut metals with exceptional precision allows for the creation of small-scale parts used in circuit boards, connectors, and other critical components. This precision ensures high-quality and reliable products, which are essential in an industry that demands extreme accuracy and performance. Moreover, laser cutters can handle various metals, including those with reflective surfaces, making them ideal for manufacturing components for smartphones, computers, and other high-tech devices. The efficiency and precision of laser cutting not only enhance production speed but also enable the creation of innovative and complex designs that drive the advancement of electronic technologies.

In construction, laser cutting technology has revolutionized the precision and efficiency of metal fabrication. Laser cutters enable highly accurate and intricate cuts on various metal types, significantly reducing material wastage and enhancing the quality of structural components. This precision is particularly beneficial for creating custom architectural elements, such as decorative panels and complex frameworks, where traditional cutting methods might fall short. Additionally, the speed of laser cutters accelerates the production process, allowing construction projects to adhere to tighter timelines and reducing overall labor costs. The automation potential of laser cutters further ensures consistency in mass production, which is crucial for maintaining uniformity in large-scale construction projects.

In the energy sector, laser cutting of metal plays a pivotal role in the manufacturing and maintenance of energy infrastructure. For instance, in the production of solar panels, laser cutters are used to create precise metal components that enhance the efficiency and durability of photovoltaic cells. In wind energy, laser cutters facilitate the fabrication of complex parts for turbines, including the blades and supporting structures, which require high precision to ensure optimal performance and safety. Furthermore, laser cutting technology is instrumental in the development of advanced battery technologies and fuel cells, where precise and clean cuts are essential for the optimal assembly of components. The ability to cut metals with minimal thermal distortion also aids in maintaining the integrity of materials, which is critical in the harsh operational environments typical in the energy sector.

The industrial equipment sector has significantly benefited from the incorporation of laser cutter metal technology, which is revolutionizing how manufacturers approach metal fabrication. Laser cutters are precise and efficient tools capable of delivering intricate designs with a high degree of accuracy, making them indispensable in industries such as automotive, aerospace, and heavy machinery. These advanced machines utilize concentrated beams of light to slice through different types of metal, including steel, aluminum, and titanium. The ability to achieve intricate cuts without physical contact reduces the risk of material distortion and minimizes waste, thereby enhancing overall production efficiency and reducing costs. Moreover, laser cutters are equipped with computer numerical control (CNC) systems, allowing for the automation of complex tasks and ensuring repeatability and consistency across large production volumes.

Beyond precision, laser cutter metal technology also offers unmatched flexibility and speed, which is crucial in meeting the evolving demands of the industrial equipment market. These machines can easily switch between different types and thicknesses of materials, facilitating rapid prototyping and quick adaptation to design changes. The high-speed cutting capabilities result in shorter lead times, enabling manufacturers to expedite their time-to-market. Additionally, laser cutters require minimal maintenance compared to traditional cutting methods, leading to decreased downtime and increased operational efficiency. As the industrial equipment industry continues to innovate and push the boundaries of what’s possible, laser cutter metal technology remains at the forefront, ensuring that manufacturers can produce high-quality, durable components with utmost precision and speed.

Laser cutters have ushered in an era of precision and efficiency in the fabrication of medical devices, revolutionizing the industry with their ability to achieve intricate designs and complex geometries. Utilizing advanced computer numeric control (CNC) systems, laser cutting technology ensures exactitude in cutting, shaping, and engraving metal components, which are paramount in creating intricate medical devices such as stents, surgical instruments, and orthopedic implants. The high degree of precision achieved with laser cutters minimizes the margin for error, thereby enhancing the safety and functionality of these medical devices. Moreover, the non-contact nature of laser cutting eliminates the risk of mechanical deformation, preserving the integrity of delicate metal parts, essential for the stringent quality requirements of the medical field.

One of the critical advantages of using laser cutters in the medical device sector is their ability to work with a wide array of biocompatible metals like stainless steel, titanium, and cobalt-chrome alloys, which are integral to the fabrication of durable and reliable medical devices. The laser cutting process is highly customizable, allowing for rapid prototyping and adaptation to specific patient needs, which is invaluable in the development of personalized medical solutions. Furthermore, the efficiency and speed of laser cutting reduce production times and costs, enabling quicker market introduction of advanced medical technologies. This technological edge not only accelerates innovation but also ensures that medical devices meet the stringent regulatory standards necessary for patient safety and efficacy, ultimately enhancing the overall quality of healthcare.

Laser cutting metal is a precision machining process widely used in manufacturing for its ability to produce intricate and high-quality cuts. This technique utilizes a focused laser beam to melt, burn, or vaporize material, achieving precise and clean edges. Its application spans across various industries including automotive, aerospace, and electronics, where complex metal parts are required. Laser cutters offer superior accuracy, reduced material waste, and the ability to cut complex shapes that would be difficult or impossible with traditional methods. They are particularly advantageous for creating prototypes and small batches of customized parts due to their flexibility and efficiency.

In the manufacturing sector, laser cutters enhance productivity by allowing for rapid and repeatable cuts with minimal setup time. This technology supports a wide range of metals, such as steel, aluminum, and titanium, accommodating diverse production needs. Furthermore, the integration of computer-aided design (CAD) software enables precise control over the cutting process, facilitating the production of intricate designs and reducing the likelihood of human error. As a result, laser cutting is not only cost-effective for large-scale production runs but also invaluable for industries that demand high precision and customization, solidifying its role as a critical tool in modern manufacturing.

Q: What types of metals can the laser cutter handle?

A: Our laser cutter can process a variety of metals, including stainless steel, carbon steel, aluminum, brass, and copper.

Q: What is the maximum thickness the laser cutter can cut?

A: The laser cutter can handle metal thicknesses up to 20mm for stainless steel and 25mm for carbon steel.

Q: What is the precision of the laser cutting process?

A: The laser cutter offers high precision with tolerances as tight as ±0.1mm, ensuring detailed and accurate cuts.

Q: What are the typical applications of laser-cut metal parts?

A: Laser-cut metal parts are used in various industries including automotive, aerospace, electronics, and construction for applications such as structural components, decorative elements, and machinery parts.

Q: How does the quality of laser-cut edges compare to other cutting methods?

A: Laser cutting produces clean, burr-free edges with minimal thermal distortion, superior to many traditional cutting methods like mechanical cutting or plasma cutting.

Q: Can SourcifyChina factory handle large volume orders?

A: Yes, SourcifyChina factory is equipped to handle both small and large volume orders efficiently, ensuring timely delivery without compromising on quality.

Q: What is the typical lead time for laser cutting orders?

A: Lead times vary depending on the complexity and volume of the order, but typically range from 5 to 15 business days.

Q: Do you offer design assistance or prototyping services?

A: Yes, we offer design assistance and prototyping services to help bring your project from concept to completion with optimal precision and efficiency.

Q: What file formats do you accept for laser cutting jobs?

A: We accept various file formats including DXF, DWG, and PDF. Please ensure files are properly scaled and include all necessary details.

Q: How do you ensure quality control in the laser cutting process?

A: We have stringent quality control measures in place, including regular equipment maintenance, trained operators, and thorough inspections to ensure each part meets the highest standards.

When considering laser cutter metal manufacturing from a SourcifyChina factory, several key tips can ensure a smooth and successful process:

1. Define Specifications Clearly: Clearly outline your material specifications, including type, thickness, and dimensions. This helps avoid misunderstandings and ensures the factory meets your exact requirements.

2. Choose the Right Laser Cutter: Ensure the factory uses suitable laser cutting technology, such as fiber lasers for metals like steel and aluminum. Fiber lasers offer high precision and efficiency, ideal for intricate designs.

3. Quality Assurance: Inquire about the factory’s quality control measures. Ask for samples and inspect them for precision, edge quality, and any signs of thermal damage. A good factory will have robust QA processes, including regular equipment calibration.

4. Lead Time and Capacity: Confirm the factory’s lead times and production capacity to ensure they can meet your deadlines. High-demand periods may affect turnaround times, so plan accordingly.

5. Cost Considerations: Get detailed quotes, including any setup fees, material costs, and shipping charges. Compare these with other suppliers to ensure competitive pricing without compromising on quality.

6. Communication: Establish clear communication channels. Regular updates and prompt responses to queries are crucial for smooth operations. Language barriers can be minimized with clear, concise instructions and regular follow-ups.

7. Certifications and Compliance: Verify that the factory complies with relevant industry standards and holds necessary certifications. This ensures the production adheres to safety and quality norms.

8. Sustainability Practices: Check if the factory employs environmentally friendly practices, such as efficient material usage and proper waste management. Sustainable practices can enhance your brand’s reputation.

9. Visit the Factory: If possible, arrange a visit to the factory. This provides firsthand insight into their operations, capabilities, and quality standards.

By following these tips, you can effectively leverage SourcifyChina’s laser cutter metal manufacturing services to meet your production needs with high quality and efficiency.

Sure, here are some frequently asked questions (FAQ) along with their answers for sourcing a laser cutter for metal from SourcifyChina factory:

1. What types of metal can your laser cutter process?

Our laser cutters are capable of processing a variety of metals including stainless steel, carbon steel, aluminum, brass, and copper.

2. What are the power options available for your laser cutters?

Our laser cutters come in various power capacities ranging from 500W to 6000W, catering to different thicknesses and types of metals.

3. What is the lead time for receiving a laser cutter from SourcifyChina factory?

The standard lead time is typically 30-45 days from the time of order confirmation, depending on the complexity and specifications of the laser cutter you need.

4. Do you provide training for operating the laser cutter?

Yes, we offer comprehensive training sessions either on-site or online to ensure your team can operate the laser cutter efficiently and safely.

5. What are the warranty terms for your laser cutters?

We provide a 2-year warranty on all our laser cutters, which covers parts and service. Extended warranty options are also available upon request.

6. Can I customize the laser cutter according to my specific needs?

Absolutely. SourcifyChina offers customization options, including size, power, and additional features, to meet your specific requirements.

7. How do I place an order for a laser cutter from SourcifyChina?

Orders can be placed by contacting our sales team via email or through our website’s inquiry form. A dedicated representative will guide you through the process.

8. What are the payment terms for purchasing a laser cutter?

We accept several payment methods including T/T (Telegraphic Transfer), L/C (Letter of Credit), and PayPal. Typically, a 30% deposit is required with the balance due before shipment.

9. What kind of technical support is available post-purchase?

We offer 24/7 technical support through our hotline, email, and online chat. On-site support can also be arranged if necessary.

10. Do you offer after-sales service and maintenance?

Yes, we provide comprehensive after-sales services including regular maintenance checks, spare parts, and machine upgrades to ensure your laser cutter operates smoothly.

Sourcing a laser cutter for metal from SourcifyChina factory involves several key steps to ensure you get the best product and deal. Here are some tips to guide you through the process:

1. Research and Verify:

– Start by researching SourcifyChina factory’s reputation. Look for reviews, ratings, and feedback from other buyers.

– Verify the factory’s certifications and compliance with international standards to ensure quality and safety.

2. Product Specifications:

– Clearly define your requirements, including the type of metal you’ll be cutting, thickness, and precision needed.

– Compare different models and features offered by SourcifyChina to find the one that best matches your needs.

3. Request for Quotation (RFQ):

– Prepare a detailed RFQ that includes your specifications, expected quantity, delivery time, and other relevant details.

– Request a comprehensive quote that covers unit price, shipping costs, and any additional fees.

4. Samples and Testing:

– If possible, request a sample of the laser cutter to test its performance and compatibility with your materials.

– Evaluate the sample for quality, precision, and durability.

5. Negotiation:

– Negotiate the terms of the deal, including price, payment terms, warranty, and after-sales support.

– Ensure that there is a clear agreement on delivery schedules and incoterms.

6. Inspection and Quality Control:

– Arrange for a third-party inspection of the laser cutter before it is shipped to verify that it meets your specifications.

– Discuss the factory’s quality control processes to ensure consistent product quality.

7. Logistics and Shipping:

– Plan the logistics for shipping, considering factors like customs clearance, import duties, and insurance.

– Choose a reliable shipping method that balances cost and delivery time.

8. After-Sales Support:

– Ensure that SourcifyChina provides adequate after-sales support, including installation guidance, maintenance, and repair services.

By following these steps, you can effectively source a high-quality laser cutter for metal from SourcifyChina factory, ensuring it meets your requirements and is delivered on time.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.